How to Streamline Thermite‑Based Processes in Industry?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Technology Evolution and Objectives

Thermite technology has a rich history dating back to its discovery in the late 19th century. Initially used for welding railway tracks, it has since evolved to find applications in various industrial processes. The evolution of thermite technology has been driven by the need for more efficient, safer, and cost-effective methods in metallurgy, materials science, and manufacturing.

In recent years, the focus has shifted towards streamlining thermite-based processes to enhance their industrial viability. This objective aligns with the broader goals of improving energy efficiency, reducing environmental impact, and increasing productivity in industrial operations. The primary aim is to optimize the thermite reaction, which involves the reduction of a metal oxide by aluminum, resulting in the production of pure metal and aluminum oxide.

One of the key evolutionary trends in thermite technology has been the development of more precise control mechanisms for the reaction. This includes advancements in ignition systems, reaction vessel design, and the formulation of thermite mixtures. These improvements have led to better control over reaction rates, temperatures, and product quality, addressing some of the historical challenges associated with thermite processes.

Another significant aspect of thermite technology evolution is the exploration of alternative reactants and additives. Researchers have been investigating various metal oxides and reducing agents to tailor the thermite reaction for specific applications. This has expanded the range of metals that can be produced using thermite processes and opened up new possibilities for material synthesis.

The objectives of current thermite technology research and development are multifaceted. Firstly, there is a strong emphasis on enhancing the safety aspects of thermite reactions, given their highly exothermic nature. This includes developing safer ignition methods, containment systems, and handling procedures. Secondly, researchers are working on improving the energy efficiency of thermite processes, aiming to maximize the utilization of the heat generated during the reaction.

Furthermore, there is a growing interest in scaling up thermite-based processes for larger industrial applications. This involves addressing challenges related to heat management, product separation, and process automation. The goal is to develop continuous or semi-continuous thermite processes that can be integrated into existing industrial production lines.

In the context of streamlining thermite-based processes, objectives also include reducing the environmental footprint of these operations. This encompasses efforts to minimize waste generation, improve the recyclability of by-products, and explore cleaner production methods. Additionally, there is a focus on developing more sustainable sources of raw materials for thermite reactions, aligning with global sustainability goals.

In recent years, the focus has shifted towards streamlining thermite-based processes to enhance their industrial viability. This objective aligns with the broader goals of improving energy efficiency, reducing environmental impact, and increasing productivity in industrial operations. The primary aim is to optimize the thermite reaction, which involves the reduction of a metal oxide by aluminum, resulting in the production of pure metal and aluminum oxide.

One of the key evolutionary trends in thermite technology has been the development of more precise control mechanisms for the reaction. This includes advancements in ignition systems, reaction vessel design, and the formulation of thermite mixtures. These improvements have led to better control over reaction rates, temperatures, and product quality, addressing some of the historical challenges associated with thermite processes.

Another significant aspect of thermite technology evolution is the exploration of alternative reactants and additives. Researchers have been investigating various metal oxides and reducing agents to tailor the thermite reaction for specific applications. This has expanded the range of metals that can be produced using thermite processes and opened up new possibilities for material synthesis.

The objectives of current thermite technology research and development are multifaceted. Firstly, there is a strong emphasis on enhancing the safety aspects of thermite reactions, given their highly exothermic nature. This includes developing safer ignition methods, containment systems, and handling procedures. Secondly, researchers are working on improving the energy efficiency of thermite processes, aiming to maximize the utilization of the heat generated during the reaction.

Furthermore, there is a growing interest in scaling up thermite-based processes for larger industrial applications. This involves addressing challenges related to heat management, product separation, and process automation. The goal is to develop continuous or semi-continuous thermite processes that can be integrated into existing industrial production lines.

In the context of streamlining thermite-based processes, objectives also include reducing the environmental footprint of these operations. This encompasses efforts to minimize waste generation, improve the recyclability of by-products, and explore cleaner production methods. Additionally, there is a focus on developing more sustainable sources of raw materials for thermite reactions, aligning with global sustainability goals.

Industrial Demand for Thermite Applications

Thermite-based processes have gained significant traction in various industrial sectors due to their unique properties and versatile applications. The demand for thermite applications spans across multiple industries, including metallurgy, welding, demolition, and pyrotechnics. In the metallurgical industry, thermite reactions are extensively used for metal purification, alloying, and the production of high-purity metals. The exothermic nature of thermite reactions makes them ideal for welding applications, particularly in railway track welding and pipeline joining.

The construction and demolition sectors have also embraced thermite-based processes for controlled demolition of structures and cutting through thick metal components. The ability of thermite reactions to generate intense heat and molten metal has made them indispensable in these applications. Furthermore, the pyrotechnic industry relies on thermite mixtures for creating spectacular visual effects in fireworks and special effects for film and entertainment purposes.

In recent years, there has been a growing demand for more efficient and environmentally friendly thermite-based processes. Industries are seeking ways to optimize the energy output of thermite reactions while minimizing waste and emissions. This has led to increased research and development efforts focused on improving the composition of thermite mixtures and refining the reaction control mechanisms.

The aerospace and defense sectors have shown particular interest in advanced thermite applications. Thermite-based materials are being explored for use in propulsion systems, thermal batteries, and incendiary devices. The demand for lightweight, high-energy materials in these industries has driven innovation in thermite formulations and application techniques.

As industries strive for greater automation and precision, there is a rising demand for controlled and repeatable thermite-based processes. This has spurred the development of sophisticated ignition systems and reaction chambers that allow for precise control over the thermite reaction. Such advancements are crucial for industries requiring high-precision welding or metal processing.

The global push towards sustainable manufacturing practices has also influenced the demand for thermite applications. Researchers are exploring eco-friendly thermite mixtures that produce less harmful byproducts and can be more easily recycled. This trend aligns with the broader industrial movement towards circular economy principles and reduced environmental impact.

The construction and demolition sectors have also embraced thermite-based processes for controlled demolition of structures and cutting through thick metal components. The ability of thermite reactions to generate intense heat and molten metal has made them indispensable in these applications. Furthermore, the pyrotechnic industry relies on thermite mixtures for creating spectacular visual effects in fireworks and special effects for film and entertainment purposes.

In recent years, there has been a growing demand for more efficient and environmentally friendly thermite-based processes. Industries are seeking ways to optimize the energy output of thermite reactions while minimizing waste and emissions. This has led to increased research and development efforts focused on improving the composition of thermite mixtures and refining the reaction control mechanisms.

The aerospace and defense sectors have shown particular interest in advanced thermite applications. Thermite-based materials are being explored for use in propulsion systems, thermal batteries, and incendiary devices. The demand for lightweight, high-energy materials in these industries has driven innovation in thermite formulations and application techniques.

As industries strive for greater automation and precision, there is a rising demand for controlled and repeatable thermite-based processes. This has spurred the development of sophisticated ignition systems and reaction chambers that allow for precise control over the thermite reaction. Such advancements are crucial for industries requiring high-precision welding or metal processing.

The global push towards sustainable manufacturing practices has also influenced the demand for thermite applications. Researchers are exploring eco-friendly thermite mixtures that produce less harmful byproducts and can be more easily recycled. This trend aligns with the broader industrial movement towards circular economy principles and reduced environmental impact.

Current Challenges in Thermite-Based Processes

Thermite-based processes in industry face several significant challenges that hinder their widespread adoption and efficiency. One of the primary issues is the control and containment of the highly exothermic reaction. The intense heat generated during thermite reactions can be difficult to manage, posing safety risks and limiting the precision of the process. This challenge is particularly acute in applications requiring fine control over the reaction rate and temperature distribution.

Another major hurdle is the scalability of thermite-based processes. While effective on a small scale, scaling up these reactions for industrial use presents complications in terms of uniformity and consistency. Ensuring an even distribution of reactants and maintaining reaction stability across larger volumes remains a significant technical challenge. This scalability issue often results in reduced efficiency and increased variability in product quality when attempting to implement thermite processes on an industrial scale.

The environmental impact of thermite reactions is also a growing concern. The production of metal oxides and other byproducts can have negative environmental consequences, particularly in large-scale industrial applications. Addressing these environmental concerns while maintaining the effectiveness of the process is a delicate balance that researchers and engineers are still working to achieve.

Material selection and preparation present another set of challenges. The purity and particle size of the reactants significantly influence the reaction's efficiency and outcome. Obtaining consistently high-quality materials at an industrial scale can be both costly and logistically complex. Furthermore, the storage and handling of these materials require special considerations due to their reactive nature.

Energy efficiency is an additional area of concern in thermite-based processes. While the reactions are highly exothermic, harnessing and utilizing this energy effectively in industrial settings remains challenging. Developing systems that can capture and repurpose the heat generated could significantly improve the overall efficiency of these processes, but current technologies fall short in this aspect.

Lastly, the integration of thermite-based processes into existing industrial workflows poses significant challenges. Many industries have established procedures and equipment that are not easily adaptable to the unique requirements of thermite reactions. Overcoming this integration barrier requires not only technical solutions but also changes in operational practices and safety protocols.

Another major hurdle is the scalability of thermite-based processes. While effective on a small scale, scaling up these reactions for industrial use presents complications in terms of uniformity and consistency. Ensuring an even distribution of reactants and maintaining reaction stability across larger volumes remains a significant technical challenge. This scalability issue often results in reduced efficiency and increased variability in product quality when attempting to implement thermite processes on an industrial scale.

The environmental impact of thermite reactions is also a growing concern. The production of metal oxides and other byproducts can have negative environmental consequences, particularly in large-scale industrial applications. Addressing these environmental concerns while maintaining the effectiveness of the process is a delicate balance that researchers and engineers are still working to achieve.

Material selection and preparation present another set of challenges. The purity and particle size of the reactants significantly influence the reaction's efficiency and outcome. Obtaining consistently high-quality materials at an industrial scale can be both costly and logistically complex. Furthermore, the storage and handling of these materials require special considerations due to their reactive nature.

Energy efficiency is an additional area of concern in thermite-based processes. While the reactions are highly exothermic, harnessing and utilizing this energy effectively in industrial settings remains challenging. Developing systems that can capture and repurpose the heat generated could significantly improve the overall efficiency of these processes, but current technologies fall short in this aspect.

Lastly, the integration of thermite-based processes into existing industrial workflows poses significant challenges. Many industries have established procedures and equipment that are not easily adaptable to the unique requirements of thermite reactions. Overcoming this integration barrier requires not only technical solutions but also changes in operational practices and safety protocols.

Existing Thermite Process Optimization Methods

01 Thermite welding for rail joints

Thermite-based processes are used to streamline rail welding operations. This method involves the exothermic reaction of aluminum and iron oxide to produce molten iron, which is used to join rail sections. The process is efficient for creating continuous welded rails, improving track stability and reducing maintenance needs.- Thermite welding for rail joints: Thermite-based processes are used for welding rail joints in railway tracks. This method involves the exothermic reaction of aluminum and iron oxide to produce molten iron, which is then used to join rail sections. The process is streamlined through improved mold designs, automated ignition systems, and precise control of the thermite mixture composition.

- Underwater thermite cutting and welding: Thermite reactions are adapted for underwater cutting and welding applications. Special formulations and delivery systems are developed to maintain the reaction in aqueous environments. This enables efficient underwater repair and maintenance operations in marine and offshore industries.

- Thermite-based heat sources for oil and gas wells: Thermite compositions are used as heat sources in oil and gas well operations. These reactions generate high temperatures to melt paraffin deposits, stimulate production, or seal off unwanted zones. The process is optimized through controlled initiation and sustained burning of the thermite mixture in downhole environments.

- Improved thermite compositions for metal purification: Advanced thermite compositions are developed for metal purification processes. These formulations are designed to reduce impurities in metals more efficiently, with controlled reaction rates and improved slag separation. The streamlined process results in higher purity metals with less energy consumption.

- Automated thermite-based additive manufacturing: Thermite reactions are integrated into additive manufacturing processes for metal components. This approach allows for rapid, localized metal deposition and joining. The process is streamlined through computer-controlled reaction initiation, precise material feeding, and optimized cooling strategies to produce complex metal parts efficiently.

02 Improved thermite compositions

Advanced thermite compositions are developed to enhance the efficiency and safety of thermite-based processes. These formulations may include additives or modified ratios of reactants to optimize the reaction, control heat generation, and improve the quality of the resulting weld or cast product.Expand Specific Solutions03 Automated thermite welding systems

Automation technologies are integrated into thermite-based processes to streamline operations. These systems may include robotic positioning of molds, precise reactant dispensing, and computer-controlled ignition and cooling processes. Automation improves consistency, reduces human error, and increases overall efficiency in thermite welding applications.Expand Specific Solutions04 Thermite-based metal purification

Thermite reactions are utilized in metal purification processes. This application leverages the high temperatures generated by thermite reactions to separate impurities from metals, resulting in higher purity products. The process can be streamlined through careful control of reaction parameters and optimized reactor designs.Expand Specific Solutions05 Thermite for underwater applications

Specialized thermite formulations and ignition systems are developed for underwater applications. These adaptations allow for thermite-based cutting, welding, or demolition processes to be performed in submerged environments, expanding the range of applications for thermite reactions and streamlining underwater operations.Expand Specific Solutions

Key Players in Thermite Industry

The thermite-based processes industry is in a mature stage, with a growing market size driven by applications in metallurgy, welding, and pyrotechnics. The technology's maturity is evident from the diverse range of players involved, including academic institutions like Chongqing University and University of Science & Technology Beijing, as well as industrial giants such as Lockheed Martin Corp. and ConocoPhillips Co. Research institutes like Pangang Group Research Institute and the Institute of Process Engineering, Chinese Academy of Sciences are actively contributing to technological advancements. The competitive landscape is characterized by a mix of established corporations and specialized research entities, indicating ongoing innovation efforts to streamline and improve thermite-based processes for various industrial applications.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based processes for industrial applications, focusing on improving efficiency and safety. Their approach involves precise control of particle size distribution and composition of thermite mixtures, optimizing the reaction kinetics. They have also implemented automated systems for handling and initiating thermite reactions, reducing human exposure to potential hazards. Additionally, Lockheed Martin has explored the use of novel additives to enhance the performance and controllability of thermite reactions in various industrial processes.

Strengths: Advanced research capabilities, strong focus on safety, and integration with automated systems. Weaknesses: High development costs and potential regulatory challenges for widespread implementation.

Pangang Group Research Institute Co., Ltd.

Technical Solution: Pangang Group Research Institute has developed a streamlined thermite-based process specifically tailored for the steel industry. Their approach focuses on optimizing the thermite reaction for steel production and refining. They have engineered a continuous feed system that allows for precise control of the thermite mixture composition and reaction rate. This system incorporates real-time monitoring of temperature and reaction progress, enabling adaptive control of the process. The institute has also developed specialized refractory materials to withstand the extreme temperatures generated during thermite reactions, extending equipment lifespan and reducing maintenance costs.

Strengths: Specialized expertise in steel industry applications, innovative continuous feed system. Weaknesses: Potentially limited applicability outside the steel industry, high initial investment costs.

Innovative Thermite Reaction Control Techniques

Metal/metal oxide fueled engine

PatentUndeterminedNZ546023A

Innovation

- A method involving the ignition of a thermite mixture in a chamber, where water or steam is introduced to control the reaction temperature, produce hydrogen, and sustain the thermite reaction, allowing the conversion of heat and pressure into mechanical energy through the use of a heat engine.

Thermite charge

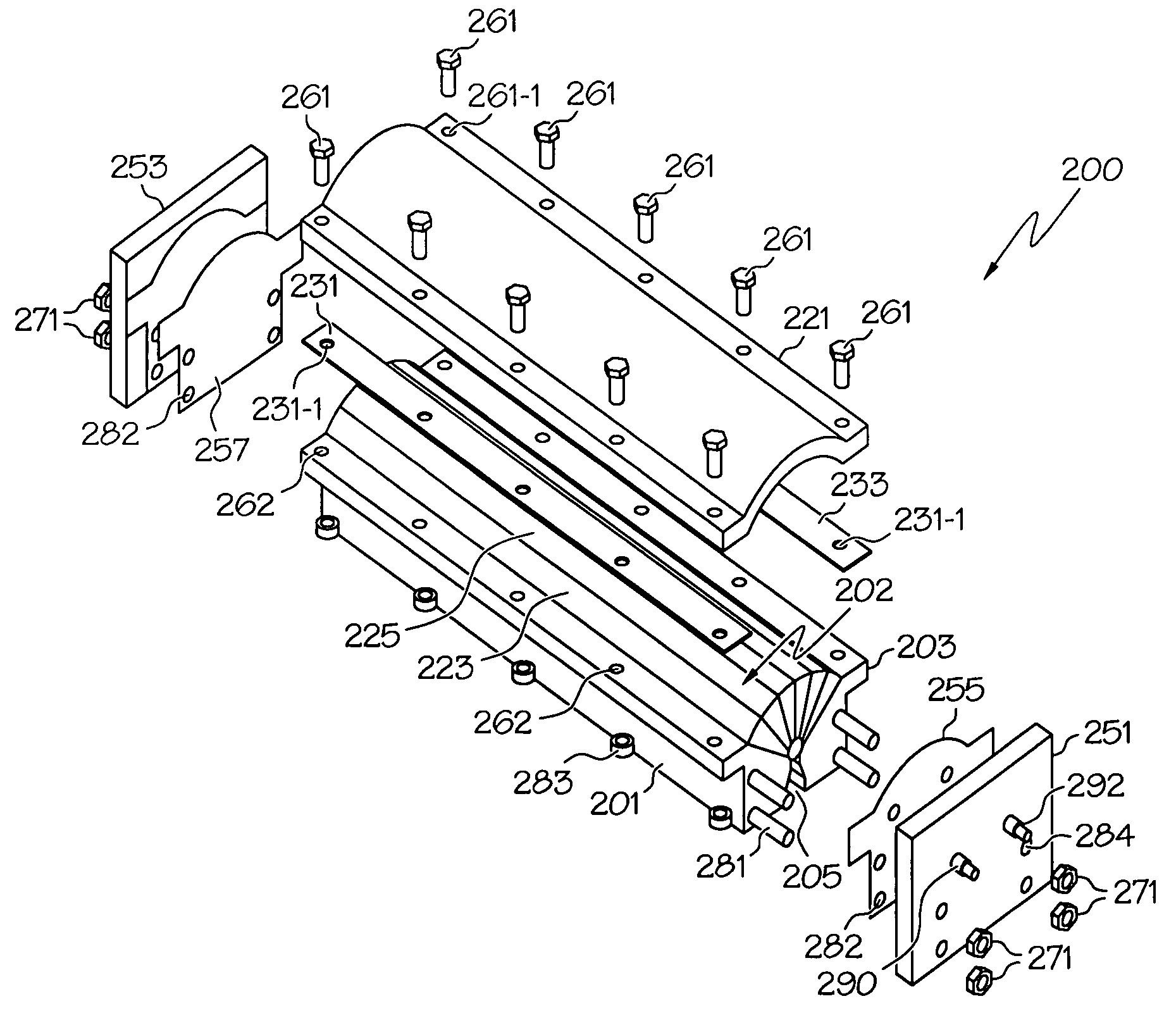

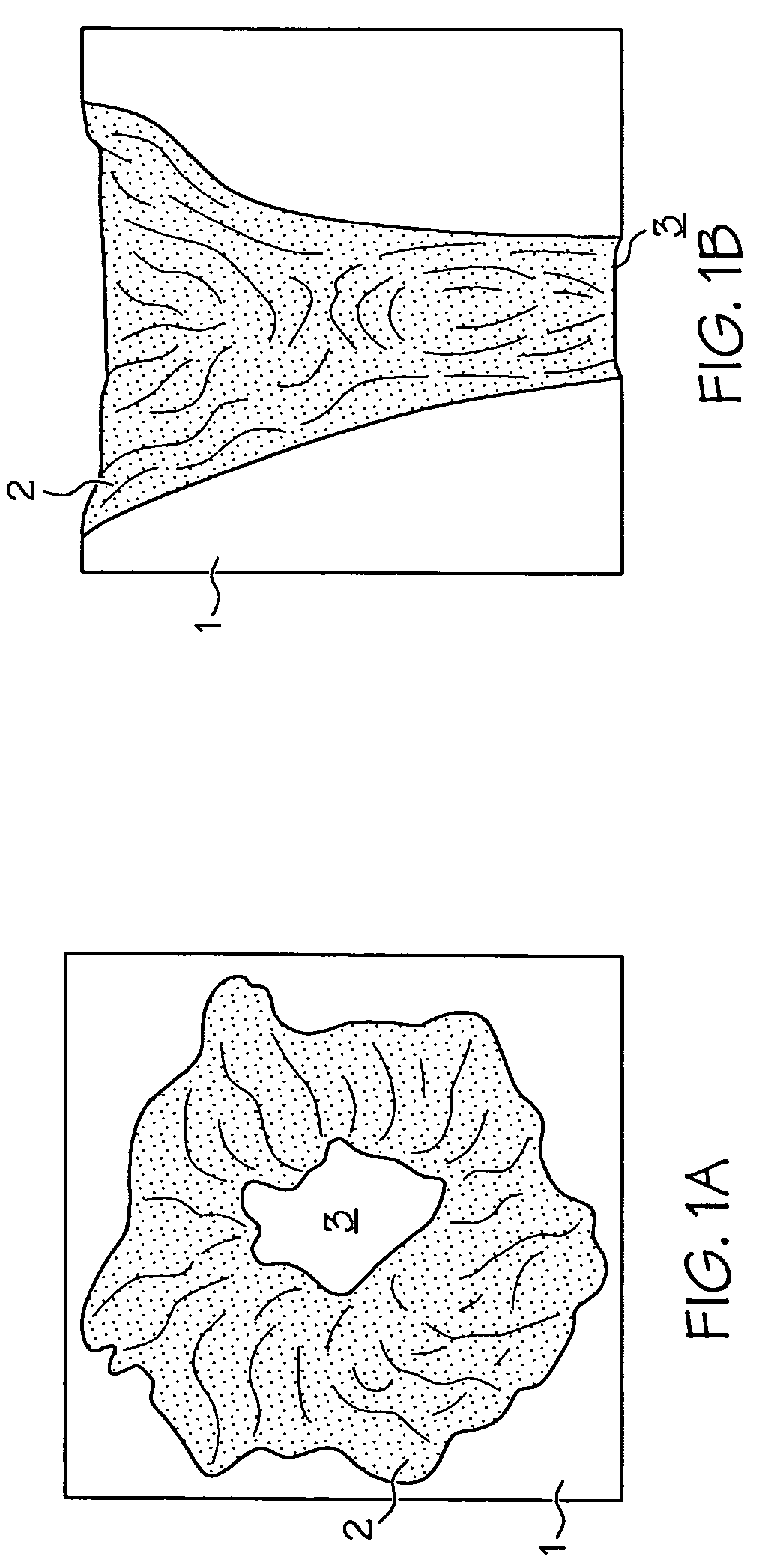

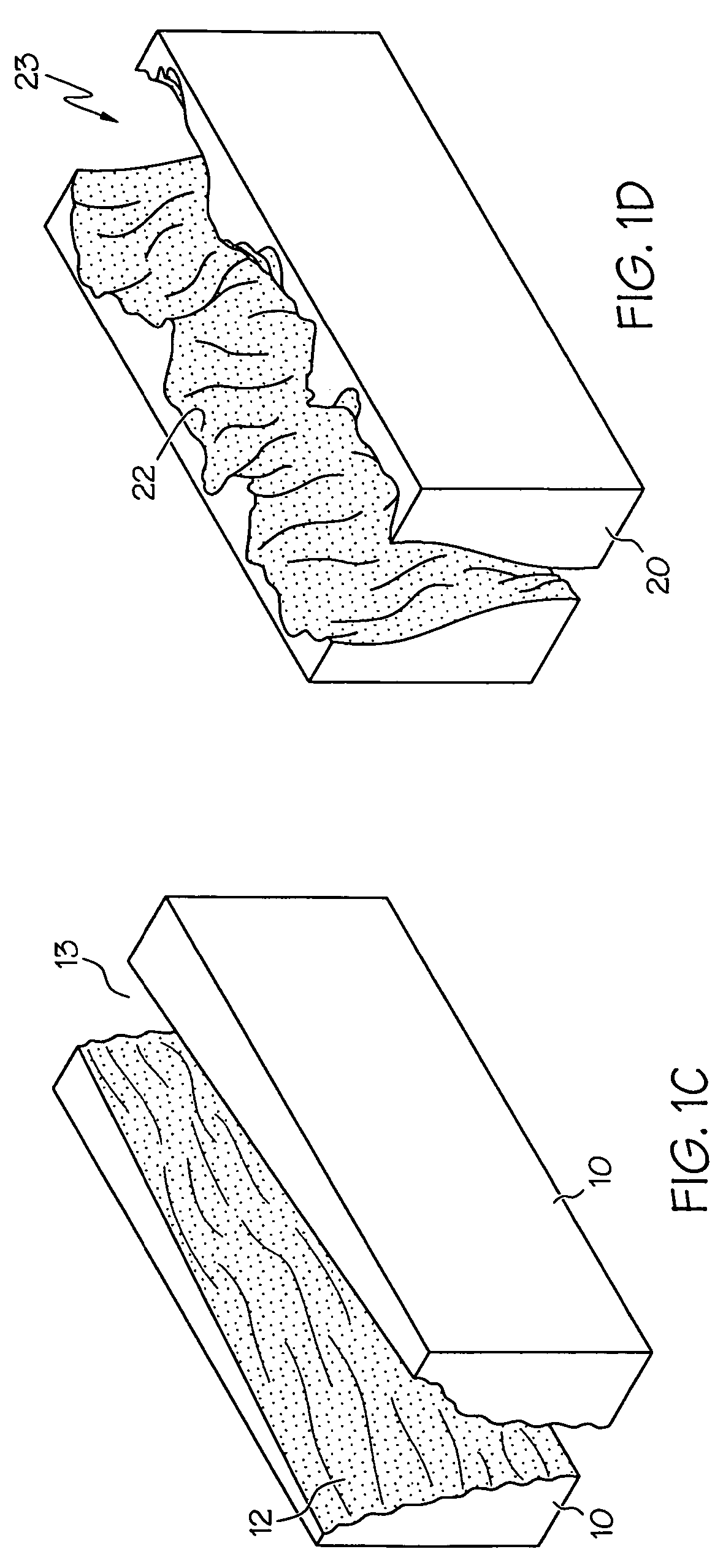

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety Regulations in Thermite Handling

Safety regulations in thermite handling are paramount in streamlining thermite-based processes in industry. The highly exothermic nature of thermite reactions necessitates stringent safety protocols to protect workers, equipment, and the environment. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have established comprehensive guidelines for the safe handling and use of thermite in industrial settings.

These regulations typically cover several key areas. Personal Protective Equipment (PPE) is a critical component, with requirements for fire-resistant clothing, face shields, and specialized gloves to protect against the extreme heat generated during thermite reactions. Proper training and certification of personnel handling thermite are also mandated, ensuring that workers are well-versed in safety procedures and emergency protocols.

Storage and transportation of thermite materials are subject to strict regulations. Thermite must be stored in dry, cool areas away from potential ignition sources and incompatible materials. During transportation, thermite is classified as a hazardous material and must be properly labeled and packaged according to international standards such as those set by the United Nations Committee of Experts on the Transport of Dangerous Goods.

Workplace design and engineering controls play a crucial role in thermite safety. Regulations often require the installation of fire suppression systems, proper ventilation to manage fumes and dust, and designated areas for thermite reactions that are isolated from other work zones. Regular maintenance and inspection of equipment used in thermite processes are also mandated to prevent accidents due to equipment failure.

Emergency response planning is another critical aspect of thermite safety regulations. Companies are required to have detailed emergency procedures in place, including evacuation plans, fire-fighting strategies specific to thermite fires, and first-aid protocols for potential injuries. Regular drills and simulations are often required to ensure that all personnel are prepared to respond effectively in case of an incident.

Environmental considerations are increasingly important in thermite safety regulations. Guidelines for the proper disposal of thermite waste and measures to prevent environmental contamination are typically included. This may involve specialized waste management procedures and monitoring of air and water quality in areas where thermite processes are conducted.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in streamlining thermite-based processes. By implementing robust safety measures, industries can minimize the risk of accidents, reduce downtime, and improve overall operational efficiency. Regular audits and continuous improvement of safety protocols ensure that thermite processes remain both safe and productive in industrial applications.

These regulations typically cover several key areas. Personal Protective Equipment (PPE) is a critical component, with requirements for fire-resistant clothing, face shields, and specialized gloves to protect against the extreme heat generated during thermite reactions. Proper training and certification of personnel handling thermite are also mandated, ensuring that workers are well-versed in safety procedures and emergency protocols.

Storage and transportation of thermite materials are subject to strict regulations. Thermite must be stored in dry, cool areas away from potential ignition sources and incompatible materials. During transportation, thermite is classified as a hazardous material and must be properly labeled and packaged according to international standards such as those set by the United Nations Committee of Experts on the Transport of Dangerous Goods.

Workplace design and engineering controls play a crucial role in thermite safety. Regulations often require the installation of fire suppression systems, proper ventilation to manage fumes and dust, and designated areas for thermite reactions that are isolated from other work zones. Regular maintenance and inspection of equipment used in thermite processes are also mandated to prevent accidents due to equipment failure.

Emergency response planning is another critical aspect of thermite safety regulations. Companies are required to have detailed emergency procedures in place, including evacuation plans, fire-fighting strategies specific to thermite fires, and first-aid protocols for potential injuries. Regular drills and simulations are often required to ensure that all personnel are prepared to respond effectively in case of an incident.

Environmental considerations are increasingly important in thermite safety regulations. Guidelines for the proper disposal of thermite waste and measures to prevent environmental contamination are typically included. This may involve specialized waste management procedures and monitoring of air and water quality in areas where thermite processes are conducted.

Compliance with these safety regulations is not only a legal requirement but also a crucial factor in streamlining thermite-based processes. By implementing robust safety measures, industries can minimize the risk of accidents, reduce downtime, and improve overall operational efficiency. Regular audits and continuous improvement of safety protocols ensure that thermite processes remain both safe and productive in industrial applications.

Environmental Impact of Thermite Processes

Thermite-based processes, while highly effective in certain industrial applications, have significant environmental implications that must be carefully considered and managed. The primary environmental concerns stem from the intense heat generated during the reaction and the resulting emissions and byproducts.

One of the most pressing environmental issues associated with thermite processes is air pollution. The reaction produces a substantial amount of smoke and particulate matter, which can contribute to local air quality degradation if not properly controlled. These emissions may contain metal oxides and other potentially harmful substances, posing risks to both human health and the surrounding ecosystem.

Water pollution is another critical concern. If thermite reactions occur near water sources or if proper containment measures are not in place, the high-temperature byproducts and residues can contaminate groundwater and surface water. This contamination may introduce heavy metals and other pollutants into aquatic ecosystems, potentially causing long-term environmental damage.

The intense heat generated by thermite reactions can also lead to soil degradation and localized thermal pollution. This can alter soil composition and structure, potentially impacting local flora and fauna. In some cases, the extreme temperatures may even cause wildfires if proper precautions are not taken, especially in dry or forested areas.

Waste management is a crucial aspect of mitigating the environmental impact of thermite processes. The slag and other byproducts produced during the reaction must be properly disposed of or recycled to prevent soil and water contamination. Improper handling of these materials can lead to the leaching of hazardous substances into the environment.

Energy consumption is another environmental factor to consider. While the thermite reaction itself is highly exothermic, the preparation and handling of materials, as well as the implementation of safety and environmental control measures, can require significant energy inputs. This indirectly contributes to greenhouse gas emissions and resource depletion if not managed efficiently.

To address these environmental concerns, industries employing thermite-based processes must implement robust pollution control systems, including advanced filtration technologies for air emissions and proper containment and treatment facilities for liquid and solid waste. Additionally, adopting cleaner production techniques, optimizing reaction conditions, and exploring alternative, more environmentally friendly processes can help reduce the overall environmental footprint of thermite-based industrial operations.

One of the most pressing environmental issues associated with thermite processes is air pollution. The reaction produces a substantial amount of smoke and particulate matter, which can contribute to local air quality degradation if not properly controlled. These emissions may contain metal oxides and other potentially harmful substances, posing risks to both human health and the surrounding ecosystem.

Water pollution is another critical concern. If thermite reactions occur near water sources or if proper containment measures are not in place, the high-temperature byproducts and residues can contaminate groundwater and surface water. This contamination may introduce heavy metals and other pollutants into aquatic ecosystems, potentially causing long-term environmental damage.

The intense heat generated by thermite reactions can also lead to soil degradation and localized thermal pollution. This can alter soil composition and structure, potentially impacting local flora and fauna. In some cases, the extreme temperatures may even cause wildfires if proper precautions are not taken, especially in dry or forested areas.

Waste management is a crucial aspect of mitigating the environmental impact of thermite processes. The slag and other byproducts produced during the reaction must be properly disposed of or recycled to prevent soil and water contamination. Improper handling of these materials can lead to the leaching of hazardous substances into the environment.

Energy consumption is another environmental factor to consider. While the thermite reaction itself is highly exothermic, the preparation and handling of materials, as well as the implementation of safety and environmental control measures, can require significant energy inputs. This indirectly contributes to greenhouse gas emissions and resource depletion if not managed efficiently.

To address these environmental concerns, industries employing thermite-based processes must implement robust pollution control systems, including advanced filtration technologies for air emissions and proper containment and treatment facilities for liquid and solid waste. Additionally, adopting cleaner production techniques, optimizing reaction conditions, and exploring alternative, more environmentally friendly processes can help reduce the overall environmental footprint of thermite-based industrial operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!