Thermite for High‑Temperature Applications: A Review

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Technology Evolution and Objectives

Thermite technology has evolved significantly since its inception in the late 19th century. Initially developed as a welding technique, thermite reactions have found applications in various high-temperature processes due to their ability to generate intense heat and molten metal. The evolution of thermite technology has been driven by the need for more efficient, controllable, and versatile exothermic reactions.

In the early stages, thermite reactions were primarily used for welding railroad tracks and repairing heavy machinery. As research progressed, the focus shifted towards optimizing the composition of thermite mixtures to achieve specific temperature profiles and reaction rates. This led to the development of tailored thermite formulations for different applications, such as metal purification, underwater welding, and incendiary devices.

The objectives of modern thermite technology research are multifaceted. One primary goal is to enhance the energy density and reaction efficiency of thermite mixtures. This involves exploring novel combinations of metal fuels and oxidizers, as well as investigating the effects of particle size and morphology on reaction kinetics. Researchers aim to develop thermite compositions that can produce higher temperatures while maintaining controllability and safety.

Another important objective is to expand the range of applications for thermite reactions in high-temperature processes. This includes developing thermite-based materials for thermal management in aerospace and defense industries, as well as exploring their potential in advanced manufacturing techniques such as additive manufacturing and self-propagating high-temperature synthesis (SHS).

Improving the safety and handling characteristics of thermite mixtures is also a crucial objective. Efforts are being made to develop less sensitive formulations that reduce the risk of accidental ignition while maintaining their reactivity when needed. This involves research into stabilizers, binders, and encapsulation techniques that can enhance the shelf life and handling properties of thermite materials.

The integration of nanotechnology into thermite research has opened up new avenues for innovation. Nanoscale thermite materials, often referred to as metastable intermolecular composites (MICs), offer enhanced reactivity and energy release rates compared to their microscale counterparts. Researchers are exploring the synthesis and characterization of these nanothermites to unlock their potential in various high-temperature applications.

As environmental concerns gain prominence, there is a growing focus on developing more sustainable thermite technologies. This includes research into environmentally friendly oxidizers and fuels, as well as investigating ways to reduce harmful emissions and byproducts from thermite reactions. The goal is to create greener alternatives that maintain the high-temperature performance of traditional thermite mixtures while minimizing their environmental impact.

In the early stages, thermite reactions were primarily used for welding railroad tracks and repairing heavy machinery. As research progressed, the focus shifted towards optimizing the composition of thermite mixtures to achieve specific temperature profiles and reaction rates. This led to the development of tailored thermite formulations for different applications, such as metal purification, underwater welding, and incendiary devices.

The objectives of modern thermite technology research are multifaceted. One primary goal is to enhance the energy density and reaction efficiency of thermite mixtures. This involves exploring novel combinations of metal fuels and oxidizers, as well as investigating the effects of particle size and morphology on reaction kinetics. Researchers aim to develop thermite compositions that can produce higher temperatures while maintaining controllability and safety.

Another important objective is to expand the range of applications for thermite reactions in high-temperature processes. This includes developing thermite-based materials for thermal management in aerospace and defense industries, as well as exploring their potential in advanced manufacturing techniques such as additive manufacturing and self-propagating high-temperature synthesis (SHS).

Improving the safety and handling characteristics of thermite mixtures is also a crucial objective. Efforts are being made to develop less sensitive formulations that reduce the risk of accidental ignition while maintaining their reactivity when needed. This involves research into stabilizers, binders, and encapsulation techniques that can enhance the shelf life and handling properties of thermite materials.

The integration of nanotechnology into thermite research has opened up new avenues for innovation. Nanoscale thermite materials, often referred to as metastable intermolecular composites (MICs), offer enhanced reactivity and energy release rates compared to their microscale counterparts. Researchers are exploring the synthesis and characterization of these nanothermites to unlock their potential in various high-temperature applications.

As environmental concerns gain prominence, there is a growing focus on developing more sustainable thermite technologies. This includes research into environmentally friendly oxidizers and fuels, as well as investigating ways to reduce harmful emissions and byproducts from thermite reactions. The goal is to create greener alternatives that maintain the high-temperature performance of traditional thermite mixtures while minimizing their environmental impact.

High-Temperature Applications Market Analysis

The high-temperature applications market has been experiencing significant growth due to increasing demand across various industries. This market segment encompasses a wide range of products and technologies designed to withstand extreme temperatures, including thermite-based solutions. The global high-temperature materials market is projected to expand at a steady rate, driven by advancements in aerospace, automotive, and industrial sectors.

In the aerospace industry, there is a growing need for materials that can withstand high temperatures in jet engines and rocket propulsion systems. The automotive sector is also contributing to market growth, with the development of more efficient engines and exhaust systems requiring materials capable of operating at elevated temperatures. Additionally, the industrial sector, particularly in metallurgy and chemical processing, continues to drive demand for high-temperature applications.

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has found increasing applications in high-temperature scenarios. Its ability to generate extreme heat through exothermic reduction-oxidation reactions makes it valuable in various industrial processes. The market for thermite-based solutions in high-temperature applications is expected to grow as industries seek more efficient and cost-effective methods for welding, metal purification, and thermal barrier coatings.

The energy sector presents another significant opportunity for high-temperature applications, including thermite-based technologies. As renewable energy sources gain prominence, there is a rising demand for materials that can withstand high temperatures in solar thermal power plants and geothermal energy systems. This trend is likely to continue as countries worldwide invest in clean energy infrastructure.

Emerging economies, particularly in Asia-Pacific and Latin America, are expected to be key growth drivers for the high-temperature applications market. Rapid industrialization and infrastructure development in these regions are creating new opportunities for advanced materials and technologies capable of operating in extreme temperature environments.

However, the market faces challenges such as high production costs and stringent environmental regulations. Manufacturers are investing in research and development to create more sustainable and cost-effective high-temperature materials, including improved thermite formulations. This focus on innovation is expected to open new avenues for market growth and product diversification in the coming years.

In the aerospace industry, there is a growing need for materials that can withstand high temperatures in jet engines and rocket propulsion systems. The automotive sector is also contributing to market growth, with the development of more efficient engines and exhaust systems requiring materials capable of operating at elevated temperatures. Additionally, the industrial sector, particularly in metallurgy and chemical processing, continues to drive demand for high-temperature applications.

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has found increasing applications in high-temperature scenarios. Its ability to generate extreme heat through exothermic reduction-oxidation reactions makes it valuable in various industrial processes. The market for thermite-based solutions in high-temperature applications is expected to grow as industries seek more efficient and cost-effective methods for welding, metal purification, and thermal barrier coatings.

The energy sector presents another significant opportunity for high-temperature applications, including thermite-based technologies. As renewable energy sources gain prominence, there is a rising demand for materials that can withstand high temperatures in solar thermal power plants and geothermal energy systems. This trend is likely to continue as countries worldwide invest in clean energy infrastructure.

Emerging economies, particularly in Asia-Pacific and Latin America, are expected to be key growth drivers for the high-temperature applications market. Rapid industrialization and infrastructure development in these regions are creating new opportunities for advanced materials and technologies capable of operating in extreme temperature environments.

However, the market faces challenges such as high production costs and stringent environmental regulations. Manufacturers are investing in research and development to create more sustainable and cost-effective high-temperature materials, including improved thermite formulations. This focus on innovation is expected to open new avenues for market growth and product diversification in the coming years.

Current Thermite Challenges and Limitations

Despite the promising potential of thermite reactions for high-temperature applications, several challenges and limitations currently hinder their widespread adoption and optimal performance. One of the primary concerns is the control and modulation of reaction rates. Thermite reactions are known for their rapid and exothermic nature, which can lead to uncontrolled combustion and potential safety hazards. This characteristic makes it challenging to harness the energy release in a controlled manner for specific applications.

Another significant limitation is the relatively low energy density of traditional thermite compositions. While thermites can generate high temperatures, the amount of energy released per unit mass or volume is often lower compared to other high-energy materials. This constraint restricts their use in applications where both high temperature and high energy output are required simultaneously.

The ignition sensitivity of thermite mixtures poses another challenge. Some compositions may be too sensitive to mechanical stimuli or electrostatic discharge, raising safety concerns during handling, storage, and transportation. Conversely, other formulations may require complex ignition systems, limiting their practicality in certain scenarios.

Thermal management is a critical issue in thermite applications. The intense heat generated during reactions can lead to material degradation, affecting the longevity and reliability of thermite-based systems. Additionally, the high temperatures produced can cause undesired side reactions or decomposition of surrounding materials, potentially compromising the integrity of the entire system.

The production of gaseous byproducts during thermite reactions presents both environmental and practical challenges. These gases can contribute to pollution and may require additional containment or filtration systems, especially in enclosed environments. Furthermore, the generation of gases can lead to pressure buildup, necessitating careful design considerations in applications where pressure control is crucial.

Scalability remains a significant hurdle in thermite technology. While thermite reactions are well-understood at small scales, translating this knowledge to larger-scale applications presents numerous engineering challenges. Issues such as heat dissipation, reaction uniformity, and product consistency become more pronounced as the scale increases.

Lastly, the cost and availability of certain thermite components, particularly for advanced or specialized formulations, can limit their widespread adoption. Some high-performance thermite mixtures require rare or expensive materials, making them economically unfeasible for large-scale or commercial applications. This economic constraint often necessitates a trade-off between performance and cost-effectiveness in practical implementations.

Another significant limitation is the relatively low energy density of traditional thermite compositions. While thermites can generate high temperatures, the amount of energy released per unit mass or volume is often lower compared to other high-energy materials. This constraint restricts their use in applications where both high temperature and high energy output are required simultaneously.

The ignition sensitivity of thermite mixtures poses another challenge. Some compositions may be too sensitive to mechanical stimuli or electrostatic discharge, raising safety concerns during handling, storage, and transportation. Conversely, other formulations may require complex ignition systems, limiting their practicality in certain scenarios.

Thermal management is a critical issue in thermite applications. The intense heat generated during reactions can lead to material degradation, affecting the longevity and reliability of thermite-based systems. Additionally, the high temperatures produced can cause undesired side reactions or decomposition of surrounding materials, potentially compromising the integrity of the entire system.

The production of gaseous byproducts during thermite reactions presents both environmental and practical challenges. These gases can contribute to pollution and may require additional containment or filtration systems, especially in enclosed environments. Furthermore, the generation of gases can lead to pressure buildup, necessitating careful design considerations in applications where pressure control is crucial.

Scalability remains a significant hurdle in thermite technology. While thermite reactions are well-understood at small scales, translating this knowledge to larger-scale applications presents numerous engineering challenges. Issues such as heat dissipation, reaction uniformity, and product consistency become more pronounced as the scale increases.

Lastly, the cost and availability of certain thermite components, particularly for advanced or specialized formulations, can limit their widespread adoption. Some high-performance thermite mixtures require rare or expensive materials, making them economically unfeasible for large-scale or commercial applications. This economic constraint often necessitates a trade-off between performance and cost-effectiveness in practical implementations.

Existing High-Temperature Thermite Solutions

01 Thermite composition and applications

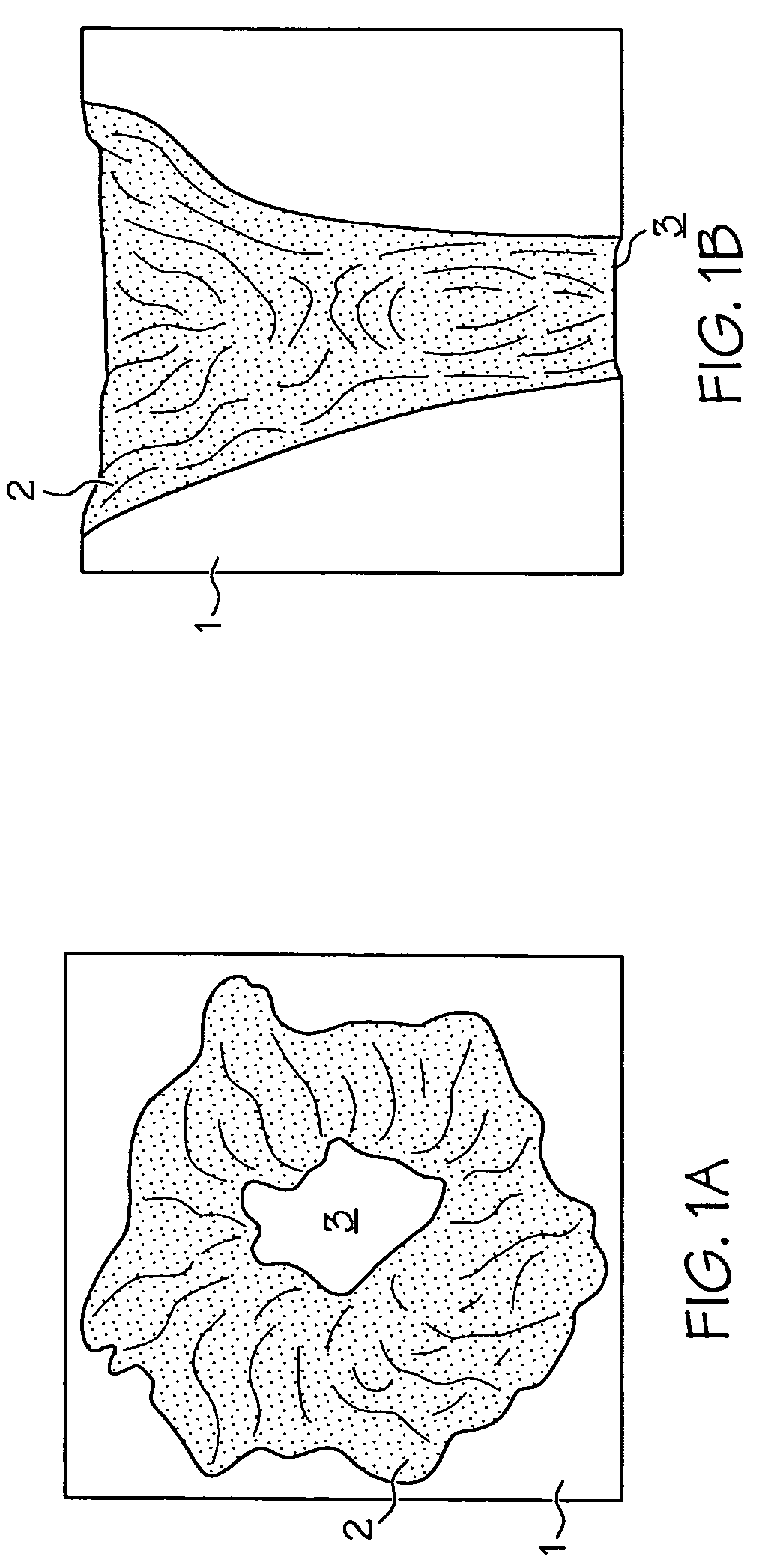

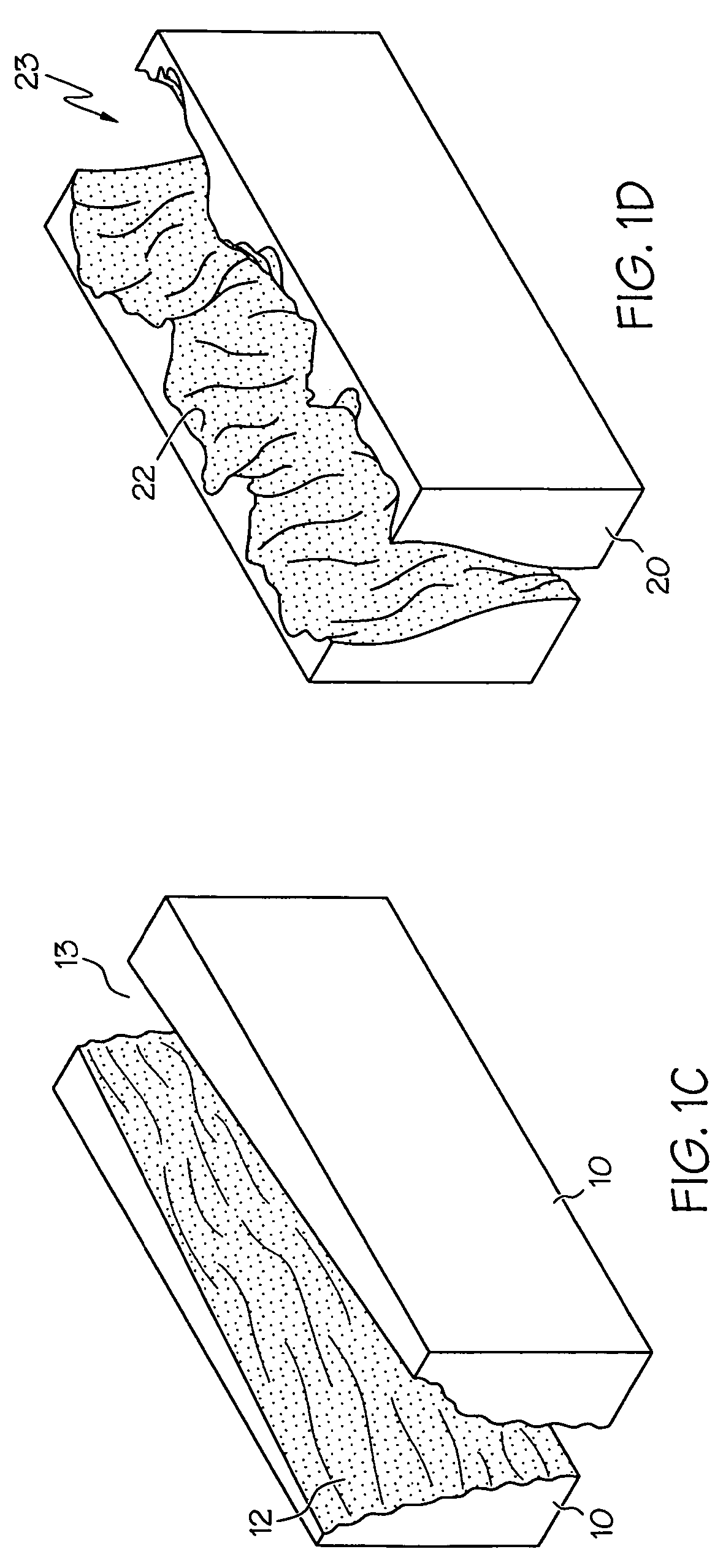

Thermite is a pyrotechnic composition of metal powder fuel and metal oxide. It's used in various applications including welding, incendiary devices, and metal purification. The reaction produces extremely high temperatures, making it suitable for cutting through metal structures or generating heat for specific processes.- Thermite composition and ignition methods: Thermite compositions typically consist of metal oxides and aluminum powder. Various ignition methods are used, including electrical, chemical, and mechanical means. The reaction produces intense heat and molten metal, making it useful for welding, incendiary devices, and metal purification.

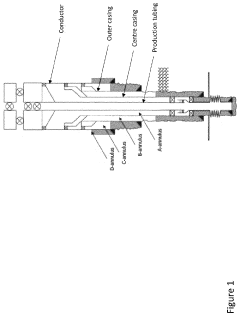

- Applications in oil and gas well operations: Thermite reactions are utilized in oil and gas well operations for various purposes. These include perforating well casings, sealing off sections of wells, and initiating downhole tools. The controlled exothermic reaction provides localized heat and pressure for specific well interventions.

- Use in welding and metal joining: Thermite reactions are employed in welding processes, particularly for joining large metal components or repairing rails. The intense heat generated by the reaction melts the metal, creating a strong bond. This method is advantageous for field repairs and joining dissimilar metals.

- Thermite in military and defense applications: Thermite compositions are used in military applications for incendiary devices, armor-piercing projectiles, and ordnance disposal. The high temperature and metal-cutting properties make it effective for disabling equipment and penetrating armored targets.

- Safety and control mechanisms for thermite reactions: Various safety measures and control mechanisms are implemented when working with thermite. These include specialized containment vessels, remote ignition systems, and precise mixture ratios. Proper handling and storage procedures are crucial to prevent accidental ignition and ensure controlled reactions.

02 Thermite in downhole tools and well operations

Thermite reactions are utilized in downhole tools and well operations. These applications include cutting tubulars, sealing wellbores, and initiating other downhole processes. The high-temperature reaction of thermite can be controlled and directed to perform specific tasks in oil and gas wells.Expand Specific Solutions03 Enhanced thermite formulations

Research focuses on improving thermite formulations for increased performance and safety. This includes developing nanoparticle-based thermites, adjusting particle sizes, and incorporating additives to control reaction rates and energy output. These enhancements aim to optimize thermite for specific applications and improve its overall efficiency.Expand Specific Solutions04 Thermite in additive manufacturing and 3D printing

Thermite materials are being explored for use in additive manufacturing and 3D printing processes. This innovative application allows for the creation of complex structures with embedded energetic materials, potentially revolutionizing fields such as aerospace and defense manufacturing.Expand Specific Solutions05 Safety and control mechanisms for thermite reactions

Given the high-energy nature of thermite reactions, significant research is devoted to developing safety mechanisms and control systems. This includes methods for precise ignition, containment of the reaction, and safe disposal of byproducts. These advancements aim to make thermite use safer in various industrial and military applications.Expand Specific Solutions

Key Thermite Industry Players

The thermite technology for high-temperature applications is in a mature development stage, with a growing market driven by increasing demand in various industries. The market size is substantial, with applications ranging from welding and metal purification to aerospace and defense. Technologically, thermite reactions are well-understood, but ongoing research focuses on enhancing performance and safety. Companies like Lockheed Martin Corp., DuPont de Nemours, Inc., and China National Petroleum Corp. are at the forefront of innovation, developing advanced thermite compositions for specific high-temperature applications. Research institutions such as the Naval Research Laboratory and universities are also contributing to the field, pushing the boundaries of thermite technology for extreme environments and specialized uses.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based materials for high-temperature applications in aerospace and defense. Their proprietary formulation combines traditional thermite components with nano-scale additives to enhance reactivity and control burn rates. This technology is applied in thermal management systems for hypersonic vehicles, where it provides rapid heat generation for de-icing and thermal protection. The company has also explored using these materials in welding and metal-joining processes for extreme environments.

Strengths: Expertise in aerospace applications, advanced nano-material integration, and controlled reactivity. Weaknesses: High cost of production and limited applications outside of aerospace and defense sectors.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of high-performance thermite materials for industrial applications. Their research focuses on creating thermite composites that combine high energy density with improved safety and handling characteristics. DuPont's thermite formulations incorporate polymer binders and stabilizers to enhance shelf life and reduce sensitivity to accidental ignition. These materials are designed for use in metal purification processes, welding applications, and as heat sources in chemical reactions. DuPont has also explored the use of these materials in self-healing composites for high-temperature environments.

Strengths: Extensive material science expertise, focus on safety and stability, wide range of industrial applications. Weaknesses: Less specialized in extreme high-temperature applications compared to aerospace-focused companies.

Core Thermite Reaction Innovations

Thermite charge

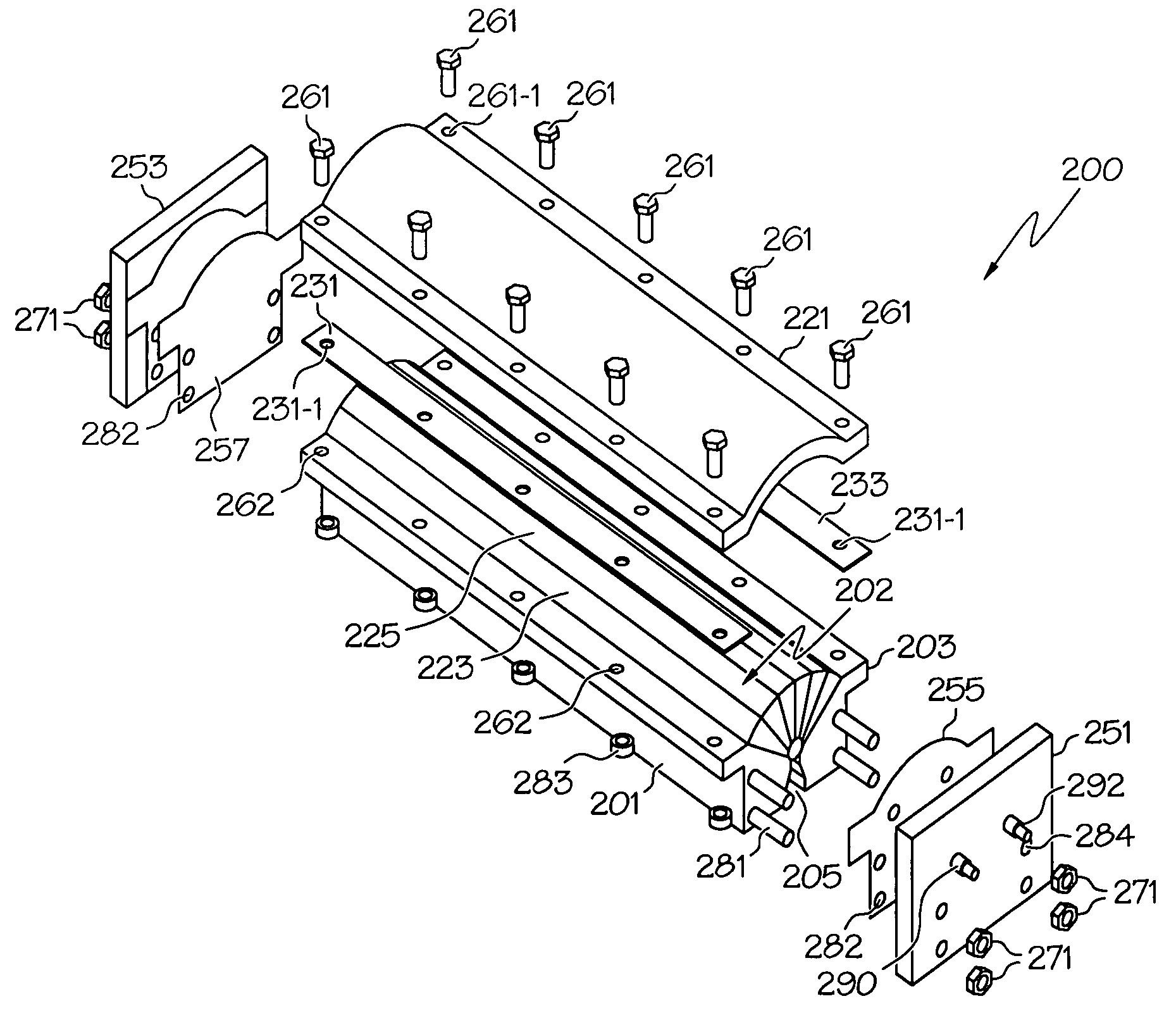

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

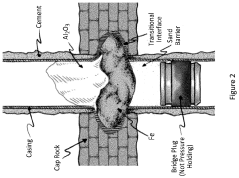

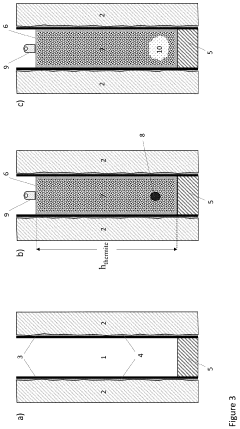

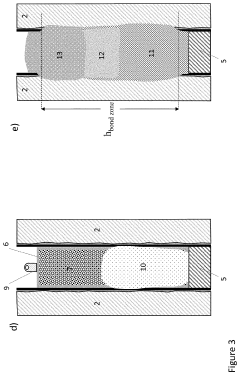

Thermite reaction charge, method for forming a threephased rock-to-rock well barrier, and a well barrier formed thereof

PatentActiveUS20230258052A1

Innovation

- A rigless method employing a bismuth oxide and fuel metal thermite reaction charge, adapted to produce sufficient heat and react slowly enough to melt downhole completion and form a three-phase rock-to-rock well barrier with bismuth, steel, and slag phases, providing a resilient bonding with the rock formation.

Safety Regulations for Thermite Usage

The use of thermite in high-temperature applications necessitates strict adherence to safety regulations due to its highly exothermic nature and potential hazards. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe handling, storage, and application of thermite materials. These regulations typically cover various aspects, including personal protective equipment (PPE), storage conditions, transportation requirements, and operational procedures.

Safety standards for thermite usage often mandate the use of specialized PPE, such as fire-resistant clothing, face shields, and respiratory protection. Storage regulations typically require thermite materials to be kept in dry, cool environments, away from potential ignition sources and incompatible substances. Transportation of thermite is subject to stringent rules, often classified as a hazardous material, requiring proper labeling, packaging, and documentation.

Operational safety protocols for thermite applications are particularly rigorous. These may include establishing exclusion zones during thermite reactions, implementing fire prevention and suppression measures, and ensuring proper ventilation in enclosed spaces. Many regulations also stipulate the need for specialized training and certification for personnel handling thermite, emphasizing the importance of competence in managing the associated risks.

Environmental considerations are increasingly prominent in thermite safety regulations. Guidelines often address the proper disposal of thermite residues and the mitigation of potential environmental impacts, such as air and soil contamination. Some jurisdictions require environmental impact assessments before large-scale thermite applications, particularly in sensitive ecological areas.

Regulatory frameworks for thermite usage vary across different countries and industries. In the United States, for instance, the Occupational Safety and Health Administration (OSHA) provides specific guidelines for thermite welding in construction and general industry. Similarly, the European Union has established harmonized standards for the use of thermite in railway track welding through the European Committee for Standardization (CEN).

Compliance with these safety regulations is crucial not only for legal reasons but also for ensuring the safe and effective use of thermite in high-temperature applications. As research continues to advance thermite technology, safety regulations are likely to evolve, potentially incorporating new findings on risk mitigation and environmental protection. This ongoing regulatory development underscores the need for continuous education and adaptation in the field of thermite applications.

Safety standards for thermite usage often mandate the use of specialized PPE, such as fire-resistant clothing, face shields, and respiratory protection. Storage regulations typically require thermite materials to be kept in dry, cool environments, away from potential ignition sources and incompatible substances. Transportation of thermite is subject to stringent rules, often classified as a hazardous material, requiring proper labeling, packaging, and documentation.

Operational safety protocols for thermite applications are particularly rigorous. These may include establishing exclusion zones during thermite reactions, implementing fire prevention and suppression measures, and ensuring proper ventilation in enclosed spaces. Many regulations also stipulate the need for specialized training and certification for personnel handling thermite, emphasizing the importance of competence in managing the associated risks.

Environmental considerations are increasingly prominent in thermite safety regulations. Guidelines often address the proper disposal of thermite residues and the mitigation of potential environmental impacts, such as air and soil contamination. Some jurisdictions require environmental impact assessments before large-scale thermite applications, particularly in sensitive ecological areas.

Regulatory frameworks for thermite usage vary across different countries and industries. In the United States, for instance, the Occupational Safety and Health Administration (OSHA) provides specific guidelines for thermite welding in construction and general industry. Similarly, the European Union has established harmonized standards for the use of thermite in railway track welding through the European Committee for Standardization (CEN).

Compliance with these safety regulations is crucial not only for legal reasons but also for ensuring the safe and effective use of thermite in high-temperature applications. As research continues to advance thermite technology, safety regulations are likely to evolve, potentially incorporating new findings on risk mitigation and environmental protection. This ongoing regulatory development underscores the need for continuous education and adaptation in the field of thermite applications.

Environmental Impact of Thermite Applications

The environmental impact of thermite applications is a critical consideration in the use of this high-temperature reactive material. Thermite reactions, while highly effective for certain industrial and military applications, can have significant environmental consequences if not properly managed and controlled.

One of the primary environmental concerns associated with thermite applications is the release of particulate matter and metal oxides into the atmosphere. The intense heat generated during thermite reactions can vaporize metals and other materials, leading to the formation of fine particles that can remain suspended in the air for extended periods. These particles, particularly those in the PM2.5 range, pose respiratory health risks to both humans and wildlife in the vicinity of thermite operations.

Additionally, the use of thermite can result in the contamination of soil and water resources. The residual products of thermite reactions, including metal oxides and slag, can leach into the surrounding environment. This leaching process may introduce heavy metals and other potentially toxic substances into ecosystems, affecting plant growth, soil microbial communities, and aquatic life.

The high temperatures associated with thermite reactions also contribute to localized thermal pollution. This can lead to the destruction of vegetation and alteration of soil properties in the immediate area of application. In some cases, the intense heat may cause long-lasting changes to the physical and chemical characteristics of the affected soil, impacting its fertility and ability to support native flora and fauna.

Furthermore, the production and transportation of thermite materials themselves have environmental implications. The mining and processing of raw materials for thermite mixtures, such as aluminum and various metal oxides, can lead to habitat destruction, energy consumption, and greenhouse gas emissions. The transportation of these materials also contributes to the overall carbon footprint of thermite applications.

It is important to note that the environmental impact of thermite can vary significantly depending on the specific application, scale of use, and environmental setting. For instance, controlled industrial applications in contained environments may have minimal environmental consequences, while large-scale military or demolition uses in open areas could have more substantial and far-reaching effects.

To mitigate these environmental concerns, ongoing research is focused on developing more environmentally friendly thermite formulations and application methods. This includes exploring the use of recyclable or biodegradable components, improving reaction efficiency to reduce waste products, and implementing advanced containment and filtration systems to minimize emissions and contamination.

One of the primary environmental concerns associated with thermite applications is the release of particulate matter and metal oxides into the atmosphere. The intense heat generated during thermite reactions can vaporize metals and other materials, leading to the formation of fine particles that can remain suspended in the air for extended periods. These particles, particularly those in the PM2.5 range, pose respiratory health risks to both humans and wildlife in the vicinity of thermite operations.

Additionally, the use of thermite can result in the contamination of soil and water resources. The residual products of thermite reactions, including metal oxides and slag, can leach into the surrounding environment. This leaching process may introduce heavy metals and other potentially toxic substances into ecosystems, affecting plant growth, soil microbial communities, and aquatic life.

The high temperatures associated with thermite reactions also contribute to localized thermal pollution. This can lead to the destruction of vegetation and alteration of soil properties in the immediate area of application. In some cases, the intense heat may cause long-lasting changes to the physical and chemical characteristics of the affected soil, impacting its fertility and ability to support native flora and fauna.

Furthermore, the production and transportation of thermite materials themselves have environmental implications. The mining and processing of raw materials for thermite mixtures, such as aluminum and various metal oxides, can lead to habitat destruction, energy consumption, and greenhouse gas emissions. The transportation of these materials also contributes to the overall carbon footprint of thermite applications.

It is important to note that the environmental impact of thermite can vary significantly depending on the specific application, scale of use, and environmental setting. For instance, controlled industrial applications in contained environments may have minimal environmental consequences, while large-scale military or demolition uses in open areas could have more substantial and far-reaching effects.

To mitigate these environmental concerns, ongoing research is focused on developing more environmentally friendly thermite formulations and application methods. This includes exploring the use of recyclable or biodegradable components, improving reaction efficiency to reduce waste products, and implementing advanced containment and filtration systems to minimize emissions and contamination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!