How to Enhance Thermite Safety Protocols in Laboratories?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Safety Background and Objectives

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has been widely used in various industrial and research applications due to its high heat generation and metal-reducing capabilities. However, its potential for extreme exothermic reactions poses significant safety risks in laboratory settings. The evolution of thermite safety protocols has been driven by a growing understanding of its reactive properties and the need to mitigate associated hazards.

The primary objective of enhancing thermite safety protocols in laboratories is to minimize the risk of accidents, protect personnel, and safeguard research facilities. This goal encompasses the development of comprehensive guidelines for handling, storage, and disposal of thermite materials, as well as the implementation of advanced safety equipment and emergency response procedures.

Historically, thermite safety measures have progressed from basic precautions to more sophisticated approaches. Early protocols focused on personal protective equipment and basic containment strategies. As research expanded, the emphasis shifted towards engineered safety systems, specialized storage solutions, and refined handling techniques. Recent advancements have incorporated real-time monitoring technologies and predictive risk assessment models to further enhance safety measures.

The current landscape of thermite safety is characterized by a multifaceted approach that integrates chemical knowledge, engineering controls, and administrative procedures. Key areas of focus include the precise control of reaction conditions, the development of fire-resistant storage facilities, and the implementation of rigorous training programs for laboratory personnel. Additionally, there is an increasing emphasis on the use of simulation tools to predict potential hazards and optimize safety protocols before conducting actual experiments.

Looking ahead, the trajectory of thermite safety research points towards several key objectives. These include the development of smart materials that can self-extinguish or control thermite reactions, the integration of artificial intelligence for real-time risk assessment and management, and the creation of standardized global safety guidelines for thermite handling in research environments. Furthermore, there is a growing interest in exploring alternative compounds that can provide similar research benefits with reduced safety risks.

The enhancement of thermite safety protocols is not only crucial for protecting human life and research assets but also plays a vital role in advancing scientific progress. By establishing robust safety measures, researchers can confidently explore the full potential of thermite reactions, potentially leading to breakthroughs in materials science, metallurgy, and other related fields. As such, the ongoing evolution of thermite safety protocols represents a critical intersection of scientific innovation and responsible research practices.

The primary objective of enhancing thermite safety protocols in laboratories is to minimize the risk of accidents, protect personnel, and safeguard research facilities. This goal encompasses the development of comprehensive guidelines for handling, storage, and disposal of thermite materials, as well as the implementation of advanced safety equipment and emergency response procedures.

Historically, thermite safety measures have progressed from basic precautions to more sophisticated approaches. Early protocols focused on personal protective equipment and basic containment strategies. As research expanded, the emphasis shifted towards engineered safety systems, specialized storage solutions, and refined handling techniques. Recent advancements have incorporated real-time monitoring technologies and predictive risk assessment models to further enhance safety measures.

The current landscape of thermite safety is characterized by a multifaceted approach that integrates chemical knowledge, engineering controls, and administrative procedures. Key areas of focus include the precise control of reaction conditions, the development of fire-resistant storage facilities, and the implementation of rigorous training programs for laboratory personnel. Additionally, there is an increasing emphasis on the use of simulation tools to predict potential hazards and optimize safety protocols before conducting actual experiments.

Looking ahead, the trajectory of thermite safety research points towards several key objectives. These include the development of smart materials that can self-extinguish or control thermite reactions, the integration of artificial intelligence for real-time risk assessment and management, and the creation of standardized global safety guidelines for thermite handling in research environments. Furthermore, there is a growing interest in exploring alternative compounds that can provide similar research benefits with reduced safety risks.

The enhancement of thermite safety protocols is not only crucial for protecting human life and research assets but also plays a vital role in advancing scientific progress. By establishing robust safety measures, researchers can confidently explore the full potential of thermite reactions, potentially leading to breakthroughs in materials science, metallurgy, and other related fields. As such, the ongoing evolution of thermite safety protocols represents a critical intersection of scientific innovation and responsible research practices.

Laboratory Demand for Enhanced Thermite Protocols

The demand for enhanced thermite safety protocols in laboratories has been steadily increasing due to the growing use of thermite reactions in various research and industrial applications. Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, is known for its high-temperature exothermic reactions, making it both valuable and potentially hazardous in laboratory settings.

Research institutions and industrial laboratories are increasingly recognizing the need for more robust safety measures when handling thermite materials. This demand is driven by several factors, including the expansion of nanotechnology research, which often involves thermite reactions at the nanoscale, and the development of new energetic materials for aerospace and defense applications.

Safety incidents involving thermite reactions, though rare, have highlighted the importance of stringent protocols. These incidents have ranged from minor burns to more serious accidents resulting in property damage and injuries. As a result, laboratory managers and safety officers are actively seeking improved guidelines and technologies to mitigate risks associated with thermite handling and experimentation.

The demand for enhanced safety protocols extends beyond just handling procedures. There is a growing interest in advanced containment systems, specialized fire suppression methods tailored for metal fires, and improved personal protective equipment (PPE) designed specifically for high-temperature reactions. Laboratories are also looking for better training programs that can effectively communicate the unique hazards of thermite reactions to researchers and technicians.

Furthermore, regulatory bodies and insurance companies are exerting pressure on laboratories to adopt more comprehensive safety measures. This has led to an increased demand for standardized safety protocols that can be universally applied across different research environments, ensuring consistency in safety practices.

The academic community is also contributing to this demand by calling for more research into the fundamental properties of thermite reactions, particularly in non-standard conditions or with novel compositions. This knowledge is crucial for developing more effective safety protocols that can anticipate and prevent potential hazards.

In response to these demands, several initiatives have emerged. These include collaborative efforts between research institutions and safety equipment manufacturers to develop specialized tools for thermite handling, as well as industry-wide forums for sharing best practices in laboratory safety. The development of digital platforms for real-time monitoring and risk assessment of thermite experiments is another area gaining traction, reflecting the integration of technology in enhancing laboratory safety protocols.

Research institutions and industrial laboratories are increasingly recognizing the need for more robust safety measures when handling thermite materials. This demand is driven by several factors, including the expansion of nanotechnology research, which often involves thermite reactions at the nanoscale, and the development of new energetic materials for aerospace and defense applications.

Safety incidents involving thermite reactions, though rare, have highlighted the importance of stringent protocols. These incidents have ranged from minor burns to more serious accidents resulting in property damage and injuries. As a result, laboratory managers and safety officers are actively seeking improved guidelines and technologies to mitigate risks associated with thermite handling and experimentation.

The demand for enhanced safety protocols extends beyond just handling procedures. There is a growing interest in advanced containment systems, specialized fire suppression methods tailored for metal fires, and improved personal protective equipment (PPE) designed specifically for high-temperature reactions. Laboratories are also looking for better training programs that can effectively communicate the unique hazards of thermite reactions to researchers and technicians.

Furthermore, regulatory bodies and insurance companies are exerting pressure on laboratories to adopt more comprehensive safety measures. This has led to an increased demand for standardized safety protocols that can be universally applied across different research environments, ensuring consistency in safety practices.

The academic community is also contributing to this demand by calling for more research into the fundamental properties of thermite reactions, particularly in non-standard conditions or with novel compositions. This knowledge is crucial for developing more effective safety protocols that can anticipate and prevent potential hazards.

In response to these demands, several initiatives have emerged. These include collaborative efforts between research institutions and safety equipment manufacturers to develop specialized tools for thermite handling, as well as industry-wide forums for sharing best practices in laboratory safety. The development of digital platforms for real-time monitoring and risk assessment of thermite experiments is another area gaining traction, reflecting the integration of technology in enhancing laboratory safety protocols.

Current Challenges in Thermite Handling

Thermite handling in laboratories presents significant challenges due to its highly reactive nature and potential for severe accidents. One of the primary concerns is the risk of unintended ignition, which can occur through various means such as static electricity, friction, or exposure to heat sources. This risk is exacerbated by the fact that once ignited, thermite reactions are difficult to extinguish and can reach extremely high temperatures, posing severe fire and burn hazards.

Another critical challenge is the proper storage and transportation of thermite materials. These compounds are sensitive to environmental conditions, and improper storage can lead to degradation or accidental activation. Laboratories must implement stringent protocols for segregating thermite components and maintaining appropriate storage conditions to prevent unwanted reactions.

The handling and measurement of thermite components also present significant challenges. Precise measurements are crucial for maintaining the intended reaction characteristics, but the process of weighing and mixing these materials carries inherent risks. Even small errors in composition can lead to unpredictable and potentially dangerous reactions.

Disposal of thermite materials and byproducts is another area of concern. Unused thermite mixtures and reaction residues require specialized disposal procedures to prevent environmental contamination and ensure safety. Many laboratories struggle with implementing effective and compliant disposal methods.

The training and education of laboratory personnel in thermite handling procedures remain an ongoing challenge. Given the high-risk nature of thermite, comprehensive and up-to-date training is essential. However, maintaining consistent training standards across different laboratory settings and ensuring that all personnel are adequately prepared to handle emergencies can be difficult.

Equipment and facility design for thermite experiments also pose challenges. Laboratories need specialized containment systems, ventilation, and safety equipment to manage thermite reactions safely. Designing and implementing these systems while balancing research needs and budget constraints is often complex.

Lastly, the regulatory landscape surrounding thermite use in laboratories is complex and evolving. Keeping up with changing safety standards, obtaining necessary permits, and ensuring compliance with local, national, and international regulations add layers of complexity to thermite handling procedures. Laboratories must navigate these regulatory challenges while maintaining their research capabilities and safety standards.

Another critical challenge is the proper storage and transportation of thermite materials. These compounds are sensitive to environmental conditions, and improper storage can lead to degradation or accidental activation. Laboratories must implement stringent protocols for segregating thermite components and maintaining appropriate storage conditions to prevent unwanted reactions.

The handling and measurement of thermite components also present significant challenges. Precise measurements are crucial for maintaining the intended reaction characteristics, but the process of weighing and mixing these materials carries inherent risks. Even small errors in composition can lead to unpredictable and potentially dangerous reactions.

Disposal of thermite materials and byproducts is another area of concern. Unused thermite mixtures and reaction residues require specialized disposal procedures to prevent environmental contamination and ensure safety. Many laboratories struggle with implementing effective and compliant disposal methods.

The training and education of laboratory personnel in thermite handling procedures remain an ongoing challenge. Given the high-risk nature of thermite, comprehensive and up-to-date training is essential. However, maintaining consistent training standards across different laboratory settings and ensuring that all personnel are adequately prepared to handle emergencies can be difficult.

Equipment and facility design for thermite experiments also pose challenges. Laboratories need specialized containment systems, ventilation, and safety equipment to manage thermite reactions safely. Designing and implementing these systems while balancing research needs and budget constraints is often complex.

Lastly, the regulatory landscape surrounding thermite use in laboratories is complex and evolving. Keeping up with changing safety standards, obtaining necessary permits, and ensuring compliance with local, national, and international regulations add layers of complexity to thermite handling procedures. Laboratories must navigate these regulatory challenges while maintaining their research capabilities and safety standards.

Existing Thermite Safety Protocols

01 Containment and control of thermite reactions

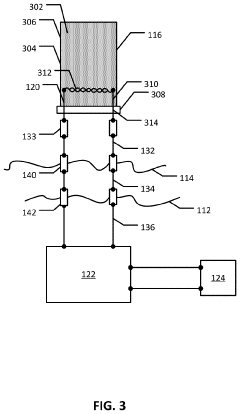

Specialized containers and control mechanisms are used to safely contain and manage thermite reactions. These include reinforced vessels, pressure relief systems, and precise ignition controls to prevent unintended reactions or explosions. Such measures ensure the controlled and safe use of thermite in various applications.- Safety mechanisms for thermite reactions: Various safety mechanisms are employed to control and contain thermite reactions. These include specialized ignition systems, containment vessels, and safety barriers. Such mechanisms help prevent accidental ignition and contain the high-temperature reaction, reducing risks associated with thermite use.

- Protective equipment for handling thermite: Personal protective equipment (PPE) is crucial when working with thermite. This includes heat-resistant clothing, face shields, and specialized gloves. Proper PPE helps protect individuals from the extreme heat and potential splatter generated during thermite reactions.

- Safe storage and transportation of thermite materials: Proper storage and transportation methods are essential for thermite safety. This involves using moisture-resistant containers, implementing temperature controls, and following strict handling protocols. These measures help prevent accidental ignition and maintain the stability of thermite components during storage and transit.

- Training and safety protocols for thermite handling: Comprehensive training programs and safety protocols are crucial for personnel working with thermite. These include emergency response procedures, proper handling techniques, and risk assessment methods. Proper training ensures that workers are prepared to handle thermite safely and respond effectively to potential incidents.

- Environmental and disposal considerations for thermite: Safe disposal of thermite residues and byproducts is essential for environmental protection. This involves proper cooling procedures, containment of reaction products, and specialized disposal methods. Implementing these practices helps minimize environmental impact and ensures safe handling of thermite waste materials.

02 Protective equipment and handling procedures

Safety protocols for handling thermite involve the use of personal protective equipment (PPE) such as heat-resistant suits, face shields, and gloves. Proper handling procedures, including storage guidelines and transportation methods, are crucial to minimize risks associated with thermite materials.Expand Specific Solutions03 Fire suppression and emergency response

Specialized fire suppression systems and emergency response protocols are developed for thermite-related incidents. These include the use of specific extinguishing agents, containment strategies, and rapid response procedures to mitigate potential hazards in case of accidental ignition or spills.Expand Specific Solutions04 Safe ignition and initiation methods

Advanced ignition systems and initiation methods are designed to ensure the safe and controlled start of thermite reactions. These include remote ignition devices, time-delay mechanisms, and fail-safe triggers that minimize the risk of premature or unintended ignition during handling and deployment.Expand Specific Solutions05 Environmental and health safety measures

Measures are implemented to address environmental and health concerns related to thermite use. These include proper disposal methods for residues, air quality monitoring systems, and health screening protocols for personnel working with thermite materials. Such measures aim to minimize long-term environmental impact and protect worker health.Expand Specific Solutions

Key Players in Lab Safety Equipment

The thermite safety protocols enhancement in laboratories is in a mature development stage, with a growing market driven by increasing safety concerns. The global laboratory safety market is expected to reach significant size in the coming years. Technologically, the field is well-established but continuously evolving, with companies like Robertson Intellectual Properties LLC, Naval Research Laboratory, and Southwest Research Institute leading innovations. Beijing Institute of Technology and Xi'an Modern Chemistry Research Institute are contributing to advancements in thermite handling techniques. Collaboration between academic institutions like Harvard College and industry players is pushing the boundaries of safety protocols, while organizations such as Battelle Memorial Institute are focusing on comprehensive risk management solutions for thermite use in laboratory settings.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced thermite safety protocols for laboratory use. Their approach includes a multi-layered containment system, utilizing specialized reaction vessels with pressure relief mechanisms and thermal insulation. They have also implemented real-time monitoring systems that track temperature, pressure, and gas evolution during thermite reactions. Additionally, they've developed a novel quenching method using inert gas flooding to rapidly suppress uncontrolled reactions.

Strengths: Comprehensive safety measures, advanced monitoring capabilities, and innovative suppression techniques. Weaknesses: Potentially high implementation costs and complexity for smaller laboratories.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has pioneered a smart thermite safety management system for laboratories. Their solution incorporates AI-driven risk assessment algorithms that analyze reaction parameters in real-time. They've also developed nano-engineered fire-resistant materials for laboratory infrastructure and personal protective equipment. Their protocol includes a tiered response system that automatically activates containment measures based on detected risk levels. Furthermore, they've implemented virtual reality training modules for laboratory personnel to practice emergency procedures in simulated thermite accidents.

Strengths: Integration of cutting-edge technologies, proactive risk management, and innovative training methods. Weaknesses: Potential over-reliance on technology and high initial setup costs.

Innovative Approaches to Thermite Safety

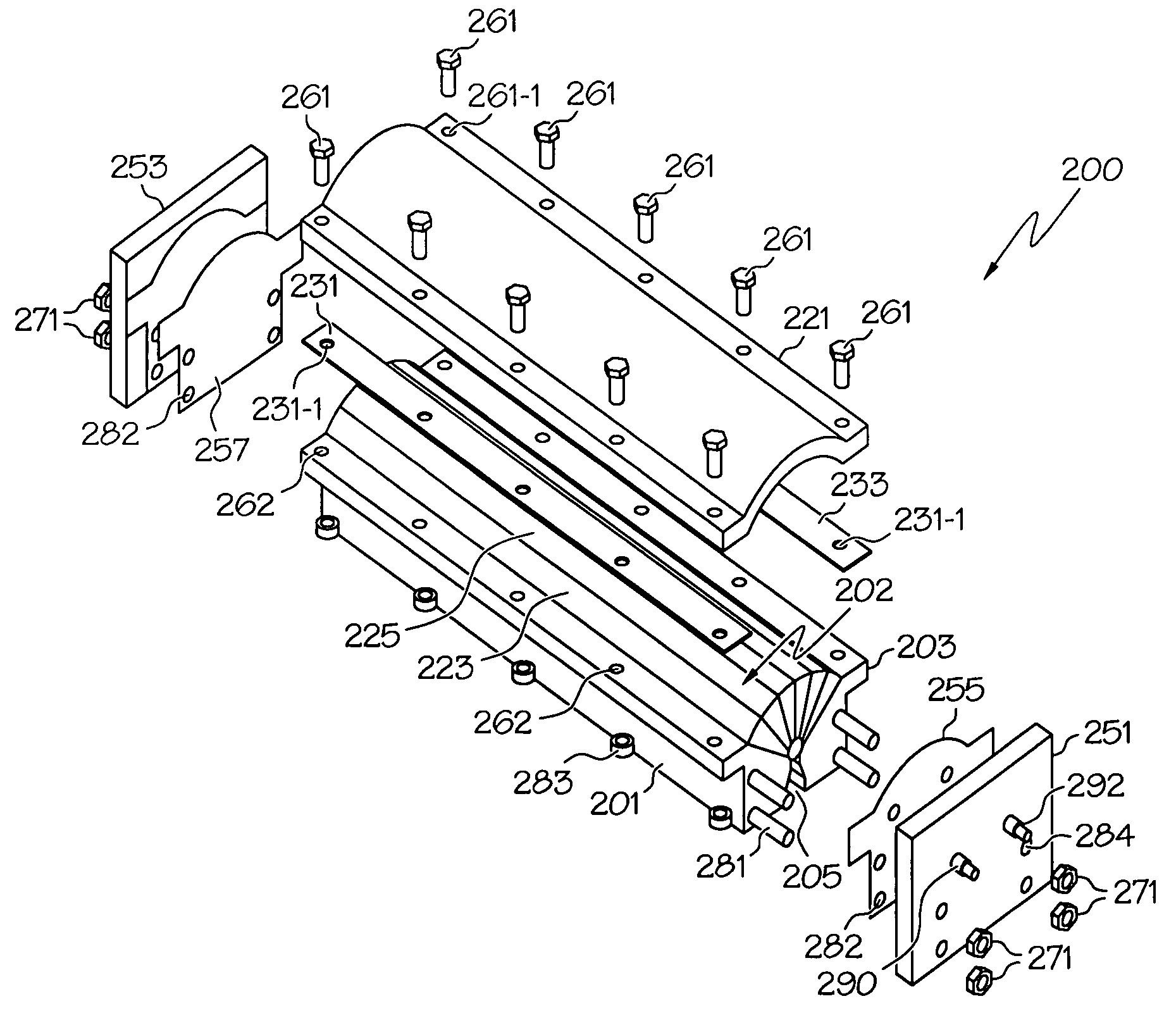

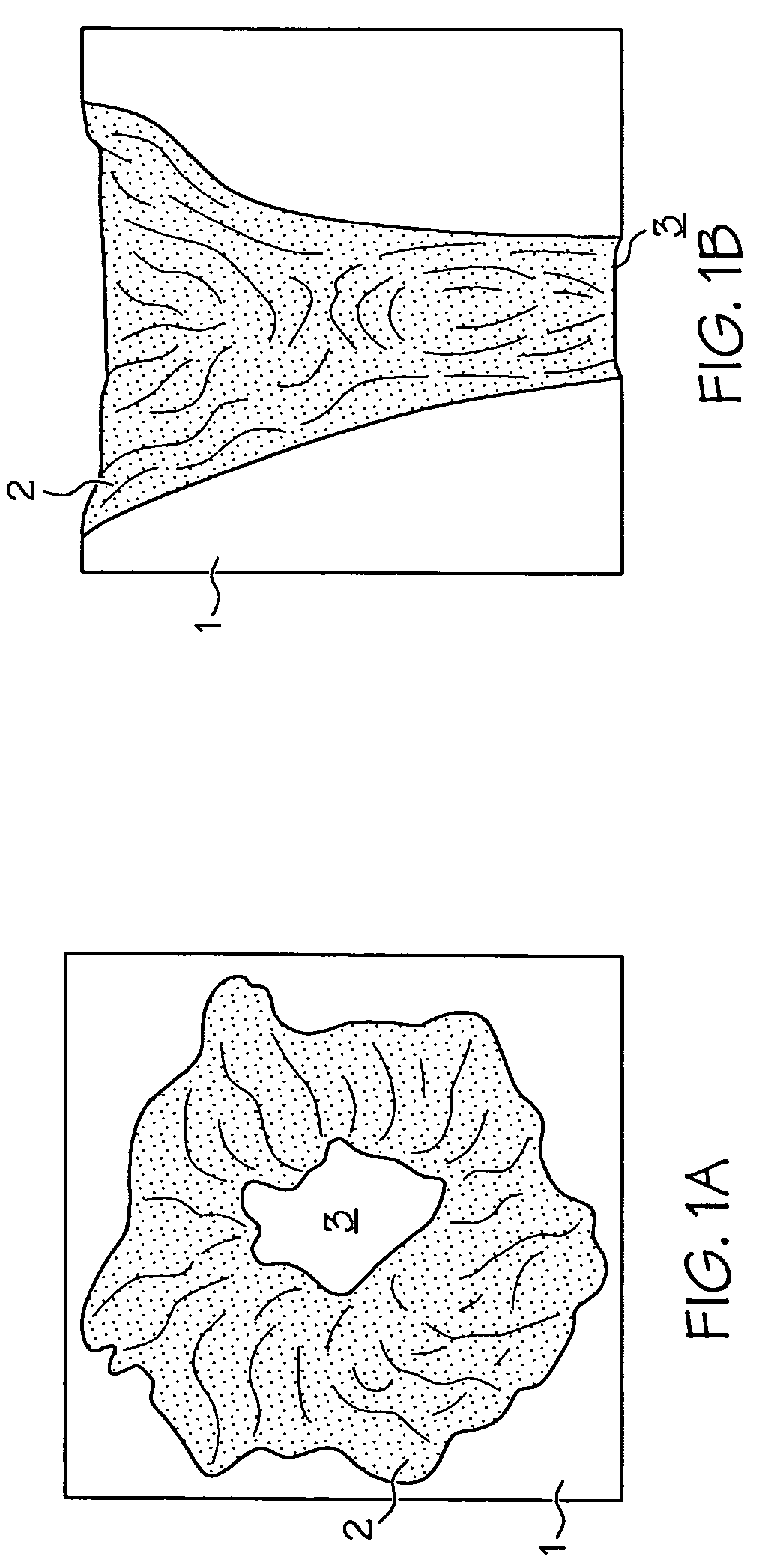

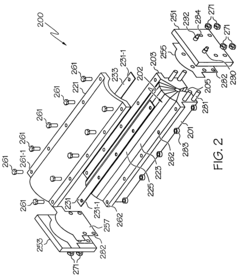

Thermite charge

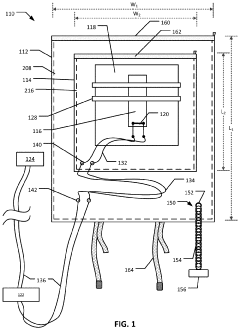

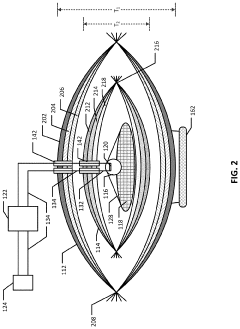

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

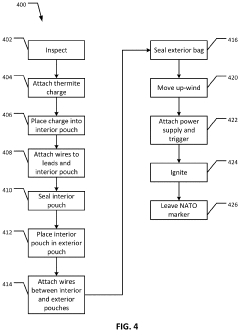

Thermite Bag For Chemical / Biological Agent Munition And Hazardous Waste Disposal System

PatentActiveUS20200080722A1

Innovation

- A thermite bag system comprising a sealable pouch with a thermite charge, igniter, and electrical connections, allowing for rapid and controlled thermal decomposition of hazardous materials, including chemical and biological agents, using a portable and lightweight design.

Regulatory Framework for Hazardous Materials

The regulatory framework for hazardous materials in laboratories, particularly concerning thermite safety protocols, is a complex and multifaceted system designed to protect researchers, facilities, and the environment. At the federal level in the United States, the Occupational Safety and Health Administration (OSHA) sets the primary standards for workplace safety, including specific guidelines for handling pyrophoric materials like thermite. These regulations mandate proper storage, handling, and disposal procedures, as well as requirements for personal protective equipment (PPE) and emergency response plans.

Complementing OSHA's regulations, the Environmental Protection Agency (EPA) enforces strict rules on the disposal and environmental impact of hazardous materials. The Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste, including thermite residues, ensuring proper disposal and preventing environmental contamination. Additionally, the Department of Transportation (DOT) regulates the transportation of hazardous materials, including thermite components, to minimize risks during transit.

At the state and local levels, regulations often build upon federal standards, sometimes imposing more stringent requirements. Many states have their own environmental protection agencies and occupational safety departments that enforce additional rules tailored to local conditions and concerns. Universities and research institutions typically have institutional review boards (IRBs) and safety committees that develop and enforce internal policies for hazardous material handling, often exceeding minimum regulatory requirements.

International standards also play a crucial role in shaping laboratory safety protocols. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, which is particularly relevant for thermite components. Many countries have adopted GHS principles, facilitating international collaboration and consistency in safety practices.

Professional organizations contribute significantly to the regulatory landscape by developing best practices and guidelines. The American Chemical Society (ACS) and the National Fire Protection Association (NFPA) provide detailed recommendations for handling pyrophoric materials, which are often incorporated into formal regulations or institutional policies. These guidelines often address specific aspects of thermite safety, such as proper storage conditions, ignition prevention, and fire suppression techniques.

Continuous improvement in regulatory frameworks is driven by ongoing research, incident analyses, and technological advancements. Regulatory bodies regularly review and update their standards to incorporate new knowledge and address emerging risks. This dynamic approach ensures that safety protocols evolve alongside scientific progress, maintaining a balance between enabling cutting-edge research and safeguarding personnel and facilities.

Complementing OSHA's regulations, the Environmental Protection Agency (EPA) enforces strict rules on the disposal and environmental impact of hazardous materials. The Resource Conservation and Recovery Act (RCRA) governs the management of hazardous waste, including thermite residues, ensuring proper disposal and preventing environmental contamination. Additionally, the Department of Transportation (DOT) regulates the transportation of hazardous materials, including thermite components, to minimize risks during transit.

At the state and local levels, regulations often build upon federal standards, sometimes imposing more stringent requirements. Many states have their own environmental protection agencies and occupational safety departments that enforce additional rules tailored to local conditions and concerns. Universities and research institutions typically have institutional review boards (IRBs) and safety committees that develop and enforce internal policies for hazardous material handling, often exceeding minimum regulatory requirements.

International standards also play a crucial role in shaping laboratory safety protocols. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards, which is particularly relevant for thermite components. Many countries have adopted GHS principles, facilitating international collaboration and consistency in safety practices.

Professional organizations contribute significantly to the regulatory landscape by developing best practices and guidelines. The American Chemical Society (ACS) and the National Fire Protection Association (NFPA) provide detailed recommendations for handling pyrophoric materials, which are often incorporated into formal regulations or institutional policies. These guidelines often address specific aspects of thermite safety, such as proper storage conditions, ignition prevention, and fire suppression techniques.

Continuous improvement in regulatory frameworks is driven by ongoing research, incident analyses, and technological advancements. Regulatory bodies regularly review and update their standards to incorporate new knowledge and address emerging risks. This dynamic approach ensures that safety protocols evolve alongside scientific progress, maintaining a balance between enabling cutting-edge research and safeguarding personnel and facilities.

Environmental Impact of Thermite Use

The environmental impact of thermite use in laboratories is a critical consideration for enhancing safety protocols. Thermite reactions, while controlled in laboratory settings, can have significant environmental consequences if not properly managed. The primary environmental concerns stem from the release of metal oxides and other byproducts during the reaction process.

Thermite reactions typically produce aluminum oxide and iron as main products, along with intense heat and light. The release of these substances into the environment can lead to air pollution, particularly in the form of fine particulate matter. These particles can remain suspended in the air for extended periods, potentially affecting air quality in the surrounding areas. Additionally, the high temperatures generated during thermite reactions can cause localized thermal pollution, impacting nearby ecosystems if not properly contained.

Water contamination is another potential environmental risk associated with thermite use. If thermite residues or byproducts come into contact with water sources, they can alter pH levels and introduce metal ions into aquatic ecosystems. This contamination can have detrimental effects on aquatic life and potentially enter the food chain, posing risks to human health if not adequately addressed.

Soil contamination is also a concern, particularly in cases of improper disposal of thermite waste or accidental spills. The metal oxides and other byproducts can accumulate in soil, potentially altering its composition and affecting plant growth. Long-term accumulation of these substances may lead to changes in soil chemistry and impact local flora and fauna.

To mitigate these environmental impacts, laboratories must implement stringent waste management protocols. This includes proper collection, storage, and disposal of thermite residues and byproducts. Specialized containment systems and filtration methods should be employed to minimize the release of particulate matter into the air. Additionally, laboratories should consider recycling and reprocessing options for thermite waste to reduce overall environmental impact.

Regular environmental monitoring around laboratory facilities using thermite is essential to detect any potential contamination early. This may include air quality assessments, soil testing, and water analysis in nearby areas. Implementing these monitoring practices can help identify and address any environmental issues promptly, ensuring the long-term sustainability of thermite use in laboratory settings.

Enhancing thermite safety protocols in laboratories must therefore include a comprehensive approach to environmental protection. This involves not only focusing on immediate safety concerns within the laboratory but also considering the broader ecological impact of thermite use. By integrating environmental considerations into safety protocols, laboratories can minimize their ecological footprint while continuing to conduct valuable research and experiments involving thermite reactions.

Thermite reactions typically produce aluminum oxide and iron as main products, along with intense heat and light. The release of these substances into the environment can lead to air pollution, particularly in the form of fine particulate matter. These particles can remain suspended in the air for extended periods, potentially affecting air quality in the surrounding areas. Additionally, the high temperatures generated during thermite reactions can cause localized thermal pollution, impacting nearby ecosystems if not properly contained.

Water contamination is another potential environmental risk associated with thermite use. If thermite residues or byproducts come into contact with water sources, they can alter pH levels and introduce metal ions into aquatic ecosystems. This contamination can have detrimental effects on aquatic life and potentially enter the food chain, posing risks to human health if not adequately addressed.

Soil contamination is also a concern, particularly in cases of improper disposal of thermite waste or accidental spills. The metal oxides and other byproducts can accumulate in soil, potentially altering its composition and affecting plant growth. Long-term accumulation of these substances may lead to changes in soil chemistry and impact local flora and fauna.

To mitigate these environmental impacts, laboratories must implement stringent waste management protocols. This includes proper collection, storage, and disposal of thermite residues and byproducts. Specialized containment systems and filtration methods should be employed to minimize the release of particulate matter into the air. Additionally, laboratories should consider recycling and reprocessing options for thermite waste to reduce overall environmental impact.

Regular environmental monitoring around laboratory facilities using thermite is essential to detect any potential contamination early. This may include air quality assessments, soil testing, and water analysis in nearby areas. Implementing these monitoring practices can help identify and address any environmental issues promptly, ensuring the long-term sustainability of thermite use in laboratory settings.

Enhancing thermite safety protocols in laboratories must therefore include a comprehensive approach to environmental protection. This involves not only focusing on immediate safety concerns within the laboratory but also considering the broader ecological impact of thermite use. By integrating environmental considerations into safety protocols, laboratories can minimize their ecological footprint while continuing to conduct valuable research and experiments involving thermite reactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!