How to Enhance the Performance of Thermite Reactions?

JUN 24, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Background and Objectives

Thermite reactions, discovered in the late 19th century, have been a subject of intense research and application due to their unique exothermic properties. These reactions involve the reduction of a metal oxide by a more reactive metal, typically aluminum, resulting in the production of a more stable oxide and the release of elemental metal. The evolution of thermite technology has seen significant advancements in various fields, including metallurgy, pyrotechnics, and military applications.

The primary objective in enhancing the performance of thermite reactions is to optimize their energy output, reaction rate, and controllability. Researchers aim to increase the reaction efficiency while maintaining safety and reliability. This involves exploring new material combinations, refining particle sizes, and developing novel ignition methods to achieve more precise and powerful reactions.

Over the years, the focus has shifted from traditional iron oxide-aluminum thermite mixtures to more advanced compositions incorporating nanomaterials and rare earth metals. These innovations have opened up new possibilities for tailoring thermite reactions to specific applications, such as welding, metal purification, and even space propulsion systems.

One of the key trends in thermite technology is the development of environmentally friendly and sustainable formulations. This aligns with the growing global emphasis on green technologies and reduced environmental impact. Researchers are exploring bio-inspired materials and recyclable components to create more eco-conscious thermite mixtures without compromising performance.

Another significant trend is the integration of smart materials and advanced sensors into thermite systems. This allows for real-time monitoring and control of the reaction process, enhancing safety and precision in various applications. The incorporation of these technologies is particularly crucial in hazardous environments and remote operations.

The future of thermite reaction enhancement lies in interdisciplinary approaches, combining expertise from materials science, chemistry, and engineering. Researchers are exploring the potential of artificial intelligence and machine learning to predict and optimize thermite compositions, potentially revolutionizing the field and leading to unprecedented levels of performance and efficiency.

The primary objective in enhancing the performance of thermite reactions is to optimize their energy output, reaction rate, and controllability. Researchers aim to increase the reaction efficiency while maintaining safety and reliability. This involves exploring new material combinations, refining particle sizes, and developing novel ignition methods to achieve more precise and powerful reactions.

Over the years, the focus has shifted from traditional iron oxide-aluminum thermite mixtures to more advanced compositions incorporating nanomaterials and rare earth metals. These innovations have opened up new possibilities for tailoring thermite reactions to specific applications, such as welding, metal purification, and even space propulsion systems.

One of the key trends in thermite technology is the development of environmentally friendly and sustainable formulations. This aligns with the growing global emphasis on green technologies and reduced environmental impact. Researchers are exploring bio-inspired materials and recyclable components to create more eco-conscious thermite mixtures without compromising performance.

Another significant trend is the integration of smart materials and advanced sensors into thermite systems. This allows for real-time monitoring and control of the reaction process, enhancing safety and precision in various applications. The incorporation of these technologies is particularly crucial in hazardous environments and remote operations.

The future of thermite reaction enhancement lies in interdisciplinary approaches, combining expertise from materials science, chemistry, and engineering. Researchers are exploring the potential of artificial intelligence and machine learning to predict and optimize thermite compositions, potentially revolutionizing the field and leading to unprecedented levels of performance and efficiency.

Market Analysis for Thermite Applications

The thermite reaction market has witnessed significant growth in recent years, driven by increasing applications across various industries. The global thermite market size was valued at approximately $350 million in 2020 and is projected to reach $500 million by 2025, growing at a CAGR of 7.5% during the forecast period. This growth is primarily attributed to the expanding use of thermite reactions in welding, metal purification, and pyrotechnics.

The welding sector remains the largest application segment for thermite reactions, accounting for over 40% of the market share. The construction industry, particularly in developing economies, is driving demand for thermite welding in large-scale infrastructure projects such as railways, bridges, and pipelines. The automotive and aerospace industries are also contributing to market growth, utilizing thermite reactions for specialized welding applications.

Metal purification represents another significant market segment, with thermite reactions being employed in the production of high-purity metals such as chromium, manganese, and vanadium. The growing demand for these metals in the electronics and alloy manufacturing industries is expected to fuel market expansion in this segment.

The pyrotechnics industry, including fireworks and special effects for entertainment, constitutes a smaller but steadily growing market for thermite reactions. Increasing disposable incomes and rising entertainment expenditures in emerging economies are driving growth in this segment.

Geographically, Asia Pacific dominates the thermite reaction market, accounting for approximately 35% of the global market share. The region's rapid industrialization, infrastructure development, and growing manufacturing sector are key factors contributing to this dominance. North America and Europe follow, with mature markets focused on advanced applications and research and development activities.

Key market players in the thermite reaction industry include Thermit Australia Pty Ltd, Siemens AG, and Goldschmidt Group. These companies are investing heavily in research and development to enhance the performance and efficiency of thermite reactions, addressing the growing demand for improved safety, reduced environmental impact, and increased energy efficiency.

The market analysis reveals several trends shaping the future of thermite applications. There is a growing focus on developing environmentally friendly thermite compositions, driven by stringent regulations and increasing awareness of sustainability. Additionally, the integration of advanced technologies such as IoT and AI in thermite reaction processes is expected to open new avenues for market growth, particularly in precision welding and metal purification applications.

The welding sector remains the largest application segment for thermite reactions, accounting for over 40% of the market share. The construction industry, particularly in developing economies, is driving demand for thermite welding in large-scale infrastructure projects such as railways, bridges, and pipelines. The automotive and aerospace industries are also contributing to market growth, utilizing thermite reactions for specialized welding applications.

Metal purification represents another significant market segment, with thermite reactions being employed in the production of high-purity metals such as chromium, manganese, and vanadium. The growing demand for these metals in the electronics and alloy manufacturing industries is expected to fuel market expansion in this segment.

The pyrotechnics industry, including fireworks and special effects for entertainment, constitutes a smaller but steadily growing market for thermite reactions. Increasing disposable incomes and rising entertainment expenditures in emerging economies are driving growth in this segment.

Geographically, Asia Pacific dominates the thermite reaction market, accounting for approximately 35% of the global market share. The region's rapid industrialization, infrastructure development, and growing manufacturing sector are key factors contributing to this dominance. North America and Europe follow, with mature markets focused on advanced applications and research and development activities.

Key market players in the thermite reaction industry include Thermit Australia Pty Ltd, Siemens AG, and Goldschmidt Group. These companies are investing heavily in research and development to enhance the performance and efficiency of thermite reactions, addressing the growing demand for improved safety, reduced environmental impact, and increased energy efficiency.

The market analysis reveals several trends shaping the future of thermite applications. There is a growing focus on developing environmentally friendly thermite compositions, driven by stringent regulations and increasing awareness of sustainability. Additionally, the integration of advanced technologies such as IoT and AI in thermite reaction processes is expected to open new avenues for market growth, particularly in precision welding and metal purification applications.

Current Challenges in Thermite Performance

Thermite reactions, known for their high exothermicity and rapid reaction rates, face several challenges that limit their performance and broader application. One of the primary issues is the control and modulation of reaction rates. While the rapid energy release is a key advantage, it can also lead to uncontrolled reactions, making it difficult to harness the energy effectively for specific applications.

Another significant challenge is the relatively low energy density of traditional thermite compositions. This limitation restricts their use in applications where weight and volume are critical factors, such as in aerospace or portable energy systems. Researchers are continually seeking ways to increase the energy output per unit mass or volume without compromising safety or stability.

The initiation of thermite reactions presents another hurdle. Conventional thermites often require high ignition temperatures, which can be impractical or dangerous in certain scenarios. Developing thermite compositions with lower ignition thresholds while maintaining stability during storage and handling remains a complex balancing act.

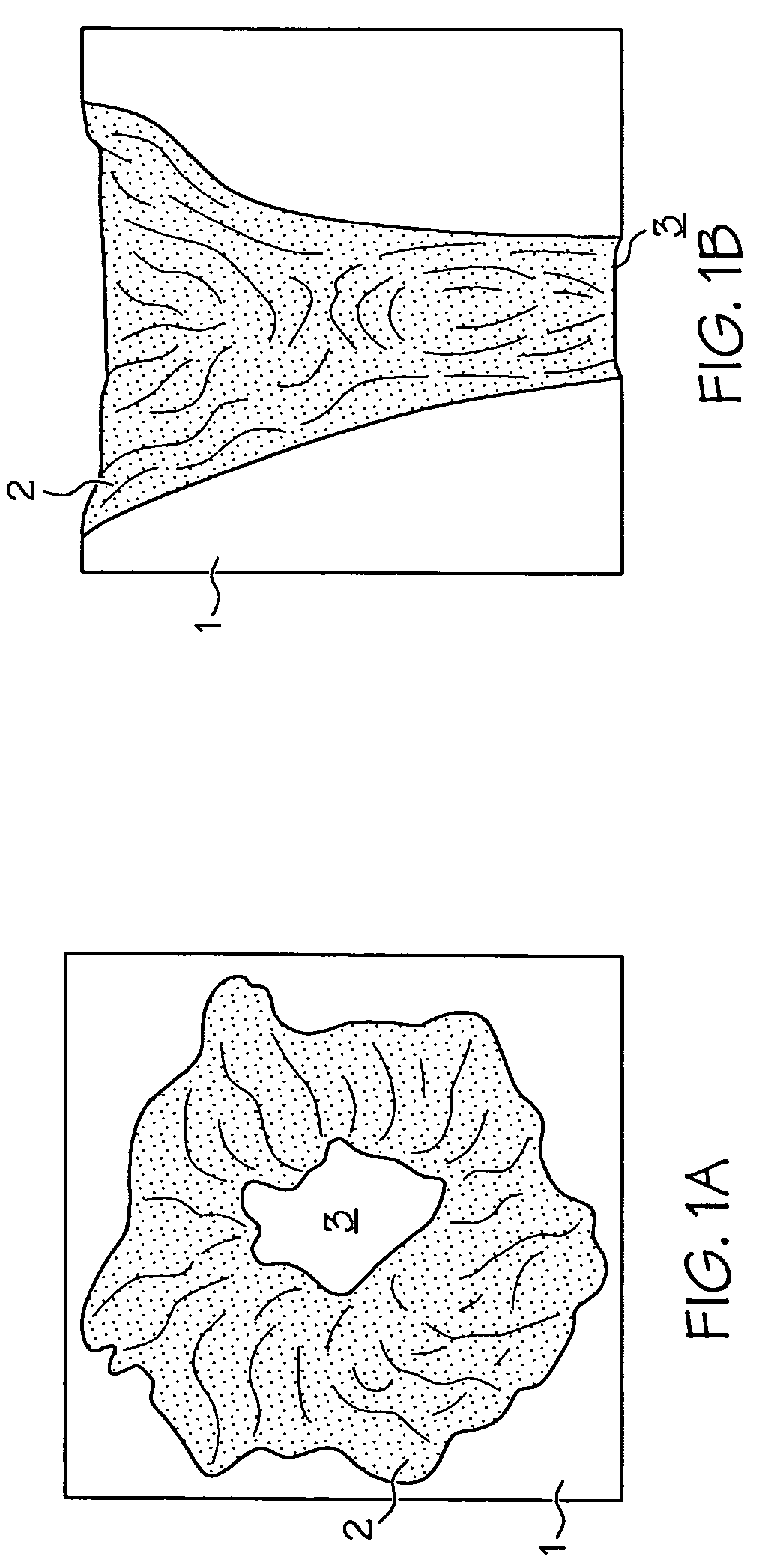

Particle size and morphology of the reactants significantly influence thermite performance. Nano-sized particles can enhance reactivity but also introduce new challenges in terms of handling, safety, and cost. Achieving uniform particle distribution and preventing agglomeration are ongoing concerns that affect reaction efficiency and reproducibility.

The incomplete combustion of reactants is another persistent issue. This not only reduces the overall energy output but also leads to the formation of unwanted by-products, which can be detrimental in certain applications. Improving the combustion efficiency and minimizing residual unreacted materials are crucial for enhancing thermite performance.

Environmental and safety concerns also pose challenges to thermite development and application. Some thermite compositions involve toxic or environmentally harmful components, necessitating the exploration of greener alternatives that maintain or improve upon existing performance characteristics.

Lastly, the scalability of thermite reactions from laboratory to industrial scales presents significant engineering challenges. Maintaining reaction characteristics and performance while scaling up production processes is crucial for the practical implementation of thermite-based technologies in various sectors.

Another significant challenge is the relatively low energy density of traditional thermite compositions. This limitation restricts their use in applications where weight and volume are critical factors, such as in aerospace or portable energy systems. Researchers are continually seeking ways to increase the energy output per unit mass or volume without compromising safety or stability.

The initiation of thermite reactions presents another hurdle. Conventional thermites often require high ignition temperatures, which can be impractical or dangerous in certain scenarios. Developing thermite compositions with lower ignition thresholds while maintaining stability during storage and handling remains a complex balancing act.

Particle size and morphology of the reactants significantly influence thermite performance. Nano-sized particles can enhance reactivity but also introduce new challenges in terms of handling, safety, and cost. Achieving uniform particle distribution and preventing agglomeration are ongoing concerns that affect reaction efficiency and reproducibility.

The incomplete combustion of reactants is another persistent issue. This not only reduces the overall energy output but also leads to the formation of unwanted by-products, which can be detrimental in certain applications. Improving the combustion efficiency and minimizing residual unreacted materials are crucial for enhancing thermite performance.

Environmental and safety concerns also pose challenges to thermite development and application. Some thermite compositions involve toxic or environmentally harmful components, necessitating the exploration of greener alternatives that maintain or improve upon existing performance characteristics.

Lastly, the scalability of thermite reactions from laboratory to industrial scales presents significant engineering challenges. Maintaining reaction characteristics and performance while scaling up production processes is crucial for the practical implementation of thermite-based technologies in various sectors.

Existing Methods for Enhancing Thermite Reactions

01 Composition and reactivity of thermite mixtures

Thermite reactions involve the combination of metal oxides and reactive metals, typically aluminum. The composition and ratio of these components significantly affect the reaction performance, including heat generation, reaction rate, and combustion temperature. Optimizing the mixture can enhance energy output and control reaction characteristics.- Composition and reactivity of thermite mixtures: Thermite reactions involve the combination of metal oxides and reactive metals, typically aluminum. The composition and ratio of these components significantly affect the reaction performance, including heat generation, reaction rate, and combustion temperature. Optimizing the mixture can enhance energy output and control reaction characteristics.

- Ignition methods and performance enhancement: Various ignition methods are employed to initiate thermite reactions, including electrical, chemical, and mechanical means. Advanced ignition techniques can improve reaction efficiency and control. Additionally, the use of additives or catalysts can enhance reaction performance by lowering ignition temperature or increasing reaction rate.

- Application in welding and metal joining: Thermite reactions are widely used in welding and metal joining processes, particularly for large structures or in-situ repairs. The performance of these reactions in welding applications depends on factors such as heat distribution, metal flow, and cooling rate. Innovations in this area focus on improving weld quality and process efficiency.

- Safety and containment of thermite reactions: Given the high temperatures and intense energy release of thermite reactions, safety and containment are crucial aspects of performance. This includes the development of specialized containers, reaction chambers, and safety protocols to manage the reaction and its byproducts effectively. Innovations in this area aim to enhance safety while maintaining reaction efficiency.

- Novel applications and performance optimization: Ongoing research explores novel applications of thermite reactions beyond traditional uses. This includes their potential in energy storage, propulsion systems, and material synthesis. Performance optimization in these new areas involves tailoring reaction kinetics, energy output, and product characteristics to suit specific application requirements.

02 Ignition methods and performance enhancement

Various ignition techniques are employed to initiate thermite reactions, including electrical, chemical, and mechanical methods. Advanced ignition systems can improve reaction consistency and efficiency. Additionally, the use of additives or catalysts can enhance reaction performance by lowering ignition temperature or increasing reaction speed.Expand Specific Solutions03 Application in welding and metal joining

Thermite reactions are widely used in welding and metal joining processes, particularly for large structures or in-situ repairs. The performance of these applications depends on factors such as heat distribution, metal flow, and cooling rate. Innovations in this area focus on improving joint strength, reducing defects, and enhancing process control.Expand Specific Solutions04 Safety and containment of thermite reactions

Given the high temperatures and intense nature of thermite reactions, safety and containment are crucial aspects of performance. This includes the development of specialized containers, reaction vessels, and safety protocols to manage heat, prevent unintended ignition, and control reaction byproducts. Improved containment designs can enhance both safety and reaction efficiency.Expand Specific Solutions05 Novel applications and performance metrics

Thermite reactions are finding new applications beyond traditional uses, such as in advanced materials synthesis, energy storage, and propulsion systems. These novel applications require specific performance metrics and optimization strategies. Research in this area focuses on tailoring reaction characteristics to meet the unique requirements of each application, including controlled energy release, specific product formation, and scalability.Expand Specific Solutions

Key Players in Thermite Industry

The thermite reaction enhancement field is in a mature development stage, with a substantial market size driven by industrial applications. The technology's maturity is evident from the diverse range of players involved, including academic institutions like Central South University and Naval Research Laboratory, as well as industry leaders such as ConocoPhillips Co. and Lockheed Martin Corp. Research efforts span from fundamental studies at universities to practical applications by companies like BiSN Oil Tools Ltd. and Elektro-Thermit GmbH & Co. KG. The competitive landscape is characterized by a mix of specialized firms, large corporations, and research institutions, indicating a well-established but still evolving technological domain with ongoing innovation potential.

Battelle Memorial Institute

Technical Solution: Battelle has developed advanced thermite compositions that incorporate nanoscale materials to enhance reaction rates and energy output. Their approach involves using precisely engineered nanoparticles of aluminum and metal oxides, which increase the surface area for reaction and improve mixing at the molecular level. This results in faster ignition, more complete combustion, and higher energy release. Additionally, they have explored the use of additives to tailor the reaction products for specific applications, such as gas generation or slag formation.

Strengths: Highly customizable reactions, improved energy density, and faster reaction rates. Weaknesses: Potentially higher production costs and challenges in large-scale manufacturing of nanoparticles.

Elektro-Thermit GmbH & Co. KG

Technical Solution: Elektro-Thermit specializes in aluminothermic welding for railway tracks, utilizing advanced thermite reactions. Their innovative approach involves carefully designed thermite mixtures with optimized particle sizes and distributions to ensure uniform heat distribution and controlled reaction rates. They have also developed proprietary ignition systems that allow for precise timing and initiation of the reaction. Furthermore, their process includes the use of specially designed molds and containment systems to direct the molten metal and control the weld geometry, resulting in high-quality, durable rail joints.

Strengths: Highly specialized for rail welding applications, proven track record in the field. Weaknesses: Limited applicability outside of rail industry, potential environmental concerns with large-scale use.

Innovative Approaches in Thermite Chemistry

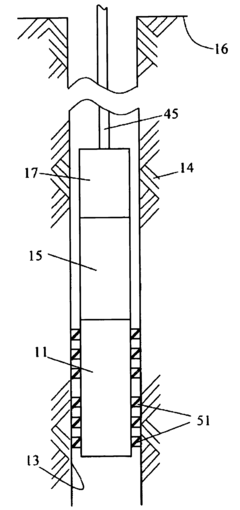

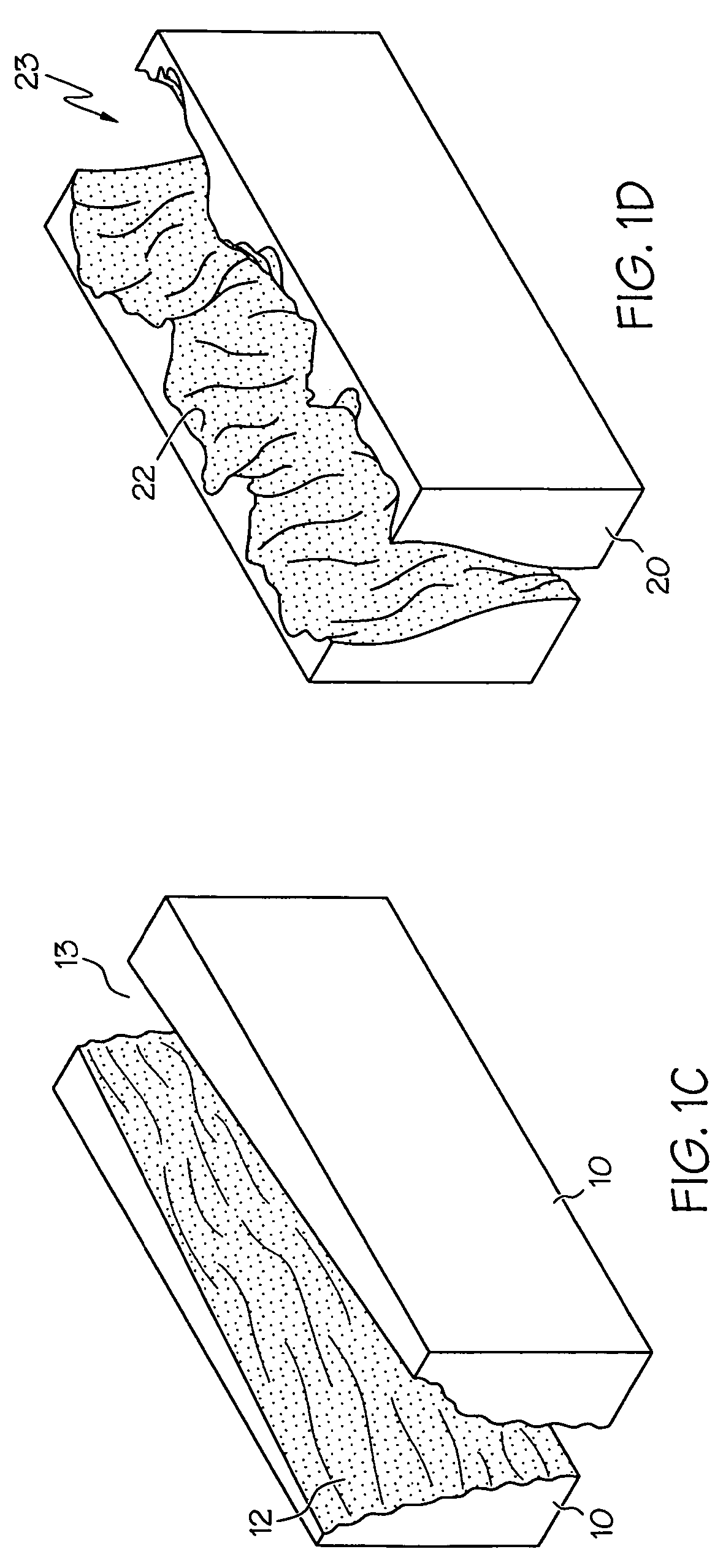

Non-explosive power source for actuating a subsurface tool

PatentActiveUS8196515B2

Innovation

- A non-explosive power source using thermite and a polymer that produces gas upon reaction, providing continuous pressure over an extended period to actuate subsurface tools without the hazards and regulatory burdens of explosive devices, and controlling heat transfer to prevent tool degradation.

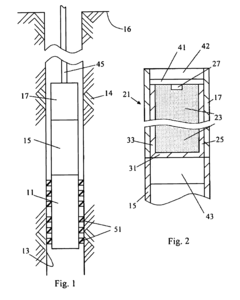

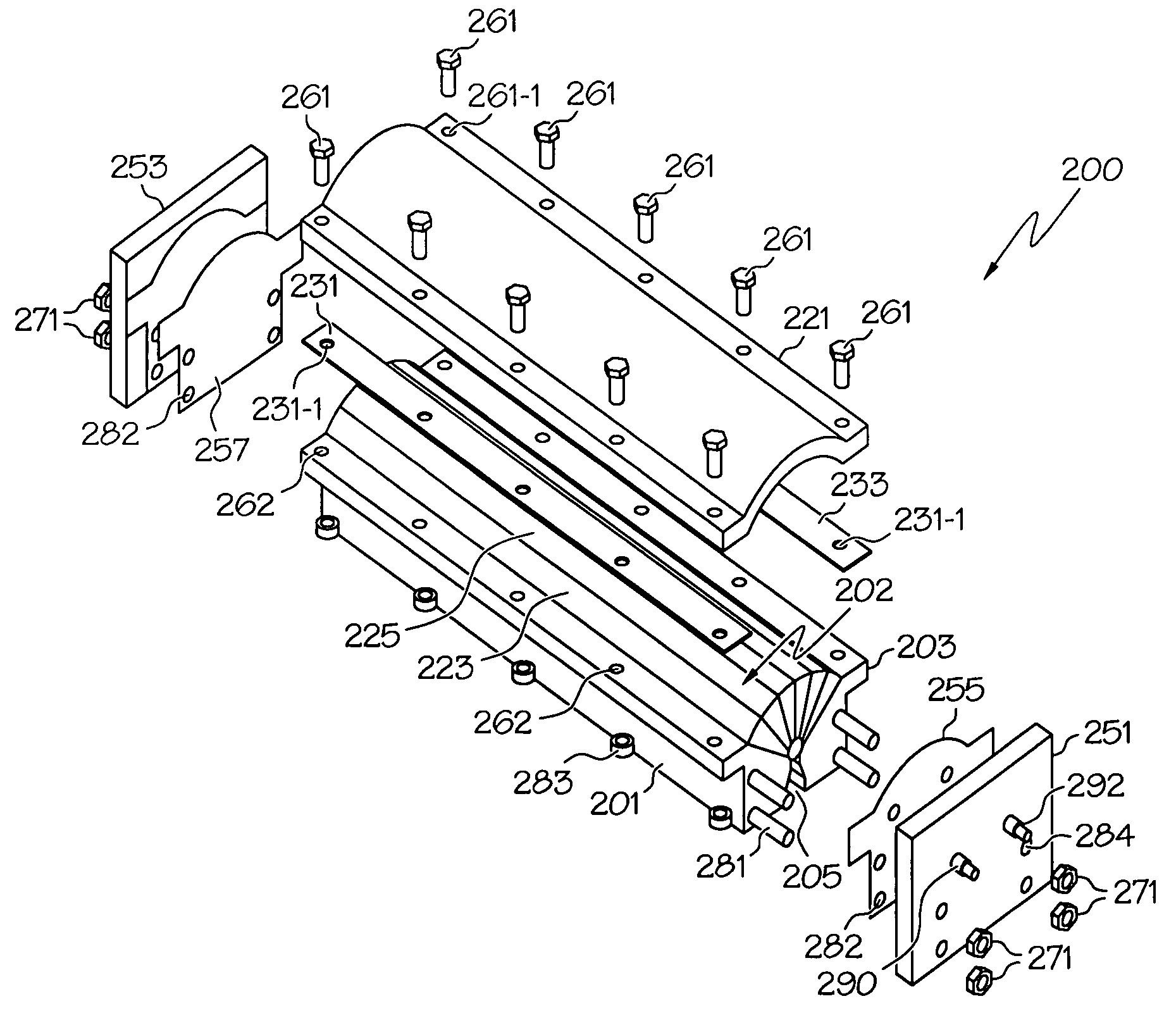

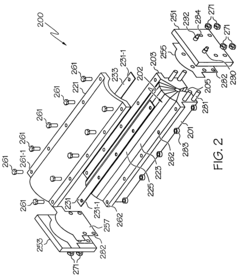

Thermite charge

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety Regulations for Thermite Usage

Safety regulations for thermite usage are critical in enhancing the performance of thermite reactions while minimizing risks. These regulations typically cover storage, handling, transportation, and application of thermite materials. Proper storage is essential, requiring thermite components to be kept in separate, sealed containers in cool, dry environments away from potential ignition sources. Handling procedures mandate the use of appropriate personal protective equipment (PPE), including fire-resistant clothing, safety goggles, and respiratory protection.

Transportation regulations often classify thermite as a hazardous material, necessitating special packaging and labeling. Vehicles transporting thermite must meet specific safety standards and follow designated routes. On-site usage regulations typically require a designated safety officer, establishment of a safety perimeter, and implementation of fire suppression measures.

Mixing and preparation guidelines are crucial for maintaining safety and optimizing performance. Regulations often specify precise ratios of fuel to oxidizer, particle size requirements, and mixing techniques to ensure uniform composition. Ignition procedures are strictly regulated, with emphasis on remote ignition methods to minimize operator exposure.

Environmental considerations are increasingly important in thermite safety regulations. Guidelines often address proper disposal of residues, containment of reaction products, and measures to prevent contamination of soil and water sources. Many jurisdictions require environmental impact assessments before large-scale thermite applications.

Training and certification requirements for personnel handling thermite are becoming more stringent. Operators must typically undergo specialized training in thermite chemistry, reaction dynamics, and emergency response procedures. Regular refresher courses and practical assessments are often mandated to maintain certification.

Incident reporting and investigation protocols form a critical component of safety regulations. These procedures help identify potential hazards, improve safety measures, and prevent future accidents. Regulatory bodies often require detailed documentation of all thermite-related activities, including safety checks, reaction parameters, and any anomalies observed.

As research continues to enhance thermite performance, safety regulations are evolving to address new formulations and applications. Emerging areas of focus include nanoscale thermite materials, which present unique safety challenges due to their increased reactivity and potential for aerosolization. Regulatory frameworks are adapting to incorporate these advancements, balancing the pursuit of improved performance with the paramount concern for safety in all aspects of thermite usage.

Transportation regulations often classify thermite as a hazardous material, necessitating special packaging and labeling. Vehicles transporting thermite must meet specific safety standards and follow designated routes. On-site usage regulations typically require a designated safety officer, establishment of a safety perimeter, and implementation of fire suppression measures.

Mixing and preparation guidelines are crucial for maintaining safety and optimizing performance. Regulations often specify precise ratios of fuel to oxidizer, particle size requirements, and mixing techniques to ensure uniform composition. Ignition procedures are strictly regulated, with emphasis on remote ignition methods to minimize operator exposure.

Environmental considerations are increasingly important in thermite safety regulations. Guidelines often address proper disposal of residues, containment of reaction products, and measures to prevent contamination of soil and water sources. Many jurisdictions require environmental impact assessments before large-scale thermite applications.

Training and certification requirements for personnel handling thermite are becoming more stringent. Operators must typically undergo specialized training in thermite chemistry, reaction dynamics, and emergency response procedures. Regular refresher courses and practical assessments are often mandated to maintain certification.

Incident reporting and investigation protocols form a critical component of safety regulations. These procedures help identify potential hazards, improve safety measures, and prevent future accidents. Regulatory bodies often require detailed documentation of all thermite-related activities, including safety checks, reaction parameters, and any anomalies observed.

As research continues to enhance thermite performance, safety regulations are evolving to address new formulations and applications. Emerging areas of focus include nanoscale thermite materials, which present unique safety challenges due to their increased reactivity and potential for aerosolization. Regulatory frameworks are adapting to incorporate these advancements, balancing the pursuit of improved performance with the paramount concern for safety in all aspects of thermite usage.

Environmental Impact of Thermite Reactions

Thermite reactions, while highly effective for certain applications, can have significant environmental impacts that must be carefully considered. The primary environmental concerns associated with thermite reactions stem from the release of various byproducts and the potential for unintended consequences in surrounding ecosystems.

One of the most notable environmental impacts is the production of metal oxide fumes during the reaction. These fumes, often containing aluminum oxide and iron oxide particles, can be harmful if inhaled and may contribute to air pollution in the immediate vicinity. The dispersion of these particles can affect local air quality and potentially impact respiratory health in nearby populations.

Additionally, the intense heat generated by thermite reactions can lead to localized thermal pollution. This sudden temperature increase may disrupt soil microbial communities and affect plant life in the surrounding area. In cases where thermite reactions are used for welding or demolition purposes, the heat can also cause damage to nearby structures or vegetation, potentially altering local habitats.

The residual slag produced by thermite reactions presents another environmental challenge. This slag, primarily composed of metal oxides, can contaminate soil and water sources if not properly managed. The leaching of heavy metals from the slag into groundwater is a particular concern, as it may have long-term effects on aquatic ecosystems and potentially enter the food chain.

In industrial applications, the disposal of thermite reaction byproducts requires careful consideration. Improper disposal can lead to soil contamination and potentially affect groundwater quality. The development of proper waste management protocols is crucial to mitigate these risks and ensure environmental compliance.

The use of thermite reactions in certain scenarios, such as underwater welding or in sensitive ecological areas, may have more pronounced environmental impacts. In aquatic environments, the reaction byproducts can directly affect water chemistry and marine life. The sudden release of heat and particles can disrupt local ecosystems and potentially harm aquatic organisms.

To address these environmental concerns, ongoing research is focused on developing cleaner thermite compositions and more efficient reaction processes. Innovations in particle size control and the use of alternative reactants aim to reduce the production of harmful fumes and minimize the overall environmental footprint of thermite reactions.

One of the most notable environmental impacts is the production of metal oxide fumes during the reaction. These fumes, often containing aluminum oxide and iron oxide particles, can be harmful if inhaled and may contribute to air pollution in the immediate vicinity. The dispersion of these particles can affect local air quality and potentially impact respiratory health in nearby populations.

Additionally, the intense heat generated by thermite reactions can lead to localized thermal pollution. This sudden temperature increase may disrupt soil microbial communities and affect plant life in the surrounding area. In cases where thermite reactions are used for welding or demolition purposes, the heat can also cause damage to nearby structures or vegetation, potentially altering local habitats.

The residual slag produced by thermite reactions presents another environmental challenge. This slag, primarily composed of metal oxides, can contaminate soil and water sources if not properly managed. The leaching of heavy metals from the slag into groundwater is a particular concern, as it may have long-term effects on aquatic ecosystems and potentially enter the food chain.

In industrial applications, the disposal of thermite reaction byproducts requires careful consideration. Improper disposal can lead to soil contamination and potentially affect groundwater quality. The development of proper waste management protocols is crucial to mitigate these risks and ensure environmental compliance.

The use of thermite reactions in certain scenarios, such as underwater welding or in sensitive ecological areas, may have more pronounced environmental impacts. In aquatic environments, the reaction byproducts can directly affect water chemistry and marine life. The sudden release of heat and particles can disrupt local ecosystems and potentially harm aquatic organisms.

To address these environmental concerns, ongoing research is focused on developing cleaner thermite compositions and more efficient reaction processes. Innovations in particle size control and the use of alternative reactants aim to reduce the production of harmful fumes and minimize the overall environmental footprint of thermite reactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!