Understanding the Catalytic Potential of Thermite Mixtures

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Catalysis Background and Objectives

Thermite reactions have been a subject of fascination and study for over a century, with their potential for high-temperature, self-sustaining reactions finding applications in various fields. The catalytic potential of thermite mixtures represents a frontier in this area, promising enhanced control, efficiency, and versatility in thermite-based processes.

The evolution of thermite technology has seen significant advancements since its discovery by Hans Goldschmidt in 1893. Initially used for welding railway tracks, thermite reactions have expanded into areas such as metal purification, incendiary devices, and more recently, as a potential energy source and in advanced materials synthesis. The progression from simple aluminum-iron oxide mixtures to complex, multi-component systems highlights the ongoing innovation in this field.

Current research trends are focusing on understanding and harnessing the catalytic properties of thermite mixtures. This shift represents a paradigm change from viewing thermites solely as energetic materials to recognizing their potential as reactive chemical systems with tunable properties. The incorporation of catalysts into thermite compositions offers the possibility of controlling reaction rates, temperatures, and product formation with unprecedented precision.

The primary objective of exploring the catalytic potential of thermite mixtures is to develop more efficient, controllable, and versatile thermite-based processes. This includes improving the initiation sensitivity, enhancing reaction propagation, and tailoring the reaction products for specific applications. By understanding the catalytic mechanisms at play, researchers aim to design thermite systems that can be fine-tuned for a wide range of applications, from materials synthesis to energy storage and conversion.

Another key goal is to expand the application scope of thermite reactions. The catalytic approach opens up possibilities for lower-temperature reactions, which could enable the use of thermites in more delicate processes or environments. Additionally, there is a growing interest in leveraging the catalytic properties of thermites for environmental remediation, such as the treatment of hazardous waste or the cleanup of contaminated soils.

The pursuit of these objectives necessitates a multidisciplinary approach, combining expertise from materials science, chemistry, physics, and engineering. Advanced characterization techniques, computational modeling, and in-situ reaction monitoring are becoming increasingly important in unraveling the complex interplay between thermite components and catalysts. As research progresses, the field is moving towards a more fundamental understanding of the reaction mechanisms, aiming to establish predictive models for thermite behavior under various conditions and compositions.

The evolution of thermite technology has seen significant advancements since its discovery by Hans Goldschmidt in 1893. Initially used for welding railway tracks, thermite reactions have expanded into areas such as metal purification, incendiary devices, and more recently, as a potential energy source and in advanced materials synthesis. The progression from simple aluminum-iron oxide mixtures to complex, multi-component systems highlights the ongoing innovation in this field.

Current research trends are focusing on understanding and harnessing the catalytic properties of thermite mixtures. This shift represents a paradigm change from viewing thermites solely as energetic materials to recognizing their potential as reactive chemical systems with tunable properties. The incorporation of catalysts into thermite compositions offers the possibility of controlling reaction rates, temperatures, and product formation with unprecedented precision.

The primary objective of exploring the catalytic potential of thermite mixtures is to develop more efficient, controllable, and versatile thermite-based processes. This includes improving the initiation sensitivity, enhancing reaction propagation, and tailoring the reaction products for specific applications. By understanding the catalytic mechanisms at play, researchers aim to design thermite systems that can be fine-tuned for a wide range of applications, from materials synthesis to energy storage and conversion.

Another key goal is to expand the application scope of thermite reactions. The catalytic approach opens up possibilities for lower-temperature reactions, which could enable the use of thermites in more delicate processes or environments. Additionally, there is a growing interest in leveraging the catalytic properties of thermites for environmental remediation, such as the treatment of hazardous waste or the cleanup of contaminated soils.

The pursuit of these objectives necessitates a multidisciplinary approach, combining expertise from materials science, chemistry, physics, and engineering. Advanced characterization techniques, computational modeling, and in-situ reaction monitoring are becoming increasingly important in unraveling the complex interplay between thermite components and catalysts. As research progresses, the field is moving towards a more fundamental understanding of the reaction mechanisms, aiming to establish predictive models for thermite behavior under various conditions and compositions.

Market Applications of Thermite Reactions

Thermite reactions have found diverse applications across various industries, leveraging their unique properties of high-temperature exothermic reactions and metal oxide reduction. In the manufacturing sector, thermite welding has become a standard technique for joining railway tracks, ensuring strong and durable connections. This method is particularly valuable in remote locations where traditional welding equipment is impractical.

The construction industry has also embraced thermite reactions for underwater welding and repair of large metal structures. The ability of thermite to generate intense heat and molten metal even in submerged conditions makes it invaluable for offshore platform maintenance and shipyard repairs. Additionally, thermite-based incendiary devices have applications in controlled demolition of obsolete structures, offering a precise and efficient alternative to traditional explosives.

In the field of materials science, thermite reactions are utilized for the production of high-purity metals and alloys. The aluminothermic process, a variant of thermite reaction, is employed in the extraction of metals like chromium, manganese, and titanium from their ores. This process is particularly advantageous for producing metals with high melting points that are challenging to extract through conventional smelting methods.

The aerospace and defense sectors have found strategic uses for thermite mixtures. Thermite-based flares are used in military aircraft for countermeasures against heat-seeking missiles. In space technology, thermite reactions have been explored for in-situ resource utilization on extraterrestrial bodies, potentially enabling the production of oxygen and metal components from local regolith.

Emerging applications of thermite reactions are being investigated in the field of renewable energy. Researchers are exploring the use of thermite-like reactions for high-temperature thermal energy storage, which could enhance the efficiency of concentrated solar power systems. Moreover, the intense heat generated by thermite reactions is being studied for potential applications in waste treatment and hazardous material disposal, offering an environmentally friendly alternative to incineration.

The automotive industry has shown interest in thermite-based airbag inflators, capitalizing on the rapid gas generation capabilities of certain thermite mixtures. This application promises more compact and efficient safety systems in vehicles. In the electronics sector, thermite reactions are being explored for self-destructing devices, addressing growing concerns about data security and electronic waste management.

The construction industry has also embraced thermite reactions for underwater welding and repair of large metal structures. The ability of thermite to generate intense heat and molten metal even in submerged conditions makes it invaluable for offshore platform maintenance and shipyard repairs. Additionally, thermite-based incendiary devices have applications in controlled demolition of obsolete structures, offering a precise and efficient alternative to traditional explosives.

In the field of materials science, thermite reactions are utilized for the production of high-purity metals and alloys. The aluminothermic process, a variant of thermite reaction, is employed in the extraction of metals like chromium, manganese, and titanium from their ores. This process is particularly advantageous for producing metals with high melting points that are challenging to extract through conventional smelting methods.

The aerospace and defense sectors have found strategic uses for thermite mixtures. Thermite-based flares are used in military aircraft for countermeasures against heat-seeking missiles. In space technology, thermite reactions have been explored for in-situ resource utilization on extraterrestrial bodies, potentially enabling the production of oxygen and metal components from local regolith.

Emerging applications of thermite reactions are being investigated in the field of renewable energy. Researchers are exploring the use of thermite-like reactions for high-temperature thermal energy storage, which could enhance the efficiency of concentrated solar power systems. Moreover, the intense heat generated by thermite reactions is being studied for potential applications in waste treatment and hazardous material disposal, offering an environmentally friendly alternative to incineration.

The automotive industry has shown interest in thermite-based airbag inflators, capitalizing on the rapid gas generation capabilities of certain thermite mixtures. This application promises more compact and efficient safety systems in vehicles. In the electronics sector, thermite reactions are being explored for self-destructing devices, addressing growing concerns about data security and electronic waste management.

Current Challenges in Thermite Mixture Optimization

Despite significant advancements in thermite mixture research, several challenges persist in optimizing these energetic materials for various applications. One of the primary obstacles is achieving precise control over reaction rates and energy release. The exothermic nature of thermite reactions often leads to rapid, uncontrolled combustion, making it difficult to harness the energy efficiently for specific purposes.

Another major challenge lies in enhancing the stability and shelf life of thermite mixtures. Many compositions are sensitive to environmental factors such as humidity and temperature, which can degrade their performance over time. This instability poses safety risks and limits the practical applications of thermite mixtures in various industries.

The scalability of thermite reactions presents a significant hurdle in their widespread adoption. While small-scale demonstrations have shown promising results, translating these outcomes to larger, industrial-scale applications remains problematic. Issues such as heat dissipation, uniform mixing, and maintaining reaction consistency across larger volumes need to be addressed.

Improving the ignition reliability and propagation characteristics of thermite mixtures is another area of ongoing research. Current ignition methods often lack precision, leading to inconsistent reaction initiation. Additionally, ensuring uniform propagation of the reaction front throughout the mixture, especially in complex geometries, remains a challenge.

The environmental impact of thermite reactions is a growing concern. Many traditional thermite compositions produce toxic byproducts or leave behind hazardous residues. Developing eco-friendly alternatives that maintain high performance while minimizing environmental footprint is a critical challenge facing researchers in this field.

Tailoring thermite mixtures for specific applications also presents difficulties. Different use cases require varying energy outputs, reaction speeds, and byproduct compositions. Creating customizable formulations that can be easily adapted to diverse requirements without compromising safety or efficiency is an ongoing challenge.

Lastly, the development of novel characterization techniques and predictive models for thermite mixtures lags behind the pace of innovation in composition design. More accurate and comprehensive methods for analyzing reaction kinetics, energy release profiles, and material properties are needed to guide future advancements in thermite technology.

Another major challenge lies in enhancing the stability and shelf life of thermite mixtures. Many compositions are sensitive to environmental factors such as humidity and temperature, which can degrade their performance over time. This instability poses safety risks and limits the practical applications of thermite mixtures in various industries.

The scalability of thermite reactions presents a significant hurdle in their widespread adoption. While small-scale demonstrations have shown promising results, translating these outcomes to larger, industrial-scale applications remains problematic. Issues such as heat dissipation, uniform mixing, and maintaining reaction consistency across larger volumes need to be addressed.

Improving the ignition reliability and propagation characteristics of thermite mixtures is another area of ongoing research. Current ignition methods often lack precision, leading to inconsistent reaction initiation. Additionally, ensuring uniform propagation of the reaction front throughout the mixture, especially in complex geometries, remains a challenge.

The environmental impact of thermite reactions is a growing concern. Many traditional thermite compositions produce toxic byproducts or leave behind hazardous residues. Developing eco-friendly alternatives that maintain high performance while minimizing environmental footprint is a critical challenge facing researchers in this field.

Tailoring thermite mixtures for specific applications also presents difficulties. Different use cases require varying energy outputs, reaction speeds, and byproduct compositions. Creating customizable formulations that can be easily adapted to diverse requirements without compromising safety or efficiency is an ongoing challenge.

Lastly, the development of novel characterization techniques and predictive models for thermite mixtures lags behind the pace of innovation in composition design. More accurate and comprehensive methods for analyzing reaction kinetics, energy release profiles, and material properties are needed to guide future advancements in thermite technology.

State-of-the-Art Thermite Mixture Compositions

01 Catalytic enhancement of thermite reactions

Certain additives can catalyze thermite reactions, increasing their efficiency and reaction rates. These catalysts can lower the activation energy required for the reaction, allowing for more controlled and rapid energy release. This has applications in various fields, including materials processing and energetic materials.- Catalytic enhancement of thermite reactions: Certain catalysts can be added to thermite mixtures to enhance their reactivity and performance. These catalysts can lower the activation energy required for the thermite reaction, leading to faster ignition and more complete combustion. This can result in higher temperatures, increased energy output, and improved efficiency of the thermite mixture.

- Nanoparticle additives in thermite compositions: Incorporating nanoparticles into thermite mixtures can significantly enhance their catalytic potential. Nanoparticles provide a larger surface area for reactions, leading to improved reactivity and energy release. Various types of nanoparticles, such as metal oxides or carbon-based materials, can be used to tailor the properties of thermite mixtures for specific applications.

- Thermite mixtures for welding and metal joining: Thermite mixtures with enhanced catalytic potential can be utilized in welding and metal joining applications. The improved reactivity and heat generation allow for more efficient and controlled welding processes. These mixtures can be tailored to specific metal combinations and joint configurations, offering advantages in various industrial settings.

- Environmental and safety considerations in thermite catalysis: The development of thermite mixtures with enhanced catalytic potential must consider environmental and safety aspects. Research focuses on creating more stable and controllable reactions, reducing harmful emissions, and improving the overall safety profile of thermite-based processes. This includes the exploration of environmentally friendly catalysts and reaction byproducts.

- Novel applications of catalytically enhanced thermite mixtures: The improved catalytic potential of thermite mixtures opens up new applications across various industries. These include advanced propulsion systems, thermal batteries, self-healing materials, and specialized cutting tools. The enhanced reactivity and energy output enable the development of more efficient and compact devices for both civilian and military applications.

02 Nanostructured thermite mixtures

Incorporating nanoparticles or nanostructured materials into thermite mixtures can significantly enhance their reactivity and energy output. The increased surface area of nanoparticles allows for more intimate contact between reactants, leading to faster reaction kinetics and potentially lower ignition temperatures.Expand Specific Solutions03 Thermite mixtures for welding and metal joining

Specialized thermite mixtures can be formulated for welding and metal joining applications. These mixtures are designed to produce specific metal alloys upon reaction, allowing for the joining of dissimilar metals or the repair of large metal structures. The catalytic potential of certain additives can improve the quality and strength of the resulting joints.Expand Specific Solutions04 Environmental and safety considerations in thermite formulations

Research into environmentally friendly and safer thermite mixtures focuses on reducing toxic byproducts and improving handling safety. This includes the development of green oxidizers, less reactive fuels, and additives that can suppress unwanted side reactions or control the reaction rate. These advancements aim to expand the potential applications of thermite reactions while minimizing environmental impact.Expand Specific Solutions05 Novel applications of catalyzed thermite reactions

The catalytic potential of thermite mixtures is being explored for novel applications beyond traditional uses. These include self-healing materials, thermal batteries, and propulsion systems. By carefully controlling the reaction kinetics through catalysts and mixture composition, researchers are developing new functional materials and energy storage solutions.Expand Specific Solutions

Key Players in Thermite Research and Industry

The catalytic potential of thermite mixtures is a field in a mature stage of development, with ongoing research and innovation. The market size for thermite applications is significant, spanning industries such as metallurgy, defense, and aerospace. Technologically, the field is well-established but continues to evolve. Companies like China Petroleum & Chemical Corp. and Lockheed Martin Corp. are at the forefront, leveraging their extensive resources for advanced research. Smaller entities like Anasphere, Inc. and BiSN Oil Tools Ltd. are driving innovation in niche applications. Academic institutions, such as Changzhou University and The Curators of the University of Missouri, contribute to fundamental research, while specialized firms like Elektro-Thermit GmbH & Co. KG focus on specific industrial applications, collectively advancing the field's technological maturity.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite mixtures for use in their aerospace and defense applications. Their research focuses on improving the energy density and reaction control of thermite compositions. They have patented a nanocomposite thermite material that combines metal oxide nanoparticles with aluminum fuel particles, resulting in faster reaction rates and higher energy output compared to traditional thermite mixtures. This technology allows for precise control over the ignition and propagation of the thermite reaction, making it suitable for various applications including propulsion systems and welding.

Strengths: High energy density, precise reaction control, fast ignition. Weaknesses: High production costs, potential safety concerns with nanoparticles.

W. R. Grace & Co.-Conn.

Technical Solution: W. R. Grace & Co. has developed innovative catalytic materials that enhance the performance of thermite mixtures. Their research focuses on creating specialized oxide materials that act as catalysts in thermite reactions, improving reaction rates and energy release. They have patented a series of mixed metal oxide catalysts that can be incorporated into thermite compositions to tailor the reaction characteristics. These catalysts allow for lower ignition temperatures, faster propagation rates, and more complete combustion of the thermite mixture. The company has also developed methods for producing these catalysts in various forms, including nanoparticles and porous structures, to optimize their performance in different thermite applications.

Strengths: Enhanced reaction efficiency, customizable reaction characteristics. Weaknesses: Increased complexity in formulation, potential cost increase.

Innovative Catalysts for Thermite Reactions

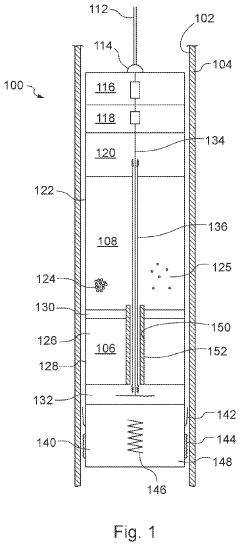

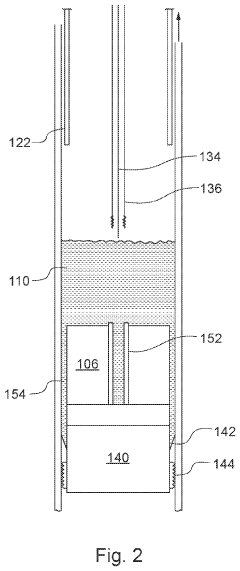

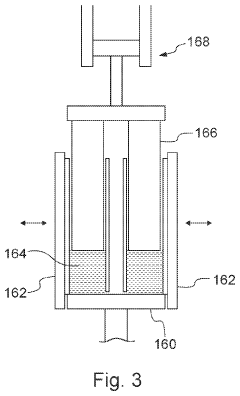

Downhole apparatus and method

PatentActiveUS20240011367A1

Innovation

- A downhole apparatus and method utilizing compressed thermite within a container, which reduces porosity and increases density, facilitating efficient heat transfer and reaction, and is combined with a low-melt-point alloy to form a solid plug, allowing for effective sealing without the need for binding agents and maintaining structural strength under pressure.

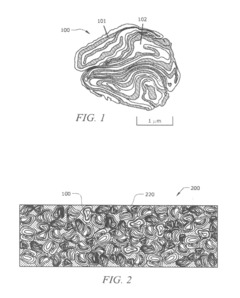

Thermite compositions from low temperature impact milling

PatentActiveUS20130068353A1

Innovation

- A process involving cryogenic milling at temperatures below −50°C to form a convoluted lamellar structure of alternating metal and metal oxide layers, which increases the interface area and prevents premature reaction initiation, allowing for better control over ignition and propagation phases.

Safety Regulations for Thermite Handling

The handling of thermite mixtures requires strict adherence to safety regulations due to their highly reactive nature and potential for causing severe burns and fires. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established comprehensive guidelines for the safe handling, storage, and use of thermite materials.

Personal protective equipment (PPE) is paramount when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and face shields. Respiratory protection may also be necessary to prevent inhalation of fine particles. All personnel involved in thermite handling must be properly trained in the use of PPE and emergency procedures.

Storage of thermite mixtures demands special consideration. They must be kept in dry, cool areas away from sources of heat, sparks, or open flames. Containers should be clearly labeled and stored separately from other combustible materials. Access to storage areas should be restricted to authorized personnel only.

Workplace safety measures are critical when using thermite. This includes maintaining a clean and organized work area, implementing proper ventilation systems, and having appropriate fire suppression equipment readily available. Emergency eyewash stations and safety showers should be installed in areas where thermite is handled.

Transportation of thermite mixtures is subject to strict regulations. They are classified as dangerous goods and must be transported in accordance with the Department of Transportation (DOT) guidelines. This includes proper packaging, labeling, and documentation.

Disposal of thermite waste requires careful consideration. Unused thermite and its byproducts must be disposed of as hazardous waste in compliance with local, state, and federal regulations. Proper documentation and tracking of waste disposal are essential.

Emergency response plans must be in place for potential thermite-related incidents. This includes procedures for fire suppression, spill containment, and evacuation. Regular drills should be conducted to ensure all personnel are familiar with these procedures.

Compliance with these safety regulations is not only a legal requirement but also essential for protecting workers, facilities, and the environment from the potential hazards associated with thermite mixtures. Regular safety audits and updates to protocols are necessary to maintain the highest standards of safety in thermite handling operations.

Personal protective equipment (PPE) is paramount when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and face shields. Respiratory protection may also be necessary to prevent inhalation of fine particles. All personnel involved in thermite handling must be properly trained in the use of PPE and emergency procedures.

Storage of thermite mixtures demands special consideration. They must be kept in dry, cool areas away from sources of heat, sparks, or open flames. Containers should be clearly labeled and stored separately from other combustible materials. Access to storage areas should be restricted to authorized personnel only.

Workplace safety measures are critical when using thermite. This includes maintaining a clean and organized work area, implementing proper ventilation systems, and having appropriate fire suppression equipment readily available. Emergency eyewash stations and safety showers should be installed in areas where thermite is handled.

Transportation of thermite mixtures is subject to strict regulations. They are classified as dangerous goods and must be transported in accordance with the Department of Transportation (DOT) guidelines. This includes proper packaging, labeling, and documentation.

Disposal of thermite waste requires careful consideration. Unused thermite and its byproducts must be disposed of as hazardous waste in compliance with local, state, and federal regulations. Proper documentation and tracking of waste disposal are essential.

Emergency response plans must be in place for potential thermite-related incidents. This includes procedures for fire suppression, spill containment, and evacuation. Regular drills should be conducted to ensure all personnel are familiar with these procedures.

Compliance with these safety regulations is not only a legal requirement but also essential for protecting workers, facilities, and the environment from the potential hazards associated with thermite mixtures. Regular safety audits and updates to protocols are necessary to maintain the highest standards of safety in thermite handling operations.

Environmental Impact of Thermite Reactions

Thermite reactions, while powerful and efficient for certain applications, can have significant environmental impacts that must be carefully considered. The primary environmental concerns associated with thermite reactions stem from the release of various byproducts and the potential for unintended consequences in surrounding ecosystems.

One of the most immediate environmental impacts of thermite reactions is the release of metal oxides as particulate matter. These fine particles can remain suspended in the air for extended periods, potentially affecting air quality and posing respiratory risks to both humans and wildlife. The specific composition of these particles depends on the metals used in the thermite mixture, but commonly includes aluminum oxide and iron oxide.

The high temperatures generated during thermite reactions can also lead to the formation of nitrogen oxides (NOx) when conducted in open-air environments. These compounds contribute to the formation of smog and acid rain, potentially impacting both local and regional air quality. Additionally, the intense heat can cause localized soil sterilization, affecting microbial communities and plant life in the immediate vicinity of the reaction.

Water contamination is another potential environmental concern, particularly when thermite reactions occur near water sources. The metal oxides and other byproducts can leach into groundwater or surface water, altering pH levels and potentially introducing toxic elements into aquatic ecosystems. This can have cascading effects on aquatic flora and fauna, disrupting local food chains and biodiversity.

The disposal of spent thermite materials also presents environmental challenges. Improper disposal can lead to soil contamination and the potential for long-term environmental degradation. The residual materials may contain unreacted components or toxic byproducts that require specialized handling and disposal methods to minimize environmental impact.

It's important to note that the environmental impact of thermite reactions can vary significantly depending on the scale of the reaction, the specific composition of the thermite mixture, and the environment in which it occurs. Large-scale industrial applications, for instance, may have more pronounced environmental effects compared to small-scale laboratory experiments or controlled demolitions.

To mitigate these environmental impacts, researchers and industry professionals are exploring various strategies. These include developing more environmentally friendly thermite compositions, implementing better containment and filtration systems for byproducts, and improving disposal and recycling methods for spent materials. Additionally, conducting thorough environmental impact assessments before large-scale thermite applications can help identify and address potential risks proactively.

One of the most immediate environmental impacts of thermite reactions is the release of metal oxides as particulate matter. These fine particles can remain suspended in the air for extended periods, potentially affecting air quality and posing respiratory risks to both humans and wildlife. The specific composition of these particles depends on the metals used in the thermite mixture, but commonly includes aluminum oxide and iron oxide.

The high temperatures generated during thermite reactions can also lead to the formation of nitrogen oxides (NOx) when conducted in open-air environments. These compounds contribute to the formation of smog and acid rain, potentially impacting both local and regional air quality. Additionally, the intense heat can cause localized soil sterilization, affecting microbial communities and plant life in the immediate vicinity of the reaction.

Water contamination is another potential environmental concern, particularly when thermite reactions occur near water sources. The metal oxides and other byproducts can leach into groundwater or surface water, altering pH levels and potentially introducing toxic elements into aquatic ecosystems. This can have cascading effects on aquatic flora and fauna, disrupting local food chains and biodiversity.

The disposal of spent thermite materials also presents environmental challenges. Improper disposal can lead to soil contamination and the potential for long-term environmental degradation. The residual materials may contain unreacted components or toxic byproducts that require specialized handling and disposal methods to minimize environmental impact.

It's important to note that the environmental impact of thermite reactions can vary significantly depending on the scale of the reaction, the specific composition of the thermite mixture, and the environment in which it occurs. Large-scale industrial applications, for instance, may have more pronounced environmental effects compared to small-scale laboratory experiments or controlled demolitions.

To mitigate these environmental impacts, researchers and industry professionals are exploring various strategies. These include developing more environmentally friendly thermite compositions, implementing better containment and filtration systems for byproducts, and improving disposal and recycling methods for spent materials. Additionally, conducting thorough environmental impact assessments before large-scale thermite applications can help identify and address potential risks proactively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!