Thermite as a Tool for Efficient Rail Infrastructure Maintenance

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Welding Evolution

Thermite welding has undergone significant evolution since its inception in the late 19th century. Initially developed by Hans Goldschmidt in 1895, this process has become a cornerstone in rail infrastructure maintenance. The early stages of thermite welding were characterized by manual operations and limited control over the welding process, resulting in inconsistent joint quality.

As the railway industry expanded rapidly in the 20th century, the demand for more efficient and reliable welding techniques grew. This led to the first major evolution in thermite welding during the 1920s and 1930s, with the introduction of improved mold designs and more precise chemical compositions of thermite mixtures. These advancements allowed for better control of the welding process and enhanced joint strength.

The post-World War II era saw a surge in railway development, prompting further refinements in thermite welding technology. The 1950s and 1960s witnessed the introduction of automated ignition systems and preheating techniques, which significantly improved the consistency and quality of welds. This period also marked the beginning of standardization efforts in thermite welding procedures across different railway networks.

In the 1970s and 1980s, the focus shifted towards improving the metallurgical properties of thermite welds. Research into alloying elements and their effects on weld microstructure led to the development of specialized thermite mixtures tailored for different rail steel grades. This era also saw the introduction of computer-aided design in mold manufacturing, resulting in more precise and efficient welding processes.

The digital revolution of the 1990s and 2000s brought about another significant leap in thermite welding technology. The integration of sensors and digital control systems allowed for real-time monitoring and adjustment of the welding process. This not only improved weld quality but also enhanced safety and reduced the reliance on operator skill.

Recent advancements in the 21st century have focused on sustainability and efficiency. The development of eco-friendly thermite mixtures with reduced emissions and improved energy efficiency has become a priority. Additionally, the integration of non-destructive testing methods, such as ultrasonic and radiographic inspection, has further enhanced the reliability and longevity of thermite welds.

Looking towards the future, the evolution of thermite welding is likely to continue with the incorporation of artificial intelligence and machine learning. These technologies promise to optimize welding parameters in real-time, predict maintenance needs, and further improve the overall efficiency of rail infrastructure maintenance.

As the railway industry expanded rapidly in the 20th century, the demand for more efficient and reliable welding techniques grew. This led to the first major evolution in thermite welding during the 1920s and 1930s, with the introduction of improved mold designs and more precise chemical compositions of thermite mixtures. These advancements allowed for better control of the welding process and enhanced joint strength.

The post-World War II era saw a surge in railway development, prompting further refinements in thermite welding technology. The 1950s and 1960s witnessed the introduction of automated ignition systems and preheating techniques, which significantly improved the consistency and quality of welds. This period also marked the beginning of standardization efforts in thermite welding procedures across different railway networks.

In the 1970s and 1980s, the focus shifted towards improving the metallurgical properties of thermite welds. Research into alloying elements and their effects on weld microstructure led to the development of specialized thermite mixtures tailored for different rail steel grades. This era also saw the introduction of computer-aided design in mold manufacturing, resulting in more precise and efficient welding processes.

The digital revolution of the 1990s and 2000s brought about another significant leap in thermite welding technology. The integration of sensors and digital control systems allowed for real-time monitoring and adjustment of the welding process. This not only improved weld quality but also enhanced safety and reduced the reliance on operator skill.

Recent advancements in the 21st century have focused on sustainability and efficiency. The development of eco-friendly thermite mixtures with reduced emissions and improved energy efficiency has become a priority. Additionally, the integration of non-destructive testing methods, such as ultrasonic and radiographic inspection, has further enhanced the reliability and longevity of thermite welds.

Looking towards the future, the evolution of thermite welding is likely to continue with the incorporation of artificial intelligence and machine learning. These technologies promise to optimize welding parameters in real-time, predict maintenance needs, and further improve the overall efficiency of rail infrastructure maintenance.

Rail Maintenance Market

The rail maintenance market has experienced significant growth in recent years, driven by the increasing demand for efficient and reliable rail transportation systems worldwide. As countries invest heavily in expanding and upgrading their rail networks, the need for effective maintenance solutions has become paramount. The global rail maintenance market is projected to reach substantial value in the coming years, with a compound annual growth rate that reflects the industry's robust expansion.

Several factors contribute to the growing demand for rail maintenance services and technologies. Aging rail infrastructure in many developed countries necessitates regular upkeep and modernization to ensure safety and operational efficiency. Additionally, the rapid development of high-speed rail networks in emerging economies has created new opportunities for maintenance providers. The increasing focus on reducing operational costs and improving service reliability has also spurred interest in innovative maintenance solutions.

The market landscape is characterized by a mix of established players and new entrants offering a wide range of maintenance services and products. These include track maintenance, rolling stock maintenance, signaling system upkeep, and infrastructure repair. Technological advancements, such as predictive maintenance systems utilizing IoT sensors and big data analytics, are reshaping the industry by enabling more proactive and cost-effective maintenance strategies.

Geographically, the rail maintenance market shows varying patterns of growth and maturity. North America and Europe, with their extensive and aging rail networks, represent significant markets for maintenance services. Asia-Pacific, particularly China and India, is experiencing rapid growth due to massive investments in rail infrastructure. The Middle East and Africa are emerging as promising markets, driven by new rail projects and modernization efforts.

Key trends shaping the rail maintenance market include the adoption of automation and robotics in maintenance processes, the integration of artificial intelligence for predictive maintenance, and the development of eco-friendly maintenance solutions. These innovations aim to enhance efficiency, reduce downtime, and minimize environmental impact.

The demand for specialized maintenance techniques, such as thermite welding for rail repair, is also on the rise. Thermite welding offers advantages in terms of speed, cost-effectiveness, and durability, making it an attractive option for rail operators seeking to minimize disruptions to service schedules. This technique aligns well with the industry's focus on efficient infrastructure maintenance, positioning it as a valuable tool in the broader context of rail maintenance solutions.

Several factors contribute to the growing demand for rail maintenance services and technologies. Aging rail infrastructure in many developed countries necessitates regular upkeep and modernization to ensure safety and operational efficiency. Additionally, the rapid development of high-speed rail networks in emerging economies has created new opportunities for maintenance providers. The increasing focus on reducing operational costs and improving service reliability has also spurred interest in innovative maintenance solutions.

The market landscape is characterized by a mix of established players and new entrants offering a wide range of maintenance services and products. These include track maintenance, rolling stock maintenance, signaling system upkeep, and infrastructure repair. Technological advancements, such as predictive maintenance systems utilizing IoT sensors and big data analytics, are reshaping the industry by enabling more proactive and cost-effective maintenance strategies.

Geographically, the rail maintenance market shows varying patterns of growth and maturity. North America and Europe, with their extensive and aging rail networks, represent significant markets for maintenance services. Asia-Pacific, particularly China and India, is experiencing rapid growth due to massive investments in rail infrastructure. The Middle East and Africa are emerging as promising markets, driven by new rail projects and modernization efforts.

Key trends shaping the rail maintenance market include the adoption of automation and robotics in maintenance processes, the integration of artificial intelligence for predictive maintenance, and the development of eco-friendly maintenance solutions. These innovations aim to enhance efficiency, reduce downtime, and minimize environmental impact.

The demand for specialized maintenance techniques, such as thermite welding for rail repair, is also on the rise. Thermite welding offers advantages in terms of speed, cost-effectiveness, and durability, making it an attractive option for rail operators seeking to minimize disruptions to service schedules. This technique aligns well with the industry's focus on efficient infrastructure maintenance, positioning it as a valuable tool in the broader context of rail maintenance solutions.

Thermite Tech Challenges

The use of thermite for rail infrastructure maintenance, while effective, presents several significant technical challenges that require careful consideration and innovative solutions. One of the primary issues is the precise control of the exothermic reaction. The thermite reaction, once initiated, is difficult to modulate or stop, which can lead to inconsistencies in weld quality and potential safety hazards if not managed correctly.

Temperature control during the welding process is another critical challenge. The extreme heat generated by the thermite reaction can cause rapid cooling rates, leading to the formation of brittle microstructures in the weld and heat-affected zones. This can compromise the structural integrity of the rail joint, potentially leading to premature failure under the high stresses of rail traffic.

The composition of the thermite mixture itself presents another set of challenges. Achieving the optimal balance of aluminum and iron oxide, along with any additives, is crucial for producing high-quality welds. Variations in composition can affect the reaction temperature, flow characteristics, and final weld properties, making consistency across multiple welds a significant technical hurdle.

Porosity and inclusion formation within the weld are persistent issues that can weaken the joint. The rapid nature of the thermite reaction can trap gases and impurities within the solidifying metal, creating potential stress concentration points and reducing the overall strength of the weld.

Environmental factors also pose challenges to thermite welding in rail maintenance. Moisture, wind, and ambient temperature can all affect the reaction and cooling processes, potentially leading to weld defects. Developing methods to mitigate these environmental influences is essential for ensuring consistent weld quality across various field conditions.

The geometry of the rail joint presents another technical challenge. Ensuring proper alignment and gap control between rail ends is critical for producing a smooth running surface. Achieving this precision in field conditions, often with worn or damaged rail ends, requires advanced preparation techniques and specialized equipment.

Lastly, the post-weld treatment and inspection of thermite welds pose significant challenges. Developing non-destructive testing methods that can reliably detect internal defects in thermite welds, without disrupting rail operations, is an ongoing area of research and development in the industry.

Temperature control during the welding process is another critical challenge. The extreme heat generated by the thermite reaction can cause rapid cooling rates, leading to the formation of brittle microstructures in the weld and heat-affected zones. This can compromise the structural integrity of the rail joint, potentially leading to premature failure under the high stresses of rail traffic.

The composition of the thermite mixture itself presents another set of challenges. Achieving the optimal balance of aluminum and iron oxide, along with any additives, is crucial for producing high-quality welds. Variations in composition can affect the reaction temperature, flow characteristics, and final weld properties, making consistency across multiple welds a significant technical hurdle.

Porosity and inclusion formation within the weld are persistent issues that can weaken the joint. The rapid nature of the thermite reaction can trap gases and impurities within the solidifying metal, creating potential stress concentration points and reducing the overall strength of the weld.

Environmental factors also pose challenges to thermite welding in rail maintenance. Moisture, wind, and ambient temperature can all affect the reaction and cooling processes, potentially leading to weld defects. Developing methods to mitigate these environmental influences is essential for ensuring consistent weld quality across various field conditions.

The geometry of the rail joint presents another technical challenge. Ensuring proper alignment and gap control between rail ends is critical for producing a smooth running surface. Achieving this precision in field conditions, often with worn or damaged rail ends, requires advanced preparation techniques and specialized equipment.

Lastly, the post-weld treatment and inspection of thermite welds pose significant challenges. Developing non-destructive testing methods that can reliably detect internal defects in thermite welds, without disrupting rail operations, is an ongoing area of research and development in the industry.

Current Thermite Methods

01 Composition optimization for thermite reactions

Improving thermite efficiency involves optimizing the composition of reactants. This includes adjusting the ratio of metal fuel to metal oxide, incorporating additives, and selecting specific particle sizes to enhance reaction rates and energy output. Careful selection and combination of materials can significantly increase the overall efficiency of thermite reactions.- Composition optimization for thermite reactions: Improving thermite efficiency involves optimizing the composition of reactants. This includes adjusting the ratio of metal fuel to metal oxide, incorporating additives, and selecting specific particle sizes to enhance reaction rates and energy output. Careful selection and combination of materials can significantly increase the overall efficiency of thermite reactions.

- Ignition and initiation techniques: Advanced ignition methods play a crucial role in thermite efficiency. Techniques such as electric ignition, laser-induced initiation, and shock wave ignition can improve reaction start times and propagation rates. Proper initiation ensures complete combustion and maximizes energy release from the thermite mixture.

- Nanostructured thermite materials: Utilizing nanostructured materials in thermite compositions can dramatically enhance reaction efficiency. Nanoscale particles increase the surface area for reactions, leading to faster reaction rates and more complete combustion. This approach can result in higher energy densities and improved overall performance of thermite systems.

- Containment and directional control: Improving thermite efficiency also involves optimizing the containment and directional control of the reaction. Specialized casings, nozzles, and reaction chambers can focus the energy release, enhance pressure build-up, and direct the output for specific applications. This approach maximizes the useful work extracted from the thermite reaction.

- Environmental and safety considerations: Enhancing thermite efficiency includes developing environmentally friendly and safer formulations. This involves using less toxic materials, reducing harmful byproducts, and improving stability during storage and handling. These considerations ensure that increased efficiency does not come at the cost of safety or environmental impact.

02 Ignition and initiation techniques

Efficient ignition methods play a crucial role in thermite efficiency. Advanced techniques such as electric ignition systems, laser-induced initiation, and shock wave ignition can improve reaction start times and ensure more complete combustion. These methods can lead to better control over the reaction and increased energy utilization.Expand Specific Solutions03 Containment and directional control

Enhancing thermite efficiency involves developing improved containment systems and methods for directional control of the reaction. This includes designing specialized casings, nozzles, and reaction chambers that can focus and direct the energy output, reducing waste and increasing the useful work performed by the thermite reaction.Expand Specific Solutions04 Heat management and energy recovery

Efficient heat management systems can significantly improve overall thermite efficiency. This involves developing methods to capture and utilize excess heat, implementing cooling systems to prevent premature ignition, and designing energy recovery systems that can harness residual thermal energy for secondary applications or to sustain the reaction.Expand Specific Solutions05 Novel thermite formulations and nanomaterials

Research into novel thermite formulations, including the use of nanomaterials, can greatly enhance efficiency. Nanostructured thermites offer increased surface area and reactivity, leading to faster reaction rates and higher energy densities. Additionally, exploring new combinations of fuels and oxidizers can yield more efficient and controllable thermite reactions.Expand Specific Solutions

Rail Welding Industry

The thermite-based rail maintenance technology is in a growth phase, with increasing market size due to the global focus on railway infrastructure modernization. The market is characterized by a mix of established players and innovative entrants, reflecting the technology's evolving nature. Companies like Railtech International SA and Holland L P are at the forefront, demonstrating advanced technical maturity in thermite welding applications. NIPPON STEEL CORP. and voestalpine Schienen GmbH contribute significant expertise in rail materials and manufacturing. Emerging players such as China Railway Shanhaiguan Bridge Group Co. Ltd. and Sichuan Jinhong Plasma Technology Co., Ltd. are driving innovation in the Asian market. Research institutions like Southwest Jiaotong University and the Railway Construction Research Institute of China Academy of Railway Sciences Group Co., Ltd. are advancing the technology's theoretical foundations and practical applications.

Railtech International SA

Technical Solution: Railtech International SA has developed an advanced thermite welding technology for rail maintenance. Their process involves a precisely controlled exothermic reaction between iron oxide and aluminum, creating molten steel that fuses rail sections. The company's patented mold design ensures optimal heat distribution and minimal porosity in the weld. They also utilize a computerized ignition system for precise timing and temperature control during the welding process, resulting in high-quality, long-lasting rail joints.

Strengths: Precise control over the welding process, high-quality joints, and reduced maintenance frequency. Weaknesses: Requires specialized training for operators and may have higher initial costs compared to traditional methods.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed a proprietary thermite welding compound specifically designed for high-speed rail applications. Their technology incorporates nano-scale additives that enhance the strength and durability of the weld. The company's process also includes a rapid cooling system that minimizes heat-affected zones, reducing the risk of rail deformation. Additionally, they have implemented a robotic application system that ensures consistent quality across large-scale rail maintenance projects.

Strengths: Enhanced weld strength, suitability for high-speed rail, and automated application for consistency. Weaknesses: May be more expensive than traditional thermite welding compounds and require specialized equipment.

Key Thermite Innovations

Thermite welding

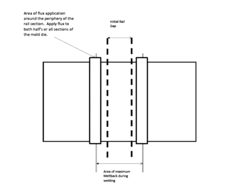

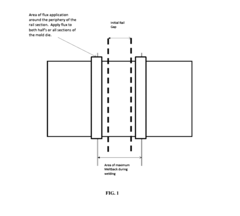

PatentInactiveUS20170028504A1

Innovation

- The use of an oxide displacing or oxide dissolving flux applied to the thermite welding dies, which initiates an exothermic reaction and enhances wetting by localizing heat and oxidation at the weld terminus, reducing the need for additional heat and improving joint geometry.

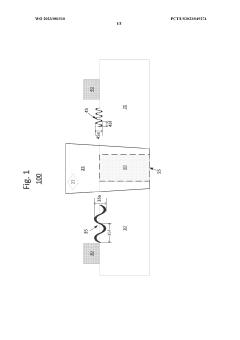

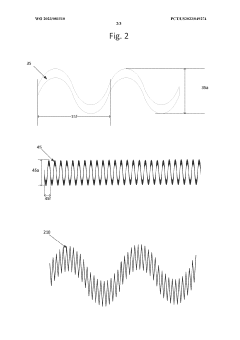

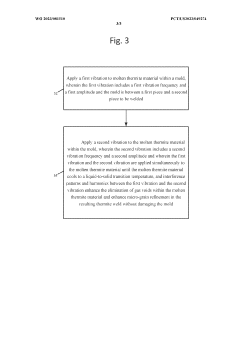

Field-applied system and method to produce thermite welds

PatentWO2023081510A1

Innovation

- A vibration process is applied to molten thermite, using a combination of low-frequency and high-frequency vibrations to eliminate gas voids and refine grain structure, enhancing the metallurgical soundness of the weld without damaging the mold, thereby increasing strength and fatigue life.

Safety Regulations

The use of thermite for rail infrastructure maintenance is subject to stringent safety regulations due to its highly exothermic nature and potential hazards. Regulatory bodies such as the Federal Railroad Administration (FRA) in the United States and the European Union Agency for Railways (ERA) in Europe have established comprehensive guidelines to ensure the safe application of thermite welding in rail maintenance operations.

These regulations typically cover various aspects of the thermite welding process, including personnel qualifications, equipment standards, and operational procedures. Workers involved in thermite welding must undergo specialized training and certification programs to demonstrate their competence in handling the materials and executing the welding process safely. This training often includes both theoretical knowledge and practical skills assessment.

Personal protective equipment (PPE) requirements are a crucial component of safety regulations. Workers are mandated to wear fire-resistant clothing, face shields, safety glasses, and appropriate gloves to protect against the intense heat and potential splatter generated during the thermite reaction. Respiratory protection may also be required to guard against inhalation of fumes and particulates.

Regulations also dictate strict protocols for the storage, transportation, and handling of thermite materials. These substances must be kept in secure, dry locations away from potential ignition sources. During transportation, thermite compounds are classified as hazardous materials and must comply with specific packaging and labeling requirements to prevent accidental ignition or exposure.

Worksite safety is another critical aspect addressed by regulations. Before commencing thermite welding operations, a designated safety zone must be established and clearly marked. This area should be free from flammable materials and unauthorized personnel. Fire suppression equipment must be readily available on-site, and in some cases, a fire watch may be required during and after the welding process.

Environmental considerations are also incorporated into safety regulations for thermite welding. Guidelines often include measures to minimize the release of harmful emissions and to properly dispose of waste materials generated during the process. Some jurisdictions may require environmental impact assessments or permits for large-scale thermite welding operations.

Regulatory bodies regularly update these safety standards to reflect advancements in technology and best practices. Compliance with these regulations is typically enforced through periodic inspections, audits, and reporting requirements. Violations can result in significant penalties, including fines and suspension of operating licenses.

As the use of thermite in rail maintenance continues to evolve, safety regulations are likely to adapt to address new challenges and opportunities. This may include the integration of automated systems, remote monitoring technologies, and enhanced risk assessment methodologies to further improve the safety and efficiency of thermite-based rail infrastructure maintenance.

These regulations typically cover various aspects of the thermite welding process, including personnel qualifications, equipment standards, and operational procedures. Workers involved in thermite welding must undergo specialized training and certification programs to demonstrate their competence in handling the materials and executing the welding process safely. This training often includes both theoretical knowledge and practical skills assessment.

Personal protective equipment (PPE) requirements are a crucial component of safety regulations. Workers are mandated to wear fire-resistant clothing, face shields, safety glasses, and appropriate gloves to protect against the intense heat and potential splatter generated during the thermite reaction. Respiratory protection may also be required to guard against inhalation of fumes and particulates.

Regulations also dictate strict protocols for the storage, transportation, and handling of thermite materials. These substances must be kept in secure, dry locations away from potential ignition sources. During transportation, thermite compounds are classified as hazardous materials and must comply with specific packaging and labeling requirements to prevent accidental ignition or exposure.

Worksite safety is another critical aspect addressed by regulations. Before commencing thermite welding operations, a designated safety zone must be established and clearly marked. This area should be free from flammable materials and unauthorized personnel. Fire suppression equipment must be readily available on-site, and in some cases, a fire watch may be required during and after the welding process.

Environmental considerations are also incorporated into safety regulations for thermite welding. Guidelines often include measures to minimize the release of harmful emissions and to properly dispose of waste materials generated during the process. Some jurisdictions may require environmental impact assessments or permits for large-scale thermite welding operations.

Regulatory bodies regularly update these safety standards to reflect advancements in technology and best practices. Compliance with these regulations is typically enforced through periodic inspections, audits, and reporting requirements. Violations can result in significant penalties, including fines and suspension of operating licenses.

As the use of thermite in rail maintenance continues to evolve, safety regulations are likely to adapt to address new challenges and opportunities. This may include the integration of automated systems, remote monitoring technologies, and enhanced risk assessment methodologies to further improve the safety and efficiency of thermite-based rail infrastructure maintenance.

Environmental Impact

The use of thermite for rail infrastructure maintenance, while efficient, raises significant environmental concerns that must be carefully considered. The high-temperature exothermic reaction of thermite produces intense heat and molten metal, which can have immediate and long-term impacts on the surrounding environment.

One of the primary environmental concerns is the release of particulate matter and potentially harmful gases during the thermite reaction. These emissions can contribute to air pollution, especially in urban areas where rail maintenance is frequently conducted. The fine particles released may pose respiratory risks to workers and nearby residents, necessitating proper safety measures and air quality monitoring during maintenance operations.

Soil contamination is another critical environmental issue associated with thermite welding. The molten metal and slag produced during the process can leach into the soil, potentially altering its chemical composition and affecting local ecosystems. This is particularly problematic in areas with sensitive soil conditions or near water bodies, where contaminants could migrate and impact aquatic life.

The intense heat generated by thermite reactions can also have localized effects on vegetation and microorganisms in the immediate vicinity of the maintenance site. This thermal impact may lead to temporary or permanent changes in the local biodiversity, especially if maintenance activities are frequent or concentrated in specific areas.

Waste management is a crucial aspect of the environmental impact of thermite use. The slag and excess materials produced during the welding process must be properly disposed of to prevent environmental contamination. Implementing effective recycling and disposal protocols is essential to minimize the environmental footprint of these maintenance activities.

Energy consumption and carbon footprint considerations are also relevant when assessing the environmental impact of thermite-based rail maintenance. While the process itself is highly efficient in terms of localized energy use, the production and transportation of thermite materials contribute to the overall environmental impact. Evaluating the lifecycle emissions and energy use of thermite-based maintenance compared to alternative methods is crucial for a comprehensive environmental assessment.

Noise pollution, although temporary, is another environmental factor to consider. The thermite reaction and associated maintenance activities can produce significant noise levels, potentially disturbing local wildlife and human populations, especially when work is conducted in residential areas or during nighttime hours.

To mitigate these environmental impacts, rail infrastructure managers must implement stringent environmental management practices. This includes using advanced emission control technologies, developing eco-friendly thermite formulations, and adopting best practices for site remediation post-maintenance. Additionally, conducting regular environmental impact assessments and exploring alternative, less environmentally intrusive maintenance techniques should be part of a comprehensive approach to sustainable rail infrastructure management.

One of the primary environmental concerns is the release of particulate matter and potentially harmful gases during the thermite reaction. These emissions can contribute to air pollution, especially in urban areas where rail maintenance is frequently conducted. The fine particles released may pose respiratory risks to workers and nearby residents, necessitating proper safety measures and air quality monitoring during maintenance operations.

Soil contamination is another critical environmental issue associated with thermite welding. The molten metal and slag produced during the process can leach into the soil, potentially altering its chemical composition and affecting local ecosystems. This is particularly problematic in areas with sensitive soil conditions or near water bodies, where contaminants could migrate and impact aquatic life.

The intense heat generated by thermite reactions can also have localized effects on vegetation and microorganisms in the immediate vicinity of the maintenance site. This thermal impact may lead to temporary or permanent changes in the local biodiversity, especially if maintenance activities are frequent or concentrated in specific areas.

Waste management is a crucial aspect of the environmental impact of thermite use. The slag and excess materials produced during the welding process must be properly disposed of to prevent environmental contamination. Implementing effective recycling and disposal protocols is essential to minimize the environmental footprint of these maintenance activities.

Energy consumption and carbon footprint considerations are also relevant when assessing the environmental impact of thermite-based rail maintenance. While the process itself is highly efficient in terms of localized energy use, the production and transportation of thermite materials contribute to the overall environmental impact. Evaluating the lifecycle emissions and energy use of thermite-based maintenance compared to alternative methods is crucial for a comprehensive environmental assessment.

Noise pollution, although temporary, is another environmental factor to consider. The thermite reaction and associated maintenance activities can produce significant noise levels, potentially disturbing local wildlife and human populations, especially when work is conducted in residential areas or during nighttime hours.

To mitigate these environmental impacts, rail infrastructure managers must implement stringent environmental management practices. This includes using advanced emission control technologies, developing eco-friendly thermite formulations, and adopting best practices for site remediation post-maintenance. Additionally, conducting regular environmental impact assessments and exploring alternative, less environmentally intrusive maintenance techniques should be part of a comprehensive approach to sustainable rail infrastructure management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!