How to Measure Thermite Reaction Energy with Precision?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Reaction Energy Measurement Background

Thermite reactions have been a subject of scientific interest and practical application for over a century. These highly exothermic reactions, typically involving a metal oxide and a more reactive metal, have found uses in various fields, from metallurgy to pyrotechnics. The precise measurement of the energy released during these reactions is crucial for understanding their behavior, optimizing their performance, and ensuring safety in their applications.

The history of thermite reaction energy measurement dates back to the early 20th century when German chemist Hans Goldschmidt first patented the thermite process. Initially, the energy released was estimated through rudimentary calorimetric methods, which provided only rough approximations. As the importance of these reactions grew in industrial and military applications, so did the need for more accurate measurement techniques.

Over the decades, the evolution of measurement methods has been driven by advancements in materials science, instrumentation, and data analysis. Early techniques relied on simple heat transfer calculations and basic calorimetry. These methods, while groundbreaking for their time, were limited by the technological constraints of the era and often resulted in significant margins of error.

The mid-20th century saw the introduction of more sophisticated calorimetric techniques, including adiabatic and bomb calorimetry. These methods allowed for more controlled environments and reduced heat loss during measurements, leading to improved accuracy. However, they still faced challenges in dealing with the rapid and intense nature of thermite reactions.

In recent years, the field has witnessed a surge in the development of high-precision measurement techniques. Advanced sensors, high-speed data acquisition systems, and computer-aided analysis have revolutionized the ability to capture and interpret the energy release profiles of thermite reactions. Modern approaches often combine multiple measurement techniques, such as calorimetry with spectroscopic methods, to provide a more comprehensive understanding of the reaction dynamics.

The drive for precision in thermite reaction energy measurement is fueled by diverse applications across industries. In metallurgy, accurate energy measurements are essential for optimizing welding and metal purification processes. The aerospace industry relies on precise energy data for the design of propulsion systems and pyrotechnic devices. In the field of energetic materials research, understanding the exact energy output is crucial for developing safer and more efficient formulations.

As we look to the future, the challenge of measuring thermite reaction energy with precision continues to evolve. Researchers are exploring novel approaches, including nanoscale calorimetry and advanced computational modeling, to push the boundaries of measurement accuracy. These efforts are not only advancing our scientific understanding but also paving the way for new applications and improved safety standards in the use of thermite reactions.

The history of thermite reaction energy measurement dates back to the early 20th century when German chemist Hans Goldschmidt first patented the thermite process. Initially, the energy released was estimated through rudimentary calorimetric methods, which provided only rough approximations. As the importance of these reactions grew in industrial and military applications, so did the need for more accurate measurement techniques.

Over the decades, the evolution of measurement methods has been driven by advancements in materials science, instrumentation, and data analysis. Early techniques relied on simple heat transfer calculations and basic calorimetry. These methods, while groundbreaking for their time, were limited by the technological constraints of the era and often resulted in significant margins of error.

The mid-20th century saw the introduction of more sophisticated calorimetric techniques, including adiabatic and bomb calorimetry. These methods allowed for more controlled environments and reduced heat loss during measurements, leading to improved accuracy. However, they still faced challenges in dealing with the rapid and intense nature of thermite reactions.

In recent years, the field has witnessed a surge in the development of high-precision measurement techniques. Advanced sensors, high-speed data acquisition systems, and computer-aided analysis have revolutionized the ability to capture and interpret the energy release profiles of thermite reactions. Modern approaches often combine multiple measurement techniques, such as calorimetry with spectroscopic methods, to provide a more comprehensive understanding of the reaction dynamics.

The drive for precision in thermite reaction energy measurement is fueled by diverse applications across industries. In metallurgy, accurate energy measurements are essential for optimizing welding and metal purification processes. The aerospace industry relies on precise energy data for the design of propulsion systems and pyrotechnic devices. In the field of energetic materials research, understanding the exact energy output is crucial for developing safer and more efficient formulations.

As we look to the future, the challenge of measuring thermite reaction energy with precision continues to evolve. Researchers are exploring novel approaches, including nanoscale calorimetry and advanced computational modeling, to push the boundaries of measurement accuracy. These efforts are not only advancing our scientific understanding but also paving the way for new applications and improved safety standards in the use of thermite reactions.

Market Demand Analysis

The market demand for precise measurement of thermite reaction energy is driven by several key factors across multiple industries. In the aerospace and defense sectors, there is a growing need for accurate energy measurements in propulsion systems and pyrotechnic devices. The increasing complexity of space missions and advanced weapon systems requires more precise control and understanding of energetic materials, creating a significant market pull for improved measurement techniques.

In the materials science and engineering field, researchers and manufacturers are constantly seeking better ways to characterize and optimize thermite reactions for various applications. This includes the development of novel materials for welding, metal purification, and thermal batteries. The ability to precisely measure reaction energy allows for more efficient material design and process optimization, potentially leading to cost savings and improved product performance.

The automotive industry is another significant driver of market demand. With the ongoing transition to electric vehicles and the development of advanced combustion engines, there is a renewed interest in high-energy density materials for both propulsion and safety systems. Accurate measurement of thermite reaction energy is crucial for designing more efficient and safer vehicle components.

In the mining and construction sectors, controlled thermite reactions are used for specialized welding and cutting operations. As these industries strive for greater efficiency and safety, the demand for precise energy measurement tools continues to grow. This enables better control of exothermic reactions in challenging environments, reducing risks and improving operational outcomes.

The renewable energy sector is also contributing to the market demand. Thermite reactions are being explored for thermal energy storage systems, which require accurate energy measurements for optimal design and operation. As the world shifts towards sustainable energy solutions, the need for advanced measurement techniques in this field is expected to increase.

Furthermore, academic and government research institutions are driving demand for high-precision measurement tools. These organizations are at the forefront of fundamental research in energetic materials and require state-of-the-art instrumentation to advance scientific understanding and develop new applications.

The global market for thermite reaction energy measurement is influenced by stringent safety regulations across industries. Regulatory bodies are increasingly demanding more accurate and reliable data on energetic materials, further stimulating the need for precise measurement techniques. This regulatory pressure is particularly strong in the aerospace, defense, and transportation sectors, where safety is paramount.

In the materials science and engineering field, researchers and manufacturers are constantly seeking better ways to characterize and optimize thermite reactions for various applications. This includes the development of novel materials for welding, metal purification, and thermal batteries. The ability to precisely measure reaction energy allows for more efficient material design and process optimization, potentially leading to cost savings and improved product performance.

The automotive industry is another significant driver of market demand. With the ongoing transition to electric vehicles and the development of advanced combustion engines, there is a renewed interest in high-energy density materials for both propulsion and safety systems. Accurate measurement of thermite reaction energy is crucial for designing more efficient and safer vehicle components.

In the mining and construction sectors, controlled thermite reactions are used for specialized welding and cutting operations. As these industries strive for greater efficiency and safety, the demand for precise energy measurement tools continues to grow. This enables better control of exothermic reactions in challenging environments, reducing risks and improving operational outcomes.

The renewable energy sector is also contributing to the market demand. Thermite reactions are being explored for thermal energy storage systems, which require accurate energy measurements for optimal design and operation. As the world shifts towards sustainable energy solutions, the need for advanced measurement techniques in this field is expected to increase.

Furthermore, academic and government research institutions are driving demand for high-precision measurement tools. These organizations are at the forefront of fundamental research in energetic materials and require state-of-the-art instrumentation to advance scientific understanding and develop new applications.

The global market for thermite reaction energy measurement is influenced by stringent safety regulations across industries. Regulatory bodies are increasingly demanding more accurate and reliable data on energetic materials, further stimulating the need for precise measurement techniques. This regulatory pressure is particularly strong in the aerospace, defense, and transportation sectors, where safety is paramount.

Current Challenges in Precision Measurement

Measuring the energy released during thermite reactions with precision presents several significant challenges that researchers and engineers must overcome. One of the primary difficulties lies in the rapid and intense nature of these reactions, which can reach temperatures exceeding 2500°C. This extreme heat makes it challenging to use conventional calorimetry methods, as many sensors and measurement devices cannot withstand such high temperatures.

Another major obstacle is the short duration of thermite reactions, typically lasting only a few seconds. This brief timeframe requires high-speed data acquisition systems and sensors with extremely fast response times to capture the energy release accurately. Traditional calorimetry techniques often lack the temporal resolution necessary for these rapid reactions, leading to potential inaccuracies in energy measurements.

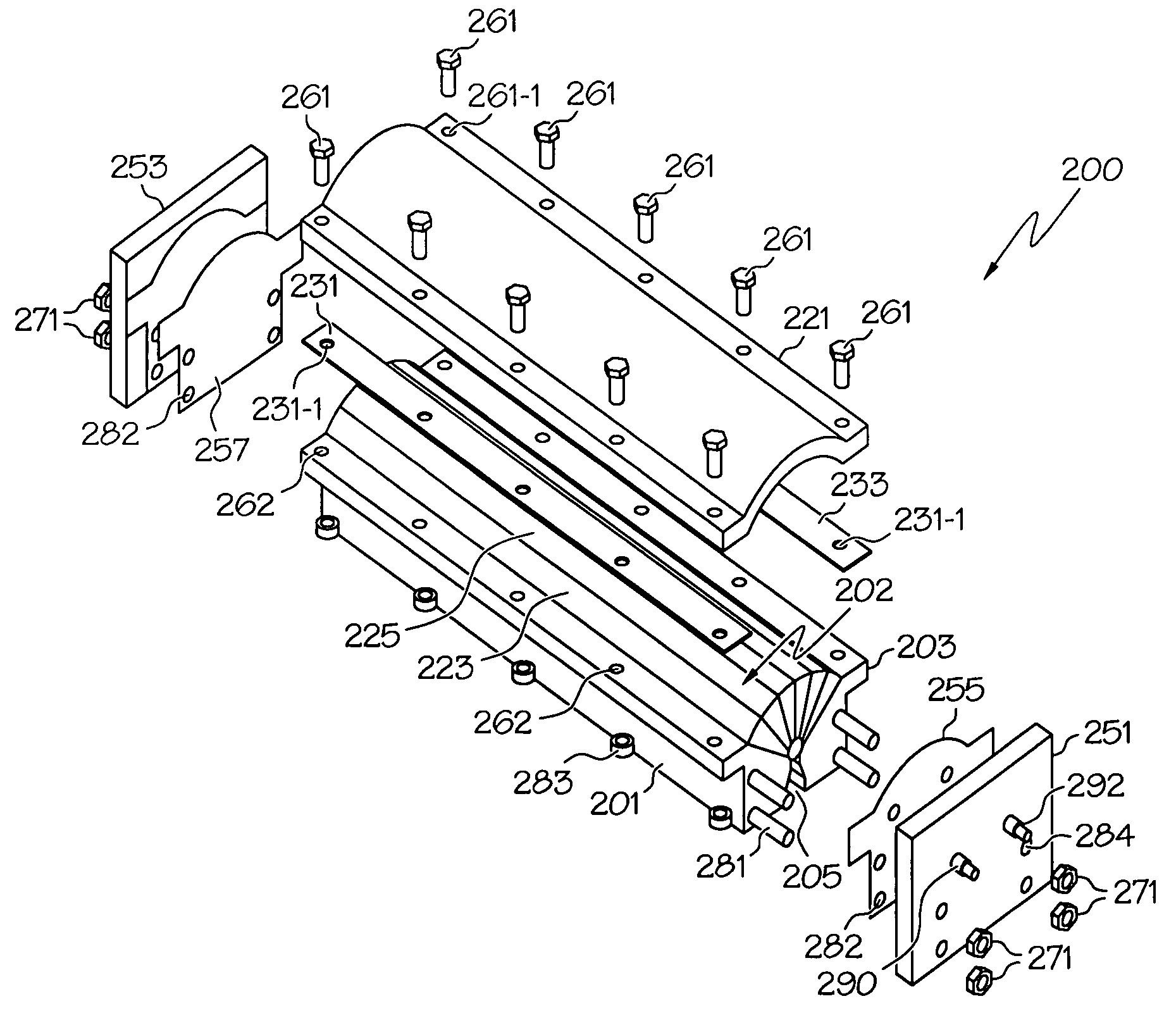

The heterogeneous nature of thermite reactions further complicates precise energy measurements. The reaction occurs at the interface between solid fuel and oxidizer particles, creating localized hot spots and temperature gradients. This non-uniform heat distribution makes it difficult to obtain representative measurements of the overall energy release, as different regions of the reaction may exhibit varying energy outputs.

Containment of the reaction products poses another challenge. The high-temperature molten metal and slag produced during thermite reactions can damage or interfere with measurement equipment. Designing containment vessels that can withstand these extreme conditions while allowing for accurate energy measurements is a complex engineering task.

The variability in particle size, composition, and mixing ratios of thermite mixtures also affects the precision of energy measurements. Small variations in these parameters can lead to significant differences in reaction rates and energy release, making it challenging to achieve reproducible results across multiple experiments.

Furthermore, the presence of impurities or moisture in the reactants can influence the reaction kinetics and energy output. Ensuring the purity and consistency of thermite components is crucial for obtaining accurate and repeatable energy measurements, but achieving this level of control can be difficult in practice.

Lastly, the potential for incomplete reactions or side reactions adds another layer of complexity to precise energy measurements. These secondary processes can consume or release energy, affecting the overall energy balance of the system. Developing methods to account for or minimize these effects is essential for improving the accuracy of thermite reaction energy measurements.

Another major obstacle is the short duration of thermite reactions, typically lasting only a few seconds. This brief timeframe requires high-speed data acquisition systems and sensors with extremely fast response times to capture the energy release accurately. Traditional calorimetry techniques often lack the temporal resolution necessary for these rapid reactions, leading to potential inaccuracies in energy measurements.

The heterogeneous nature of thermite reactions further complicates precise energy measurements. The reaction occurs at the interface between solid fuel and oxidizer particles, creating localized hot spots and temperature gradients. This non-uniform heat distribution makes it difficult to obtain representative measurements of the overall energy release, as different regions of the reaction may exhibit varying energy outputs.

Containment of the reaction products poses another challenge. The high-temperature molten metal and slag produced during thermite reactions can damage or interfere with measurement equipment. Designing containment vessels that can withstand these extreme conditions while allowing for accurate energy measurements is a complex engineering task.

The variability in particle size, composition, and mixing ratios of thermite mixtures also affects the precision of energy measurements. Small variations in these parameters can lead to significant differences in reaction rates and energy release, making it challenging to achieve reproducible results across multiple experiments.

Furthermore, the presence of impurities or moisture in the reactants can influence the reaction kinetics and energy output. Ensuring the purity and consistency of thermite components is crucial for obtaining accurate and repeatable energy measurements, but achieving this level of control can be difficult in practice.

Lastly, the potential for incomplete reactions or side reactions adds another layer of complexity to precise energy measurements. These secondary processes can consume or release energy, affecting the overall energy balance of the system. Developing methods to account for or minimize these effects is essential for improving the accuracy of thermite reaction energy measurements.

Existing Precision Measurement Solutions

01 Thermite reaction for welding and metal joining

Thermite reactions are utilized in welding and metal joining processes. The high-temperature exothermic reaction between a metal oxide and a more reactive metal produces molten metal and slag, which can be used to join metal components. This technique is particularly useful in railway track welding and pipe joining.- Thermite reaction for welding applications: Thermite reactions are utilized in welding processes, particularly for joining railway tracks and large metal components. The high-temperature exothermic reaction between aluminum and metal oxides produces molten metal and slag, which can be used to fuse metal parts together. This application harnesses the energy released during the thermite reaction for practical industrial purposes.

- Energy release in thermite-based incendiary devices: Thermite reactions are employed in incendiary devices due to their high energy output. The reaction between aluminum and metal oxides produces intense heat and molten metal, making it effective for military and demolition applications. The energy released can be used to penetrate armor or ignite secondary explosives.

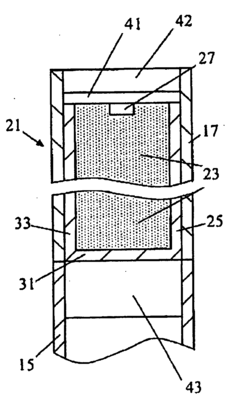

- Controlled energy release in oil and gas well operations: Thermite reactions are used in oil and gas well operations for various purposes, including perforating casings, stimulating production, and sealing off unwanted zones. The controlled release of energy from the thermite reaction can be precisely directed to achieve specific downhole objectives without damaging the surrounding formation.

- Thermite reaction for metal purification and recovery: The high temperatures and reducing conditions generated by thermite reactions are utilized in metallurgical processes for metal purification and recovery. This application takes advantage of the reaction's ability to reduce metal oxides to their pure metal form, allowing for the extraction of valuable metals from ores or recycled materials.

- Energy storage and rapid heat generation: Thermite mixtures are explored as a means of energy storage and rapid heat generation. The stable nature of the reactants allows for long-term storage, while the reaction can be initiated on-demand to produce intense heat quickly. This property is being investigated for various applications, including emergency heating systems and thermal batteries.

02 Energy release in thermite reactions

Thermite reactions are known for their significant energy release. The exothermic nature of these reactions produces intense heat and light, making them suitable for various applications. The energy released can be harnessed for specific purposes, such as metal purification, incendiary devices, or as a heat source in certain industrial processes.Expand Specific Solutions03 Thermite reaction in downhole tools

Thermite reactions are employed in downhole tools for oil and gas well operations. The controlled release of energy from thermite reactions can be used to actuate tools, create perforations, or initiate other downhole processes. This application takes advantage of the high-temperature and high-pressure environment in well bores.Expand Specific Solutions04 Thermite compositions and additives

Various thermite compositions and additives are developed to enhance or control the reaction. These may include different metal oxide and metal combinations, particle sizes, or additional components to modify the reaction rate, temperature, or byproducts. Tailoring the composition allows for optimization of the thermite reaction for specific applications.Expand Specific Solutions05 Safety and control mechanisms for thermite reactions

Due to the high energy release of thermite reactions, safety and control mechanisms are crucial. This includes methods for initiating the reaction in a controlled manner, containing the reaction products, and ensuring safe handling of the materials. Innovations in this area focus on improving the reliability and safety of thermite-based processes and devices.Expand Specific Solutions

Key Players in Thermite Research and Measurement

The thermite reaction energy measurement landscape is in a mature phase, with established techniques and ongoing research for precision improvements. The market size is moderate, primarily driven by industrial and academic applications. Technologically, the field is advanced but still evolving. Companies like Mettler-Toledo AG and Endress+hauser Optical Analysis Inc. are at the forefront, developing high-precision calorimetry instruments. Academic institutions such as Central South University and Northeastern University contribute significantly to research advancements. Collaborations between industry leaders like Aluminum Corp. of China Ltd. and research institutions are pushing the boundaries of measurement accuracy. The competitive landscape is characterized by a mix of specialized instrument manufacturers and research-driven entities, with ongoing efforts to enhance measurement precision and reliability.

Mettler-Toledo AG

Technical Solution: Mettler-Toledo AG has developed a high-precision calorimetry system specifically designed for measuring thermite reaction energy. Their system utilizes a combination of differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to provide accurate and comprehensive data on the energy released during thermite reactions. The system incorporates advanced temperature control mechanisms and highly sensitive heat flow sensors to capture even minute energy changes. Additionally, they have implemented specialized sample preparation techniques and data analysis software to account for the rapid and intense nature of thermite reactions.

Strengths: High precision measurements, integrated DSC-TGA capabilities, advanced temperature control. Weaknesses: Potentially high cost, may require specialized training for operation.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse Electric Co. LLC has developed a robust calorimetry system for measuring thermite reaction energy in nuclear applications. Their approach combines bomb calorimetry with advanced radiation shielding and remote operation capabilities. The system uses a specially designed reaction chamber that can withstand the high temperatures and pressures associated with thermite reactions. They have also implemented sophisticated gas analysis techniques to account for any gaseous products formed during the reaction, ensuring a comprehensive energy measurement. The system is equipped with multiple redundant sensors and safety features to ensure accurate measurements in potentially hazardous environments.

Strengths: Suitable for high-energy reactions, advanced safety features, comprehensive measurement approach. Weaknesses: Potentially limited to specific industrial applications, high initial investment cost.

Core Innovations in Thermite Energy Quantification

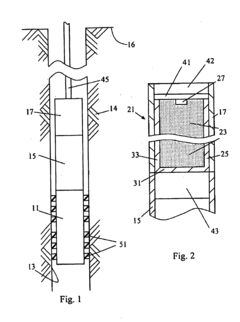

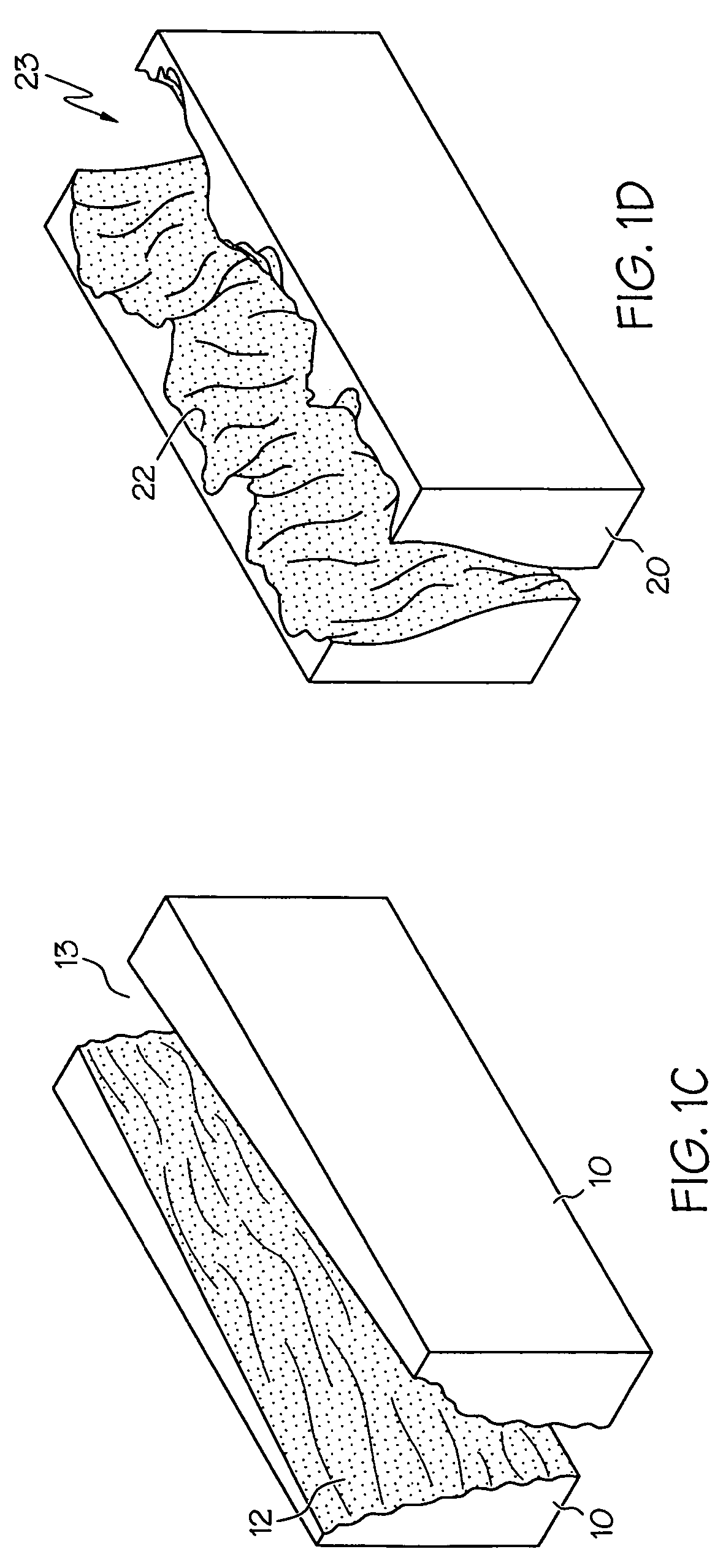

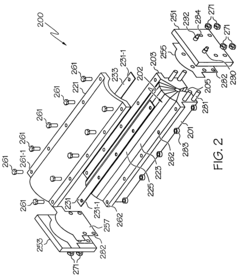

Non-explosive power source for actuating a subsurface tool

PatentActiveUS20140137761A1

Innovation

- A thermite-based power source that uses non-explosive, reactive components with a polymer to generate continuous pressure, avoiding explosive shockwaves and excessive heat, and providing pressure sufficient for tool actuation and alignment.

Thermite charge

PatentActiveUS7555986B2

Innovation

- A linear or curvilinear thermite charge apparatus with a compartmentalized design and modular structure, using potassium permanganate and potassium ferrate to enhance cutting power, and oxygen augmentation to produce a sustained high-temperature jet for efficient cutting through materials like steel, concrete, and rock without explosive hazards.

Safety Protocols and Regulations

Measuring thermite reaction energy with precision requires strict adherence to safety protocols and regulations due to the highly exothermic nature of the reaction. Proper safety measures are essential to protect researchers, equipment, and the environment. All personnel involved in thermite experiments must undergo comprehensive safety training and be familiar with emergency procedures.

Personal protective equipment (PPE) is mandatory and includes fire-resistant lab coats, safety goggles, face shields, heat-resistant gloves, and closed-toe shoes. The experimental area should be equipped with fire extinguishers, safety showers, and eyewash stations. Thermite reactions must be conducted in a designated area with proper ventilation and fire suppression systems.

Regulatory compliance is crucial when handling thermite materials. Researchers must adhere to local, state, and federal regulations governing the storage, handling, and disposal of reactive substances. Proper documentation and record-keeping are necessary to maintain compliance with these regulations.

The storage of thermite components requires special attention. Aluminum powder and metal oxides should be stored separately in sealed, moisture-proof containers in a cool, dry area away from potential ignition sources. Access to these materials should be restricted to authorized personnel only.

Before conducting any thermite reaction experiments, a detailed risk assessment must be performed. This assessment should identify potential hazards, evaluate risks, and outline mitigation strategies. Standard operating procedures (SOPs) should be developed and followed for each step of the experimental process, including material preparation, reaction initiation, and post-reaction handling.

During the experiment, remote ignition methods should be employed to maintain a safe distance from the reaction. Blast shields or other physical barriers should be used to protect researchers and equipment from potential projectiles or excessive heat. Real-time monitoring systems should be in place to detect any unexpected temperature increases or pressure buildup.

Proper waste disposal procedures must be followed for any unreacted materials or reaction products. These may include neutralization, containment, or specialized disposal through certified waste management services. Environmental regulations must be considered to prevent contamination of soil or water sources.

Regular safety audits and equipment inspections should be conducted to ensure all safety measures remain effective. Any incidents or near-misses must be thoroughly investigated, and lessons learned should be incorporated into updated safety protocols. Continuous improvement of safety practices is essential to maintain a secure research environment for precise thermite reaction energy measurements.

Personal protective equipment (PPE) is mandatory and includes fire-resistant lab coats, safety goggles, face shields, heat-resistant gloves, and closed-toe shoes. The experimental area should be equipped with fire extinguishers, safety showers, and eyewash stations. Thermite reactions must be conducted in a designated area with proper ventilation and fire suppression systems.

Regulatory compliance is crucial when handling thermite materials. Researchers must adhere to local, state, and federal regulations governing the storage, handling, and disposal of reactive substances. Proper documentation and record-keeping are necessary to maintain compliance with these regulations.

The storage of thermite components requires special attention. Aluminum powder and metal oxides should be stored separately in sealed, moisture-proof containers in a cool, dry area away from potential ignition sources. Access to these materials should be restricted to authorized personnel only.

Before conducting any thermite reaction experiments, a detailed risk assessment must be performed. This assessment should identify potential hazards, evaluate risks, and outline mitigation strategies. Standard operating procedures (SOPs) should be developed and followed for each step of the experimental process, including material preparation, reaction initiation, and post-reaction handling.

During the experiment, remote ignition methods should be employed to maintain a safe distance from the reaction. Blast shields or other physical barriers should be used to protect researchers and equipment from potential projectiles or excessive heat. Real-time monitoring systems should be in place to detect any unexpected temperature increases or pressure buildup.

Proper waste disposal procedures must be followed for any unreacted materials or reaction products. These may include neutralization, containment, or specialized disposal through certified waste management services. Environmental regulations must be considered to prevent contamination of soil or water sources.

Regular safety audits and equipment inspections should be conducted to ensure all safety measures remain effective. Any incidents or near-misses must be thoroughly investigated, and lessons learned should be incorporated into updated safety protocols. Continuous improvement of safety practices is essential to maintain a secure research environment for precise thermite reaction energy measurements.

Environmental Impact Assessment

The environmental impact assessment of thermite reaction energy measurement is a critical aspect that requires careful consideration. Thermite reactions, known for their high-temperature exothermic nature, can potentially have significant environmental consequences if not properly managed and controlled during the measurement process.

One of the primary environmental concerns is the release of particulate matter and gaseous emissions. The thermite reaction produces metal oxides and elemental metals as byproducts, which can be dispersed into the air as fine particles. These particulates may pose respiratory risks to both humans and wildlife in the vicinity of the measurement site. Additionally, the high temperatures generated during the reaction can lead to the formation of nitrogen oxides (NOx) and other potentially harmful gases, contributing to air pollution and potentially affecting local air quality.

The intense heat generated by thermite reactions also presents a risk of fire and thermal pollution. Improper containment or accidental ignition could lead to uncontrolled fires, potentially damaging surrounding vegetation and wildlife habitats. The heat dissipated into the environment may also cause localized temperature increases, affecting nearby ecosystems and potentially disrupting local microclimates.

Soil contamination is another environmental concern associated with thermite reaction energy measurements. The reaction products, including metal oxides and residual unreacted materials, can leach into the soil, potentially altering its chemical composition and affecting plant growth. This contamination may persist long after the measurement process, potentially impacting soil fertility and ecosystem health in the affected area.

Water resources near the measurement site may also be at risk. Runoff from the reaction area could carry contaminants into nearby water bodies, affecting aquatic ecosystems and potentially compromising water quality for both wildlife and human use. The high temperatures involved in the reaction could also lead to rapid evaporation of nearby water sources, disrupting local hydrological cycles.

To mitigate these environmental impacts, it is crucial to implement stringent safety measures and containment protocols. This includes conducting measurements in controlled environments with proper ventilation and filtration systems to minimize air pollution. Containment structures should be designed to prevent the spread of reaction products and heat to the surrounding environment. Proper disposal of reaction byproducts and thorough site cleanup are essential to minimize soil and water contamination.

Furthermore, the selection of measurement locations should take into account the sensitivity of surrounding ecosystems. Avoiding areas with high biodiversity or critical habitats can help minimize the ecological impact of the measurement process. Regular environmental monitoring before, during, and after the measurements can help identify and address any unforeseen environmental effects promptly.

One of the primary environmental concerns is the release of particulate matter and gaseous emissions. The thermite reaction produces metal oxides and elemental metals as byproducts, which can be dispersed into the air as fine particles. These particulates may pose respiratory risks to both humans and wildlife in the vicinity of the measurement site. Additionally, the high temperatures generated during the reaction can lead to the formation of nitrogen oxides (NOx) and other potentially harmful gases, contributing to air pollution and potentially affecting local air quality.

The intense heat generated by thermite reactions also presents a risk of fire and thermal pollution. Improper containment or accidental ignition could lead to uncontrolled fires, potentially damaging surrounding vegetation and wildlife habitats. The heat dissipated into the environment may also cause localized temperature increases, affecting nearby ecosystems and potentially disrupting local microclimates.

Soil contamination is another environmental concern associated with thermite reaction energy measurements. The reaction products, including metal oxides and residual unreacted materials, can leach into the soil, potentially altering its chemical composition and affecting plant growth. This contamination may persist long after the measurement process, potentially impacting soil fertility and ecosystem health in the affected area.

Water resources near the measurement site may also be at risk. Runoff from the reaction area could carry contaminants into nearby water bodies, affecting aquatic ecosystems and potentially compromising water quality for both wildlife and human use. The high temperatures involved in the reaction could also lead to rapid evaporation of nearby water sources, disrupting local hydrological cycles.

To mitigate these environmental impacts, it is crucial to implement stringent safety measures and containment protocols. This includes conducting measurements in controlled environments with proper ventilation and filtration systems to minimize air pollution. Containment structures should be designed to prevent the spread of reaction products and heat to the surrounding environment. Proper disposal of reaction byproducts and thorough site cleanup are essential to minimize soil and water contamination.

Furthermore, the selection of measurement locations should take into account the sensitivity of surrounding ecosystems. Avoiding areas with high biodiversity or critical habitats can help minimize the ecological impact of the measurement process. Regular environmental monitoring before, during, and after the measurements can help identify and address any unforeseen environmental effects promptly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!