Thermite‑Bonded Joint Testing: Achieving Structural Integrity

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Bonding Overview

Thermite bonding is a revolutionary joining technique that utilizes the exothermic reaction of thermite to create strong, durable connections between materials. This process, also known as exothermic welding or cadwelding, has gained significant attention in various industries due to its unique properties and advantages over traditional joining methods.

The thermite reaction, first discovered by German chemist Hans Goldschmidt in 1893, involves the reduction of a metal oxide by aluminum, producing intense heat and molten metal. In the context of bonding, this reaction is harnessed to create a metallurgical bond between two or more components. The process typically employs a mixture of aluminum powder and metal oxide, most commonly iron oxide, which is ignited to produce temperatures exceeding 2500°C.

Thermite bonding offers several key advantages that make it particularly suitable for achieving structural integrity in joints. Firstly, the high temperature generated during the reaction ensures complete fusion of the base materials, resulting in a strong, homogeneous bond. This is especially beneficial when joining dissimilar metals or materials with high melting points. Secondly, the process is self-contained and does not require external heat sources or complex equipment, making it ideal for on-site applications and remote locations.

The versatility of thermite bonding extends to various materials, including steel, copper, and aluminum. It has found widespread use in industries such as railway track welding, electrical grounding connections, and pipeline joining. In these applications, the thermite-bonded joints demonstrate excellent mechanical properties, corrosion resistance, and long-term reliability.

One of the critical aspects of thermite bonding is the precise control of the reaction and the resulting joint properties. This involves careful selection of the thermite mixture composition, mold design, and process parameters. Recent advancements in thermite formulations and ignition systems have further improved the consistency and quality of the bonds, addressing some of the challenges associated with earlier iterations of the technology.

As the demand for high-performance, durable joints continues to grow across various industries, thermite bonding has emerged as a promising solution. Its ability to create strong, reliable connections, coupled with its adaptability to different materials and environments, positions it as a valuable technique in the pursuit of structural integrity. Ongoing research and development efforts are focused on expanding the application range of thermite bonding and optimizing its performance for increasingly demanding engineering challenges.

The thermite reaction, first discovered by German chemist Hans Goldschmidt in 1893, involves the reduction of a metal oxide by aluminum, producing intense heat and molten metal. In the context of bonding, this reaction is harnessed to create a metallurgical bond between two or more components. The process typically employs a mixture of aluminum powder and metal oxide, most commonly iron oxide, which is ignited to produce temperatures exceeding 2500°C.

Thermite bonding offers several key advantages that make it particularly suitable for achieving structural integrity in joints. Firstly, the high temperature generated during the reaction ensures complete fusion of the base materials, resulting in a strong, homogeneous bond. This is especially beneficial when joining dissimilar metals or materials with high melting points. Secondly, the process is self-contained and does not require external heat sources or complex equipment, making it ideal for on-site applications and remote locations.

The versatility of thermite bonding extends to various materials, including steel, copper, and aluminum. It has found widespread use in industries such as railway track welding, electrical grounding connections, and pipeline joining. In these applications, the thermite-bonded joints demonstrate excellent mechanical properties, corrosion resistance, and long-term reliability.

One of the critical aspects of thermite bonding is the precise control of the reaction and the resulting joint properties. This involves careful selection of the thermite mixture composition, mold design, and process parameters. Recent advancements in thermite formulations and ignition systems have further improved the consistency and quality of the bonds, addressing some of the challenges associated with earlier iterations of the technology.

As the demand for high-performance, durable joints continues to grow across various industries, thermite bonding has emerged as a promising solution. Its ability to create strong, reliable connections, coupled with its adaptability to different materials and environments, positions it as a valuable technique in the pursuit of structural integrity. Ongoing research and development efforts are focused on expanding the application range of thermite bonding and optimizing its performance for increasingly demanding engineering challenges.

Market Demand Analysis

The market demand for thermite-bonded joint testing and structural integrity solutions has been steadily increasing across various industries. This growth is primarily driven by the expanding infrastructure development, particularly in sectors such as construction, transportation, and energy. As global urbanization continues to accelerate, there is a heightened focus on ensuring the longevity and safety of large-scale structures, creating a robust demand for advanced bonding and testing technologies.

In the construction industry, thermite-bonded joints are increasingly utilized in high-rise buildings, bridges, and other critical infrastructure projects. The need for reliable testing methods to verify the structural integrity of these joints has become paramount, especially in regions prone to seismic activities or extreme weather conditions. This has led to a surge in demand for sophisticated testing equipment and procedures that can accurately assess the strength and durability of thermite-bonded connections.

The transportation sector, particularly rail networks, represents another significant market for thermite-bonded joint testing. As countries invest in expanding and upgrading their rail infrastructure, the demand for high-quality, long-lasting rail joints has intensified. Thermite welding is widely used in rail track construction, and ensuring the integrity of these joints is crucial for safety and operational efficiency. Consequently, there is a growing market for advanced testing solutions that can detect potential weaknesses or failures in thermite-bonded rail joints before they lead to accidents or service disruptions.

Energy infrastructure, including oil and gas pipelines, also contributes substantially to the market demand for thermite-bonded joint testing. With the global push towards energy security and the expansion of pipeline networks, the need for reliable joining methods and rigorous testing protocols has never been greater. Thermite-bonded joints in pipelines must withstand extreme pressures and environmental conditions, making comprehensive testing essential to prevent leaks and ensure operational safety.

The aerospace and defense industries are emerging as potential growth areas for thermite-bonded joint applications and testing. As these sectors continually seek lighter, stronger materials and joining methods, thermite bonding presents an attractive option for certain applications. This expansion into new industries is expected to further drive the demand for specialized testing equipment and methodologies.

Market analysts project that the global market for structural integrity testing, including thermite-bonded joint assessment, will experience significant growth in the coming years. This growth is attributed to increasing safety regulations, the need for infrastructure rehabilitation in developed countries, and rapid infrastructure development in emerging economies. Additionally, the rising awareness of the long-term cost benefits of ensuring structural integrity through comprehensive testing is expected to fuel market expansion.

In the construction industry, thermite-bonded joints are increasingly utilized in high-rise buildings, bridges, and other critical infrastructure projects. The need for reliable testing methods to verify the structural integrity of these joints has become paramount, especially in regions prone to seismic activities or extreme weather conditions. This has led to a surge in demand for sophisticated testing equipment and procedures that can accurately assess the strength and durability of thermite-bonded connections.

The transportation sector, particularly rail networks, represents another significant market for thermite-bonded joint testing. As countries invest in expanding and upgrading their rail infrastructure, the demand for high-quality, long-lasting rail joints has intensified. Thermite welding is widely used in rail track construction, and ensuring the integrity of these joints is crucial for safety and operational efficiency. Consequently, there is a growing market for advanced testing solutions that can detect potential weaknesses or failures in thermite-bonded rail joints before they lead to accidents or service disruptions.

Energy infrastructure, including oil and gas pipelines, also contributes substantially to the market demand for thermite-bonded joint testing. With the global push towards energy security and the expansion of pipeline networks, the need for reliable joining methods and rigorous testing protocols has never been greater. Thermite-bonded joints in pipelines must withstand extreme pressures and environmental conditions, making comprehensive testing essential to prevent leaks and ensure operational safety.

The aerospace and defense industries are emerging as potential growth areas for thermite-bonded joint applications and testing. As these sectors continually seek lighter, stronger materials and joining methods, thermite bonding presents an attractive option for certain applications. This expansion into new industries is expected to further drive the demand for specialized testing equipment and methodologies.

Market analysts project that the global market for structural integrity testing, including thermite-bonded joint assessment, will experience significant growth in the coming years. This growth is attributed to increasing safety regulations, the need for infrastructure rehabilitation in developed countries, and rapid infrastructure development in emerging economies. Additionally, the rising awareness of the long-term cost benefits of ensuring structural integrity through comprehensive testing is expected to fuel market expansion.

Technical Challenges

Thermite-bonded joint testing for structural integrity faces several significant technical challenges that researchers and engineers must address to ensure the reliability and safety of these connections. One of the primary obstacles is the difficulty in accurately simulating the extreme thermal conditions experienced during the thermite reaction. The rapid and intense heat generation, which can reach temperatures exceeding 2500°C, poses challenges for conventional testing equipment and methodologies.

Another critical challenge lies in the development of standardized testing protocols. Due to the unique nature of thermite-bonded joints, existing standards for traditional welding or mechanical fastening may not be directly applicable. This lack of standardization makes it challenging to compare results across different studies and ensure consistent quality control in industrial applications.

The heterogeneous nature of the thermite reaction products introduces complexity in predicting and analyzing the joint's mechanical properties. The formation of various intermetallic compounds and the potential for porosity or inclusions within the joint can lead to inconsistent strength and durability characteristics. Consequently, developing reliable non-destructive testing methods to assess the internal structure and integrity of thermite-bonded joints remains a significant technical hurdle.

Thermal stress management presents another formidable challenge. The extreme temperature gradients generated during the thermite reaction can induce severe thermal stresses in the surrounding materials. These stresses may lead to distortion, cracking, or premature failure of the joint. Developing strategies to mitigate these thermal effects while maintaining the desired bond strength is crucial for achieving long-term structural integrity.

The environmental sensitivity of thermite-bonded joints also poses technical difficulties. Factors such as humidity, ambient temperature, and atmospheric conditions can significantly impact the reaction kinetics and resulting joint quality. Ensuring consistent performance across various environmental conditions requires sophisticated control mechanisms and robust testing methodologies.

Lastly, the scalability of thermite-bonded joint testing presents a considerable challenge. While small-scale laboratory tests may provide valuable insights, translating these results to full-scale industrial applications can be problematic. Developing testing procedures that accurately represent real-world conditions while remaining practical and cost-effective is an ongoing area of research and development in the field of thermite-bonded joint testing.

Another critical challenge lies in the development of standardized testing protocols. Due to the unique nature of thermite-bonded joints, existing standards for traditional welding or mechanical fastening may not be directly applicable. This lack of standardization makes it challenging to compare results across different studies and ensure consistent quality control in industrial applications.

The heterogeneous nature of the thermite reaction products introduces complexity in predicting and analyzing the joint's mechanical properties. The formation of various intermetallic compounds and the potential for porosity or inclusions within the joint can lead to inconsistent strength and durability characteristics. Consequently, developing reliable non-destructive testing methods to assess the internal structure and integrity of thermite-bonded joints remains a significant technical hurdle.

Thermal stress management presents another formidable challenge. The extreme temperature gradients generated during the thermite reaction can induce severe thermal stresses in the surrounding materials. These stresses may lead to distortion, cracking, or premature failure of the joint. Developing strategies to mitigate these thermal effects while maintaining the desired bond strength is crucial for achieving long-term structural integrity.

The environmental sensitivity of thermite-bonded joints also poses technical difficulties. Factors such as humidity, ambient temperature, and atmospheric conditions can significantly impact the reaction kinetics and resulting joint quality. Ensuring consistent performance across various environmental conditions requires sophisticated control mechanisms and robust testing methodologies.

Lastly, the scalability of thermite-bonded joint testing presents a considerable challenge. While small-scale laboratory tests may provide valuable insights, translating these results to full-scale industrial applications can be problematic. Developing testing procedures that accurately represent real-world conditions while remaining practical and cost-effective is an ongoing area of research and development in the field of thermite-bonded joint testing.

Current Testing Methods

01 Thermite welding techniques for structural joints

Thermite welding is used to create strong, durable joints in various structural applications. This process involves the exothermic reaction of metal oxides with aluminum, producing high temperatures that melt and fuse the joint materials. The technique is particularly useful for joining large metal components in construction, railway, and industrial settings, providing high structural integrity.- Thermite welding for structural joints: Thermite welding is used to create strong, durable joints in structural applications. This process involves an exothermic reaction that generates high temperatures, melting the metal components and fusing them together. The resulting joint exhibits high structural integrity and resistance to environmental factors.

- Monitoring and analysis of thermite-bonded joints: Advanced monitoring and analysis techniques are employed to assess the structural integrity of thermite-bonded joints. These methods may include non-destructive testing, acoustic emission monitoring, and stress analysis to evaluate joint performance and detect potential issues before failure occurs.

- Optimization of thermite mixture composition: The composition of the thermite mixture is crucial for achieving optimal joint integrity. Research focuses on developing improved formulations that enhance bonding strength, reduce porosity, and increase overall joint performance. This may involve adjusting the ratio of metal oxides and reducing agents or incorporating additives to enhance specific properties.

- Application in oil and gas industry: Thermite-bonded joints find extensive use in the oil and gas industry, particularly in well completion and pipeline construction. These joints offer advantages such as corrosion resistance, high-temperature stability, and the ability to withstand extreme pressures, making them suitable for challenging downhole environments.

- Quality control and testing procedures: Rigorous quality control and testing procedures are implemented to ensure the structural integrity of thermite-bonded joints. These may include visual inspections, radiographic testing, hydrostatic pressure tests, and mechanical property evaluations to verify joint strength and reliability before deployment in critical applications.

02 Non-destructive testing of thermite-bonded joints

Various non-destructive testing methods are employed to assess the structural integrity of thermite-bonded joints. These include ultrasonic testing, radiographic inspection, and acoustic emission monitoring. Such techniques allow for the evaluation of joint quality, detection of defects, and assessment of long-term performance without compromising the structure.Expand Specific Solutions03 Thermal stress management in thermite-bonded joints

Managing thermal stresses is crucial for maintaining the structural integrity of thermite-bonded joints. This involves careful material selection, design considerations to accommodate thermal expansion, and the use of stress-relieving techniques. Proper thermal management ensures the longevity and reliability of the joint under varying temperature conditions.Expand Specific Solutions04 Composite materials in thermite-bonded joints

The incorporation of composite materials in thermite-bonded joints can enhance structural integrity. These materials, such as fiber-reinforced polymers or metal matrix composites, can improve strength-to-weight ratios, corrosion resistance, and fatigue performance of the joint. The selection and integration of composites are tailored to specific application requirements.Expand Specific Solutions05 Environmental factors affecting joint integrity

Environmental factors such as moisture, temperature fluctuations, and chemical exposure can significantly impact the structural integrity of thermite-bonded joints. Protective measures, including coatings, sealants, and design modifications, are implemented to mitigate these effects and ensure long-term joint performance in various operational conditions.Expand Specific Solutions

Industry Leaders

The thermite-bonded joint testing market is in a growth phase, driven by increasing demand for structural integrity in various industries. The global market size is expanding, with key players like The Boeing Co., Air Products & Chemicals, Inc., and China Petroleum & Chemical Corp. leading innovation. Technology maturity varies, with established companies like Fraunhofer-Gesellschaft eV and emerging players such as Xi'an Thermal Power Research Institute Co., Ltd. contributing to advancements. Research institutions like Tianjin University and Zhejiang University are pushing boundaries in testing methodologies, while industry giants like Northrop Grumman Systems Corp. and Saudi Arabian Oil Co. are implementing cutting-edge solutions. The competitive landscape is diverse, with a mix of aerospace, energy, and materials science companies driving progress in thermite-bonded joint testing technologies.

The Boeing Co.

Technical Solution: Boeing has developed an advanced thermite-bonded joint testing system for achieving structural integrity in aerospace applications. Their approach involves using a proprietary thermite mixture and precise application techniques to create high-strength bonds between metal components. The testing process includes thermal imaging, ultrasonic inspection, and mechanical stress tests to ensure the joints meet rigorous aerospace standards. Boeing's method also incorporates real-time monitoring during the bonding process to detect and correct any anomalies immediately.

Strengths: Highly specialized for aerospace applications, excellent quality control, and integration with advanced inspection technologies. Weaknesses: Potentially high cost and limited applicability outside of aerospace industry.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed a comprehensive thermite-bonded joint testing protocol for power plant applications. Their approach focuses on high-temperature resistance and long-term durability under extreme thermal cycling conditions. The institute utilizes a combination of non-destructive testing methods, including acoustic emission analysis and high-resolution X-ray tomography, to assess joint integrity. They have also implemented a novel accelerated aging process to simulate decades of thermal stress in a shorter timeframe, allowing for more accurate predictions of joint longevity in power plant environments.

Strengths: Specialized for power plant conditions, advanced simulation capabilities for long-term performance. Weaknesses: May be less applicable to low-temperature or non-industrial applications.

Key Innovations

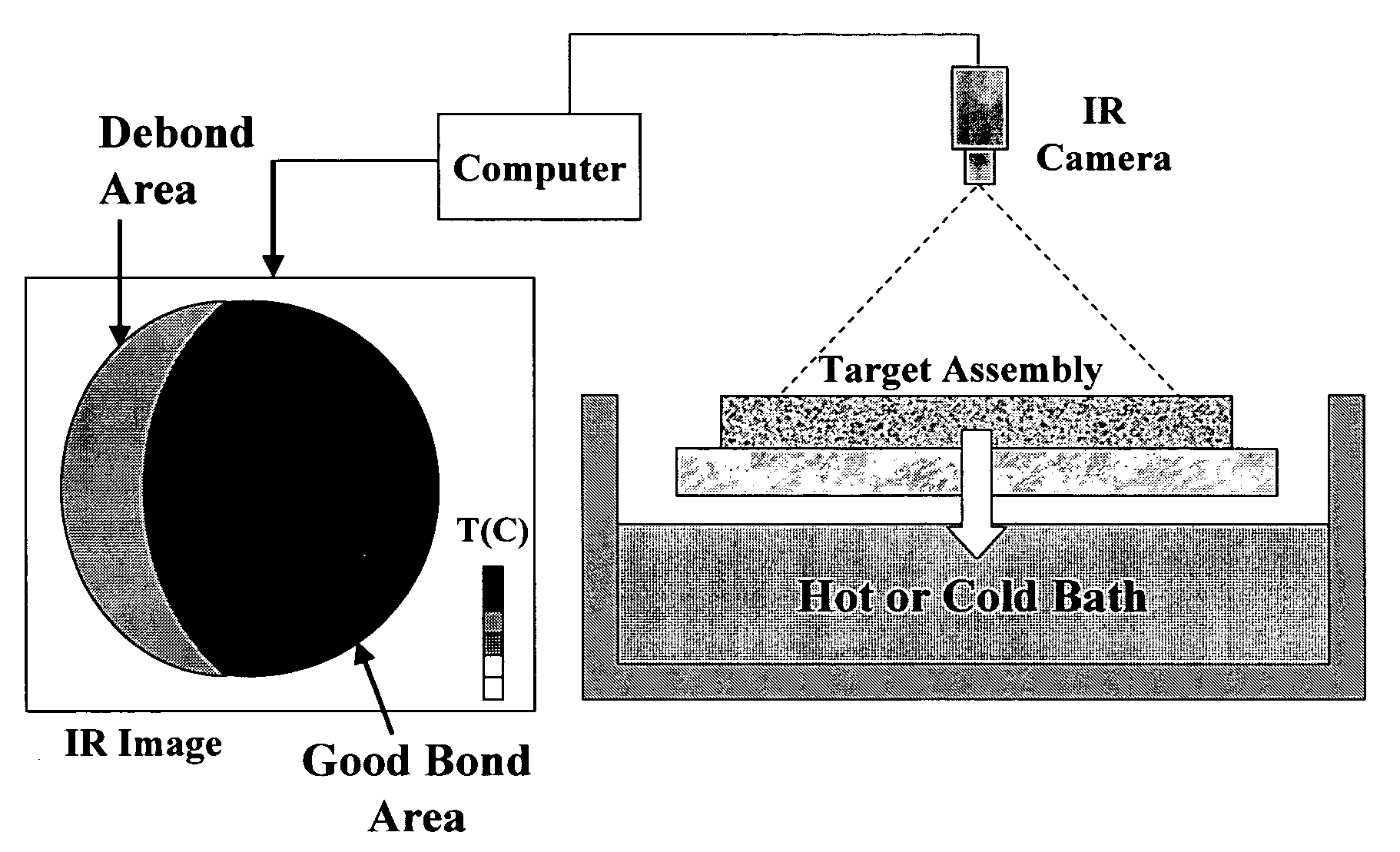

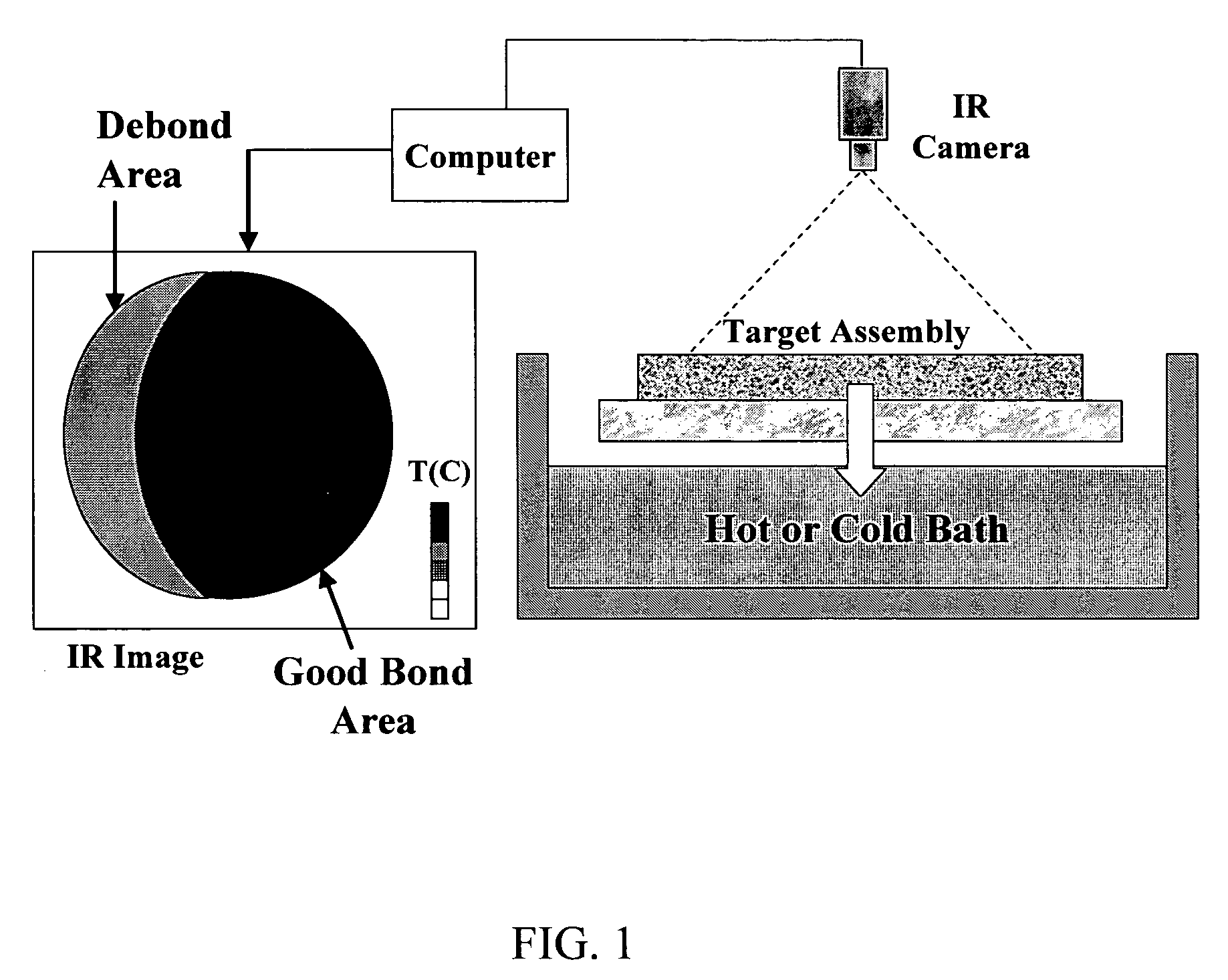

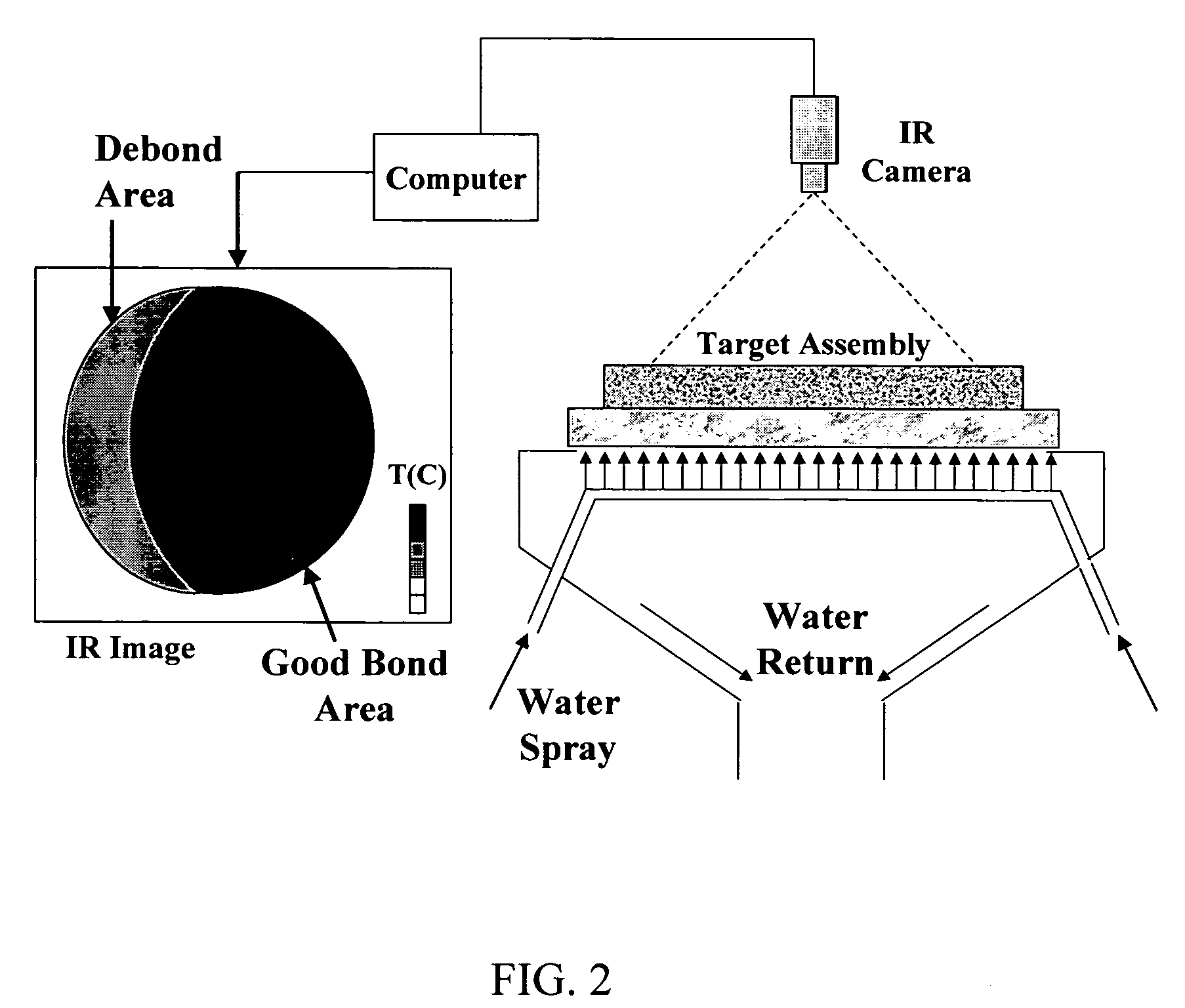

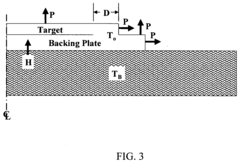

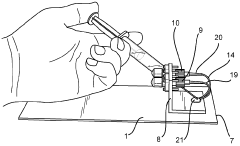

Thermography test method and apparatus for bonding evaluation in sputtering targets

PatentInactiveUS20050147150A1

Innovation

- A thermographic analysis method that involves heating or cooling the backing plate of a sputtering target assembly, imaging the surface using infrared thermography to acquire time-temperature curves, and comparing these curves to reference curves to determine bond integrity, allowing for the detection of debonded areas through temperature gradients.

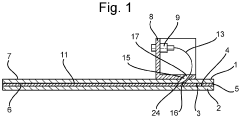

Assessing integrity of bonded joints

PatentInactiveGB2521421A

Innovation

- An assembly with a passage through the bonded joint allows an optical fibre to emerge externally, supported by a flexible casing and protected with adhesive tape and epoxy resin to prevent damage, enabling the assessment of bond integrity while minimizing interference with the structure's strength.

Safety Considerations

Safety considerations are paramount when conducting thermite-bonded joint testing to ensure structural integrity. The high temperatures and exothermic reactions involved in thermite welding pose significant risks that must be carefully managed throughout the testing process.

Proper personal protective equipment (PPE) is essential for all personnel involved in the testing. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and face shields to protect against potential splatter and intense heat. Respiratory protection may also be necessary to guard against fumes and particulates generated during the reaction.

The testing environment must be carefully controlled to minimize fire hazards. A designated testing area should be established, free from flammable materials and equipped with appropriate fire suppression systems. Adequate ventilation is crucial to disperse heat and potentially harmful gases produced during the thermite reaction.

Handling and storage of thermite materials require strict protocols. The components should be stored separately in sealed, moisture-proof containers to prevent accidental ignition. Only trained personnel should be allowed to handle and mix the thermite materials, following precise measurements and procedures to ensure consistent and safe reactions.

Emergency response plans must be in place and regularly reviewed. This includes clear evacuation procedures, readily accessible fire extinguishers, and first aid equipment. All personnel should be trained in emergency protocols and the proper use of safety equipment.

Monitoring and control systems play a vital role in maintaining safety during testing. Temperature sensors and thermal imaging cameras can be employed to track heat distribution and identify potential hotspots. Automated shut-off mechanisms should be implemented to halt the process if predetermined safety thresholds are exceeded.

Risk assessments should be conducted prior to each test, taking into account the specific materials, equipment, and environmental conditions involved. These assessments should inform the development of detailed safety procedures tailored to each testing scenario.

Post-test safety measures are equally important. Adequate cooling time must be allowed before handling or inspecting the bonded joint. Proper disposal procedures for any residual materials or waste products should be followed to prevent environmental contamination or accidental ignition.

Regular safety audits and continuous improvement of safety protocols are essential to address evolving risks and incorporate lessons learned from previous tests. This proactive approach helps maintain a culture of safety and ensures that thermite-bonded joint testing can be conducted with minimal risk to personnel and facilities while achieving the desired structural integrity outcomes.

Proper personal protective equipment (PPE) is essential for all personnel involved in the testing. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and face shields to protect against potential splatter and intense heat. Respiratory protection may also be necessary to guard against fumes and particulates generated during the reaction.

The testing environment must be carefully controlled to minimize fire hazards. A designated testing area should be established, free from flammable materials and equipped with appropriate fire suppression systems. Adequate ventilation is crucial to disperse heat and potentially harmful gases produced during the thermite reaction.

Handling and storage of thermite materials require strict protocols. The components should be stored separately in sealed, moisture-proof containers to prevent accidental ignition. Only trained personnel should be allowed to handle and mix the thermite materials, following precise measurements and procedures to ensure consistent and safe reactions.

Emergency response plans must be in place and regularly reviewed. This includes clear evacuation procedures, readily accessible fire extinguishers, and first aid equipment. All personnel should be trained in emergency protocols and the proper use of safety equipment.

Monitoring and control systems play a vital role in maintaining safety during testing. Temperature sensors and thermal imaging cameras can be employed to track heat distribution and identify potential hotspots. Automated shut-off mechanisms should be implemented to halt the process if predetermined safety thresholds are exceeded.

Risk assessments should be conducted prior to each test, taking into account the specific materials, equipment, and environmental conditions involved. These assessments should inform the development of detailed safety procedures tailored to each testing scenario.

Post-test safety measures are equally important. Adequate cooling time must be allowed before handling or inspecting the bonded joint. Proper disposal procedures for any residual materials or waste products should be followed to prevent environmental contamination or accidental ignition.

Regular safety audits and continuous improvement of safety protocols are essential to address evolving risks and incorporate lessons learned from previous tests. This proactive approach helps maintain a culture of safety and ensures that thermite-bonded joint testing can be conducted with minimal risk to personnel and facilities while achieving the desired structural integrity outcomes.

Environmental Impact

The environmental impact of thermite-bonded joint testing is a critical consideration in achieving structural integrity. This process involves the use of thermite, a pyrotechnic composition of metal powder fuel and metal oxide, which can have significant environmental implications if not properly managed.

Thermite reactions produce high temperatures and molten metal, which can potentially release harmful emissions into the atmosphere. These emissions may include particulate matter, metal fumes, and various gases depending on the specific composition of the thermite mixture. The release of such pollutants can contribute to air quality degradation and pose risks to both human health and the surrounding ecosystem.

Soil contamination is another environmental concern associated with thermite-bonded joint testing. The molten metal produced during the reaction can potentially leach into the soil, introducing heavy metals and other contaminants. This contamination may persist in the environment for extended periods, affecting soil quality, plant growth, and potentially entering the food chain through bioaccumulation.

Water resources near testing sites may also be impacted by thermite-bonded joint testing. Runoff from testing areas can carry contaminants into nearby water bodies, potentially affecting aquatic ecosystems and water quality. The high temperatures generated during the process can also lead to localized thermal pollution in water sources if proper containment measures are not implemented.

To mitigate these environmental impacts, it is crucial to implement stringent control measures and best practices during thermite-bonded joint testing. This includes proper containment of the reaction area, efficient fume and particulate capture systems, and appropriate disposal of waste materials. Additionally, the use of environmentally friendly thermite compositions and alternative bonding methods should be explored to reduce the overall environmental footprint of the process.

Long-term monitoring of testing sites is essential to assess and manage any potential environmental impacts. This includes regular soil and water quality testing, as well as air quality monitoring in the vicinity of testing facilities. Such data can inform ongoing environmental management strategies and help in the development of more sustainable testing practices.

The development of closed-system testing environments and the implementation of recycling processes for waste materials can significantly reduce the environmental impact of thermite-bonded joint testing. By containing the reaction and its byproducts within a controlled environment, emissions and contamination risks can be minimized. Furthermore, recycling and proper disposal of waste materials can help prevent the accumulation of potentially harmful substances in the environment.

As the focus on environmental sustainability grows across industries, it is imperative that the structural integrity testing sector, including thermite-bonded joint testing, adapts to meet these challenges. Ongoing research and development efforts should prioritize the creation of more environmentally friendly testing methods and materials, ensuring that structural integrity can be achieved without compromising environmental health.

Thermite reactions produce high temperatures and molten metal, which can potentially release harmful emissions into the atmosphere. These emissions may include particulate matter, metal fumes, and various gases depending on the specific composition of the thermite mixture. The release of such pollutants can contribute to air quality degradation and pose risks to both human health and the surrounding ecosystem.

Soil contamination is another environmental concern associated with thermite-bonded joint testing. The molten metal produced during the reaction can potentially leach into the soil, introducing heavy metals and other contaminants. This contamination may persist in the environment for extended periods, affecting soil quality, plant growth, and potentially entering the food chain through bioaccumulation.

Water resources near testing sites may also be impacted by thermite-bonded joint testing. Runoff from testing areas can carry contaminants into nearby water bodies, potentially affecting aquatic ecosystems and water quality. The high temperatures generated during the process can also lead to localized thermal pollution in water sources if proper containment measures are not implemented.

To mitigate these environmental impacts, it is crucial to implement stringent control measures and best practices during thermite-bonded joint testing. This includes proper containment of the reaction area, efficient fume and particulate capture systems, and appropriate disposal of waste materials. Additionally, the use of environmentally friendly thermite compositions and alternative bonding methods should be explored to reduce the overall environmental footprint of the process.

Long-term monitoring of testing sites is essential to assess and manage any potential environmental impacts. This includes regular soil and water quality testing, as well as air quality monitoring in the vicinity of testing facilities. Such data can inform ongoing environmental management strategies and help in the development of more sustainable testing practices.

The development of closed-system testing environments and the implementation of recycling processes for waste materials can significantly reduce the environmental impact of thermite-bonded joint testing. By containing the reaction and its byproducts within a controlled environment, emissions and contamination risks can be minimized. Furthermore, recycling and proper disposal of waste materials can help prevent the accumulation of potentially harmful substances in the environment.

As the focus on environmental sustainability grows across industries, it is imperative that the structural integrity testing sector, including thermite-bonded joint testing, adapts to meet these challenges. Ongoing research and development efforts should prioritize the creation of more environmentally friendly testing methods and materials, ensuring that structural integrity can be achieved without compromising environmental health.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!