How to Investigate Thermite Mixes for Optimal Performance?

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Mix Background and Objectives

Thermite mixtures have been a subject of scientific and industrial interest for over a century, with their unique exothermic properties finding applications in various fields. The development of thermite technology can be traced back to the late 19th century when German chemist Hans Goldschmidt discovered the thermite reaction. Since then, the technology has evolved significantly, driven by the need for more efficient and controllable reactions in diverse applications.

The primary objective of investigating thermite mixes for optimal performance is to enhance the efficiency, safety, and versatility of these reactions. This involves a comprehensive understanding of the chemical and physical processes involved in thermite reactions, as well as the factors that influence their performance. By optimizing thermite mixtures, researchers aim to achieve higher energy outputs, improved reaction control, and increased safety in handling and storage.

One of the key trends in thermite technology is the development of nano-thermite materials, which offer significantly higher reaction rates and energy densities compared to traditional thermite mixtures. This advancement has opened up new possibilities for applications in areas such as propulsion systems, welding, and materials synthesis. Additionally, there is a growing focus on environmentally friendly thermite formulations that minimize harmful byproducts and reduce the overall environmental impact of these reactions.

The investigation of thermite mixes for optimal performance encompasses several critical aspects. These include the selection and combination of fuel and oxidizer materials, particle size optimization, and the incorporation of additives to enhance specific properties. Researchers are also exploring novel ignition methods and reaction containment strategies to improve the controllability and safety of thermite reactions.

As the field progresses, there is an increasing emphasis on developing multi-functional thermite mixtures that can serve multiple purposes simultaneously. This trend is particularly evident in aerospace and defense applications, where weight and space constraints drive the need for materials with combined propulsive and structural properties. Furthermore, the integration of thermite technology with other advanced materials and systems, such as smart materials and nanotechnology, is expected to yield innovative solutions for complex engineering challenges.

The ultimate goal of these investigations is to push the boundaries of what is possible with thermite technology, unlocking new applications and improving existing ones. By achieving optimal performance in thermite mixtures, researchers aim to address critical needs in various industries, from metallurgy and materials processing to energy storage and propulsion systems. This ongoing research not only promises to enhance the capabilities of thermite-based technologies but also contributes to broader advancements in materials science and energy engineering.

The primary objective of investigating thermite mixes for optimal performance is to enhance the efficiency, safety, and versatility of these reactions. This involves a comprehensive understanding of the chemical and physical processes involved in thermite reactions, as well as the factors that influence their performance. By optimizing thermite mixtures, researchers aim to achieve higher energy outputs, improved reaction control, and increased safety in handling and storage.

One of the key trends in thermite technology is the development of nano-thermite materials, which offer significantly higher reaction rates and energy densities compared to traditional thermite mixtures. This advancement has opened up new possibilities for applications in areas such as propulsion systems, welding, and materials synthesis. Additionally, there is a growing focus on environmentally friendly thermite formulations that minimize harmful byproducts and reduce the overall environmental impact of these reactions.

The investigation of thermite mixes for optimal performance encompasses several critical aspects. These include the selection and combination of fuel and oxidizer materials, particle size optimization, and the incorporation of additives to enhance specific properties. Researchers are also exploring novel ignition methods and reaction containment strategies to improve the controllability and safety of thermite reactions.

As the field progresses, there is an increasing emphasis on developing multi-functional thermite mixtures that can serve multiple purposes simultaneously. This trend is particularly evident in aerospace and defense applications, where weight and space constraints drive the need for materials with combined propulsive and structural properties. Furthermore, the integration of thermite technology with other advanced materials and systems, such as smart materials and nanotechnology, is expected to yield innovative solutions for complex engineering challenges.

The ultimate goal of these investigations is to push the boundaries of what is possible with thermite technology, unlocking new applications and improving existing ones. By achieving optimal performance in thermite mixtures, researchers aim to address critical needs in various industries, from metallurgy and materials processing to energy storage and propulsion systems. This ongoing research not only promises to enhance the capabilities of thermite-based technologies but also contributes to broader advancements in materials science and energy engineering.

Market Analysis for Thermite Applications

The thermite market has experienced significant growth in recent years, driven by increasing applications across various industries. The global thermite market size was valued at approximately $350 million in 2020 and is projected to reach $500 million by 2025, growing at a CAGR of 7.5% during the forecast period. This growth is primarily attributed to the expanding use of thermite in welding, metal purification, and pyrotechnic applications.

The construction sector remains the largest consumer of thermite, accounting for nearly 40% of the market share. The demand for thermite in construction is fueled by its use in rail welding, particularly in the installation and maintenance of railway tracks. As countries continue to invest in railway infrastructure, the demand for thermite in this sector is expected to remain strong.

The metal and mining industry is another significant market for thermite applications, representing about 30% of the total market. Thermite reactions are widely used in metal purification processes, especially in the production of high-purity metals such as chromium and manganese. The growing demand for these metals in various industrial applications is driving the thermite market in this sector.

The defense and aerospace industries are emerging as promising markets for thermite applications, currently accounting for about 15% of the market share. Thermite is used in incendiary devices, pyrotechnics, and specialized welding applications in these sectors. The increasing defense budgets of several countries and the growing aerospace industry are expected to boost the demand for thermite in these applications.

Geographically, Asia Pacific dominates the thermite market, accounting for approximately 40% of the global market share. The region's rapid industrialization, extensive railway networks, and growing metal production are the key factors driving the demand for thermite. North America and Europe follow, each representing about 25% of the market, with established industries and ongoing infrastructure development projects supporting the market growth.

Key players in the thermite market include Thermit Australia Pty Ltd, Siemens AG, Elektro-Thermit GmbH & Co. KG, and Kuehne + Nagel International AG. These companies are focusing on product innovation and strategic partnerships to maintain their market positions and capitalize on emerging opportunities.

The market analysis reveals a growing trend towards the development of environmentally friendly thermite formulations. This trend is driven by increasing environmental regulations and a shift towards sustainable practices across industries. Manufacturers are investing in research and development to create thermite mixes that produce fewer emissions and have reduced environmental impact, while maintaining or improving performance characteristics.

The construction sector remains the largest consumer of thermite, accounting for nearly 40% of the market share. The demand for thermite in construction is fueled by its use in rail welding, particularly in the installation and maintenance of railway tracks. As countries continue to invest in railway infrastructure, the demand for thermite in this sector is expected to remain strong.

The metal and mining industry is another significant market for thermite applications, representing about 30% of the total market. Thermite reactions are widely used in metal purification processes, especially in the production of high-purity metals such as chromium and manganese. The growing demand for these metals in various industrial applications is driving the thermite market in this sector.

The defense and aerospace industries are emerging as promising markets for thermite applications, currently accounting for about 15% of the market share. Thermite is used in incendiary devices, pyrotechnics, and specialized welding applications in these sectors. The increasing defense budgets of several countries and the growing aerospace industry are expected to boost the demand for thermite in these applications.

Geographically, Asia Pacific dominates the thermite market, accounting for approximately 40% of the global market share. The region's rapid industrialization, extensive railway networks, and growing metal production are the key factors driving the demand for thermite. North America and Europe follow, each representing about 25% of the market, with established industries and ongoing infrastructure development projects supporting the market growth.

Key players in the thermite market include Thermit Australia Pty Ltd, Siemens AG, Elektro-Thermit GmbH & Co. KG, and Kuehne + Nagel International AG. These companies are focusing on product innovation and strategic partnerships to maintain their market positions and capitalize on emerging opportunities.

The market analysis reveals a growing trend towards the development of environmentally friendly thermite formulations. This trend is driven by increasing environmental regulations and a shift towards sustainable practices across industries. Manufacturers are investing in research and development to create thermite mixes that produce fewer emissions and have reduced environmental impact, while maintaining or improving performance characteristics.

Current Challenges in Thermite Performance

Despite significant advancements in thermite technology, several challenges persist in achieving optimal performance. One of the primary issues is the control of reaction rates and energy release. Thermite reactions are typically rapid and exothermic, making it difficult to modulate the speed and intensity of the reaction for specific applications. This lack of precise control can lead to inconsistent results and potential safety hazards in industrial settings.

Another challenge lies in the particle size and distribution of the reactants. The efficiency of thermite reactions is heavily dependent on the surface area contact between the fuel and oxidizer particles. Achieving a uniform and optimal particle size distribution remains a complex task, as it directly impacts the reaction kinetics and overall performance of the thermite mixture.

The stability and shelf life of thermite compositions also present ongoing challenges. Many thermite mixtures are sensitive to environmental factors such as humidity and temperature, which can degrade their performance over time. Developing stable formulations that maintain their reactivity and effectiveness under various storage conditions is crucial for practical applications.

Thermal management during thermite reactions is another significant hurdle. The extreme temperatures generated can lead to material degradation and unwanted side reactions. Efficiently channeling and utilizing the heat produced while minimizing thermal losses and potential damage to surrounding structures or equipment remains a key area of research.

Furthermore, the environmental impact of thermite reactions is a growing concern. Traditional thermite compositions often contain materials that can produce harmful byproducts or leave residues that are difficult to dispose of safely. Developing more environmentally friendly alternatives without compromising performance is an ongoing challenge in the field.

Scaling up thermite reactions for industrial applications also presents difficulties. What works effectively on a small scale in laboratory settings may not translate directly to larger-scale operations. Issues such as heat dissipation, reaction propagation, and product collection become more complex as the scale increases.

Lastly, the characterization and prediction of thermite performance remain challenging. Current analytical techniques and modeling approaches often struggle to accurately capture the complex, multiphase nature of thermite reactions. Improving our ability to predict and analyze thermite behavior under various conditions is essential for optimizing performance and expanding applications.

Another challenge lies in the particle size and distribution of the reactants. The efficiency of thermite reactions is heavily dependent on the surface area contact between the fuel and oxidizer particles. Achieving a uniform and optimal particle size distribution remains a complex task, as it directly impacts the reaction kinetics and overall performance of the thermite mixture.

The stability and shelf life of thermite compositions also present ongoing challenges. Many thermite mixtures are sensitive to environmental factors such as humidity and temperature, which can degrade their performance over time. Developing stable formulations that maintain their reactivity and effectiveness under various storage conditions is crucial for practical applications.

Thermal management during thermite reactions is another significant hurdle. The extreme temperatures generated can lead to material degradation and unwanted side reactions. Efficiently channeling and utilizing the heat produced while minimizing thermal losses and potential damage to surrounding structures or equipment remains a key area of research.

Furthermore, the environmental impact of thermite reactions is a growing concern. Traditional thermite compositions often contain materials that can produce harmful byproducts or leave residues that are difficult to dispose of safely. Developing more environmentally friendly alternatives without compromising performance is an ongoing challenge in the field.

Scaling up thermite reactions for industrial applications also presents difficulties. What works effectively on a small scale in laboratory settings may not translate directly to larger-scale operations. Issues such as heat dissipation, reaction propagation, and product collection become more complex as the scale increases.

Lastly, the characterization and prediction of thermite performance remain challenging. Current analytical techniques and modeling approaches often struggle to accurately capture the complex, multiphase nature of thermite reactions. Improving our ability to predict and analyze thermite behavior under various conditions is essential for optimizing performance and expanding applications.

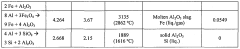

Existing Thermite Mix Optimization Methods

01 Composition optimization for enhanced performance

Thermite mixes can be optimized by adjusting the composition of fuel and oxidizer components. This includes varying the ratios of aluminum powder, metal oxides, and other additives to achieve desired reaction rates, energy output, and combustion characteristics. Proper particle size distribution and mixing techniques are crucial for improving overall performance.- Composition optimization for enhanced performance: Thermite mixes can be optimized by adjusting the composition of fuel and oxidizer components. This includes varying the ratios of aluminum powder, metal oxides, and other additives to achieve desired reaction rates, energy output, and combustion characteristics. Proper particle size distribution and mixing techniques are crucial for improving overall performance.

- Additives for improved ignition and combustion: Various additives can be incorporated into thermite mixes to enhance ignition sensitivity, combustion stability, and energy release. These may include catalysts, binders, and energetic materials that promote more efficient and controlled reactions. Such additives can significantly improve the performance and reliability of thermite-based systems.

- Novel thermite formulations for specific applications: Specialized thermite formulations can be developed for specific applications such as welding, metal purification, or pyrotechnics. These formulations may incorporate unique combinations of metals, oxides, and other compounds to achieve desired properties like increased heat output, reduced smoke production, or controlled reaction speeds.

- Nanostructured materials for enhanced reactivity: Incorporating nanostructured materials into thermite mixes can significantly enhance their reactivity and performance. Nanoscale aluminum particles, for example, offer increased surface area and improved mixing with oxidizers, leading to faster reaction rates and higher energy densities. This approach can result in more efficient and powerful thermite compositions.

- Environmental and safety considerations in thermite design: Modern thermite mix designs increasingly focus on environmental and safety aspects. This includes developing formulations with reduced toxicity, minimized harmful emissions, and improved stability during storage and handling. Such considerations aim to enhance the overall safety profile and ecological impact of thermite-based applications without compromising performance.

02 Additives for improved ignition and combustion

Various additives can be incorporated into thermite mixes to enhance ignition sensitivity, combustion stability, and energy release. These may include catalysts, binders, or energetic materials that promote more efficient and controlled reactions. Such additives can significantly improve the performance and reliability of thermite-based systems.Expand Specific Solutions03 Novel formulations for specific applications

Specialized thermite formulations can be developed for specific applications such as welding, metal purification, or pyrotechnics. These formulations may involve unique combinations of reactants or the inclusion of additional components to tailor the reaction products or thermal output for particular use cases.Expand Specific Solutions04 Processing techniques for enhanced reactivity

Advanced processing techniques can be employed to improve the reactivity and performance of thermite mixes. These may include mechanical activation, nanostructuring of components, or the use of novel synthesis methods to create more intimate mixing of reactants. Such techniques can lead to faster reaction kinetics and higher energy densities.Expand Specific Solutions05 Safety and stability improvements

Enhancing the safety and stability of thermite mixes is crucial for practical applications. This can involve the development of less sensitive formulations, incorporation of stabilizing agents, or design of specialized containment systems. Improved safety features can allow for broader use of thermite reactions while maintaining high performance characteristics.Expand Specific Solutions

Key Players in Thermite Industry

The investigation of thermite mixes for optimal performance is currently in a growth phase, with increasing market size and technological advancements. The global market for thermite-related applications is expanding, driven by demand in sectors like defense, aerospace, and metallurgy. Technological maturity varies across different applications, with companies like Lockheed Martin Corp. and Naval Research Laboratory leading in advanced research and development. Other key players such as BASF Plant Science LLC and Xi'an Modern Chemistry Research Institute are contributing to the field's progress. The competitive landscape is diverse, with both established corporations and specialized research institutions actively pursuing innovations in thermite mix optimization, indicating a dynamic and evolving technological ecosystem.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced thermite compositions for military applications. Their research focuses on optimizing the performance of thermite reactions through precise control of particle size, composition, and additives. They have explored the use of nanoscale aluminum particles and various metal oxides to enhance reaction rates and energy output. Their approach involves systematic testing of different thermite formulations under controlled conditions to evaluate ignition sensitivity, reaction propagation, and heat generation.

Strengths: Access to advanced research facilities and expertise in energetic materials. Weaknesses: Limited commercial applications due to focus on military use.

Xi'an Modern Chemistry Research Institute

Technical Solution: Xi'an Modern Chemistry Research Institute has conducted extensive research on thermite mixtures for various applications. Their approach involves the synthesis of novel metal fuel and oxidizer combinations, including the use of rare earth metals to enhance reactivity. They have developed methods for precise control of particle morphology and surface chemistry to optimize thermite performance. Their research also includes the development of environmentally friendly thermite compositions with reduced toxicity and improved stability.

Strengths: Strong expertise in material synthesis and characterization. Weaknesses: Potential limitations in scaling up laboratory results to industrial production.

Core Innovations in Thermite Chemistry

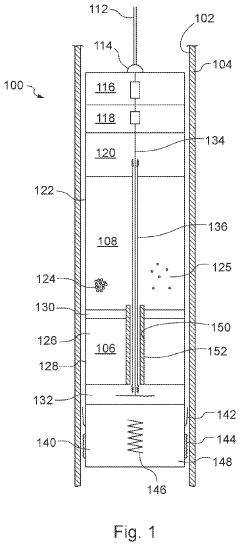

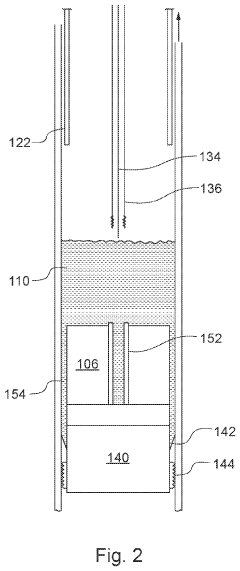

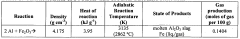

Downhole apparatus and method

PatentActiveUS20240011367A1

Innovation

- A downhole apparatus and method utilizing compressed thermite within a container, which reduces porosity and increases density, facilitating efficient heat transfer and reaction, and is combined with a low-melt-point alloy to form a solid plug, allowing for effective sealing without the need for binding agents and maintaining structural strength under pressure.

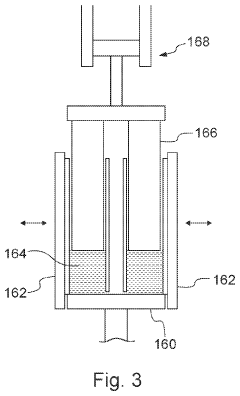

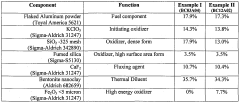

Solid-state thermite composition based heating device

PatentWO2010117857A2

Innovation

- A solid-state thermite reaction composition comprising a fuel component, primary oxidizer, initiating oxidizers, thermal diluent, and fluxing agents, integrated with a heating device featuring a reaction chamber and actuable trigger mechanism, allowing controlled thermite reactions for precise heat generation, with activation mechanisms like piezoelectric spark ignitors or exothermic couples to initiate the reaction safely.

Safety Regulations for Thermite Handling

Safety regulations for thermite handling are crucial in ensuring the optimal performance and risk mitigation when investigating thermite mixes. These regulations encompass a wide range of protocols and guidelines designed to protect researchers, facilities, and the environment from potential hazards associated with thermite reactions.

Personal protective equipment (PPE) is a fundamental aspect of thermite safety. Researchers must wear fire-resistant clothing, including lab coats, gloves, and closed-toe shoes. Eye protection, such as safety goggles or face shields, is mandatory to guard against potential splashes or debris. Respiratory protection may also be necessary, depending on the specific compounds used and the scale of the experiment.

Proper storage and handling of thermite components are essential. Oxidizers and metal powders should be stored separately in cool, dry areas away from potential ignition sources. Containers must be clearly labeled and kept sealed when not in use. Access to these materials should be restricted to authorized personnel only, with inventory controls in place to track usage and prevent unauthorized access.

Workspace design plays a critical role in thermite safety. Experiments should be conducted in designated areas equipped with appropriate fire suppression systems, such as Class D fire extinguishers specifically designed for metal fires. Adequate ventilation is necessary to remove potentially harmful fumes or dust. Emergency eyewash stations and safety showers should be readily accessible in case of accidental exposure.

Training and education are paramount for anyone working with thermite mixtures. Researchers must be thoroughly familiar with the properties of the materials they are handling, potential hazards, and emergency procedures. Regular safety briefings and drills should be conducted to ensure all personnel are prepared for potential incidents.

Waste disposal regulations for thermite materials are stringent due to their reactive nature. Unused materials and reaction products must be disposed of according to local, state, and federal guidelines. This often involves specialized waste management procedures to prevent accidental ignition or environmental contamination.

Emergency response planning is a critical component of thermite safety regulations. Facilities must have clear protocols in place for various scenarios, including fires, spills, and personnel injuries. This includes evacuation procedures, communication systems, and coordination with local emergency services.

Documentation and record-keeping are essential for compliance with safety regulations. Detailed logs of experiments, including quantities of materials used, reaction conditions, and safety measures implemented, must be maintained. These records are valuable for ongoing safety assessments and may be required by regulatory agencies.

By adhering to these comprehensive safety regulations, researchers can minimize risks and focus on optimizing thermite mix performance while ensuring the well-being of personnel and the integrity of research facilities.

Personal protective equipment (PPE) is a fundamental aspect of thermite safety. Researchers must wear fire-resistant clothing, including lab coats, gloves, and closed-toe shoes. Eye protection, such as safety goggles or face shields, is mandatory to guard against potential splashes or debris. Respiratory protection may also be necessary, depending on the specific compounds used and the scale of the experiment.

Proper storage and handling of thermite components are essential. Oxidizers and metal powders should be stored separately in cool, dry areas away from potential ignition sources. Containers must be clearly labeled and kept sealed when not in use. Access to these materials should be restricted to authorized personnel only, with inventory controls in place to track usage and prevent unauthorized access.

Workspace design plays a critical role in thermite safety. Experiments should be conducted in designated areas equipped with appropriate fire suppression systems, such as Class D fire extinguishers specifically designed for metal fires. Adequate ventilation is necessary to remove potentially harmful fumes or dust. Emergency eyewash stations and safety showers should be readily accessible in case of accidental exposure.

Training and education are paramount for anyone working with thermite mixtures. Researchers must be thoroughly familiar with the properties of the materials they are handling, potential hazards, and emergency procedures. Regular safety briefings and drills should be conducted to ensure all personnel are prepared for potential incidents.

Waste disposal regulations for thermite materials are stringent due to their reactive nature. Unused materials and reaction products must be disposed of according to local, state, and federal guidelines. This often involves specialized waste management procedures to prevent accidental ignition or environmental contamination.

Emergency response planning is a critical component of thermite safety regulations. Facilities must have clear protocols in place for various scenarios, including fires, spills, and personnel injuries. This includes evacuation procedures, communication systems, and coordination with local emergency services.

Documentation and record-keeping are essential for compliance with safety regulations. Detailed logs of experiments, including quantities of materials used, reaction conditions, and safety measures implemented, must be maintained. These records are valuable for ongoing safety assessments and may be required by regulatory agencies.

By adhering to these comprehensive safety regulations, researchers can minimize risks and focus on optimizing thermite mix performance while ensuring the well-being of personnel and the integrity of research facilities.

Environmental Impact of Thermite Usage

The environmental impact of thermite usage is a critical consideration in the investigation of optimal thermite mixes. Thermite reactions, while highly effective for certain applications, can have significant environmental consequences that must be carefully evaluated and mitigated.

One of the primary environmental concerns associated with thermite usage is the release of particulate matter and metal oxides into the atmosphere. The high-temperature reaction between metal fuel and metal oxide produces fine particles that can remain suspended in the air for extended periods. These particles may contribute to air pollution and pose respiratory risks to both humans and wildlife in the vicinity of thermite applications.

Additionally, the intense heat generated during thermite reactions can lead to localized soil degradation and potential contamination. The extreme temperatures may alter soil composition, affecting its ability to support plant life and microorganisms. This can result in long-term ecological disruptions in areas where thermite is frequently used or improperly managed.

Water contamination is another significant environmental risk associated with thermite usage. Residual metal oxides and unreacted materials can leach into groundwater or surface water systems, potentially affecting aquatic ecosystems and water quality. The introduction of these substances into water bodies may have far-reaching consequences for both flora and fauna.

The production and disposal of thermite materials also contribute to its environmental footprint. The manufacturing process of thermite components often involves energy-intensive procedures and the use of potentially hazardous chemicals. Proper disposal of unused or spent thermite mixtures is crucial to prevent environmental contamination and ensure compliance with regulatory standards.

To mitigate these environmental impacts, researchers investigating optimal thermite mixes should focus on developing more environmentally friendly formulations. This may include exploring alternative metal fuels and oxidizers that produce less harmful byproducts or incorporating additives that reduce particulate emissions. Additionally, optimizing the reaction efficiency can minimize waste and reduce the overall environmental impact of thermite usage.

Implementing strict containment and cleanup protocols is essential for minimizing the environmental footprint of thermite applications. This includes proper ventilation systems to capture airborne particles, containment measures to prevent soil and water contamination, and comprehensive post-use cleanup procedures to remove residual materials from the environment.

In conclusion, while thermite mixes offer unique capabilities for various applications, their environmental impact must be carefully considered and addressed in the pursuit of optimal performance. Balancing efficacy with environmental responsibility is crucial for the sustainable development and use of thermite technologies.

One of the primary environmental concerns associated with thermite usage is the release of particulate matter and metal oxides into the atmosphere. The high-temperature reaction between metal fuel and metal oxide produces fine particles that can remain suspended in the air for extended periods. These particles may contribute to air pollution and pose respiratory risks to both humans and wildlife in the vicinity of thermite applications.

Additionally, the intense heat generated during thermite reactions can lead to localized soil degradation and potential contamination. The extreme temperatures may alter soil composition, affecting its ability to support plant life and microorganisms. This can result in long-term ecological disruptions in areas where thermite is frequently used or improperly managed.

Water contamination is another significant environmental risk associated with thermite usage. Residual metal oxides and unreacted materials can leach into groundwater or surface water systems, potentially affecting aquatic ecosystems and water quality. The introduction of these substances into water bodies may have far-reaching consequences for both flora and fauna.

The production and disposal of thermite materials also contribute to its environmental footprint. The manufacturing process of thermite components often involves energy-intensive procedures and the use of potentially hazardous chemicals. Proper disposal of unused or spent thermite mixtures is crucial to prevent environmental contamination and ensure compliance with regulatory standards.

To mitigate these environmental impacts, researchers investigating optimal thermite mixes should focus on developing more environmentally friendly formulations. This may include exploring alternative metal fuels and oxidizers that produce less harmful byproducts or incorporating additives that reduce particulate emissions. Additionally, optimizing the reaction efficiency can minimize waste and reduce the overall environmental impact of thermite usage.

Implementing strict containment and cleanup protocols is essential for minimizing the environmental footprint of thermite applications. This includes proper ventilation systems to capture airborne particles, containment measures to prevent soil and water contamination, and comprehensive post-use cleanup procedures to remove residual materials from the environment.

In conclusion, while thermite mixes offer unique capabilities for various applications, their environmental impact must be carefully considered and addressed in the pursuit of optimal performance. Balancing efficacy with environmental responsibility is crucial for the sustainable development and use of thermite technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!