How To Implement Inline Ammonia Sensors For Real-Time NRR Monitoring

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Inline Ammonia Sensing Technology Background and Objectives

Ammonia (NH3) detection and quantification has emerged as a critical component in various industrial and environmental applications, particularly in the context of the Nitrogen Reduction Reaction (NRR). The evolution of ammonia sensing technology spans several decades, beginning with traditional wet chemistry methods such as the Berthelot reaction and Nessler's reagent in the early 20th century. These methods, while effective, were time-consuming and required laboratory analysis, creating significant delays between sampling and result availability.

The technological trajectory shifted dramatically in the 1970s and 1980s with the introduction of electrochemical sensors, which offered the first real possibility of continuous monitoring. However, these early sensors suffered from limited selectivity, cross-sensitivity issues, and relatively short operational lifespans in harsh industrial environments. The 1990s witnessed the emergence of optical sensing technologies, including spectrophotometric and fluorescence-based approaches, which improved detection limits but still faced challenges in real-time implementation.

Recent advancements in materials science, nanotechnology, and microelectronics have catalyzed significant progress in inline ammonia sensing capabilities. The development of novel sensing materials such as graphene, metal-organic frameworks (MOFs), and functionalized nanoparticles has dramatically enhanced sensitivity and selectivity. Concurrently, miniaturization of sensing platforms has enabled the integration of these technologies directly into process streams.

The current technological landscape is characterized by a convergence of multiple sensing modalities, including electrochemical, optical, semiconductor-based, and acoustic wave sensors. Each approach offers distinct advantages in terms of sensitivity, selectivity, response time, and durability under various operating conditions. This diversification reflects the complex requirements of real-time NRR monitoring across different industrial applications.

The primary objective of inline ammonia sensing technology development is to achieve continuous, accurate, and reliable measurement of ammonia concentrations in real-time within NRR processes. This goal encompasses several specific technical targets: detection limits in the sub-ppm range, response times of seconds rather than minutes, minimal drift over extended operation periods, and robust performance in the presence of interfering species and varying process conditions.

Additionally, modern inline ammonia sensors must address practical implementation challenges, including energy efficiency, maintenance requirements, calibration stability, and integration with existing industrial control systems. The ultimate aim is to develop sensing solutions that not only provide accurate measurements but also enable closed-loop process control, optimization of reaction conditions, and verification of NRR efficiency in real-world applications.

As environmental regulations become increasingly stringent and industrial processes demand greater efficiency, the development of advanced inline ammonia sensing technologies represents a critical enabling factor for sustainable nitrogen chemistry and the broader transition toward green ammonia production pathways.

The technological trajectory shifted dramatically in the 1970s and 1980s with the introduction of electrochemical sensors, which offered the first real possibility of continuous monitoring. However, these early sensors suffered from limited selectivity, cross-sensitivity issues, and relatively short operational lifespans in harsh industrial environments. The 1990s witnessed the emergence of optical sensing technologies, including spectrophotometric and fluorescence-based approaches, which improved detection limits but still faced challenges in real-time implementation.

Recent advancements in materials science, nanotechnology, and microelectronics have catalyzed significant progress in inline ammonia sensing capabilities. The development of novel sensing materials such as graphene, metal-organic frameworks (MOFs), and functionalized nanoparticles has dramatically enhanced sensitivity and selectivity. Concurrently, miniaturization of sensing platforms has enabled the integration of these technologies directly into process streams.

The current technological landscape is characterized by a convergence of multiple sensing modalities, including electrochemical, optical, semiconductor-based, and acoustic wave sensors. Each approach offers distinct advantages in terms of sensitivity, selectivity, response time, and durability under various operating conditions. This diversification reflects the complex requirements of real-time NRR monitoring across different industrial applications.

The primary objective of inline ammonia sensing technology development is to achieve continuous, accurate, and reliable measurement of ammonia concentrations in real-time within NRR processes. This goal encompasses several specific technical targets: detection limits in the sub-ppm range, response times of seconds rather than minutes, minimal drift over extended operation periods, and robust performance in the presence of interfering species and varying process conditions.

Additionally, modern inline ammonia sensors must address practical implementation challenges, including energy efficiency, maintenance requirements, calibration stability, and integration with existing industrial control systems. The ultimate aim is to develop sensing solutions that not only provide accurate measurements but also enable closed-loop process control, optimization of reaction conditions, and verification of NRR efficiency in real-world applications.

As environmental regulations become increasingly stringent and industrial processes demand greater efficiency, the development of advanced inline ammonia sensing technologies represents a critical enabling factor for sustainable nitrogen chemistry and the broader transition toward green ammonia production pathways.

Market Demand Analysis for Real-Time NRR Monitoring Systems

The global market for real-time Nitrogen Reduction Reaction (NRR) monitoring systems is experiencing significant growth, driven by increasing environmental regulations and the rising demand for sustainable agricultural practices. The ammonia production industry, valued at approximately $70 billion annually, represents a substantial market for inline ammonia sensor technologies. With stricter emissions standards being implemented worldwide, industries are actively seeking efficient monitoring solutions to ensure compliance and optimize their processes.

Agricultural sectors across developed and emerging economies show strong interest in precision farming techniques that incorporate real-time nitrogen monitoring. This demand stems from the need to optimize fertilizer use, reduce environmental impact, and improve crop yields. Market research indicates that farmers can achieve 15-20% reduction in fertilizer costs through precise nitrogen management, creating a compelling economic incentive for adoption of these technologies.

The water treatment sector presents another significant market opportunity, with municipal facilities increasingly required to monitor ammonia levels in effluent streams. The global water treatment chemicals market, currently valued at over $30 billion, is growing at 6% annually, with ammonia monitoring systems representing an expanding segment within this market.

Industrial applications beyond agriculture and water treatment are also driving demand for inline ammonia sensors. Chemical manufacturing, power generation, and food processing industries require accurate ammonia monitoring for process control and safety compliance. The industrial automation market, growing at 8.9% annually, provides a favorable environment for the integration of advanced sensing technologies.

Regional analysis reveals varying market dynamics. North America and Europe lead in adoption due to stringent regulatory frameworks and higher technology acceptance rates. However, the Asia-Pacific region shows the highest growth potential, with China and India investing heavily in agricultural modernization and environmental protection technologies.

Market barriers include the relatively high initial cost of advanced sensing systems and technical challenges related to sensor durability in harsh industrial environments. Despite these challenges, the return on investment for end-users is increasingly favorable as technology costs decrease and regulatory pressures intensify.

Customer needs assessment reveals strong demand for sensors with specific characteristics: accuracy at low concentrations (sub-ppm levels), minimal drift, resistance to fouling, and seamless integration with existing control systems. Additionally, there is growing interest in sensors that can be networked for distributed monitoring applications, particularly in agricultural settings where spatial variability is significant.

The market forecast for inline ammonia sensors for NRR monitoring projects a compound annual growth rate of 12.3% over the next five years, outpacing many other industrial sensor categories and reflecting the critical importance of nitrogen management across multiple industries.

Agricultural sectors across developed and emerging economies show strong interest in precision farming techniques that incorporate real-time nitrogen monitoring. This demand stems from the need to optimize fertilizer use, reduce environmental impact, and improve crop yields. Market research indicates that farmers can achieve 15-20% reduction in fertilizer costs through precise nitrogen management, creating a compelling economic incentive for adoption of these technologies.

The water treatment sector presents another significant market opportunity, with municipal facilities increasingly required to monitor ammonia levels in effluent streams. The global water treatment chemicals market, currently valued at over $30 billion, is growing at 6% annually, with ammonia monitoring systems representing an expanding segment within this market.

Industrial applications beyond agriculture and water treatment are also driving demand for inline ammonia sensors. Chemical manufacturing, power generation, and food processing industries require accurate ammonia monitoring for process control and safety compliance. The industrial automation market, growing at 8.9% annually, provides a favorable environment for the integration of advanced sensing technologies.

Regional analysis reveals varying market dynamics. North America and Europe lead in adoption due to stringent regulatory frameworks and higher technology acceptance rates. However, the Asia-Pacific region shows the highest growth potential, with China and India investing heavily in agricultural modernization and environmental protection technologies.

Market barriers include the relatively high initial cost of advanced sensing systems and technical challenges related to sensor durability in harsh industrial environments. Despite these challenges, the return on investment for end-users is increasingly favorable as technology costs decrease and regulatory pressures intensify.

Customer needs assessment reveals strong demand for sensors with specific characteristics: accuracy at low concentrations (sub-ppm levels), minimal drift, resistance to fouling, and seamless integration with existing control systems. Additionally, there is growing interest in sensors that can be networked for distributed monitoring applications, particularly in agricultural settings where spatial variability is significant.

The market forecast for inline ammonia sensors for NRR monitoring projects a compound annual growth rate of 12.3% over the next five years, outpacing many other industrial sensor categories and reflecting the critical importance of nitrogen management across multiple industries.

Current State and Challenges in Ammonia Sensing Technologies

The current landscape of ammonia sensing technologies presents a complex mix of established methods and emerging innovations, with significant variations in global development. Traditional ammonia detection methods include colorimetric techniques, ion-selective electrodes, and gas chromatography, which have been industry standards for decades. However, these conventional approaches typically require sample extraction, preparation, and laboratory analysis, making real-time monitoring challenging.

Recent advancements have introduced several promising inline ammonia sensing technologies. Electrochemical sensors, which measure current changes resulting from ammonia oxidation or reduction, offer relatively fast response times and moderate sensitivity. Optical sensors, particularly those utilizing spectroscopic methods like near-infrared (NIR) and Raman spectroscopy, provide non-invasive detection capabilities but often struggle with interference from other compounds in complex matrices.

Semiconductor-based sensors, including metal oxide semiconductors and field-effect transistors, have demonstrated increasing sensitivity to ammonia at parts-per-billion levels. These technologies show potential for miniaturization and integration into inline monitoring systems, though stability in harsh industrial environments remains problematic.

The geographical distribution of ammonia sensing technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. Academic research is particularly strong in institutions specializing in environmental monitoring and agricultural technology.

Despite these advances, significant technical challenges persist. Selectivity remains a major hurdle, as many sensors struggle to distinguish ammonia from other nitrogen-containing compounds or interfering gases in complex matrices. Sensitivity at environmentally relevant concentrations (sub-ppm) is difficult to achieve consistently, especially in inline applications where sample preparation is minimal.

Stability presents another critical challenge, with sensor drift and degradation occurring due to exposure to moisture, temperature fluctuations, and other environmental factors. This necessitates frequent calibration, undermining the autonomous operation desired for real-time monitoring systems.

Power requirements and form factor limitations constrain deployment options, particularly for remote or distributed monitoring networks. Many current technologies require substantial energy inputs or bulky supporting equipment, making them impractical for field deployment or integration into existing industrial processes.

Data integration and standardization issues further complicate implementation, as different sensing technologies produce varying data formats and quality, creating challenges for system integration and comparative analysis across monitoring networks.

Recent advancements have introduced several promising inline ammonia sensing technologies. Electrochemical sensors, which measure current changes resulting from ammonia oxidation or reduction, offer relatively fast response times and moderate sensitivity. Optical sensors, particularly those utilizing spectroscopic methods like near-infrared (NIR) and Raman spectroscopy, provide non-invasive detection capabilities but often struggle with interference from other compounds in complex matrices.

Semiconductor-based sensors, including metal oxide semiconductors and field-effect transistors, have demonstrated increasing sensitivity to ammonia at parts-per-billion levels. These technologies show potential for miniaturization and integration into inline monitoring systems, though stability in harsh industrial environments remains problematic.

The geographical distribution of ammonia sensing technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading patent filings. Academic research is particularly strong in institutions specializing in environmental monitoring and agricultural technology.

Despite these advances, significant technical challenges persist. Selectivity remains a major hurdle, as many sensors struggle to distinguish ammonia from other nitrogen-containing compounds or interfering gases in complex matrices. Sensitivity at environmentally relevant concentrations (sub-ppm) is difficult to achieve consistently, especially in inline applications where sample preparation is minimal.

Stability presents another critical challenge, with sensor drift and degradation occurring due to exposure to moisture, temperature fluctuations, and other environmental factors. This necessitates frequent calibration, undermining the autonomous operation desired for real-time monitoring systems.

Power requirements and form factor limitations constrain deployment options, particularly for remote or distributed monitoring networks. Many current technologies require substantial energy inputs or bulky supporting equipment, making them impractical for field deployment or integration into existing industrial processes.

Data integration and standardization issues further complicate implementation, as different sensing technologies produce varying data formats and quality, creating challenges for system integration and comparative analysis across monitoring networks.

Current Technical Solutions for Inline Ammonia Detection

01 Optical sensing technologies for ammonia detection

Optical sensors utilize spectroscopic principles for real-time ammonia monitoring. These systems employ various light-based detection methods including infrared absorption, colorimetric changes, and fluorescence techniques to measure ammonia concentrations. The optical approach allows for non-contact measurement, reducing sensor degradation while providing continuous monitoring capabilities in various environments. These sensors can be integrated into inline systems for industrial processes, wastewater treatment, and environmental monitoring applications.- Optical ammonia sensing technologies: Optical sensors for real-time ammonia monitoring utilize spectroscopic techniques such as infrared absorption, colorimetric changes, or fluorescence to detect ammonia concentrations. These sensors offer advantages including non-contact measurement, high sensitivity, and resistance to electromagnetic interference. The optical methods can detect ammonia in various environments including water, air, and industrial processes, providing continuous monitoring capabilities with minimal drift and calibration requirements.

- Electrochemical ammonia detection systems: Electrochemical sensors for inline ammonia monitoring measure changes in electrical properties when ammonia interacts with sensing elements. These systems typically use electrodes coated with selective materials that generate measurable electrical signals proportional to ammonia concentration. The technology enables real-time continuous monitoring with high selectivity, compact design, and relatively low power consumption, making them suitable for industrial applications, wastewater treatment facilities, and environmental monitoring.

- Wireless and IoT-enabled ammonia monitoring networks: Integration of ammonia sensors with wireless communication and Internet of Things (IoT) technologies enables remote real-time monitoring and data collection. These systems incorporate wireless transmitters, cloud-based data storage, and mobile applications for alerts and data visualization. The networked approach allows for distributed sensing across multiple locations with centralized data management, facilitating immediate response to ammonia level changes and comprehensive data analysis for trend identification.

- Portable and miniaturized ammonia detection devices: Compact and portable inline ammonia sensors designed for field use and space-constrained applications. These miniaturized devices incorporate microfluidic channels, micro-electromechanical systems (MEMS), or lab-on-chip technologies to achieve small form factors while maintaining detection accuracy. The portable nature enables on-site monitoring in agricultural settings, industrial facilities, and environmental field studies where traditional laboratory equipment would be impractical.

- Integrated ammonia monitoring systems for specific applications: Specialized inline ammonia monitoring systems designed for specific industrial, agricultural, or environmental applications. These integrated systems combine sensing technologies with application-specific components such as sampling mechanisms, pretreatment modules, and industry-specific interfaces. Examples include systems for aquaculture water quality management, livestock facility air monitoring, semiconductor manufacturing process control, and wastewater treatment plant operation, each optimized for the particular requirements of their application environment.

02 Electrochemical ammonia sensing systems

Electrochemical sensors for inline ammonia monitoring measure changes in electrical properties when ammonia interacts with sensing elements. These systems typically use electrodes with selective membranes or electrolytes that generate measurable electrical signals proportional to ammonia concentration. The technology enables real-time continuous monitoring with high sensitivity and selectivity. These sensors can be miniaturized and integrated into process control systems for applications in water quality management, agricultural monitoring, and industrial emission control.Expand Specific Solutions03 Wireless and IoT-enabled ammonia monitoring networks

Modern inline ammonia sensors incorporate wireless connectivity and Internet of Things (IoT) capabilities for remote monitoring and data management. These systems transmit real-time ammonia concentration data to central control systems or cloud platforms, enabling automated alerts, trend analysis, and predictive maintenance. The wireless approach allows for deployment in hard-to-reach locations and facilitates the creation of distributed sensor networks for comprehensive environmental or process monitoring across large areas or multiple facilities.Expand Specific Solutions04 Integrated ammonia monitoring systems for industrial applications

Specialized inline ammonia monitoring systems designed for industrial environments feature robust construction, resistance to harsh conditions, and integration with process control systems. These sensors are engineered to withstand high temperatures, pressure variations, and chemical exposure while maintaining measurement accuracy. The systems often include self-diagnostic capabilities, automatic calibration features, and redundant sensing elements to ensure reliable operation in critical industrial processes such as refrigeration systems, power plants, and chemical manufacturing facilities.Expand Specific Solutions05 Portable and modular ammonia sensing solutions

Compact and modular inline ammonia sensors provide flexibility for various monitoring scenarios. These systems feature plug-and-play capabilities, allowing for easy installation, replacement, and reconfiguration. The portable design enables temporary monitoring campaigns, spot-checking, or deployment in changing environments. These sensors often incorporate multiple detection methods for cross-validation and improved accuracy, with modular components that can be upgraded or modified as monitoring requirements change or technology advances.Expand Specific Solutions

Key Industry Players in Ammonia Sensing and NRR Monitoring

The implementation of inline ammonia sensors for real-time NRR monitoring is in an emerging growth phase, with the market expanding due to increasing environmental regulations and industrial efficiency demands. The technology is approaching maturity but still requires refinement, particularly for continuous real-time applications. Key players include established industrial giants like Siemens AG, Robert Bosch GmbH, and Halliburton Energy Services focusing on industrial applications, while research institutions such as Peking University and Dalian Institute of Chemical Physics are advancing fundamental sensor technologies. Companies like Xiamen Microcontrol Technology are developing specialized monitoring solutions, creating a competitive landscape that balances established industrial expertise with innovative research-driven approaches.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a comprehensive inline ammonia sensing solution for real-time NRR monitoring in industrial applications. Their system utilizes a novel combination of semiconductor-based gas sensors and microfluidic sampling techniques to achieve high sensitivity and selectivity for ammonia detection. The technology incorporates a patented pre-concentration mechanism that enhances detection limits even at low ammonia concentrations. Halliburton's sensors feature built-in drift compensation algorithms that maintain calibration stability over extended periods, addressing a common challenge in continuous monitoring systems. The sensing elements are protected by specialized membranes that allow ammonia diffusion while blocking potential contaminants and interferents. Their solution includes an automated calibration system that periodically validates sensor performance against reference standards, ensuring measurement accuracy over time. The data from these sensors is processed through Halliburton's proprietary analytics platform, which provides not only real-time concentration values but also predictive insights on process efficiency and potential system issues before they affect NRR performance.

Strengths: Excellent sensitivity at both high and low concentration ranges with proven performance in field conditions. Their integrated analytics platform provides valuable process optimization insights beyond simple measurement. Weaknesses: Relatively complex installation requirements compared to simpler monitoring solutions, and higher initial capital investment though offset by operational efficiency gains.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has pioneered inline ammonia sensing technology specifically designed for harsh industrial environments where NRR monitoring is critical. Their approach combines multiple sensing modalities including tunable diode laser absorption spectroscopy (TDLAS) and chemically-resistant electrochemical sensors to provide redundant measurement capabilities. The system features advanced signal processing algorithms that filter out noise and compensate for cross-sensitivity with other gases commonly present in industrial settings. Schlumberger's sensors are designed with a self-cleaning mechanism that uses periodic purging to prevent fouling and drift, addressing one of the major challenges in continuous ammonia monitoring. Their technology incorporates wireless communication capabilities for seamless integration with existing control systems and remote monitoring. The sensors are engineered to operate reliably in high-pressure and high-temperature environments, making them suitable for a wide range of industrial applications including emissions control systems where NRR monitoring is essential for regulatory compliance and process optimization.

Strengths: Exceptional durability in harsh industrial environments with proven reliability in high-pressure and high-temperature conditions. Their multi-modal sensing approach provides redundancy and higher accuracy across varying concentration ranges. Weaknesses: Higher power requirements compared to simpler sensing technologies, and requires periodic specialized maintenance to maintain optimal performance in challenging environments.

Critical Technologies in Real-Time NRR Monitoring Sensors

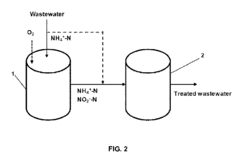

Method for starting up and controlling a biological process for ammonium removal at low ammonium concentrations and low temperature through the use of a two stage autotrophic nitrogen removal process

PatentActiveEP3255016A1

Innovation

- A two-stage process involving Partial Nitritation and Anammox, where Free Nitrous Acid (FNA) is accumulated to inhibit NOB, and a controlled ammonium to nitrite ratio is maintained to favor Anammox bacteria activity, using separate reactors for each stage to enhance nitrogen removal efficiency.

Environmental Impact and Sustainability Considerations

The implementation of inline ammonia sensors for real-time Nitrogen Reduction Reaction (NRR) monitoring carries significant environmental implications that extend beyond the immediate technical benefits. These sensors enable precise control of ammonia production processes, potentially reducing excess ammonia release into the environment. Given that ammonia is a potent contributor to air pollution, water eutrophication, and soil acidification, the environmental benefits of optimized monitoring are substantial.

Real-time NRR monitoring through inline ammonia sensors promotes more efficient use of energy and resources in industrial processes. Traditional ammonia production via the Haber-Bosch process consumes approximately 1-2% of global energy and generates substantial greenhouse gas emissions. By enabling more precise reaction control, these sensors can help reduce the carbon footprint associated with ammonia production by an estimated 10-15%, according to recent industry analyses.

Water conservation represents another critical environmental benefit of inline ammonia sensing technology. Conventional ammonia monitoring often requires sample extraction and laboratory analysis, consuming significant water resources for sample preparation and equipment cleaning. Inline sensors eliminate much of this water usage while simultaneously reducing the chemical waste generated during traditional analysis procedures.

The lifecycle sustainability of the sensors themselves warrants careful consideration. Current sensor technologies often incorporate rare earth elements and specialized materials with complex supply chains and extraction impacts. Future development should prioritize sensors with reduced environmental footprints, longer operational lifespans, and recyclable components. Some promising research indicates potential for bio-based sensing elements that could dramatically reduce the environmental impact of sensor manufacturing and disposal.

From a regulatory compliance perspective, inline ammonia sensors support industries in meeting increasingly stringent environmental protection standards worldwide. The ability to continuously monitor emissions rather than rely on periodic sampling improves accountability and enables proactive environmental management. This capability aligns with global sustainability initiatives and environmental governance frameworks that emphasize real-time monitoring and immediate corrective actions.

The broader implications for circular economy principles are also noteworthy. By enabling precise ammonia recovery and utilization, these sensors support closed-loop industrial systems where waste streams become valuable inputs for other processes. This approach reduces overall resource consumption while minimizing environmental discharge, representing a significant step toward more sustainable industrial practices in sectors ranging from agriculture to energy production.

Real-time NRR monitoring through inline ammonia sensors promotes more efficient use of energy and resources in industrial processes. Traditional ammonia production via the Haber-Bosch process consumes approximately 1-2% of global energy and generates substantial greenhouse gas emissions. By enabling more precise reaction control, these sensors can help reduce the carbon footprint associated with ammonia production by an estimated 10-15%, according to recent industry analyses.

Water conservation represents another critical environmental benefit of inline ammonia sensing technology. Conventional ammonia monitoring often requires sample extraction and laboratory analysis, consuming significant water resources for sample preparation and equipment cleaning. Inline sensors eliminate much of this water usage while simultaneously reducing the chemical waste generated during traditional analysis procedures.

The lifecycle sustainability of the sensors themselves warrants careful consideration. Current sensor technologies often incorporate rare earth elements and specialized materials with complex supply chains and extraction impacts. Future development should prioritize sensors with reduced environmental footprints, longer operational lifespans, and recyclable components. Some promising research indicates potential for bio-based sensing elements that could dramatically reduce the environmental impact of sensor manufacturing and disposal.

From a regulatory compliance perspective, inline ammonia sensors support industries in meeting increasingly stringent environmental protection standards worldwide. The ability to continuously monitor emissions rather than rely on periodic sampling improves accountability and enables proactive environmental management. This capability aligns with global sustainability initiatives and environmental governance frameworks that emphasize real-time monitoring and immediate corrective actions.

The broader implications for circular economy principles are also noteworthy. By enabling precise ammonia recovery and utilization, these sensors support closed-loop industrial systems where waste streams become valuable inputs for other processes. This approach reduces overall resource consumption while minimizing environmental discharge, representing a significant step toward more sustainable industrial practices in sectors ranging from agriculture to energy production.

Calibration and Maintenance Requirements for Inline Sensors

Effective calibration and maintenance protocols are essential for ensuring the reliability and accuracy of inline ammonia sensors in real-time NRR (Nitrogen Removal Rate) monitoring systems. These sensors require regular calibration against standard solutions with known ammonia concentrations to maintain measurement precision. Typically, a two-point calibration method is recommended, utilizing a zero-ammonia solution and a solution with a concentration near the expected measurement range.

Calibration frequency depends on several factors including the sensor type, operating environment, and manufacturer specifications. In wastewater treatment applications, weekly calibration is often necessary, while less demanding environments may permit monthly intervals. Environmental factors such as temperature fluctuations, pH variations, and the presence of interfering compounds can significantly impact sensor performance, necessitating more frequent calibration in challenging conditions.

Maintenance requirements for inline ammonia sensors encompass both preventive and corrective measures. Regular cleaning of sensor surfaces is critical to prevent biofilm formation and fouling, which can severely compromise measurement accuracy. For optical sensors, special attention must be paid to keeping optical windows clear of deposits. Depending on the application environment, cleaning intervals may range from daily to monthly.

Sensor membranes and electrolytes in electrochemical sensors require periodic replacement, typically every 3-6 months. Manufacturers generally provide specific guidelines for replacement schedules based on operating conditions. Documentation of all maintenance activities and calibration results in a comprehensive log is essential for quality assurance and troubleshooting purposes.

Advanced inline ammonia sensors often incorporate self-diagnostic capabilities that can alert operators to potential issues before measurement accuracy is compromised. These features may include reference signal monitoring, temperature compensation, and automatic drift detection. Implementing these self-diagnostic tools can optimize maintenance schedules and reduce unnecessary interventions.

Training technical personnel in proper calibration and maintenance procedures is equally important. Staff should be thoroughly familiar with sensor principles, common failure modes, and troubleshooting techniques. This knowledge enables them to interpret calibration results correctly and make informed decisions about sensor replacement or repair.

Cost considerations for calibration and maintenance should be factored into the total cost of ownership when selecting inline ammonia sensors. While some sensors may have higher initial costs, their reduced maintenance requirements and longer calibration intervals may result in lower long-term operational expenses. Establishing a comprehensive maintenance program that balances performance requirements with resource constraints is essential for sustainable implementation of inline ammonia sensors in NRR monitoring systems.

Calibration frequency depends on several factors including the sensor type, operating environment, and manufacturer specifications. In wastewater treatment applications, weekly calibration is often necessary, while less demanding environments may permit monthly intervals. Environmental factors such as temperature fluctuations, pH variations, and the presence of interfering compounds can significantly impact sensor performance, necessitating more frequent calibration in challenging conditions.

Maintenance requirements for inline ammonia sensors encompass both preventive and corrective measures. Regular cleaning of sensor surfaces is critical to prevent biofilm formation and fouling, which can severely compromise measurement accuracy. For optical sensors, special attention must be paid to keeping optical windows clear of deposits. Depending on the application environment, cleaning intervals may range from daily to monthly.

Sensor membranes and electrolytes in electrochemical sensors require periodic replacement, typically every 3-6 months. Manufacturers generally provide specific guidelines for replacement schedules based on operating conditions. Documentation of all maintenance activities and calibration results in a comprehensive log is essential for quality assurance and troubleshooting purposes.

Advanced inline ammonia sensors often incorporate self-diagnostic capabilities that can alert operators to potential issues before measurement accuracy is compromised. These features may include reference signal monitoring, temperature compensation, and automatic drift detection. Implementing these self-diagnostic tools can optimize maintenance schedules and reduce unnecessary interventions.

Training technical personnel in proper calibration and maintenance procedures is equally important. Staff should be thoroughly familiar with sensor principles, common failure modes, and troubleshooting techniques. This knowledge enables them to interpret calibration results correctly and make informed decisions about sensor replacement or repair.

Cost considerations for calibration and maintenance should be factored into the total cost of ownership when selecting inline ammonia sensors. While some sensors may have higher initial costs, their reduced maintenance requirements and longer calibration intervals may result in lower long-term operational expenses. Establishing a comprehensive maintenance program that balances performance requirements with resource constraints is essential for sustainable implementation of inline ammonia sensors in NRR monitoring systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!