How To Transition From Lab-Scale NRR Demonstrators To Pilot Scale Reactors

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NRR Technology Evolution and Scaling Objectives

Nitrogen Reduction Reaction (NRR) technology has evolved significantly over the past decade, transitioning from theoretical concepts to laboratory demonstrations. The journey began with fundamental electrochemical studies in controlled environments, progressing through catalyst development phases that initially focused on noble metals before expanding to more sustainable alternatives like transition metal nitrides and carbon-based materials. Recent breakthroughs in ambient-condition nitrogen fixation represent a critical inflection point in NRR development, demonstrating the possibility of energy-efficient ammonia synthesis outside the traditional Haber-Bosch process parameters.

The current technological landscape shows laboratory-scale NRR systems achieving Faradaic efficiencies of 10-30% and ammonia production rates of 10^-10 to 10^-8 mol cm^-2 s^-1. While these metrics represent significant scientific achievements, they fall short of commercial viability by several orders of magnitude. The gap between laboratory performance and industrial requirements defines our primary scaling objective: developing systems that maintain or improve efficiency while increasing production volume by 100-1000x.

Scaling objectives must address multiple dimensions simultaneously. First, reactor size must increase from typical laboratory setups (1-10 cm^2 electrode area) to pilot scale (0.1-1 m^2), requiring innovations in electrode fabrication, membrane technology, and system integration. Second, operational stability must extend from hours to months, necessitating catalyst designs resistant to poisoning and degradation. Third, energy efficiency must improve to approach theoretical minimums, requiring advances in electrode architecture and reaction selectivity.

Technical objectives for the transition include standardizing performance metrics across different reactor designs to enable meaningful comparisons. Current literature shows inconsistent reporting practices that complicate technology assessment. Additionally, scaling requires developing in-situ characterization methods capable of monitoring reaction kinetics and catalyst behavior in real-time under industrial conditions, moving beyond the ex-situ analytical techniques common in laboratory settings.

The evolution pathway necessitates a multidisciplinary approach combining electrochemistry, materials science, chemical engineering, and process design. Intermediate milestones include developing modular reactor designs that facilitate the transition from laboratory to pilot scale, establishing accelerated testing protocols that can predict long-term performance, and creating digital twins that model system behavior across different operating conditions.

Success in this technological evolution will be measured not only by ammonia production rates but also by system integration metrics such as start-up/shutdown cycles, response to variable renewable energy inputs, and compatibility with existing infrastructure. The ultimate objective remains creating economically viable alternatives to the Haber-Bosch process that can operate efficiently at distributed scales using renewable electricity.

The current technological landscape shows laboratory-scale NRR systems achieving Faradaic efficiencies of 10-30% and ammonia production rates of 10^-10 to 10^-8 mol cm^-2 s^-1. While these metrics represent significant scientific achievements, they fall short of commercial viability by several orders of magnitude. The gap between laboratory performance and industrial requirements defines our primary scaling objective: developing systems that maintain or improve efficiency while increasing production volume by 100-1000x.

Scaling objectives must address multiple dimensions simultaneously. First, reactor size must increase from typical laboratory setups (1-10 cm^2 electrode area) to pilot scale (0.1-1 m^2), requiring innovations in electrode fabrication, membrane technology, and system integration. Second, operational stability must extend from hours to months, necessitating catalyst designs resistant to poisoning and degradation. Third, energy efficiency must improve to approach theoretical minimums, requiring advances in electrode architecture and reaction selectivity.

Technical objectives for the transition include standardizing performance metrics across different reactor designs to enable meaningful comparisons. Current literature shows inconsistent reporting practices that complicate technology assessment. Additionally, scaling requires developing in-situ characterization methods capable of monitoring reaction kinetics and catalyst behavior in real-time under industrial conditions, moving beyond the ex-situ analytical techniques common in laboratory settings.

The evolution pathway necessitates a multidisciplinary approach combining electrochemistry, materials science, chemical engineering, and process design. Intermediate milestones include developing modular reactor designs that facilitate the transition from laboratory to pilot scale, establishing accelerated testing protocols that can predict long-term performance, and creating digital twins that model system behavior across different operating conditions.

Success in this technological evolution will be measured not only by ammonia production rates but also by system integration metrics such as start-up/shutdown cycles, response to variable renewable energy inputs, and compatibility with existing infrastructure. The ultimate objective remains creating economically viable alternatives to the Haber-Bosch process that can operate efficiently at distributed scales using renewable electricity.

Market Analysis for Industrial-Scale Nitrogen Reduction

The global market for industrial-scale nitrogen reduction technologies is experiencing significant growth, driven by increasing demand for sustainable ammonia production methods. Traditional ammonia synthesis via the Haber-Bosch process consumes approximately 1-2% of global energy production and generates substantial CO2 emissions. This creates a compelling market opportunity for electrochemical nitrogen reduction reaction (NRR) technologies that can operate at ambient conditions with renewable electricity.

Current market projections indicate the green ammonia market could reach $7.8 billion by 2030, growing at a CAGR of 72.9% from 2021. This rapid expansion is fueled by increasing governmental regulations on carbon emissions, rising fertilizer demand to support global food security, and growing interest in ammonia as a carbon-free energy carrier and hydrogen storage medium.

Key market segments for industrial-scale NRR include agricultural fertilizer production, which accounts for approximately 80% of current ammonia usage, chemical manufacturing, and emerging applications in clean energy storage. Geographically, initial market penetration is expected in regions with strong renewable energy infrastructure and stringent carbon regulations, particularly in Europe, North America, and parts of Asia.

The economic viability of NRR technologies depends critically on achieving competitive production costs. Current estimates suggest electrochemical ammonia production costs need to fall below $450-500 per ton to compete with conventional methods. This represents a significant challenge as laboratory-scale demonstrations typically operate at costs several times higher.

Market analysis reveals strong interest from both established chemical companies seeking to decarbonize their operations and startups focused exclusively on green ammonia production. Major industrial players including BASF, Yara, and CF Industries have announced investments in pilot-scale electrochemical ammonia synthesis projects, signaling industry confidence in the technology's future commercial potential.

Customer requirements for industrial adoption center on four key metrics: energy efficiency (targeting <10 MWh/ton NH3), capital expenditure (<$1,000/ton annual capacity), catalyst durability (>5,000 hours operation), and nitrogen conversion rates (>10%). Current laboratory demonstrations typically achieve only one or two of these metrics simultaneously, highlighting the technical gap that must be bridged for successful market entry.

The market timing appears favorable, with increasing policy support for green chemical production and rising carbon prices improving the economic case for alternative synthesis routes. However, widespread adoption will likely follow a phased approach, beginning with premium niche applications before expanding to mainstream fertilizer production as technology matures and economies of scale are realized.

Current market projections indicate the green ammonia market could reach $7.8 billion by 2030, growing at a CAGR of 72.9% from 2021. This rapid expansion is fueled by increasing governmental regulations on carbon emissions, rising fertilizer demand to support global food security, and growing interest in ammonia as a carbon-free energy carrier and hydrogen storage medium.

Key market segments for industrial-scale NRR include agricultural fertilizer production, which accounts for approximately 80% of current ammonia usage, chemical manufacturing, and emerging applications in clean energy storage. Geographically, initial market penetration is expected in regions with strong renewable energy infrastructure and stringent carbon regulations, particularly in Europe, North America, and parts of Asia.

The economic viability of NRR technologies depends critically on achieving competitive production costs. Current estimates suggest electrochemical ammonia production costs need to fall below $450-500 per ton to compete with conventional methods. This represents a significant challenge as laboratory-scale demonstrations typically operate at costs several times higher.

Market analysis reveals strong interest from both established chemical companies seeking to decarbonize their operations and startups focused exclusively on green ammonia production. Major industrial players including BASF, Yara, and CF Industries have announced investments in pilot-scale electrochemical ammonia synthesis projects, signaling industry confidence in the technology's future commercial potential.

Customer requirements for industrial adoption center on four key metrics: energy efficiency (targeting <10 MWh/ton NH3), capital expenditure (<$1,000/ton annual capacity), catalyst durability (>5,000 hours operation), and nitrogen conversion rates (>10%). Current laboratory demonstrations typically achieve only one or two of these metrics simultaneously, highlighting the technical gap that must be bridged for successful market entry.

The market timing appears favorable, with increasing policy support for green chemical production and rising carbon prices improving the economic case for alternative synthesis routes. However, widespread adoption will likely follow a phased approach, beginning with premium niche applications before expanding to mainstream fertilizer production as technology matures and economies of scale are realized.

Current Challenges in NRR Scale-up

The transition from laboratory-scale Nitrogen Reduction Reaction (NRR) demonstrators to pilot-scale reactors faces significant technical hurdles that must be addressed systematically. Current lab-scale NRR systems typically operate at capacities of less than 1 gram of ammonia per day, while commercially viable systems would need to produce at least several kilograms daily. This scaling gap represents a critical challenge in the development pathway.

One of the primary obstacles is maintaining catalytic performance during scale-up. Laboratory catalysts often show promising nitrogen fixation rates and selectivity under controlled conditions, but these metrics frequently deteriorate when implemented in larger systems. This degradation stems from non-uniform reaction environments, catalyst deactivation mechanisms, and mass transport limitations that become more pronounced at larger scales.

Energy efficiency presents another substantial barrier. Current lab-scale NRR demonstrations typically operate at Faradaic efficiencies below 30%, with many systems achieving less than 10%. These efficiencies must be dramatically improved for pilot-scale operations, as energy consumption represents a major component of operational costs. The theoretical minimum energy requirement for electrochemical ammonia synthesis is approximately 20 kWh/kg NH₃, but most laboratory systems currently operate at over 100 kWh/kg NH₃.

Reactor design complexity increases exponentially with scale. Larger systems must address heat management, pressure distribution, electrode stability, and membrane durability simultaneously. The integration of these components while maintaining optimal reaction conditions becomes increasingly difficult as dimensions increase. Current reactor designs often fail to account for these scaling factors, resulting in performance bottlenecks.

Feedstock purity and delivery systems represent another significant challenge. Laboratory setups typically utilize high-purity nitrogen sources and carefully controlled electrolytes. Pilot-scale operations must function with more economical inputs while maintaining performance, requiring robust purification systems and more sophisticated feed management strategies.

Stability and durability issues become more pronounced at larger scales. While laboratory demonstrations may operate for hours or days, commercial viability demands continuous operation for months. Current catalyst systems and reactor components show significant degradation over extended operation periods, with performance losses of 30-50% after just 100 hours of operation being common in research literature.

Process control and monitoring systems must also evolve substantially. Laboratory setups typically employ extensive analytical equipment that cannot be practically implemented at larger scales. Developing reliable, cost-effective monitoring solutions for real-time performance assessment represents a critical gap in current technology development efforts.

One of the primary obstacles is maintaining catalytic performance during scale-up. Laboratory catalysts often show promising nitrogen fixation rates and selectivity under controlled conditions, but these metrics frequently deteriorate when implemented in larger systems. This degradation stems from non-uniform reaction environments, catalyst deactivation mechanisms, and mass transport limitations that become more pronounced at larger scales.

Energy efficiency presents another substantial barrier. Current lab-scale NRR demonstrations typically operate at Faradaic efficiencies below 30%, with many systems achieving less than 10%. These efficiencies must be dramatically improved for pilot-scale operations, as energy consumption represents a major component of operational costs. The theoretical minimum energy requirement for electrochemical ammonia synthesis is approximately 20 kWh/kg NH₃, but most laboratory systems currently operate at over 100 kWh/kg NH₃.

Reactor design complexity increases exponentially with scale. Larger systems must address heat management, pressure distribution, electrode stability, and membrane durability simultaneously. The integration of these components while maintaining optimal reaction conditions becomes increasingly difficult as dimensions increase. Current reactor designs often fail to account for these scaling factors, resulting in performance bottlenecks.

Feedstock purity and delivery systems represent another significant challenge. Laboratory setups typically utilize high-purity nitrogen sources and carefully controlled electrolytes. Pilot-scale operations must function with more economical inputs while maintaining performance, requiring robust purification systems and more sophisticated feed management strategies.

Stability and durability issues become more pronounced at larger scales. While laboratory demonstrations may operate for hours or days, commercial viability demands continuous operation for months. Current catalyst systems and reactor components show significant degradation over extended operation periods, with performance losses of 30-50% after just 100 hours of operation being common in research literature.

Process control and monitoring systems must also evolve substantially. Laboratory setups typically employ extensive analytical equipment that cannot be practically implemented at larger scales. Developing reliable, cost-effective monitoring solutions for real-time performance assessment represents a critical gap in current technology development efforts.

Existing Scale-up Methodologies for NRR Systems

01 Reactor design for NRR scale-up

Specialized reactor designs are crucial for scaling up nitrogen reduction reactions from laboratory to industrial scale. These designs focus on optimizing reaction chambers, flow dynamics, and catalyst bed configurations to maintain efficiency during scale transition. Key considerations include heat and mass transfer characteristics, pressure distribution, and residence time control to ensure consistent performance across different scales.- Reactor design for nitrogen reduction reaction scale-up: Various reactor designs have been developed to facilitate the scale-up of nitrogen reduction reaction (NRR) processes. These designs focus on optimizing reaction conditions, improving catalyst distribution, and enhancing mass transfer to maintain efficiency at larger scales. Key considerations include reactor geometry, flow patterns, and heat management systems that allow for consistent performance when transitioning from laboratory to industrial scale.

- Catalyst systems for industrial-scale NRR applications: Advanced catalyst systems are crucial for successful scale transition in NRR reactors. These catalysts are designed to maintain high activity and selectivity at industrial scales while minimizing degradation over extended operation periods. Innovations include supported metal catalysts, nanostructured materials, and composite systems that can withstand the rigorous conditions of large-scale nitrogen reduction processes while maintaining high conversion efficiency.

- Process control and monitoring systems for scaled-up NRR: Sophisticated process control and monitoring systems are essential for managing NRR reactors during scale transition. These systems include advanced sensors, real-time analytics, and automated control mechanisms that maintain optimal reaction conditions across larger reactor volumes. By continuously monitoring parameters such as temperature, pressure, and reactant concentrations, these systems ensure consistent performance and product quality in scaled-up operations.

- Energy efficiency improvements for large-scale NRR reactors: Energy efficiency is a critical factor in the successful scale-up of NRR reactors. Innovations in this area include heat recovery systems, optimized electrical input for electrocatalytic processes, and improved reactor insulation. These advancements reduce the energy requirements per unit of ammonia or nitrogen-based products produced, making large-scale NRR processes more economically viable and environmentally sustainable.

- Integration of NRR reactors with renewable energy sources: The integration of NRR reactors with renewable energy sources represents an important advancement in scale transition. These systems couple nitrogen reduction processes with intermittent renewable energy inputs such as solar or wind power, often incorporating energy storage solutions to manage variability. This integration enables more sustainable large-scale nitrogen fixation while addressing challenges related to the high energy demands of traditional ammonia synthesis methods.

02 Catalyst systems for industrial-scale NRR

Advanced catalyst systems are developed specifically for large-scale nitrogen reduction reactions. These catalysts are designed to maintain high activity and selectivity while offering improved stability and longevity under industrial conditions. Innovations include supported nanostructured catalysts, hierarchical catalyst architectures, and novel compositions that minimize deactivation during extended operation periods.Expand Specific Solutions03 Process control and optimization for scaled NRR systems

Sophisticated process control strategies are essential when transitioning NRR technology to larger scales. These include advanced monitoring systems, feedback control loops, and predictive modeling to maintain optimal reaction conditions. Parameters such as temperature profiles, reactant ratios, and flow rates must be precisely controlled to maximize nitrogen conversion efficiency while minimizing energy consumption and byproduct formation.Expand Specific Solutions04 Energy efficiency improvements for commercial NRR

Energy optimization is critical for economically viable large-scale nitrogen reduction processes. Innovations focus on reducing the high energy demands traditionally associated with nitrogen fixation through improved reactor thermal management, energy recovery systems, and alternative energy inputs. These developments include renewable energy integration, electrochemical approaches, and novel heating methods that significantly lower the carbon footprint of industrial NRR operations.Expand Specific Solutions05 Modular and continuous flow systems for NRR scale transition

Modular and continuous flow technologies facilitate smoother scale transition for nitrogen reduction reactions. These systems employ standardized reactor units that can be multiplied or enlarged while maintaining performance characteristics. Continuous processing eliminates batch-to-batch variations and improves throughput, while modular designs allow for incremental capacity expansion and simplified maintenance. This approach bridges the gap between laboratory development and full industrial implementation.Expand Specific Solutions

Leading Organizations in NRR Research and Commercialization

The nitrogen reduction reaction (NRR) technology landscape is currently transitioning from early-stage development to commercial viability, with significant challenges in scaling from laboratory demonstrations to pilot reactors. The market, though nascent, shows promising growth potential as sustainable ammonia production becomes increasingly critical for decarbonization efforts. Technical maturity varies considerably among key players: academic institutions like Zhejiang University and Technical University of Denmark lead fundamental research, while industrial entities including ExxonMobil, Caterpillar, and TerraPower are advancing practical applications. Established chemical companies such as Bayer Technology Services and Covestro Deutschland possess valuable process engineering expertise essential for scale-up. The competitive landscape reflects a collaborative ecosystem where partnerships between research institutions and industrial players are accelerating the technology's progression toward commercial implementation.

hte AG the high throughput experimentation Co.

Technical Solution: hte AG has developed a specialized methodology for accelerating the transition of NRR (Novel Reaction Research) technologies from laboratory to pilot scale through their "Parallel Scale-up" approach. Their framework centers on the simultaneous testing of multiple reaction parameters across different scales, utilizing proprietary high-throughput testing platforms that can evaluate hundreds of reaction conditions in parallel. hte's methodology begins with miniaturized reactor arrays that establish fundamental performance parameters, followed by progressive scale-up through their modular "Scale-X" reactor systems that maintain geometric and process similarities across different size regimes. A key innovation in their approach is the development of specialized catalyst characterization techniques that can be applied consistently from milligram to kilogram scales, ensuring performance metrics remain comparable throughout the scaling process. hte has pioneered advanced statistical design of experiments (DoE) methodologies specifically optimized for reaction scale-up, significantly reducing the number of experiments required to establish robust operating parameters. Their approach incorporates extensive use of in-situ spectroscopic monitoring techniques that provide real-time performance data across different reactor scales, enabling rapid identification of scale-dependent phenomena.

Strengths: Unparalleled high-throughput testing capabilities enable rapid evaluation of multiple scale-up parameters simultaneously; Specialized data analytics platforms efficiently process large experimental datasets to identify optimal conditions; Extensive experience across multiple reaction classes provides broad applicability. Weaknesses: Service-oriented business model may limit depth of engagement with any single technology; Focus on catalyst performance may not address all aspects of reactor engineering required for full-scale implementation; Relatively small company size may limit resources for very large-scale demonstrations.

AREVA GmbH

Technical Solution: AREVA (now part of Framatome) has developed a systematic methodology for transitioning NRR technologies from laboratory to pilot scale through their "Progressive Scale-up Framework." This approach begins with fundamental phenomenon testing in laboratory environments, followed by separate effects testing that isolates key components for detailed characterization. Their framework emphasizes the development of specialized scaling laws that maintain critical physical relationships while transitioning between different size regimes. AREVA's methodology incorporates extensive use of computational fluid dynamics (CFD) and multi-physics modeling to predict performance at larger scales, with validation occurring at each transition point. A key innovation in their approach is the development of "hybrid testing platforms" that combine physical components with real-time simulation to evaluate integrated system performance before committing to full-scale construction. Their ANTARES project demonstrated this methodology by successfully scaling high-temperature gas reactor technology through progressive test facilities before moving to demonstration scale. AREVA has also pioneered specialized instrumentation systems that can be deployed across different scale facilities, ensuring consistent measurement methodologies throughout the development process.

Strengths: Extensive experience with multiple reactor technologies provides broad applicability of scaling methodologies; Strong integration between computational modeling and physical testing reduces development iterations; Established relationships with regulatory bodies facilitate approval processes. Weaknesses: Complex organizational structure following corporate restructuring can slow decision-making processes; High capital requirements for intermediate test facilities create financial barriers; European regulatory focus may require adaptation for global deployment.

Critical Patents and Breakthroughs in NRR Scale-up

Nitrate removal

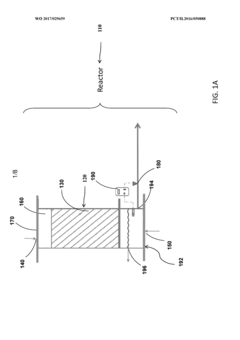

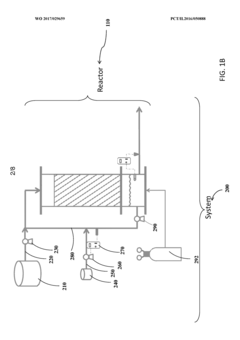

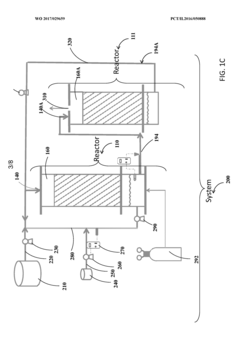

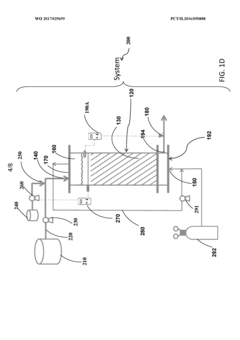

PatentWO2017029659A1

Innovation

- A reactor design with a container for denitrifying bacterial biofilm growth, a gas inlet for hydrogen delivery, and a headspace sealed to the atmosphere, allowing for efficient hydrogen utilization and increased surface area for biofilm growth, coupled with a system for recirculating water and gas to enhance denitrification rates.

Economic Feasibility Assessment

The economic feasibility of transitioning from laboratory-scale Nitrogen Reduction Reaction (NRR) demonstrators to pilot-scale reactors represents a critical consideration for stakeholders in this emerging technology sector. Current cost analyses indicate that lab-scale NRR systems operate at significantly higher production costs compared to conventional Haber-Bosch processes, with estimates ranging from $3,000 to $15,000 per ton of ammonia versus $400-600 for industrial production.

Capital expenditure requirements for pilot-scale NRR facilities present substantial financial barriers. Initial investment for a modest pilot plant (producing 1-5 tons of ammonia daily) typically ranges between $5-15 million, encompassing reactor systems, catalysts, separation equipment, and control infrastructure. These figures vary considerably based on the specific NRR technology pathway selected, with electrochemical approaches generally requiring lower initial investment than photocatalytic or plasma-assisted methods.

Operational expenditures constitute another significant economic consideration. Energy consumption remains particularly challenging, with most lab-scale NRR demonstrations exhibiting energy efficiencies below 10%, translating to electricity costs of $1,200-2,500 per ton of ammonia at industrial electricity rates. Catalyst costs and replacement schedules further impact operational economics, especially for precious metal-based systems that may require replacement every 3-6 months under continuous operation.

Scale-up economics demonstrate potential for significant cost reductions through economies of scale. Modeling suggests that increasing production capacity from laboratory (grams per day) to pilot scale (tons per day) could reduce unit production costs by 60-75%, primarily through improved energy efficiency and reduced labor costs per unit output. However, these projections remain theoretical until validated through actual pilot operations.

Return on investment timelines present challenges for commercial adoption. Even with optimistic performance improvements, financial models indicate payback periods of 7-12 years for pilot facilities without substantial policy support or premium pricing for "green ammonia." This timeline exceeds typical industrial investment thresholds of 3-5 years, necessitating strategic partnerships or public funding to bridge the commercialization gap.

Sensitivity analysis reveals that electricity costs and catalyst performance (particularly Faradaic efficiency and stability) represent the most influential variables affecting economic viability. A 20% improvement in either parameter could reduce production costs by approximately 15-25%, highlighting priority areas for technological advancement to achieve commercial feasibility in the transition from laboratory to pilot scale operations.

Capital expenditure requirements for pilot-scale NRR facilities present substantial financial barriers. Initial investment for a modest pilot plant (producing 1-5 tons of ammonia daily) typically ranges between $5-15 million, encompassing reactor systems, catalysts, separation equipment, and control infrastructure. These figures vary considerably based on the specific NRR technology pathway selected, with electrochemical approaches generally requiring lower initial investment than photocatalytic or plasma-assisted methods.

Operational expenditures constitute another significant economic consideration. Energy consumption remains particularly challenging, with most lab-scale NRR demonstrations exhibiting energy efficiencies below 10%, translating to electricity costs of $1,200-2,500 per ton of ammonia at industrial electricity rates. Catalyst costs and replacement schedules further impact operational economics, especially for precious metal-based systems that may require replacement every 3-6 months under continuous operation.

Scale-up economics demonstrate potential for significant cost reductions through economies of scale. Modeling suggests that increasing production capacity from laboratory (grams per day) to pilot scale (tons per day) could reduce unit production costs by 60-75%, primarily through improved energy efficiency and reduced labor costs per unit output. However, these projections remain theoretical until validated through actual pilot operations.

Return on investment timelines present challenges for commercial adoption. Even with optimistic performance improvements, financial models indicate payback periods of 7-12 years for pilot facilities without substantial policy support or premium pricing for "green ammonia." This timeline exceeds typical industrial investment thresholds of 3-5 years, necessitating strategic partnerships or public funding to bridge the commercialization gap.

Sensitivity analysis reveals that electricity costs and catalyst performance (particularly Faradaic efficiency and stability) represent the most influential variables affecting economic viability. A 20% improvement in either parameter could reduce production costs by approximately 15-25%, highlighting priority areas for technological advancement to achieve commercial feasibility in the transition from laboratory to pilot scale operations.

Environmental Impact and Sustainability Considerations

The transition from laboratory-scale Nitrogen Reduction Reaction (NRR) demonstrators to pilot-scale reactors necessitates comprehensive consideration of environmental impacts and sustainability factors. Current ammonia production via the Haber-Bosch process consumes approximately 1-2% of global energy and generates significant greenhouse gas emissions. NRR technology offers a promising alternative with potentially lower environmental footprints, particularly when powered by renewable energy sources.

Life cycle assessment (LCA) studies indicate that electrochemical NRR systems could reduce carbon emissions by 30-60% compared to conventional ammonia production methods, depending on the electricity source. When powered by solar or wind energy, these systems approach carbon neutrality, representing a significant advancement in sustainable chemical manufacturing. However, full environmental benefit realization requires careful management of catalyst materials, many of which contain precious or rare earth metals.

Water consumption presents another critical environmental consideration. While electrochemical NRR processes generally require less water than traditional methods, the water used must be highly purified, which introduces additional energy demands and potential waste streams. Innovative water recycling systems integrated into pilot-scale reactors could minimize this impact, potentially reducing freshwater requirements by up to 80% compared to conventional systems.

Waste management strategies must address spent catalysts, membrane materials, and electrolytes. Recent research demonstrates promising recycling pathways for platinum-group catalysts with recovery rates exceeding 90%, significantly reducing the environmental burden of these materials. Additionally, membrane regeneration techniques have advanced considerably, extending operational lifetimes from months to several years in laboratory settings.

Land use impacts vary significantly between centralized and distributed production models. Distributed NRR systems could reduce transportation-related emissions by 15-25% by enabling localized ammonia production near agricultural centers. This approach aligns with circular economy principles, particularly when integrated with existing renewable energy infrastructure.

Regulatory frameworks will play a decisive role in the environmental performance of scaled NRR technologies. Early engagement with environmental protection agencies and sustainability certification bodies can help establish appropriate standards for this emerging technology. Several pilot projects in Europe and Asia have already begun implementing environmental management systems that exceed current regulatory requirements, setting promising precedents for the industry.

The transition to pilot scale also presents opportunities to incorporate environmental monitoring systems that provide real-time data on emissions, resource consumption, and process efficiency. These systems not only ensure compliance but enable continuous improvement of environmental performance as the technology matures toward commercial deployment.

Life cycle assessment (LCA) studies indicate that electrochemical NRR systems could reduce carbon emissions by 30-60% compared to conventional ammonia production methods, depending on the electricity source. When powered by solar or wind energy, these systems approach carbon neutrality, representing a significant advancement in sustainable chemical manufacturing. However, full environmental benefit realization requires careful management of catalyst materials, many of which contain precious or rare earth metals.

Water consumption presents another critical environmental consideration. While electrochemical NRR processes generally require less water than traditional methods, the water used must be highly purified, which introduces additional energy demands and potential waste streams. Innovative water recycling systems integrated into pilot-scale reactors could minimize this impact, potentially reducing freshwater requirements by up to 80% compared to conventional systems.

Waste management strategies must address spent catalysts, membrane materials, and electrolytes. Recent research demonstrates promising recycling pathways for platinum-group catalysts with recovery rates exceeding 90%, significantly reducing the environmental burden of these materials. Additionally, membrane regeneration techniques have advanced considerably, extending operational lifetimes from months to several years in laboratory settings.

Land use impacts vary significantly between centralized and distributed production models. Distributed NRR systems could reduce transportation-related emissions by 15-25% by enabling localized ammonia production near agricultural centers. This approach aligns with circular economy principles, particularly when integrated with existing renewable energy infrastructure.

Regulatory frameworks will play a decisive role in the environmental performance of scaled NRR technologies. Early engagement with environmental protection agencies and sustainability certification bodies can help establish appropriate standards for this emerging technology. Several pilot projects in Europe and Asia have already begun implementing environmental management systems that exceed current regulatory requirements, setting promising precedents for the industry.

The transition to pilot scale also presents opportunities to incorporate environmental monitoring systems that provide real-time data on emissions, resource consumption, and process efficiency. These systems not only ensure compliance but enable continuous improvement of environmental performance as the technology matures toward commercial deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!