How to Implement Reduction Methods for Coil Whine in Audio Equipment?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Reduction Background and Objectives

Coil whine, a persistent challenge in audio equipment manufacturing, has been a focus of research and development efforts for decades. This high-frequency noise, typically ranging from 1 kHz to 20 kHz, is caused by electromagnetic forces acting on the windings of transformers, inductors, or other magnetic components. The phenomenon has become increasingly prominent as electronic devices have become more compact and powerful, leading to higher switching frequencies and greater power densities.

The primary objective of coil whine reduction methods is to minimize or eliminate this audible noise without compromising the performance or efficiency of the audio equipment. This goal aligns with the broader industry trend towards creating high-fidelity audio experiences while maintaining energy efficiency and compact form factors. As consumer expectations for audio quality continue to rise, addressing coil whine has become a critical factor in product differentiation and market success.

The evolution of coil whine reduction techniques has been closely tied to advancements in materials science, electromagnetic design, and signal processing. Early approaches focused primarily on mechanical solutions, such as improved winding techniques and the use of damping materials. However, as the understanding of the underlying physics has grown, more sophisticated methods have emerged, including active noise cancellation and advanced circuit design strategies.

Recent technological developments have opened up new avenues for coil whine reduction. The integration of digital signal processing (DSP) in audio equipment has enabled real-time monitoring and adaptive noise suppression. Additionally, the advent of wide-bandgap semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC), has allowed for higher switching frequencies and more efficient power conversion, potentially reducing the conditions that lead to coil whine.

The pursuit of effective coil whine reduction methods intersects with several other key trends in audio technology, including the push for higher power output in smaller devices, the demand for extended battery life in portable audio equipment, and the growing market for high-resolution audio formats. As such, innovations in this area have the potential to impact a wide range of audio products, from consumer-grade headphones to professional studio monitors and high-end home audio systems.

Looking ahead, the objectives for coil whine reduction extend beyond mere noise suppression. Future solutions will need to address the root causes of the phenomenon, potentially revolutionizing the design of magnetic components and power supply circuits. There is also a growing emphasis on developing predictive models and simulation tools to anticipate and mitigate coil whine issues early in the product design phase, reducing time-to-market and development costs for audio equipment manufacturers.

The primary objective of coil whine reduction methods is to minimize or eliminate this audible noise without compromising the performance or efficiency of the audio equipment. This goal aligns with the broader industry trend towards creating high-fidelity audio experiences while maintaining energy efficiency and compact form factors. As consumer expectations for audio quality continue to rise, addressing coil whine has become a critical factor in product differentiation and market success.

The evolution of coil whine reduction techniques has been closely tied to advancements in materials science, electromagnetic design, and signal processing. Early approaches focused primarily on mechanical solutions, such as improved winding techniques and the use of damping materials. However, as the understanding of the underlying physics has grown, more sophisticated methods have emerged, including active noise cancellation and advanced circuit design strategies.

Recent technological developments have opened up new avenues for coil whine reduction. The integration of digital signal processing (DSP) in audio equipment has enabled real-time monitoring and adaptive noise suppression. Additionally, the advent of wide-bandgap semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC), has allowed for higher switching frequencies and more efficient power conversion, potentially reducing the conditions that lead to coil whine.

The pursuit of effective coil whine reduction methods intersects with several other key trends in audio technology, including the push for higher power output in smaller devices, the demand for extended battery life in portable audio equipment, and the growing market for high-resolution audio formats. As such, innovations in this area have the potential to impact a wide range of audio products, from consumer-grade headphones to professional studio monitors and high-end home audio systems.

Looking ahead, the objectives for coil whine reduction extend beyond mere noise suppression. Future solutions will need to address the root causes of the phenomenon, potentially revolutionizing the design of magnetic components and power supply circuits. There is also a growing emphasis on developing predictive models and simulation tools to anticipate and mitigate coil whine issues early in the product design phase, reducing time-to-market and development costs for audio equipment manufacturers.

Audio Equipment Market Demand Analysis

The audio equipment market has experienced significant growth in recent years, driven by increasing consumer demand for high-quality sound experiences across various applications. This demand extends from professional audio systems to consumer electronics, including home theater systems, portable speakers, and headphones. The global audio equipment market was valued at approximately $30 billion in 2020 and is projected to reach $50 billion by 2026, growing at a CAGR of around 8% during the forecast period.

One of the key factors driving market growth is the rising popularity of smart speakers and voice-controlled devices. These products have gained traction due to their convenience and integration with smart home ecosystems. Additionally, the increasing adoption of wireless audio devices, such as Bluetooth headphones and true wireless stereo (TWS) earbuds, has contributed significantly to market expansion.

The professional audio segment, including equipment for live performances, recording studios, and broadcast applications, has also shown steady growth. This is partly attributed to the increasing number of live events, concerts, and music festivals worldwide, as well as the growing demand for high-quality audio production in the entertainment industry.

In recent years, there has been a notable shift towards premium audio products, with consumers willing to invest in higher-quality sound experiences. This trend has led to increased demand for audiophile-grade equipment and high-end audio systems, driving innovation in audio technology and materials.

The COVID-19 pandemic has had a mixed impact on the audio equipment market. While it initially caused disruptions in supply chains and reduced consumer spending, it also led to increased demand for home entertainment systems and personal audio devices as people spent more time at home. This shift in consumer behavior has accelerated the adoption of smart home audio solutions and high-quality headphones for remote work and entertainment purposes.

Looking ahead, emerging technologies such as 3D audio, spatial sound, and AI-enhanced audio processing are expected to shape the future of the audio equipment market. These advancements promise to deliver more immersive and personalized audio experiences, potentially opening new market segments and driving further innovation in the industry.

However, challenges such as audio quality issues, including coil whine, remain significant concerns for manufacturers and consumers alike. Addressing these technical challenges is crucial for maintaining product quality and meeting the increasing expectations of discerning audio enthusiasts. As such, the development of effective reduction methods for coil whine in audio equipment represents a key area of focus for industry players seeking to enhance their competitive edge in this growing market.

One of the key factors driving market growth is the rising popularity of smart speakers and voice-controlled devices. These products have gained traction due to their convenience and integration with smart home ecosystems. Additionally, the increasing adoption of wireless audio devices, such as Bluetooth headphones and true wireless stereo (TWS) earbuds, has contributed significantly to market expansion.

The professional audio segment, including equipment for live performances, recording studios, and broadcast applications, has also shown steady growth. This is partly attributed to the increasing number of live events, concerts, and music festivals worldwide, as well as the growing demand for high-quality audio production in the entertainment industry.

In recent years, there has been a notable shift towards premium audio products, with consumers willing to invest in higher-quality sound experiences. This trend has led to increased demand for audiophile-grade equipment and high-end audio systems, driving innovation in audio technology and materials.

The COVID-19 pandemic has had a mixed impact on the audio equipment market. While it initially caused disruptions in supply chains and reduced consumer spending, it also led to increased demand for home entertainment systems and personal audio devices as people spent more time at home. This shift in consumer behavior has accelerated the adoption of smart home audio solutions and high-quality headphones for remote work and entertainment purposes.

Looking ahead, emerging technologies such as 3D audio, spatial sound, and AI-enhanced audio processing are expected to shape the future of the audio equipment market. These advancements promise to deliver more immersive and personalized audio experiences, potentially opening new market segments and driving further innovation in the industry.

However, challenges such as audio quality issues, including coil whine, remain significant concerns for manufacturers and consumers alike. Addressing these technical challenges is crucial for maintaining product quality and meeting the increasing expectations of discerning audio enthusiasts. As such, the development of effective reduction methods for coil whine in audio equipment represents a key area of focus for industry players seeking to enhance their competitive edge in this growing market.

Current Challenges in Coil Whine Mitigation

Coil whine remains a persistent challenge in audio equipment, presenting significant obstacles for manufacturers and engineers striving to deliver high-quality sound experiences. One of the primary difficulties lies in the inherent nature of coil whine itself, which stems from electromagnetic forces causing physical vibrations in electronic components. These vibrations, often occurring at frequencies within the audible range, can produce unwanted noise that compromises audio fidelity.

The complexity of modern audio systems exacerbates this issue. As devices become more compact and powerful, the proximity of components increases, leading to greater potential for electromagnetic interference and resonance. This miniaturization trend makes it increasingly challenging to isolate and dampen vibrations effectively, requiring innovative approaches to component layout and shielding.

Another significant hurdle is the variability of coil whine across different units of the same product model. Due to manufacturing tolerances and slight differences in component characteristics, the intensity and frequency of coil whine can vary substantially between otherwise identical devices. This inconsistency makes it difficult to implement a one-size-fits-all solution, necessitating more adaptive and robust mitigation strategies.

The cost-effectiveness of coil whine reduction methods poses another challenge. High-end solutions, such as using premium components or advanced dampening materials, can significantly increase production costs, potentially pricing products out of their target market segments. Balancing performance improvements against cost considerations remains a delicate task for manufacturers.

Environmental factors further complicate coil whine mitigation efforts. Temperature fluctuations, humidity, and even atmospheric pressure can influence the behavior of electronic components, potentially exacerbating or altering coil whine characteristics over time. Designing solutions that remain effective across a wide range of operating conditions adds another layer of complexity to the problem.

The dynamic nature of audio signals presents an additional challenge. Coil whine can vary in intensity and frequency depending on the audio content being processed, making it difficult to implement static reduction methods. Solutions must be capable of adapting to changing signal characteristics in real-time without introducing latency or distortion to the audio output.

Regulatory compliance and electromagnetic compatibility (EMC) standards introduce further constraints on potential solutions. Mitigation techniques must not only effectively reduce coil whine but also ensure that the equipment meets stringent EMC requirements, limiting the range of available interventions.

As the audio industry continues to evolve, with trends towards higher resolution audio and more powerful processing capabilities, the challenges associated with coil whine mitigation are likely to persist and potentially intensify. Addressing these multifaceted issues requires a comprehensive approach that combines innovative engineering, material science, and signal processing techniques.

The complexity of modern audio systems exacerbates this issue. As devices become more compact and powerful, the proximity of components increases, leading to greater potential for electromagnetic interference and resonance. This miniaturization trend makes it increasingly challenging to isolate and dampen vibrations effectively, requiring innovative approaches to component layout and shielding.

Another significant hurdle is the variability of coil whine across different units of the same product model. Due to manufacturing tolerances and slight differences in component characteristics, the intensity and frequency of coil whine can vary substantially between otherwise identical devices. This inconsistency makes it difficult to implement a one-size-fits-all solution, necessitating more adaptive and robust mitigation strategies.

The cost-effectiveness of coil whine reduction methods poses another challenge. High-end solutions, such as using premium components or advanced dampening materials, can significantly increase production costs, potentially pricing products out of their target market segments. Balancing performance improvements against cost considerations remains a delicate task for manufacturers.

Environmental factors further complicate coil whine mitigation efforts. Temperature fluctuations, humidity, and even atmospheric pressure can influence the behavior of electronic components, potentially exacerbating or altering coil whine characteristics over time. Designing solutions that remain effective across a wide range of operating conditions adds another layer of complexity to the problem.

The dynamic nature of audio signals presents an additional challenge. Coil whine can vary in intensity and frequency depending on the audio content being processed, making it difficult to implement static reduction methods. Solutions must be capable of adapting to changing signal characteristics in real-time without introducing latency or distortion to the audio output.

Regulatory compliance and electromagnetic compatibility (EMC) standards introduce further constraints on potential solutions. Mitigation techniques must not only effectively reduce coil whine but also ensure that the equipment meets stringent EMC requirements, limiting the range of available interventions.

As the audio industry continues to evolve, with trends towards higher resolution audio and more powerful processing capabilities, the challenges associated with coil whine mitigation are likely to persist and potentially intensify. Addressing these multifaceted issues requires a comprehensive approach that combines innovative engineering, material science, and signal processing techniques.

Existing Coil Whine Reduction Methods

01 Electromagnetic shielding techniques

Implementing electromagnetic shielding techniques can help reduce coil whine by containing electromagnetic interference. This may involve using conductive materials or specialized coatings to encapsulate the coil or surrounding components, effectively blocking the transmission of high-frequency noise.- Electromagnetic shielding techniques: Implementing electromagnetic shielding techniques can effectively reduce coil whine. This involves using materials or structures that block electromagnetic interference, such as metal enclosures or specialized coatings. By containing the electromagnetic fields generated by the coils, the audible noise can be significantly reduced.

- Vibration dampening and isolation: Employing vibration dampening and isolation methods can minimize coil whine. This includes using rubber or silicone mounts, foam padding, or other shock-absorbing materials to isolate the coils from the surrounding structure. By reducing mechanical vibrations, the audible noise associated with coil whine can be decreased.

- Coil design optimization: Optimizing the design of the coils themselves can help reduce whine. This may involve adjusting the coil winding pattern, using different core materials, or modifying the coil geometry. By optimizing the coil design, the electromagnetic forces that cause vibrations can be minimized, resulting in reduced noise.

- Active noise cancellation: Implementing active noise cancellation techniques can counteract coil whine. This involves using sensors to detect the noise and generating an inverse sound wave to cancel it out. By actively canceling the unwanted noise, the perceived coil whine can be significantly reduced or eliminated.

- Power supply and signal filtering: Improving power supply quality and implementing signal filtering can reduce coil whine. This includes using high-quality power supplies with stable voltage output, as well as incorporating filters to remove high-frequency noise from the power and signal lines. By providing cleaner power and signals to the coils, the likelihood of generating audible noise can be reduced.

02 Vibration dampening materials

Incorporating vibration dampening materials in the design can significantly reduce coil whine. These materials absorb and dissipate the mechanical vibrations that contribute to the audible noise. Applying such materials to the coil itself or to surrounding structures can help minimize the transmission of vibrations.Expand Specific Solutions03 Optimized coil design and winding techniques

Improving the coil design and winding techniques can help reduce the occurrence of coil whine. This may include using specialized winding patterns, adjusting the coil geometry, or employing advanced manufacturing processes to minimize gaps and inconsistencies in the windings that can contribute to noise generation.Expand Specific Solutions04 Active noise cancellation systems

Implementing active noise cancellation systems can effectively reduce coil whine. These systems work by generating sound waves that are out of phase with the coil whine, effectively canceling out the unwanted noise. This approach may involve the use of microphones, signal processing, and additional speakers or actuators.Expand Specific Solutions05 Frequency modulation and power management

Employing frequency modulation techniques and advanced power management strategies can help mitigate coil whine. This may involve dynamically adjusting the operating frequency of the coil or implementing sophisticated power delivery systems to reduce the likelihood of resonant frequencies that contribute to audible noise.Expand Specific Solutions

Key Players in Audio Equipment Industry

The reduction of coil whine in audio equipment is a growing concern in the mature audio technology market. The industry is in a phase of refinement and optimization, with a focus on enhancing user experience through noise reduction. The global market for audio equipment is substantial, driven by increasing demand for high-quality sound in consumer electronics and professional audio systems. Technologically, companies like LG Electronics, Sony, and Harman are at the forefront, leveraging their expertise in acoustics and electronics to develop advanced solutions. Emerging players such as GoerTek and AAC Technologies are also making significant strides, particularly in miniaturization and integration of audio components for mobile devices and wearables.

GoerTek Inc.

Technical Solution: GoerTek has developed a multi-pronged approach to address coil whine in audio equipment, focusing on miniaturization and integration. Their strategy involves the use of highly integrated system-on-chip (SoC) solutions that combine audio processing, power management, and amplification on a single die, reducing the number of discrete components that can contribute to coil whine[13]. GoerTek has also pioneered the use of micro-electromechanical systems (MEMS) based inductors and transformers, which exhibit significantly lower magnetic field leakage compared to traditional wound components[14]. Additionally, they have implemented advanced thermal management techniques, using phase-change materials and heat spreading technologies to maintain stable operating temperatures and reduce thermal-induced variations in component characteristics that can lead to coil whine[15]. GoerTek's approach also includes the development of smart power distribution algorithms that optimize current flow through various audio subsystems, minimizing the occurrence of sudden load changes that can trigger coil whine.

Strengths: Highly integrated solutions suitable for compact audio devices; innovative use of MEMS technology. Weaknesses: May have limitations in high-power audio applications; potential for increased complexity in troubleshooting and repair.

Sony Group Corp.

Technical Solution: Sony has developed a multi-faceted approach to reduce coil whine in audio equipment. Their method involves a combination of advanced circuit design, material selection, and mechanical isolation. They utilize low-noise operational amplifiers and implement careful PCB layout techniques to minimize electromagnetic interference. Sony's engineers have also developed proprietary magnetic core materials that exhibit lower magnetostriction, reducing the physical vibration that causes coil whine[1]. Additionally, they employ advanced encapsulation techniques, using specialized resins to dampen vibrations in transformer and inductor windings[3]. Sony has also implemented active noise cancellation algorithms in their digital signal processing chips to further mitigate any residual coil whine that may occur during operation[5].

Strengths: Comprehensive approach addressing multiple aspects of coil whine reduction; proprietary materials and algorithms. Weaknesses: Potentially higher production costs; may require frequent updates to DSP algorithms for different product lines.

Core Innovations in Noise Suppression Technology

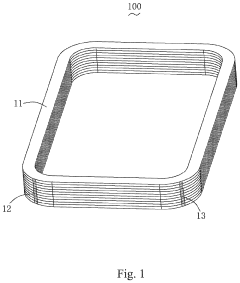

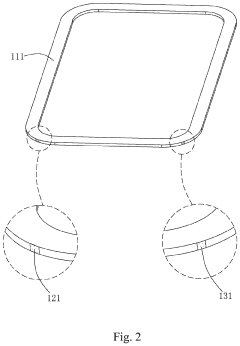

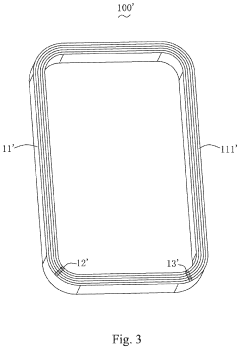

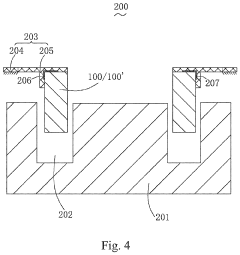

Voice Coil and Sounding Device Using Same

PatentActiveUS20240064469A1

Innovation

- A voice coil design featuring at least two sub coils with incoming and outgoing wire ends welded together to form a single current path, allowing for a lighter weight wire with greater resistance, reducing the overall weight of the vibration system and enhancing mid-frequency performance.

Acoustic Testing and Quality Control Measures

Acoustic testing and quality control measures play a crucial role in identifying and mitigating coil whine issues in audio equipment. These processes involve a comprehensive approach to ensure that the final product meets the desired standards of audio quality and performance.

One of the primary methods for acoustic testing is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for precise audio measurements. Within these chambers, audio equipment can be tested for coil whine using high-sensitivity microphones and advanced signal processing techniques. This allows engineers to detect even the slightest presence of unwanted noise and pinpoint its source within the device.

Frequency response analysis is another essential aspect of acoustic testing. By sweeping through a range of frequencies, technicians can identify specific frequency bands where coil whine is most prominent. This information is invaluable for implementing targeted reduction methods and fine-tuning the equipment's overall audio performance.

Quality control measures often include the implementation of automated testing systems. These systems can rapidly assess large quantities of audio equipment, ensuring consistency and efficiency in the production process. Automated tests typically involve playing predetermined audio signals through the device and analyzing the output for any anomalies, including coil whine.

Subjective listening tests conducted by trained audio professionals complement the objective measurements. These experts can detect subtle nuances in sound quality that may not be immediately apparent in automated tests. Their feedback is crucial for identifying coil whine issues that might be perceived differently by human ears compared to machine measurements.

Thermal imaging is another valuable tool in the quality control process. Since coil whine can be exacerbated by temperature fluctuations, thermal cameras can help identify hotspots within the audio equipment that may contribute to the problem. This information guides engineers in optimizing component placement and thermal management strategies.

To ensure ongoing quality, manufacturers often implement statistical process control (SPC) techniques. By continuously monitoring key parameters related to coil whine, such as frequency response and noise levels, producers can detect trends or shifts in production quality before they become significant issues. This proactive approach allows for timely adjustments to manufacturing processes or component sourcing.

Finally, accelerated life testing is employed to simulate long-term use and environmental conditions. By subjecting audio equipment to elevated temperatures, humidity, and extended operation periods, manufacturers can assess the likelihood of coil whine developing over time and make necessary design improvements to enhance product longevity and performance.

One of the primary methods for acoustic testing is the use of anechoic chambers. These specialized rooms are designed to eliminate external noise and reflections, providing an ideal environment for precise audio measurements. Within these chambers, audio equipment can be tested for coil whine using high-sensitivity microphones and advanced signal processing techniques. This allows engineers to detect even the slightest presence of unwanted noise and pinpoint its source within the device.

Frequency response analysis is another essential aspect of acoustic testing. By sweeping through a range of frequencies, technicians can identify specific frequency bands where coil whine is most prominent. This information is invaluable for implementing targeted reduction methods and fine-tuning the equipment's overall audio performance.

Quality control measures often include the implementation of automated testing systems. These systems can rapidly assess large quantities of audio equipment, ensuring consistency and efficiency in the production process. Automated tests typically involve playing predetermined audio signals through the device and analyzing the output for any anomalies, including coil whine.

Subjective listening tests conducted by trained audio professionals complement the objective measurements. These experts can detect subtle nuances in sound quality that may not be immediately apparent in automated tests. Their feedback is crucial for identifying coil whine issues that might be perceived differently by human ears compared to machine measurements.

Thermal imaging is another valuable tool in the quality control process. Since coil whine can be exacerbated by temperature fluctuations, thermal cameras can help identify hotspots within the audio equipment that may contribute to the problem. This information guides engineers in optimizing component placement and thermal management strategies.

To ensure ongoing quality, manufacturers often implement statistical process control (SPC) techniques. By continuously monitoring key parameters related to coil whine, such as frequency response and noise levels, producers can detect trends or shifts in production quality before they become significant issues. This proactive approach allows for timely adjustments to manufacturing processes or component sourcing.

Finally, accelerated life testing is employed to simulate long-term use and environmental conditions. By subjecting audio equipment to elevated temperatures, humidity, and extended operation periods, manufacturers can assess the likelihood of coil whine developing over time and make necessary design improvements to enhance product longevity and performance.

Environmental Impact of Noise Reduction Solutions

The implementation of reduction methods for coil whine in audio equipment has significant environmental implications that warrant careful consideration. As manufacturers and consumers increasingly prioritize sustainability, the environmental impact of noise reduction solutions becomes a crucial factor in product development and consumer choice.

One of the primary environmental concerns associated with coil whine reduction methods is the use of additional materials. Many solutions involve the application of damping compounds, insulating materials, or additional components to suppress vibrations. These materials often include synthetic polymers, resins, or metals, which may have varying degrees of environmental impact in terms of production, disposal, and potential for recycling.

The manufacturing processes required to implement certain noise reduction techniques can also contribute to increased energy consumption and carbon emissions. For instance, precision engineering and advanced manufacturing techniques needed for optimizing coil designs or implementing active noise cancellation systems may require more energy-intensive processes compared to standard production methods.

Furthermore, the longevity and repairability of audio equipment can be affected by the implementation of coil whine reduction methods. If these solutions involve complex integrated systems or specialized components, it may make the equipment more challenging to repair or upgrade, potentially leading to increased electronic waste. This aspect is particularly relevant in the context of the growing right-to-repair movement and circular economy initiatives.

On the positive side, effective coil whine reduction can lead to improved energy efficiency in audio equipment. By minimizing unwanted vibrations and electromagnetic interference, the overall power consumption of the device may be reduced, resulting in lower energy usage over its lifetime. This efficiency gain can translate to reduced environmental impact through decreased electricity consumption.

The choice of materials for noise reduction solutions also presents an opportunity for environmental improvement. Manufacturers are increasingly exploring eco-friendly alternatives, such as biodegradable damping compounds or recycled materials for insulation. These innovations can significantly reduce the environmental footprint of noise reduction techniques while maintaining their effectiveness.

In the broader context, the reduction of coil whine contributes to a decrease in noise pollution, which has indirect environmental benefits. Lower noise levels can positively impact urban ecosystems and reduce stress on wildlife in areas where audio equipment is frequently used. This aspect aligns with growing awareness of the ecological effects of anthropogenic noise.

As the audio industry continues to evolve, balancing effective noise reduction with environmental responsibility will be crucial. Future research and development in this field should focus on sustainable materials, energy-efficient manufacturing processes, and designs that facilitate easy repair and recycling. By considering the full lifecycle impact of noise reduction solutions, manufacturers can contribute to more environmentally friendly audio equipment without compromising on performance or user experience.

One of the primary environmental concerns associated with coil whine reduction methods is the use of additional materials. Many solutions involve the application of damping compounds, insulating materials, or additional components to suppress vibrations. These materials often include synthetic polymers, resins, or metals, which may have varying degrees of environmental impact in terms of production, disposal, and potential for recycling.

The manufacturing processes required to implement certain noise reduction techniques can also contribute to increased energy consumption and carbon emissions. For instance, precision engineering and advanced manufacturing techniques needed for optimizing coil designs or implementing active noise cancellation systems may require more energy-intensive processes compared to standard production methods.

Furthermore, the longevity and repairability of audio equipment can be affected by the implementation of coil whine reduction methods. If these solutions involve complex integrated systems or specialized components, it may make the equipment more challenging to repair or upgrade, potentially leading to increased electronic waste. This aspect is particularly relevant in the context of the growing right-to-repair movement and circular economy initiatives.

On the positive side, effective coil whine reduction can lead to improved energy efficiency in audio equipment. By minimizing unwanted vibrations and electromagnetic interference, the overall power consumption of the device may be reduced, resulting in lower energy usage over its lifetime. This efficiency gain can translate to reduced environmental impact through decreased electricity consumption.

The choice of materials for noise reduction solutions also presents an opportunity for environmental improvement. Manufacturers are increasingly exploring eco-friendly alternatives, such as biodegradable damping compounds or recycled materials for insulation. These innovations can significantly reduce the environmental footprint of noise reduction techniques while maintaining their effectiveness.

In the broader context, the reduction of coil whine contributes to a decrease in noise pollution, which has indirect environmental benefits. Lower noise levels can positively impact urban ecosystems and reduce stress on wildlife in areas where audio equipment is frequently used. This aspect aligns with growing awareness of the ecological effects of anthropogenic noise.

As the audio industry continues to evolve, balancing effective noise reduction with environmental responsibility will be crucial. Future research and development in this field should focus on sustainable materials, energy-efficient manufacturing processes, and designs that facilitate easy repair and recycling. By considering the full lifecycle impact of noise reduction solutions, manufacturers can contribute to more environmentally friendly audio equipment without compromising on performance or user experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!