How to Improve Hydrogels With Sodium Alginate Properties?

JUL 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogel-Alginate Tech Evolution

The evolution of hydrogel-alginate technology has been marked by significant advancements in material science and bioengineering. Initially, hydrogels were simple polymeric networks with limited functionality. The introduction of sodium alginate, a natural polysaccharide derived from brown seaweed, marked a pivotal moment in hydrogel development.

In the early stages, researchers focused on understanding the basic properties of alginate-based hydrogels. These materials exhibited unique characteristics such as biocompatibility, biodegradability, and the ability to form gels under mild conditions. However, their mechanical strength and stability were often insufficient for many applications.

The next phase of evolution saw efforts to enhance the mechanical properties of alginate hydrogels. Cross-linking techniques were refined, incorporating divalent cations like calcium to create stronger ionic bonds within the gel structure. This improved the overall stability and durability of the hydrogels, expanding their potential uses in fields such as tissue engineering and drug delivery.

A significant breakthrough came with the development of hybrid hydrogels, combining sodium alginate with synthetic polymers. This approach allowed for the fine-tuning of mechanical and chemical properties, creating materials with enhanced strength, elasticity, and responsiveness to external stimuli.

Recent years have witnessed a surge in research focused on smart hydrogels incorporating sodium alginate. These advanced materials can respond to environmental changes such as pH, temperature, or specific biomolecules. This responsiveness has opened up new possibilities in controlled drug release and regenerative medicine.

The integration of nanotechnology has further propelled the field forward. Nanocomposite alginate hydrogels, incorporating materials like graphene or nanocellulose, have demonstrated remarkable improvements in mechanical strength and functionality. These nanocomposites offer enhanced properties while maintaining the biocompatibility of traditional alginate hydrogels.

Current research is exploring the potential of 3D printing technologies in fabricating complex alginate-based hydrogel structures. This approach allows for precise control over the spatial distribution of properties within the hydrogel, enabling the creation of biomimetic structures for tissue engineering applications.

Looking ahead, the evolution of hydrogel-alginate technology is likely to focus on further enhancing the multifunctionality of these materials. Researchers are exploring ways to incorporate multiple responsive elements into a single hydrogel system, creating materials that can adapt to complex biological environments. Additionally, efforts are being made to improve the scalability and reproducibility of advanced alginate hydrogels, paving the way for their widespread adoption in medical and industrial applications.

In the early stages, researchers focused on understanding the basic properties of alginate-based hydrogels. These materials exhibited unique characteristics such as biocompatibility, biodegradability, and the ability to form gels under mild conditions. However, their mechanical strength and stability were often insufficient for many applications.

The next phase of evolution saw efforts to enhance the mechanical properties of alginate hydrogels. Cross-linking techniques were refined, incorporating divalent cations like calcium to create stronger ionic bonds within the gel structure. This improved the overall stability and durability of the hydrogels, expanding their potential uses in fields such as tissue engineering and drug delivery.

A significant breakthrough came with the development of hybrid hydrogels, combining sodium alginate with synthetic polymers. This approach allowed for the fine-tuning of mechanical and chemical properties, creating materials with enhanced strength, elasticity, and responsiveness to external stimuli.

Recent years have witnessed a surge in research focused on smart hydrogels incorporating sodium alginate. These advanced materials can respond to environmental changes such as pH, temperature, or specific biomolecules. This responsiveness has opened up new possibilities in controlled drug release and regenerative medicine.

The integration of nanotechnology has further propelled the field forward. Nanocomposite alginate hydrogels, incorporating materials like graphene or nanocellulose, have demonstrated remarkable improvements in mechanical strength and functionality. These nanocomposites offer enhanced properties while maintaining the biocompatibility of traditional alginate hydrogels.

Current research is exploring the potential of 3D printing technologies in fabricating complex alginate-based hydrogel structures. This approach allows for precise control over the spatial distribution of properties within the hydrogel, enabling the creation of biomimetic structures for tissue engineering applications.

Looking ahead, the evolution of hydrogel-alginate technology is likely to focus on further enhancing the multifunctionality of these materials. Researchers are exploring ways to incorporate multiple responsive elements into a single hydrogel system, creating materials that can adapt to complex biological environments. Additionally, efforts are being made to improve the scalability and reproducibility of advanced alginate hydrogels, paving the way for their widespread adoption in medical and industrial applications.

Market Demand Analysis

The market demand for improved hydrogels with sodium alginate properties has been steadily increasing across various industries. This growth is primarily driven by the expanding applications of these advanced materials in healthcare, pharmaceuticals, food and beverage, and cosmetics sectors.

In the healthcare industry, there is a significant demand for hydrogels with enhanced sodium alginate properties for wound dressing applications. These materials offer superior moisture retention, biocompatibility, and controlled drug release capabilities, making them ideal for advanced wound care products. The global wound care market is projected to reach substantial growth in the coming years, with hydrogels playing a crucial role in this expansion.

The pharmaceutical sector is another key driver of market demand for improved sodium alginate-based hydrogels. These materials are increasingly used in drug delivery systems due to their ability to encapsulate and release active pharmaceutical ingredients in a controlled manner. The growing focus on personalized medicine and targeted drug delivery has further amplified the need for advanced hydrogel formulations.

In the food and beverage industry, there is a rising demand for natural and sustainable thickening agents and stabilizers. Improved hydrogels with sodium alginate properties offer excellent gelling and stabilizing characteristics, making them valuable in various food applications. The clean label trend and consumer preference for plant-based ingredients have contributed to the increased adoption of these materials in food products.

The cosmetics and personal care sector has also shown significant interest in advanced hydrogels. These materials are used in skincare formulations, hair care products, and color cosmetics due to their moisturizing properties and ability to deliver active ingredients effectively. The growing consumer demand for natural and eco-friendly beauty products has further boosted the market for sodium alginate-based hydrogels in this sector.

Environmental applications represent an emerging market for improved hydrogels with sodium alginate properties. These materials show promise in water treatment, soil remediation, and agricultural applications, driven by increasing environmental concerns and the need for sustainable solutions.

The market demand for these advanced hydrogels is expected to continue its upward trajectory, fueled by ongoing research and development efforts to enhance their properties and expand their applications. As industries seek more sustainable and efficient materials, the versatility and biocompatibility of improved sodium alginate-based hydrogels position them as attractive solutions across multiple sectors.

In the healthcare industry, there is a significant demand for hydrogels with enhanced sodium alginate properties for wound dressing applications. These materials offer superior moisture retention, biocompatibility, and controlled drug release capabilities, making them ideal for advanced wound care products. The global wound care market is projected to reach substantial growth in the coming years, with hydrogels playing a crucial role in this expansion.

The pharmaceutical sector is another key driver of market demand for improved sodium alginate-based hydrogels. These materials are increasingly used in drug delivery systems due to their ability to encapsulate and release active pharmaceutical ingredients in a controlled manner. The growing focus on personalized medicine and targeted drug delivery has further amplified the need for advanced hydrogel formulations.

In the food and beverage industry, there is a rising demand for natural and sustainable thickening agents and stabilizers. Improved hydrogels with sodium alginate properties offer excellent gelling and stabilizing characteristics, making them valuable in various food applications. The clean label trend and consumer preference for plant-based ingredients have contributed to the increased adoption of these materials in food products.

The cosmetics and personal care sector has also shown significant interest in advanced hydrogels. These materials are used in skincare formulations, hair care products, and color cosmetics due to their moisturizing properties and ability to deliver active ingredients effectively. The growing consumer demand for natural and eco-friendly beauty products has further boosted the market for sodium alginate-based hydrogels in this sector.

Environmental applications represent an emerging market for improved hydrogels with sodium alginate properties. These materials show promise in water treatment, soil remediation, and agricultural applications, driven by increasing environmental concerns and the need for sustainable solutions.

The market demand for these advanced hydrogels is expected to continue its upward trajectory, fueled by ongoing research and development efforts to enhance their properties and expand their applications. As industries seek more sustainable and efficient materials, the versatility and biocompatibility of improved sodium alginate-based hydrogels position them as attractive solutions across multiple sectors.

Current Challenges

Hydrogels with sodium alginate properties face several significant challenges that hinder their widespread application and optimal performance. One of the primary issues is the limited mechanical strength of these hydrogels, which restricts their use in load-bearing applications. The inherent weakness of the alginate network structure often results in poor durability and susceptibility to deformation under stress.

Another critical challenge is the rapid degradation rate of sodium alginate-based hydrogels in physiological conditions. This characteristic, while beneficial in some biomedical applications, can be a drawback in scenarios requiring long-term stability. The quick dissolution of these hydrogels in aqueous environments limits their effectiveness in sustained drug delivery systems and tissue engineering scaffolds.

The control of swelling behavior presents another hurdle in the development of sodium alginate hydrogels. Excessive swelling can lead to loss of structural integrity and altered mechanical properties, potentially compromising the intended functionality of the hydrogel. Conversely, insufficient swelling may restrict the hydrogel's ability to absorb and retain water, which is crucial for many applications.

Biocompatibility and cell adhesion properties of sodium alginate hydrogels also require improvement. While generally considered biocompatible, these hydrogels often lack cell-binding sites, which can limit cell attachment and proliferation. This deficiency poses challenges in tissue engineering applications where cell-material interactions are crucial for tissue regeneration and integration.

The crosslinking process of sodium alginate hydrogels presents its own set of challenges. Current crosslinking methods, such as ionic crosslinking with calcium ions, often result in heterogeneous structures with varying degrees of crosslinking density. This non-uniformity can lead to inconsistent mechanical properties and unpredictable degradation profiles across the hydrogel matrix.

Furthermore, the limited functionalization options of sodium alginate restrict the ability to tailor hydrogel properties for specific applications. The lack of easily modifiable functional groups on the alginate backbone makes it challenging to incorporate additional bioactive molecules or adjust the hydrogel's physicochemical properties without compromising its inherent characteristics.

Lastly, the scalability and reproducibility of sodium alginate hydrogel production remain significant challenges. Variations in alginate sources and extraction methods can lead to inconsistencies in the final product, making it difficult to achieve standardized hydrogel formulations for industrial-scale production and clinical applications.

Another critical challenge is the rapid degradation rate of sodium alginate-based hydrogels in physiological conditions. This characteristic, while beneficial in some biomedical applications, can be a drawback in scenarios requiring long-term stability. The quick dissolution of these hydrogels in aqueous environments limits their effectiveness in sustained drug delivery systems and tissue engineering scaffolds.

The control of swelling behavior presents another hurdle in the development of sodium alginate hydrogels. Excessive swelling can lead to loss of structural integrity and altered mechanical properties, potentially compromising the intended functionality of the hydrogel. Conversely, insufficient swelling may restrict the hydrogel's ability to absorb and retain water, which is crucial for many applications.

Biocompatibility and cell adhesion properties of sodium alginate hydrogels also require improvement. While generally considered biocompatible, these hydrogels often lack cell-binding sites, which can limit cell attachment and proliferation. This deficiency poses challenges in tissue engineering applications where cell-material interactions are crucial for tissue regeneration and integration.

The crosslinking process of sodium alginate hydrogels presents its own set of challenges. Current crosslinking methods, such as ionic crosslinking with calcium ions, often result in heterogeneous structures with varying degrees of crosslinking density. This non-uniformity can lead to inconsistent mechanical properties and unpredictable degradation profiles across the hydrogel matrix.

Furthermore, the limited functionalization options of sodium alginate restrict the ability to tailor hydrogel properties for specific applications. The lack of easily modifiable functional groups on the alginate backbone makes it challenging to incorporate additional bioactive molecules or adjust the hydrogel's physicochemical properties without compromising its inherent characteristics.

Lastly, the scalability and reproducibility of sodium alginate hydrogel production remain significant challenges. Variations in alginate sources and extraction methods can lead to inconsistencies in the final product, making it difficult to achieve standardized hydrogel formulations for industrial-scale production and clinical applications.

Existing Enhancement Methods

01 Biocompatibility and biodegradability

Hydrogels with sodium alginate are known for their excellent biocompatibility and biodegradability. These properties make them suitable for various biomedical applications, including tissue engineering, drug delivery, and wound healing. The natural origin of sodium alginate contributes to its safety and compatibility with biological systems.- Biocompatibility and biodegradability: Sodium alginate-based hydrogels are known for their excellent biocompatibility and biodegradability. These properties make them suitable for various biomedical applications, including tissue engineering, drug delivery, and wound healing. The natural origin of sodium alginate contributes to its low toxicity and ability to be safely degraded in the body.

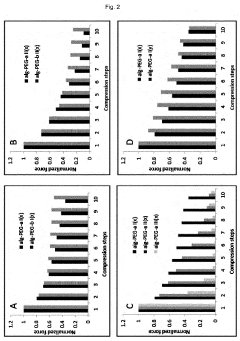

- Mechanical properties and stability: Hydrogels containing sodium alginate exhibit tunable mechanical properties and stability. The crosslinking density and type of crosslinking agents used can be adjusted to control the hydrogel's strength, elasticity, and durability. These hydrogels can maintain their structural integrity in various physiological conditions, making them suitable for long-term applications.

- Swelling behavior and water retention: Sodium alginate hydrogels demonstrate excellent swelling behavior and water retention capabilities. These properties are crucial for applications requiring controlled release of drugs or absorption of wound exudates. The hydrophilic nature of sodium alginate allows the hydrogels to absorb and retain large amounts of water while maintaining their structure.

- Functionalization and composite formation: Sodium alginate hydrogels can be easily functionalized or combined with other materials to form composites with enhanced properties. This versatility allows for the incorporation of various active ingredients, nanoparticles, or other polymers to tailor the hydrogel's properties for specific applications. Such modifications can improve mechanical strength, bioactivity, or introduce stimuli-responsive behavior.

- Gelation mechanisms and crosslinking: The gelation of sodium alginate hydrogels can be achieved through various mechanisms, including ionic crosslinking, covalent crosslinking, and physical entanglement. The choice of crosslinking method significantly influences the hydrogel's properties, such as mechanical strength, degradation rate, and drug release kinetics. Understanding and controlling these gelation mechanisms is crucial for tailoring hydrogels for specific applications.

02 Mechanical properties and stability

Sodium alginate-based hydrogels exhibit tunable mechanical properties and stability. By adjusting the concentration of sodium alginate and crosslinking agents, the strength, elasticity, and durability of the hydrogels can be controlled. This versatility allows for the creation of hydrogels with specific mechanical characteristics suited for various applications.Expand Specific Solutions03 Swelling behavior and water absorption

Hydrogels containing sodium alginate demonstrate excellent swelling behavior and water absorption capabilities. These properties are crucial for applications such as wound dressings, where maintaining a moist environment is essential for healing. The hydrophilic nature of sodium alginate contributes to its ability to absorb and retain large amounts of water.Expand Specific Solutions04 Stimuli-responsive properties

Sodium alginate-based hydrogels can be designed to exhibit stimuli-responsive properties. These smart hydrogels can respond to external stimuli such as pH, temperature, or ionic strength changes. This feature enables the development of controlled release systems and sensors for various applications in biomedicine and environmental monitoring.Expand Specific Solutions05 Functionalization and composite formation

Hydrogels with sodium alginate can be easily functionalized or combined with other materials to form composites. This allows for the incorporation of additional properties such as antimicrobial activity, enhanced mechanical strength, or specific biological functions. The versatility in functionalization expands the potential applications of these hydrogels in various fields.Expand Specific Solutions

Key Industry Players

The hydrogel market with sodium alginate properties is in a growth phase, driven by increasing applications in biomedical and pharmaceutical industries. The global market size for advanced hydrogels is projected to reach several billion dollars by 2025, with a compound annual growth rate of over 6%. Technological maturity varies across different applications, with some areas like wound dressing being more established, while others like drug delivery systems are still evolving. Key players in this field include research institutions like Université Claude Bernard Lyon 1 and Centre National de la Recherche Scientifique, as well as companies such as FUJIFILM Manufacturing Europe BV and Kolmar Korea Co., Ltd. These organizations are actively working on improving hydrogel properties, focusing on aspects like biocompatibility, mechanical strength, and controlled release capabilities.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed a novel approach to improve hydrogels with sodium alginate properties by incorporating nanocomposite materials. Their method involves the integration of cellulose nanocrystals (CNCs) into the alginate matrix, resulting in enhanced mechanical strength and stability[1]. The researchers have optimized the crosslinking process using calcium ions, which allows for better control over the hydrogel's structure and properties[2]. Additionally, they have explored the use of 3D printing techniques to create complex hydrogel structures with tailored mechanical and biological properties, suitable for tissue engineering applications[3].

Strengths: Enhanced mechanical properties, improved stability, and ability to create complex structures. Weaknesses: Potential challenges in scaling up production and ensuring consistent quality across larger batches.

National University of Singapore

Technical Solution: NUS has developed a novel approach to improve hydrogels with sodium alginate properties by incorporating graphene oxide (GO) into the alginate matrix. This nanocomposite hydrogel exhibits significantly enhanced mechanical properties, including improved tensile strength and elasticity[4]. The researchers have also explored the use of dual crosslinking methods, combining ionic crosslinking with covalent bonding, to further improve the hydrogel's stability and responsiveness to external stimuli[5]. Additionally, they have investigated the incorporation of bioactive molecules into the hydrogel network, enhancing its potential for drug delivery and tissue engineering applications[6].

Strengths: Significantly improved mechanical properties, enhanced stability, and potential for biomedical applications. Weaknesses: Possible concerns regarding the long-term biocompatibility of graphene oxide in vivo.

Innovative Alginate Research

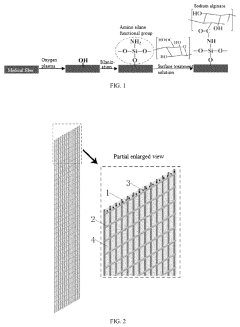

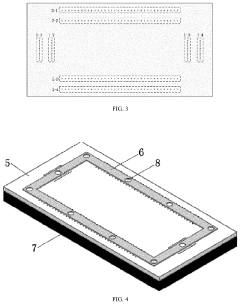

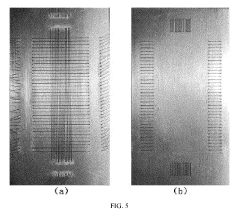

High-strength medical fiber composite material

PatentPendingUS20240157032A1

Innovation

- A high-strength medical fiber composite material is developed by embedding a fiber framework of reinforcing and supporting fibers, chemically anchored to a sodium alginate hydrogel, with the fibers arranged orthogonally and treated with specific surface modifications to enhance mechanical properties.

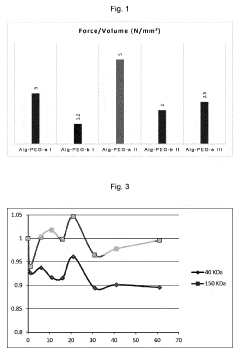

Hydrogels based on functionalized polysaccharides

PatentInactiveEP3295933A1

Innovation

- Functionalized hydrogel networks are developed by grafting heterobifunctional PEG derivatives onto alginate, enhancing mechanical properties and permselectivity through covalent cross-linking and ionotropic gelation, allowing for tunable stability and biocompatibility.

Biocompatibility Assessment

Biocompatibility assessment is a critical aspect of improving hydrogels with sodium alginate properties. Sodium alginate, derived from brown seaweed, has gained significant attention in biomedical applications due to its inherent biocompatibility and biodegradability. The evaluation of biocompatibility for these hydrogels involves a comprehensive analysis of their interactions with biological systems, ensuring they do not elicit adverse responses when in contact with living tissues or fluids.

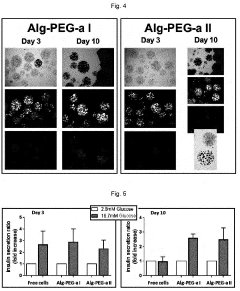

One of the primary considerations in biocompatibility assessment is cytotoxicity testing. This involves exposing cells to the hydrogel material and evaluating cell viability, proliferation, and morphology. Studies have shown that sodium alginate-based hydrogels generally exhibit low cytotoxicity, making them suitable for various biomedical applications. However, the concentration of sodium alginate and the presence of other components in the hydrogel formulation can influence cytotoxicity levels, necessitating careful optimization.

In vivo biocompatibility testing is another crucial aspect of the assessment process. This involves implanting the hydrogel into animal models and evaluating the host response over time. Factors such as inflammation, immune response, and tissue integration are closely monitored. Sodium alginate hydrogels have demonstrated favorable in vivo biocompatibility in numerous studies, with minimal inflammatory responses and good tissue integration observed in various animal models.

The degradation profile of sodium alginate hydrogels is an important consideration in biocompatibility assessment. The rate at which the hydrogel breaks down in the body can affect its long-term biocompatibility and functionality. Researchers have explored various methods to control the degradation rate of sodium alginate hydrogels, such as crosslinking with divalent cations or incorporating other polymers, to tailor their properties for specific biomedical applications.

Hemocompatibility is another critical aspect of biocompatibility assessment, particularly for hydrogels intended for use in blood-contacting applications. This involves evaluating the hydrogel's interactions with blood components, including potential thrombogenicity and hemolysis. Sodium alginate hydrogels have shown promising results in hemocompatibility studies, with minimal platelet adhesion and activation observed in many cases.

To further improve the biocompatibility of sodium alginate hydrogels, researchers have explored various strategies. One approach involves the incorporation of bioactive molecules or growth factors into the hydrogel matrix. This can enhance cell adhesion, proliferation, and tissue regeneration, leading to improved biocompatibility and functionality. Additionally, surface modification techniques, such as plasma treatment or grafting of biocompatible polymers, have been investigated to enhance the hydrogel's interactions with biological systems.

In conclusion, biocompatibility assessment plays a crucial role in the development and improvement of hydrogels with sodium alginate properties. By thoroughly evaluating cytotoxicity, in vivo response, degradation profiles, and hemocompatibility, researchers can optimize these hydrogels for various biomedical applications, ensuring their safety and efficacy in clinical settings.

One of the primary considerations in biocompatibility assessment is cytotoxicity testing. This involves exposing cells to the hydrogel material and evaluating cell viability, proliferation, and morphology. Studies have shown that sodium alginate-based hydrogels generally exhibit low cytotoxicity, making them suitable for various biomedical applications. However, the concentration of sodium alginate and the presence of other components in the hydrogel formulation can influence cytotoxicity levels, necessitating careful optimization.

In vivo biocompatibility testing is another crucial aspect of the assessment process. This involves implanting the hydrogel into animal models and evaluating the host response over time. Factors such as inflammation, immune response, and tissue integration are closely monitored. Sodium alginate hydrogels have demonstrated favorable in vivo biocompatibility in numerous studies, with minimal inflammatory responses and good tissue integration observed in various animal models.

The degradation profile of sodium alginate hydrogels is an important consideration in biocompatibility assessment. The rate at which the hydrogel breaks down in the body can affect its long-term biocompatibility and functionality. Researchers have explored various methods to control the degradation rate of sodium alginate hydrogels, such as crosslinking with divalent cations or incorporating other polymers, to tailor their properties for specific biomedical applications.

Hemocompatibility is another critical aspect of biocompatibility assessment, particularly for hydrogels intended for use in blood-contacting applications. This involves evaluating the hydrogel's interactions with blood components, including potential thrombogenicity and hemolysis. Sodium alginate hydrogels have shown promising results in hemocompatibility studies, with minimal platelet adhesion and activation observed in many cases.

To further improve the biocompatibility of sodium alginate hydrogels, researchers have explored various strategies. One approach involves the incorporation of bioactive molecules or growth factors into the hydrogel matrix. This can enhance cell adhesion, proliferation, and tissue regeneration, leading to improved biocompatibility and functionality. Additionally, surface modification techniques, such as plasma treatment or grafting of biocompatible polymers, have been investigated to enhance the hydrogel's interactions with biological systems.

In conclusion, biocompatibility assessment plays a crucial role in the development and improvement of hydrogels with sodium alginate properties. By thoroughly evaluating cytotoxicity, in vivo response, degradation profiles, and hemocompatibility, researchers can optimize these hydrogels for various biomedical applications, ensuring their safety and efficacy in clinical settings.

Regulatory Considerations

The regulatory landscape surrounding hydrogels with sodium alginate properties is complex and multifaceted, requiring careful consideration throughout the development and commercialization process. As these materials find applications in various fields, including biomedical, pharmaceutical, and food industries, they are subject to oversight from multiple regulatory bodies.

In the medical and pharmaceutical sectors, hydrogels with sodium alginate properties often fall under the purview of agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These organizations have established guidelines for the evaluation of biomaterials, including hydrogels, used in medical devices and drug delivery systems. Manufacturers must demonstrate the safety and efficacy of their products through rigorous testing and clinical trials before obtaining regulatory approval.

The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices that incorporate hydrogels. Depending on the intended use and risk classification, these products may require premarket approval (PMA) or 510(k) clearance. For drug delivery applications, the Center for Drug Evaluation and Research (CDER) oversees the regulatory process, which includes extensive preclinical and clinical studies to establish the biocompatibility and performance of the hydrogel-based formulations.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) provide the regulatory framework for hydrogels used in medical applications. These regulations emphasize the importance of risk management, clinical evaluation, and post-market surveillance throughout the product lifecycle.

For food applications, regulatory bodies such as the FDA's Center for Food Safety and Applied Nutrition (CFSAN) and the European Food Safety Authority (EFSA) govern the use of sodium alginate-based hydrogels. These agencies assess the safety of food additives and novel food ingredients, requiring manufacturers to provide scientific evidence supporting their products' safety and functionality.

Environmental regulations also play a crucial role in the development and production of hydrogels with sodium alginate properties. Agencies like the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) oversee the registration, evaluation, and authorization of chemical substances used in these materials. Compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the EU is essential for manufacturers operating in the global market.

As the field of hydrogel technology continues to advance, regulatory frameworks are evolving to address emerging challenges and applications. Researchers and manufacturers must stay informed about the latest regulatory developments and engage in proactive dialogue with regulatory authorities to ensure compliance and facilitate the successful commercialization of innovative hydrogel products.

In the medical and pharmaceutical sectors, hydrogels with sodium alginate properties often fall under the purview of agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These organizations have established guidelines for the evaluation of biomaterials, including hydrogels, used in medical devices and drug delivery systems. Manufacturers must demonstrate the safety and efficacy of their products through rigorous testing and clinical trials before obtaining regulatory approval.

The FDA's Center for Devices and Radiological Health (CDRH) is responsible for regulating medical devices that incorporate hydrogels. Depending on the intended use and risk classification, these products may require premarket approval (PMA) or 510(k) clearance. For drug delivery applications, the Center for Drug Evaluation and Research (CDER) oversees the regulatory process, which includes extensive preclinical and clinical studies to establish the biocompatibility and performance of the hydrogel-based formulations.

In the European Union, the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) provide the regulatory framework for hydrogels used in medical applications. These regulations emphasize the importance of risk management, clinical evaluation, and post-market surveillance throughout the product lifecycle.

For food applications, regulatory bodies such as the FDA's Center for Food Safety and Applied Nutrition (CFSAN) and the European Food Safety Authority (EFSA) govern the use of sodium alginate-based hydrogels. These agencies assess the safety of food additives and novel food ingredients, requiring manufacturers to provide scientific evidence supporting their products' safety and functionality.

Environmental regulations also play a crucial role in the development and production of hydrogels with sodium alginate properties. Agencies like the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) oversee the registration, evaluation, and authorization of chemical substances used in these materials. Compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in the EU is essential for manufacturers operating in the global market.

As the field of hydrogel technology continues to advance, regulatory frameworks are evolving to address emerging challenges and applications. Researchers and manufacturers must stay informed about the latest regulatory developments and engage in proactive dialogue with regulatory authorities to ensure compliance and facilitate the successful commercialization of innovative hydrogel products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!