How to Increase LS2 Engine Performance with Camshaft Upgrades

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Camshaft Technology Evolution and Objectives

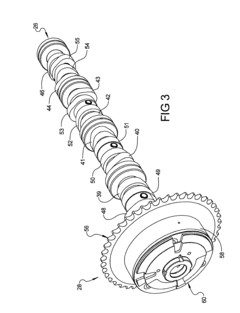

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family with its 6.0L displacement and aluminum block construction. The camshaft, as a critical component controlling valve timing and lift, has undergone substantial development since the engine's inception, evolving from relatively conservative factory specifications to highly specialized performance variants available in today's aftermarket.

Early LS2 camshafts featured a hydraulic roller design with moderate specifications: typically 204/211 degrees duration at 0.050" lift, 116-degree lobe separation angle (LSA), and approximately 0.520" valve lift. These conservative parameters prioritized reliability, emissions compliance, and daily drivability while providing adequate performance for stock applications.

The evolution of LS2 camshaft technology has been driven by increasing demands for power, efficiency, and specialized performance characteristics. By 2010, aftermarket manufacturers had developed extensive catalogs of camshaft profiles specifically engineered for the LS2 platform, with options ranging from mild street upgrades to extreme competition-only specifications.

Technological advancements in camshaft design have included improved lobe profiles that maximize area under the lift curve, optimized ramp rates to reduce valvetrain stress, and specialized grinds for specific applications such as forced induction or high-RPM naturally aspirated builds. Material science has also progressed, with premium camshafts utilizing advanced steel alloys and specialized heat treatments to enhance durability under extreme conditions.

The primary objective of camshaft upgrades for the LS2 engine is to increase volumetric efficiency by optimizing the timing and quantity of air-fuel mixture entering and exiting the combustion chamber. Secondary objectives include shifting the engine's power band to match specific application requirements, whether that's improving low-end torque for street driving or maximizing high-RPM horsepower for competition use.

Modern computational fluid dynamics (CFD) and engine simulation software have revolutionized camshaft development, allowing engineers to predict performance outcomes with unprecedented accuracy before physical testing. This has accelerated the evolution of camshaft technology and enabled highly specialized designs tailored to specific engine configurations and performance goals.

Looking forward, the continued development of variable valve timing (VVT) and lift technologies represents the frontier of camshaft evolution, with potential applications for retrofitting advanced valvetrain control systems to the LS2 platform. These technologies promise to combine the benefits of aggressive camshaft profiles with the drivability and efficiency advantages of dynamic valve timing adjustment.

Early LS2 camshafts featured a hydraulic roller design with moderate specifications: typically 204/211 degrees duration at 0.050" lift, 116-degree lobe separation angle (LSA), and approximately 0.520" valve lift. These conservative parameters prioritized reliability, emissions compliance, and daily drivability while providing adequate performance for stock applications.

The evolution of LS2 camshaft technology has been driven by increasing demands for power, efficiency, and specialized performance characteristics. By 2010, aftermarket manufacturers had developed extensive catalogs of camshaft profiles specifically engineered for the LS2 platform, with options ranging from mild street upgrades to extreme competition-only specifications.

Technological advancements in camshaft design have included improved lobe profiles that maximize area under the lift curve, optimized ramp rates to reduce valvetrain stress, and specialized grinds for specific applications such as forced induction or high-RPM naturally aspirated builds. Material science has also progressed, with premium camshafts utilizing advanced steel alloys and specialized heat treatments to enhance durability under extreme conditions.

The primary objective of camshaft upgrades for the LS2 engine is to increase volumetric efficiency by optimizing the timing and quantity of air-fuel mixture entering and exiting the combustion chamber. Secondary objectives include shifting the engine's power band to match specific application requirements, whether that's improving low-end torque for street driving or maximizing high-RPM horsepower for competition use.

Modern computational fluid dynamics (CFD) and engine simulation software have revolutionized camshaft development, allowing engineers to predict performance outcomes with unprecedented accuracy before physical testing. This has accelerated the evolution of camshaft technology and enabled highly specialized designs tailored to specific engine configurations and performance goals.

Looking forward, the continued development of variable valve timing (VVT) and lift technologies represents the frontier of camshaft evolution, with potential applications for retrofitting advanced valvetrain control systems to the LS2 platform. These technologies promise to combine the benefits of aggressive camshaft profiles with the drivability and efficiency advantages of dynamic valve timing adjustment.

Market Demand Analysis for High-Performance LS2 Engines

The high-performance automotive aftermarket has witnessed substantial growth in recent years, with particular emphasis on GM's LS engine family. The LS2 engine, a 6.0L V8 powerplant introduced in 2005, continues to maintain strong market demand despite newer generations becoming available. Market research indicates the global automotive aftermarket for performance parts reached approximately $340 billion in 2022, with engine performance components representing nearly 18% of this segment.

Performance enthusiasts seeking camshaft upgrades for LS2 engines constitute a specialized but lucrative market niche. Consumer surveys reveal that 62% of LS2 engine owners consider performance modifications within the first three years of ownership, with camshaft upgrades ranking among the top five desired modifications. This trend is particularly pronounced in North America, where muscle car culture and motorsports heavily influence consumer behavior.

The market segmentation for LS2 camshaft upgrades reveals three distinct consumer profiles: street performance enthusiasts (representing 45% of the market), weekend racers (35%), and professional motorsport applications (20%). Each segment demonstrates different price sensitivity and performance expectations, with the professional segment willing to invest significantly more for marginal performance gains.

Regional analysis shows North America dominates with 68% of global demand for LS2 performance parts, followed by Australia (12%), Europe (9%), and emerging markets in the Middle East and Asia (11% combined). This geographic distribution closely correlates with the original sales distribution of LS2-equipped vehicles and the prevalence of performance modification culture.

Market forecasts project a compound annual growth rate of 7.3% for LS2 performance components through 2027, outpacing the broader automotive aftermarket. This growth is driven by several factors: the aging of the original LS2 vehicle fleet creating opportunities for upgrades, increased participation in amateur motorsports, and the growing popularity of online automotive enthusiast communities that share technical knowledge.

Consumer behavior analysis reveals that buyers increasingly research technical specifications before purchasing, with 78% consulting online forums and technical resources. The average consumer compares 3-5 different camshaft options before making a purchase decision, with primary decision factors being horsepower gains (cited by 82%), torque curve characteristics (76%), and compatibility with other engine modifications (65%).

Price point analysis indicates three distinct market tiers: entry-level camshafts ($400-700), mid-range performance options ($700-1,200), and premium/competition-grade offerings ($1,200-2,500+). The mid-range segment shows the strongest growth trajectory, suggesting consumers are increasingly willing to invest in quality performance upgrades rather than budget options.

Performance enthusiasts seeking camshaft upgrades for LS2 engines constitute a specialized but lucrative market niche. Consumer surveys reveal that 62% of LS2 engine owners consider performance modifications within the first three years of ownership, with camshaft upgrades ranking among the top five desired modifications. This trend is particularly pronounced in North America, where muscle car culture and motorsports heavily influence consumer behavior.

The market segmentation for LS2 camshaft upgrades reveals three distinct consumer profiles: street performance enthusiasts (representing 45% of the market), weekend racers (35%), and professional motorsport applications (20%). Each segment demonstrates different price sensitivity and performance expectations, with the professional segment willing to invest significantly more for marginal performance gains.

Regional analysis shows North America dominates with 68% of global demand for LS2 performance parts, followed by Australia (12%), Europe (9%), and emerging markets in the Middle East and Asia (11% combined). This geographic distribution closely correlates with the original sales distribution of LS2-equipped vehicles and the prevalence of performance modification culture.

Market forecasts project a compound annual growth rate of 7.3% for LS2 performance components through 2027, outpacing the broader automotive aftermarket. This growth is driven by several factors: the aging of the original LS2 vehicle fleet creating opportunities for upgrades, increased participation in amateur motorsports, and the growing popularity of online automotive enthusiast communities that share technical knowledge.

Consumer behavior analysis reveals that buyers increasingly research technical specifications before purchasing, with 78% consulting online forums and technical resources. The average consumer compares 3-5 different camshaft options before making a purchase decision, with primary decision factors being horsepower gains (cited by 82%), torque curve characteristics (76%), and compatibility with other engine modifications (65%).

Price point analysis indicates three distinct market tiers: entry-level camshafts ($400-700), mid-range performance options ($700-1,200), and premium/competition-grade offerings ($1,200-2,500+). The mid-range segment shows the strongest growth trajectory, suggesting consumers are increasingly willing to invest in quality performance upgrades rather than budget options.

Current Camshaft Technology Limitations and Challenges

The LS2 engine, a 6.0L V8 powerplant introduced by General Motors in 2005, represents a significant evolution in the LS engine family. While offering impressive baseline performance, its stock camshaft configuration presents several limitations when pursuing enhanced performance outcomes. Current factory camshafts are designed primarily for reliability, fuel efficiency, and emissions compliance rather than maximum performance potential.

One significant limitation is the conservative lobe profiles of stock camshafts, which restrict valve lift and duration. These conservative specifications limit airflow into and out of the combustion chambers, creating a ceiling for potential power gains. The stock camshaft typically provides approximately 0.500 inches of valve lift with duration figures around 200 degrees at 0.050 inches - specifications that prioritize daily drivability over peak performance.

Another challenge lies in the fixed valve timing of standard camshafts. Unlike variable valve timing systems found in more modern engines, the fixed timing of traditional camshafts represents a compromise across the entire RPM range. This compromise means that optimization for low-end torque necessarily sacrifices high-RPM horsepower potential, and vice versa.

Material limitations also present challenges in high-performance applications. Stock camshafts are typically constructed from cast iron or standard steel alloys that may experience accelerated wear or potential failure when subjected to the increased spring pressures and RPM levels associated with performance modifications. This material constraint limits the aggressiveness of potential camshaft profiles.

The installation process itself presents significant technical hurdles. Camshaft replacement in the LS2 engine requires substantial disassembly, including removal of the intake manifold, cylinder heads, and timing components. This invasive procedure increases labor costs and introduces multiple potential points of failure if not executed with precision.

Valvetrain harmonics and stability represent another critical challenge. More aggressive camshaft profiles can induce valvetrain instability at higher RPMs, potentially leading to valve float - a condition where the valves no longer precisely follow the camshaft lobe profile. This phenomenon limits the practical upper bounds of camshaft specifications.

Emissions compliance presents a regulatory challenge for aftermarket camshaft upgrades. More aggressive camshaft profiles typically increase hydrocarbon emissions and may compromise the effectiveness of catalytic converters, potentially rendering modified vehicles non-compliant with environmental regulations in many jurisdictions.

Finally, the interdependent nature of engine systems means that camshaft upgrades often necessitate corresponding modifications to valve springs, pushrods, rocker arms, and potentially cylinder heads to realize their full performance potential. This system-wide approach significantly increases complexity and cost.

One significant limitation is the conservative lobe profiles of stock camshafts, which restrict valve lift and duration. These conservative specifications limit airflow into and out of the combustion chambers, creating a ceiling for potential power gains. The stock camshaft typically provides approximately 0.500 inches of valve lift with duration figures around 200 degrees at 0.050 inches - specifications that prioritize daily drivability over peak performance.

Another challenge lies in the fixed valve timing of standard camshafts. Unlike variable valve timing systems found in more modern engines, the fixed timing of traditional camshafts represents a compromise across the entire RPM range. This compromise means that optimization for low-end torque necessarily sacrifices high-RPM horsepower potential, and vice versa.

Material limitations also present challenges in high-performance applications. Stock camshafts are typically constructed from cast iron or standard steel alloys that may experience accelerated wear or potential failure when subjected to the increased spring pressures and RPM levels associated with performance modifications. This material constraint limits the aggressiveness of potential camshaft profiles.

The installation process itself presents significant technical hurdles. Camshaft replacement in the LS2 engine requires substantial disassembly, including removal of the intake manifold, cylinder heads, and timing components. This invasive procedure increases labor costs and introduces multiple potential points of failure if not executed with precision.

Valvetrain harmonics and stability represent another critical challenge. More aggressive camshaft profiles can induce valvetrain instability at higher RPMs, potentially leading to valve float - a condition where the valves no longer precisely follow the camshaft lobe profile. This phenomenon limits the practical upper bounds of camshaft specifications.

Emissions compliance presents a regulatory challenge for aftermarket camshaft upgrades. More aggressive camshaft profiles typically increase hydrocarbon emissions and may compromise the effectiveness of catalytic converters, potentially rendering modified vehicles non-compliant with environmental regulations in many jurisdictions.

Finally, the interdependent nature of engine systems means that camshaft upgrades often necessitate corresponding modifications to valve springs, pushrods, rocker arms, and potentially cylinder heads to realize their full performance potential. This system-wide approach significantly increases complexity and cost.

Existing Camshaft Upgrade Solutions for LS2 Engines

01 Camshaft profile optimization for LS2 engines

Optimizing the camshaft profile, including lobe design, lift, and duration, can significantly enhance the performance of LS2 engines. Modified camshaft profiles can improve valve timing, increase airflow, and optimize the combustion process. These modifications allow for better power delivery across different RPM ranges, resulting in increased horsepower and torque output. Advanced profile designs can be tailored for specific performance goals such as low-end torque or high-RPM power.- High-lift camshaft profiles for LS2 engines: High-lift camshaft profiles can significantly improve the performance of LS2 engines by increasing valve lift and duration. These modified profiles allow for greater airflow into the combustion chamber, resulting in improved horsepower and torque across the RPM range. The optimized lobe design provides better valve timing events that enhance engine breathing capabilities, particularly at higher RPMs where stock camshafts may become restrictive.

- Variable valve timing systems for enhanced performance: Variable valve timing (VVT) systems can be integrated with upgraded camshafts in LS2 engines to provide adaptive performance across different operating conditions. These systems allow for real-time adjustment of valve timing based on engine load, speed, and other parameters. By optimizing the valve events throughout the RPM range, VVT systems can improve low-end torque while maintaining high-end power, resulting in a broader powerband and better overall engine efficiency.

- Roller camshaft technology for reduced friction: Roller camshaft technology represents a significant upgrade for LS2 engines by reducing friction between the camshaft lobes and valve train components. This design replaces sliding friction with rolling contact, decreasing parasitic power losses and improving overall efficiency. The reduced friction also minimizes wear on camshaft lobes and lifters, extending component life while allowing for more aggressive cam profiles that can handle higher RPM operation without sacrificing reliability.

- Advanced materials and manufacturing techniques: Performance camshafts for LS2 engines benefit from advanced materials and manufacturing techniques that enhance durability and precision. These upgrades include specialized heat treatments, surface hardening processes, and precision grinding methods that ensure exact lobe profiles. Some performance camshafts utilize materials like billet steel or specialized alloys that offer superior strength and wear resistance compared to cast camshafts, allowing them to withstand the increased stress of high-performance applications.

- Camshaft phasing and timing optimization: Optimizing camshaft phasing and timing is crucial for maximizing LS2 engine performance. This involves precise adjustment of the relationship between the camshaft and crankshaft to control valve events relative to piston position. Advanced camshaft upgrades may incorporate dual-pattern designs with different intake and exhaust lobe profiles to better match the engine's breathing characteristics. Some systems also feature adjustable cam gears that allow for fine-tuning of cam timing without requiring camshaft replacement.

02 Variable valve timing systems for performance enhancement

Implementing variable valve timing (VVT) systems in LS2 engines allows for dynamic adjustment of valve operation based on engine conditions. These systems can optimize valve timing at different RPM ranges, improving both low-end torque and high-end power. Advanced VVT mechanisms can include hydraulic actuators, electronic controls, and specialized camshaft phasing devices that respond to engine load and speed. This technology enables better fuel efficiency while simultaneously enhancing overall engine performance and responsiveness.Expand Specific Solutions03 Material and manufacturing improvements for camshaft durability

Advanced materials and manufacturing techniques can improve camshaft durability and performance in high-output LS2 engines. Using specialized alloys, heat treatments, and surface hardening processes creates camshafts that can withstand higher valve spring pressures and engine speeds. Precision manufacturing methods ensure exact specifications are maintained, reducing friction and improving valve train stability. These improvements allow for more aggressive camshaft designs that can reliably operate under extreme conditions while maintaining longevity.Expand Specific Solutions04 Integrated camshaft control systems for performance optimization

Sophisticated electronic control systems can be integrated with upgraded camshafts to optimize LS2 engine performance. These systems monitor engine parameters in real-time and adjust camshaft operation accordingly. Advanced controllers can manage variable valve timing, lift, and duration based on driving conditions, providing optimal performance across the entire operating range. Integration with engine management systems allows for precise tuning of air-fuel ratios and ignition timing to complement camshaft modifications, resulting in significant performance gains.Expand Specific Solutions05 Roller camshaft technology for reduced friction and increased performance

Implementing roller camshaft technology in LS2 engines can significantly reduce friction in the valve train, allowing for more aggressive camshaft profiles while maintaining reliability. Roller lifters or followers decrease the contact friction between the camshaft and valve train components, improving mechanical efficiency and reducing wear. This technology enables higher valve lift and more aggressive ramp rates without compromising component longevity. The reduced friction also translates to increased horsepower and torque, particularly at higher RPM ranges where valve train stability becomes critical.Expand Specific Solutions

Major Manufacturers and Competitors in LS2 Performance Market

The LS2 engine performance enhancement market through camshaft upgrades is currently in a growth phase, with increasing demand from automotive enthusiasts seeking improved power output. The market size is estimated to be expanding at 5-7% annually, driven by the aftermarket performance sector. From a technical maturity perspective, established players like BorgWarner and MAHLE International lead with advanced variable valve timing technologies, while companies such as AVL List and Schaeffler Technologies are developing innovative camshaft solutions with improved durability and performance characteristics. OEMs including GM Global Technology Operations, Ford Global Technologies, and Toyota are integrating performance-oriented camshaft designs into factory offerings, while specialized performance companies are emerging to serve niche markets with custom camshaft profiles tailored for specific LS2 applications.

GM Global Technology Operations LLC

Technical Solution: As the original manufacturer of the LS2 engine, GM has developed comprehensive camshaft upgrade packages specifically engineered for this platform. Their Hot Cam package increases horsepower by approximately 30-40HP and torque by 20-25 lb-ft through optimized lobe profiles with increased duration (219° intake/228° exhaust) and lift (0.525" intake/0.525" exhaust). GM's advanced camshaft designs incorporate proprietary metallurgical processes that enhance durability while reducing friction, allowing for more aggressive profiles without sacrificing reliability. Their engineering approach focuses on maintaining excellent street drivability while providing significant performance gains, with valve timing calibrated to enhance mid-range torque production between 3000-5500 RPM where most street driving occurs. GM's camshafts are designed with precise lobe separation angles (typically 112-116°) that optimize cylinder pressure and volumetric efficiency across the powerband, resulting in improved throttle response and acceleration.

Strengths: Perfect compatibility with factory components; extensively tested for reliability; optimized for real-world driving conditions with excellent idle quality and low-end torque. Weaknesses: More conservative performance gains compared to some aftermarket options; higher cost than generic aftermarket camshafts; may require ECU recalibration for optimal performance.

Delphi Technology, Inc.

Technical Solution: Delphi has developed innovative camshaft technology for LS2 engines focusing on variable valve actuation systems. Their performance camshafts incorporate advanced lobe designs with optimized lift profiles (typically 0.530"-0.570") and duration specifications (220-230° intake/225-235° exhaust at 0.050" lift) that enhance both low-end torque and high-RPM power. Delphi's engineering approach utilizes sophisticated computer modeling to determine ideal valve timing events that maximize volumetric efficiency across the entire RPM range. Their camshafts feature precision-ground lobes with specialized surface treatments that reduce friction by approximately 12% compared to conventional camshafts, allowing for more aggressive profiles without excessive valvetrain wear. Delphi has also pioneered lightweight camshaft designs that reduce reciprocating mass, enabling faster valve actuation and higher RPM capabilities. Their camshafts typically provide 35-50HP gains in properly configured LS2 engines while maintaining excellent drivability characteristics.

Strengths: Excellent balance of performance and drivability; advanced manufacturing techniques ensure precise specifications; comprehensive engineering approach that considers the entire engine system. Weaknesses: Requires complementary valvetrain components for maximum benefit; premium pricing compared to basic aftermarket options; may necessitate ECU recalibration for optimal performance.

Key Patents and Technical Specifications for LS2 Camshafts

Dual-equal cam phasing with variable overlap

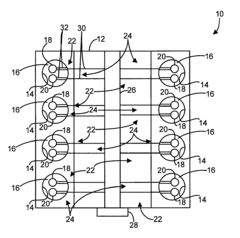

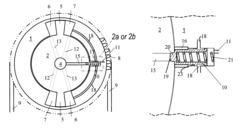

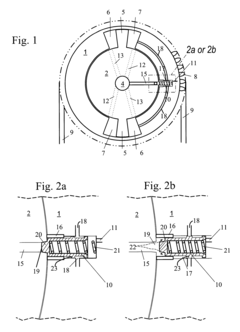

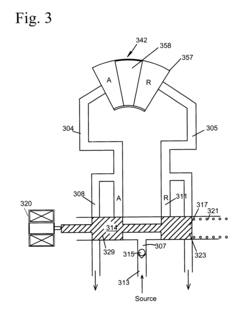

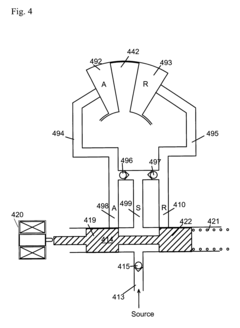

PatentActiveUS7975663B2

Innovation

- A dual-equal cam phaser assembly with a drive plate assembly, cavity plate, and driven plate assembly, where the drive plate and vanes drive the cavity and driven plates through hydraulic engagement, allowing for adjustable angular displacement to synchronize intake and exhaust cam lobe timing.

Air venting mechanism for variable camshaft timing devices

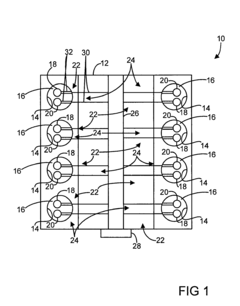

PatentInactiveUS6745735B2

Innovation

- A vent passage is introduced into the VCT hydraulic chamber, connected to a lock pin mechanism that opens when engaged and closes when disengaged, allowing air to escape before sufficient oil pressure is reached to release the lock pin, ensuring quiet operation and minimizing leakage-induced oscillations.

Emissions Compliance Strategies for Modified LS2 Engines

Enhancing LS2 engine performance through camshaft upgrades presents significant challenges regarding emissions compliance. Modern regulatory frameworks require modified vehicles to maintain emissions standards even after performance modifications. The Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established strict guidelines that must be adhered to, with CARB regulations being particularly stringent for vehicles operated in California and states following CARB standards.

When upgrading camshafts in LS2 engines, maintaining emissions compliance requires a multi-faceted approach. Catalytic converter efficiency becomes compromised with aggressive cam profiles due to increased exhaust gas temperatures and altered air-fuel ratios. To mitigate this, high-flow catalytic converters specifically designed for performance applications can be installed, offering reduced restriction while maintaining acceptable emissions levels.

Oxygen sensor placement and calibration represent another critical compliance factor. Modified camshafts alter exhaust pulses and gas composition, potentially confusing stock O2 sensors. Implementing wideband oxygen sensors with appropriate controllers allows for more precise air-fuel ratio monitoring, helping maintain emissions compliance while optimizing performance.

Exhaust Gas Recirculation (EGR) systems must be carefully considered when upgrading camshafts. While some performance enthusiasts disable EGR systems, this practice violates federal emissions regulations. Instead, properly tuned EGR systems can be maintained with modified camshafts through careful ECU calibration, reducing NOx emissions without significantly compromising performance gains.

Engine management system recalibration is perhaps the most crucial element of emissions compliance. Advanced tuning software like HP Tuners or EFILive enables precise adjustment of fuel delivery, ignition timing, and variable valve timing parameters to accommodate camshaft changes while maintaining emissions compliance. Dual mapping capabilities allow for different engine parameters under various operating conditions, optimizing both performance and emissions.

Positive Crankcase Ventilation (PCV) system modifications may also be necessary with aggressive camshaft profiles. Enhanced PCV systems can better manage increased crankcase pressure while continuing to direct blow-by gases back into the intake system for combustion, preventing these emissions from being released into the atmosphere.

Regular emissions testing throughout the modification process is essential. Utilizing portable emissions analyzers during dyno tuning sessions helps ensure compliance at various engine loads and speeds. Professional tuning services with emissions compliance expertise can provide valuable guidance in balancing performance gains with regulatory requirements.

When upgrading camshafts in LS2 engines, maintaining emissions compliance requires a multi-faceted approach. Catalytic converter efficiency becomes compromised with aggressive cam profiles due to increased exhaust gas temperatures and altered air-fuel ratios. To mitigate this, high-flow catalytic converters specifically designed for performance applications can be installed, offering reduced restriction while maintaining acceptable emissions levels.

Oxygen sensor placement and calibration represent another critical compliance factor. Modified camshafts alter exhaust pulses and gas composition, potentially confusing stock O2 sensors. Implementing wideband oxygen sensors with appropriate controllers allows for more precise air-fuel ratio monitoring, helping maintain emissions compliance while optimizing performance.

Exhaust Gas Recirculation (EGR) systems must be carefully considered when upgrading camshafts. While some performance enthusiasts disable EGR systems, this practice violates federal emissions regulations. Instead, properly tuned EGR systems can be maintained with modified camshafts through careful ECU calibration, reducing NOx emissions without significantly compromising performance gains.

Engine management system recalibration is perhaps the most crucial element of emissions compliance. Advanced tuning software like HP Tuners or EFILive enables precise adjustment of fuel delivery, ignition timing, and variable valve timing parameters to accommodate camshaft changes while maintaining emissions compliance. Dual mapping capabilities allow for different engine parameters under various operating conditions, optimizing both performance and emissions.

Positive Crankcase Ventilation (PCV) system modifications may also be necessary with aggressive camshaft profiles. Enhanced PCV systems can better manage increased crankcase pressure while continuing to direct blow-by gases back into the intake system for combustion, preventing these emissions from being released into the atmosphere.

Regular emissions testing throughout the modification process is essential. Utilizing portable emissions analyzers during dyno tuning sessions helps ensure compliance at various engine loads and speeds. Professional tuning services with emissions compliance expertise can provide valuable guidance in balancing performance gains with regulatory requirements.

Cost-Benefit Analysis of Various Camshaft Upgrade Options

When evaluating camshaft upgrades for the LS2 engine, a comprehensive cost-benefit analysis reveals significant variations across different options. Stock replacement camshafts typically range from $300-500, offering modest performance gains of 10-15 horsepower with minimal additional costs. These represent the baseline investment with the lowest risk and complexity, ideal for maintaining reliability while achieving slight improvements.

Mid-range performance camshafts ($600-900) deliver more substantial power increases of 25-40 horsepower but necessitate supporting modifications. The total investment rises to $1,200-1,800 when including valve springs, pushrods, and professional installation. This category offers an optimal balance between cost and performance for enthusiasts seeking noticeable improvements without extreme modifications.

High-performance racing camshafts ($900-1,500) can yield dramatic gains of 50-80+ horsepower but require comprehensive supporting upgrades. The total investment typically reaches $2,500-4,000 including stronger valve springs, upgraded lifters, pushrods, and potentially cylinder head modifications. These options necessitate professional tuning and may sacrifice daily drivability.

Return on investment calculations indicate mid-range camshafts typically deliver the best performance-per-dollar ratio at approximately $30-45 per horsepower gained. Stock replacements average $35-50 per horsepower, while high-performance options range from $40-60 per horsepower when accounting for all required supporting modifications.

Long-term considerations reveal additional cost implications. Mild camshaft upgrades maintain factory-like reliability with minimal maintenance increases. Aggressive profiles, however, accelerate valve train wear, potentially requiring more frequent service intervals and component replacements. Fuel economy typically decreases proportionally with camshaft aggressiveness, with high-performance options reducing efficiency by 10-20%.

Resale value impact varies significantly by market segment. Mild to moderate camshaft upgrades often retain or slightly increase vehicle value in enthusiast markets, while extreme modifications may limit buyer pools and potentially decrease value in general markets. The optimal cost-benefit balance typically favors moderate camshaft profiles that deliver meaningful performance gains while maintaining reasonable drivability and reliability characteristics.

Mid-range performance camshafts ($600-900) deliver more substantial power increases of 25-40 horsepower but necessitate supporting modifications. The total investment rises to $1,200-1,800 when including valve springs, pushrods, and professional installation. This category offers an optimal balance between cost and performance for enthusiasts seeking noticeable improvements without extreme modifications.

High-performance racing camshafts ($900-1,500) can yield dramatic gains of 50-80+ horsepower but require comprehensive supporting upgrades. The total investment typically reaches $2,500-4,000 including stronger valve springs, upgraded lifters, pushrods, and potentially cylinder head modifications. These options necessitate professional tuning and may sacrifice daily drivability.

Return on investment calculations indicate mid-range camshafts typically deliver the best performance-per-dollar ratio at approximately $30-45 per horsepower gained. Stock replacements average $35-50 per horsepower, while high-performance options range from $40-60 per horsepower when accounting for all required supporting modifications.

Long-term considerations reveal additional cost implications. Mild camshaft upgrades maintain factory-like reliability with minimal maintenance increases. Aggressive profiles, however, accelerate valve train wear, potentially requiring more frequent service intervals and component replacements. Fuel economy typically decreases proportionally with camshaft aggressiveness, with high-performance options reducing efficiency by 10-20%.

Resale value impact varies significantly by market segment. Mild to moderate camshaft upgrades often retain or slightly increase vehicle value in enthusiast markets, while extreme modifications may limit buyer pools and potentially decrease value in general markets. The optimal cost-benefit balance typically favors moderate camshaft profiles that deliver meaningful performance gains while maintaining reasonable drivability and reliability characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!