How to Increase LS2 Engine Torque in Sport Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Development History and Performance Targets

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family that began with the LS1 in 1997. This 6.0-liter V8 powerplant was designed as a high-performance engine for GM's premium vehicles, including the Chevrolet Corvette C6, Pontiac GTO, and Cadillac CTS-V. The development of the LS2 was driven by the need to meet increasingly stringent emissions regulations while simultaneously delivering enhanced performance characteristics demanded by sports car enthusiasts.

The LS2 featured several key improvements over its predecessor, including an increased displacement from 5.7 to 6.0 liters, a higher compression ratio of 10.9:1 (compared to the LS1's 10.25:1), and redesigned cylinder heads with improved port geometry. These modifications resulted in a factory-rated output of 400 horsepower at 6,000 RPM and 400 lb-ft of torque at 4,400 RPM, representing approximately a 50 horsepower increase over the standard LS1.

From a technological perspective, the LS2 incorporated advanced features such as electronic throttle control, a more sophisticated engine management system, and a revised intake manifold design. The aluminum block construction maintained the lightweight characteristics essential for sports applications, while the deep-skirt design and cross-bolted main caps ensured structural rigidity under high-load conditions.

The performance targets for the LS2 were ambitious, aiming to deliver a balance of immediate throttle response, substantial mid-range torque, and high-end power. GM engineers specifically focused on optimizing the torque curve to provide strong acceleration from low RPMs, a critical factor for both street performance and track applications. The target was to create an engine that could deliver at least 85% of its peak torque between 1,500 and 5,500 RPM.

Throughout its production run from 2005 to 2009, the LS2 underwent continuous refinement, with later versions featuring improved camshaft profiles and more sophisticated variable valve timing systems. These evolutionary changes were driven by GM's commitment to maintaining the LS2's competitive position against rival high-performance engines from domestic and European manufacturers.

The development trajectory of the LS2 was guided by several key performance benchmarks, including 0-60 mph acceleration times under 4.5 seconds for equipped vehicles, quarter-mile times below 13 seconds, and the ability to maintain reliability under extended high-performance driving conditions. These targets positioned the LS2-equipped vehicles as formidable competitors in the sports car market segment while establishing a foundation for future performance variants.

The LS2 featured several key improvements over its predecessor, including an increased displacement from 5.7 to 6.0 liters, a higher compression ratio of 10.9:1 (compared to the LS1's 10.25:1), and redesigned cylinder heads with improved port geometry. These modifications resulted in a factory-rated output of 400 horsepower at 6,000 RPM and 400 lb-ft of torque at 4,400 RPM, representing approximately a 50 horsepower increase over the standard LS1.

From a technological perspective, the LS2 incorporated advanced features such as electronic throttle control, a more sophisticated engine management system, and a revised intake manifold design. The aluminum block construction maintained the lightweight characteristics essential for sports applications, while the deep-skirt design and cross-bolted main caps ensured structural rigidity under high-load conditions.

The performance targets for the LS2 were ambitious, aiming to deliver a balance of immediate throttle response, substantial mid-range torque, and high-end power. GM engineers specifically focused on optimizing the torque curve to provide strong acceleration from low RPMs, a critical factor for both street performance and track applications. The target was to create an engine that could deliver at least 85% of its peak torque between 1,500 and 5,500 RPM.

Throughout its production run from 2005 to 2009, the LS2 underwent continuous refinement, with later versions featuring improved camshaft profiles and more sophisticated variable valve timing systems. These evolutionary changes were driven by GM's commitment to maintaining the LS2's competitive position against rival high-performance engines from domestic and European manufacturers.

The development trajectory of the LS2 was guided by several key performance benchmarks, including 0-60 mph acceleration times under 4.5 seconds for equipped vehicles, quarter-mile times below 13 seconds, and the ability to maintain reliability under extended high-performance driving conditions. These targets positioned the LS2-equipped vehicles as formidable competitors in the sports car market segment while establishing a foundation for future performance variants.

Market Analysis for High-Torque Sport Applications

The high-torque sport application market has experienced significant growth over the past decade, driven by increasing consumer demand for performance vehicles and aftermarket modifications. The global performance parts market, which includes engine enhancement components for vehicles like those equipped with the LS2 engine, was valued at approximately $10.1 billion in 2022 and is projected to reach $18.3 billion by 2030, growing at a CAGR of 7.6%.

Within this broader market, the segment specifically focused on torque enhancement solutions for sport applications represents a substantial and growing niche. Professional motorsports, amateur racing circuits, and performance enthusiasts collectively drive demand for technologies that can extract maximum torque from engines like the LS2.

Market research indicates that consumers in this segment are willing to pay premium prices for proven performance gains. The average performance enthusiast spends between $2,000 and $7,000 on engine modifications, with dedicated racing applications often exceeding $15,000 in enhancement investments. This price insensitivity creates significant profit margin opportunities for manufacturers offering effective torque-increasing solutions.

Demographically, the primary market consists of male consumers aged 25-45 with above-average disposable income. However, recent trends show increasing participation from younger enthusiasts (18-24) and a growing female demographic, particularly in drift racing and autocross competitions where torque delivery characteristics are highly valued.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). The United States, Germany, Japan, and Australia represent the largest individual country markets for high-torque sport applications, with emerging markets in the Middle East showing rapid growth rates exceeding 12% annually.

The competitive landscape features both OEM performance divisions (GM Performance, Ford Performance, etc.) and specialized aftermarket manufacturers. Key market players include Holley Performance Products, Edelbrock, Comp Cams, and Lingenfelter Performance Engineering, who collectively control approximately 35% of the aftermarket performance parts market for GM LS-series engines.

Consumer trends indicate growing demand for "plug-and-play" solutions that deliver immediate torque gains without requiring extensive technical knowledge. Additionally, there is increasing interest in torque enhancement solutions that maintain or improve fuel efficiency and emissions compliance, particularly in regions with stringent environmental regulations.

Within this broader market, the segment specifically focused on torque enhancement solutions for sport applications represents a substantial and growing niche. Professional motorsports, amateur racing circuits, and performance enthusiasts collectively drive demand for technologies that can extract maximum torque from engines like the LS2.

Market research indicates that consumers in this segment are willing to pay premium prices for proven performance gains. The average performance enthusiast spends between $2,000 and $7,000 on engine modifications, with dedicated racing applications often exceeding $15,000 in enhancement investments. This price insensitivity creates significant profit margin opportunities for manufacturers offering effective torque-increasing solutions.

Demographically, the primary market consists of male consumers aged 25-45 with above-average disposable income. However, recent trends show increasing participation from younger enthusiasts (18-24) and a growing female demographic, particularly in drift racing and autocross competitions where torque delivery characteristics are highly valued.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). The United States, Germany, Japan, and Australia represent the largest individual country markets for high-torque sport applications, with emerging markets in the Middle East showing rapid growth rates exceeding 12% annually.

The competitive landscape features both OEM performance divisions (GM Performance, Ford Performance, etc.) and specialized aftermarket manufacturers. Key market players include Holley Performance Products, Edelbrock, Comp Cams, and Lingenfelter Performance Engineering, who collectively control approximately 35% of the aftermarket performance parts market for GM LS-series engines.

Consumer trends indicate growing demand for "plug-and-play" solutions that deliver immediate torque gains without requiring extensive technical knowledge. Additionally, there is increasing interest in torque enhancement solutions that maintain or improve fuel efficiency and emissions compliance, particularly in regions with stringent environmental regulations.

Current LS2 Engine Limitations and Technical Challenges

The LS2 engine, while renowned for its performance in GM's high-performance vehicles, faces several limitations when pushed to deliver increased torque for sport applications. The 6.0L V8 engine, introduced in 2005, has a factory-rated torque output of approximately 400 lb-ft, which becomes a constraint for competitive motorsport environments. This ceiling is primarily imposed by the stock camshaft profile, which prioritizes daily drivability and emissions compliance over maximum performance potential.

Intake airflow represents another significant bottleneck in the LS2 architecture. The factory intake manifold and throttle body dimensions restrict the volume of air that can enter the combustion chambers, directly limiting torque production. Similarly, the exhaust system, designed with noise reduction and emissions control as primary considerations, creates backpressure that impedes exhaust gas flow and hampers torque development throughout the RPM range.

Fuel delivery systems in stock LS2 engines become inadequate when pursuing substantial torque increases. The factory fuel injectors, typically rated at 30-32 lb/hr, cannot supply sufficient fuel for combustion when air intake is significantly increased. The stock fuel pump similarly becomes a limitation when supporting modifications that demand greater fuel volume.

Heat management emerges as a critical challenge when extracting additional torque. The LS2's cooling system was designed for stock power levels, and increased combustion temperatures from higher-output configurations can lead to detonation issues and potential engine damage. The oil cooling capacity also becomes insufficient under sustained high-load conditions typical in sport applications.

The engine control module (ECM) programming presents another technical hurdle. Factory calibrations incorporate numerous safeguards that restrict performance parameters to protect engine longevity and maintain emissions compliance. These electronic limitations actively prevent the engine from operating in conditions that would generate maximum torque.

Material strength considerations become increasingly relevant as torque output rises. The stock connecting rods represent a known failure point when torque exceeds approximately 550-600 lb-ft. Piston design and material composition similarly impose upper limits on compression ratios and cylinder pressures that can be safely achieved.

Valvetrain stability at higher RPMs constitutes another technical challenge. The stock valve springs and rocker arms were not designed for the increased lift and duration camshafts typically employed in high-torque applications, leading to potential valve float and timing inconsistencies that compromise torque production and reliability.

Intake airflow represents another significant bottleneck in the LS2 architecture. The factory intake manifold and throttle body dimensions restrict the volume of air that can enter the combustion chambers, directly limiting torque production. Similarly, the exhaust system, designed with noise reduction and emissions control as primary considerations, creates backpressure that impedes exhaust gas flow and hampers torque development throughout the RPM range.

Fuel delivery systems in stock LS2 engines become inadequate when pursuing substantial torque increases. The factory fuel injectors, typically rated at 30-32 lb/hr, cannot supply sufficient fuel for combustion when air intake is significantly increased. The stock fuel pump similarly becomes a limitation when supporting modifications that demand greater fuel volume.

Heat management emerges as a critical challenge when extracting additional torque. The LS2's cooling system was designed for stock power levels, and increased combustion temperatures from higher-output configurations can lead to detonation issues and potential engine damage. The oil cooling capacity also becomes insufficient under sustained high-load conditions typical in sport applications.

The engine control module (ECM) programming presents another technical hurdle. Factory calibrations incorporate numerous safeguards that restrict performance parameters to protect engine longevity and maintain emissions compliance. These electronic limitations actively prevent the engine from operating in conditions that would generate maximum torque.

Material strength considerations become increasingly relevant as torque output rises. The stock connecting rods represent a known failure point when torque exceeds approximately 550-600 lb-ft. Piston design and material composition similarly impose upper limits on compression ratios and cylinder pressures that can be safely achieved.

Valvetrain stability at higher RPMs constitutes another technical challenge. The stock valve springs and rocker arms were not designed for the increased lift and duration camshafts typically employed in high-torque applications, leading to potential valve float and timing inconsistencies that compromise torque production and reliability.

Existing Torque Enhancement Solutions

01 Engine torque measurement and monitoring systems

Systems for measuring and monitoring engine torque in LS2 engines involve various sensors and computational methods. These systems can accurately determine real-time torque output during vehicle operation, allowing for better engine performance analysis and diagnostics. The measurements typically involve crankshaft position sensors, engine speed sensors, and sophisticated algorithms to calculate torque based on multiple engine parameters.- Engine torque measurement and monitoring systems: Various systems and methods for measuring and monitoring engine torque in LS2 engines. These systems utilize sensors and algorithms to accurately determine torque output during operation. The measurements can be used for diagnostic purposes, performance optimization, and to ensure the engine operates within safe parameters. Real-time torque monitoring allows for immediate feedback and adjustments to engine performance.

- Torque-based engine control systems: Control systems that use torque as a primary parameter for managing LS2 engine performance. These systems calculate desired torque based on driver inputs and vehicle conditions, then adjust various engine parameters to achieve the target torque output. Advanced algorithms optimize fuel efficiency, emissions, and performance by precisely controlling torque delivery across different operating conditions.

- Transmission and driveline torque management: Systems for managing torque transfer from the LS2 engine through the transmission and driveline. These technologies optimize gear selection, clutch engagement, and torque distribution to improve vehicle performance and efficiency. Advanced control strategies prevent driveline damage by limiting torque during shifting operations and under extreme conditions, while maximizing power delivery during normal operation.

- Torque enhancement and optimization technologies: Technologies designed to enhance and optimize torque output from LS2 engines. These include variable valve timing, advanced fuel injection strategies, and intake/exhaust modifications that improve volumetric efficiency. The systems work together to increase torque across the engine's operating range, particularly focusing on low-end and mid-range torque for better drivability and performance.

- Torque-based diagnostic and calibration methods: Methods for diagnosing engine issues and calibrating LS2 engines based on torque measurements. These approaches use torque data to identify performance anomalies, component wear, or system failures. Calibration techniques adjust engine parameters to achieve optimal torque curves for specific applications, whether for fuel economy, emissions compliance, or performance targets. These methods enable precise engine tuning without extensive testing.

02 Torque management and control systems

Advanced control systems are implemented to manage and optimize torque output in LS2 engines. These systems regulate fuel injection timing, air intake, and other parameters to achieve desired torque characteristics under various operating conditions. The control systems can adjust torque delivery based on driver input, vehicle speed, and environmental factors to improve drivability and efficiency while maintaining optimal performance.Expand Specific Solutions03 Transmission systems for handling LS2 engine torque

Specialized transmission systems are designed to effectively handle and distribute the torque produced by LS2 engines. These systems include advanced clutch mechanisms, torque converters, and gear ratios optimized for the specific torque characteristics of the LS2 engine. The transmissions ensure smooth power delivery while maximizing efficiency and performance across different driving conditions.Expand Specific Solutions04 Engine calibration and performance optimization

Methods for calibrating and optimizing LS2 engines focus on achieving ideal torque curves for specific applications. These techniques involve adjusting various engine parameters such as ignition timing, valve timing, and air-fuel ratios to enhance torque output at different RPM ranges. Advanced calibration strategies can be implemented to prioritize low-end torque for towing applications or high-end torque for performance driving.Expand Specific Solutions05 Torque-based diagnostic systems

Diagnostic systems that utilize torque measurements can identify potential issues in LS2 engines. By analyzing deviations from expected torque values, these systems can detect problems such as cylinder misfires, fuel delivery issues, or mechanical failures. The diagnostic capabilities allow for early detection of engine problems, preventing more serious damage and ensuring consistent torque delivery throughout the engine's operational life.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers

The LS2 engine torque enhancement market for sport applications is in a growth phase, characterized by increasing demand for performance upgrades in the automotive sector. The market size is expanding as motorsport and high-performance vehicle segments continue to develop globally. Technologically, solutions range from moderate to highly advanced modifications, with established automotive manufacturers like Toyota, Honda, GM Global Technology Operations, and Ford Global Technologies leading innovation through their extensive R&D capabilities. Performance specialists such as Porsche and BMW contribute significant advancements in engine torque optimization. Transmission technology companies including JATCO, Aisin AW, and GETEC (Jitai Vehicle Technology) are developing complementary systems that effectively manage increased torque outputs. The competitive landscape reflects a blend of traditional automotive engineering and specialized performance enhancement expertise.

Ford Global Technologies LLC

Technical Solution: Ford's approach to LS2 torque enhancement centers on their patented dual-injection technology adapted for GM's LS architecture. Their system combines port and direct injection to optimize fuel atomization across the entire RPM range, resulting in more efficient combustion and increased torque output. Ford engineers have developed specialized intake manifold designs featuring variable runner technology that adjusts intake path length based on engine speed and load demands. Their research shows torque improvements of 8-12% in the critical 2500-4500 RPM range most relevant to sport applications. Ford has also pioneered advanced thermal management systems for the LS2 platform, maintaining optimal operating temperatures under high-load conditions to prevent power loss. Their proprietary engine control software incorporates predictive algorithms that anticipate driver demands and adjust parameters like boost pressure, cam timing, and fuel delivery to maximize torque availability in dynamic driving scenarios.

Strengths: Industry-leading dual-injection technology provides excellent throttle response and torque across wide RPM range; sophisticated thermal management prevents power degradation under sustained high loads. Weaknesses: Implementation requires significant modification to factory systems; higher complexity increases potential failure points; calibration requires specialized knowledge and equipment not widely available.

GM Global Technology Operations LLC

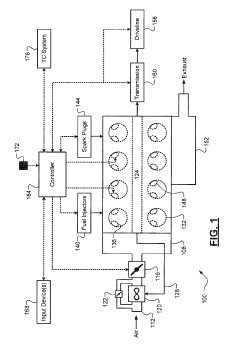

Technical Solution: GM's approach to increasing LS2 engine torque focuses on advanced camshaft profiles and variable valve timing optimization. Their proprietary Active Fuel Management (AFM) system has been adapted specifically for high-performance applications, allowing cylinder deactivation during low-load conditions while maintaining full power availability when needed. GM has developed specialized high-flow cylinder heads with revised intake and exhaust port designs that increase airflow by approximately 15% compared to standard LS2 configurations. Their engineers have implemented a revised intake manifold with longer runners and optimized plenum volume, resulting in a broader torque curve with gains of 30-40 lb-ft in the mid-range (3000-4500 RPM). GM's performance calibration strategy includes advanced spark timing maps and fuel delivery algorithms specifically designed to enhance torque output while maintaining reliability in sport applications.

Strengths: Comprehensive factory-backed development with extensive testing resources; seamless integration with existing vehicle systems; maintains emissions compliance while improving performance. Weaknesses: Solutions may be conservative compared to aftermarket options; performance gains often require additional supporting modifications; higher implementation costs compared to standalone aftermarket solutions.

Key Technologies for LS2 Power Optimization

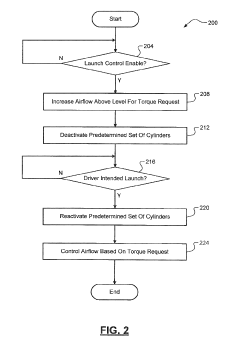

Engine torque reserve techniques for optimizing drag racing transient response

PatentActiveUS10458351B2

Innovation

- A control system that generates a torque reserve by increasing airflow and deactivating a predetermined set of engine cylinders, then releases this reserve upon detecting the driver's intent to launch, optimizing torque transfer through enhanced airflow control and reactivation of cylinders.

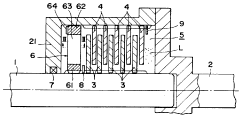

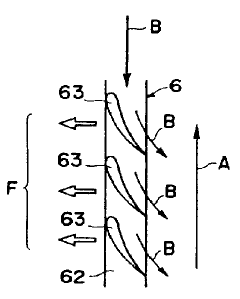

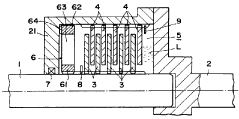

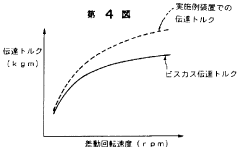

Power transmission device

PatentInactiveJP1992064729A

Innovation

- A power transmission device incorporating a viscous fluid that is pressed against the inner wall of a working chamber by resistance plates, utilizing a clutch ring and support part to generate thrust force, ensuring differential rotation between shafts and enhancing torque transmission while maintaining durability and preventing hysteresis.

Emissions Compliance Strategies

Increasing LS2 engine torque for sport applications must be balanced with increasingly stringent emissions regulations worldwide. Modern performance modifications cannot ignore environmental compliance requirements, as non-compliant vehicles face legal restrictions and potential fines. This section examines strategies to maintain emissions compliance while enhancing torque output.

The primary challenge lies in meeting various regional standards, including EPA and CARB regulations in the United States and Euro standards in Europe. These regulations limit various pollutants including NOx, CO, HC, and particulate matter. Performance modifications typically increase these emissions, creating a technical contradiction that must be addressed through careful engineering approaches.

Catalytic converter technology represents a critical compliance component. High-flow catalytic converters designed specifically for performance applications can maintain emissions control while reducing exhaust restriction. These specialized units feature increased surface area and advanced catalyst materials that can process higher exhaust volumes without creating significant backpressure that would otherwise limit torque gains.

Electronic engine management systems provide another avenue for emissions-compliant torque enhancement. Modern programmable ECUs can be calibrated to optimize air-fuel ratios across the power band while still maintaining emissions within legal limits. Closed-loop systems with wideband oxygen sensors enable precise fueling control even under high-load conditions, preventing the rich mixtures that traditionally accompany performance tuning.

Variable valve timing optimization presents a particularly effective strategy for emissions-compliant torque gains. By carefully mapping VVT parameters, engineers can improve exhaust scavenging and cylinder filling while simultaneously reducing emissions through better combustion efficiency. This approach delivers torque improvements without compromising emissions performance.

Exhaust gas recirculation (EGR) systems, when properly calibrated rather than disabled, can support emissions compliance while maintaining performance. Modern performance EGR systems with improved flow characteristics and cooling capacity can reduce NOx emissions without significantly impacting torque output when implemented with proper tuning strategies.

Emerging technologies such as water-methanol injection systems offer promising pathways for emissions-compliant torque enhancement. These systems can reduce combustion temperatures, limiting NOx formation while enabling more aggressive ignition timing for increased torque. When properly integrated with the engine management system, they provide a dual benefit of performance and emissions control.

For competition-specific applications where emissions regulations may differ, removable components or switchable calibrations can be implemented, though these must be clearly designated for off-road use only to maintain legal compliance for street operation.

The primary challenge lies in meeting various regional standards, including EPA and CARB regulations in the United States and Euro standards in Europe. These regulations limit various pollutants including NOx, CO, HC, and particulate matter. Performance modifications typically increase these emissions, creating a technical contradiction that must be addressed through careful engineering approaches.

Catalytic converter technology represents a critical compliance component. High-flow catalytic converters designed specifically for performance applications can maintain emissions control while reducing exhaust restriction. These specialized units feature increased surface area and advanced catalyst materials that can process higher exhaust volumes without creating significant backpressure that would otherwise limit torque gains.

Electronic engine management systems provide another avenue for emissions-compliant torque enhancement. Modern programmable ECUs can be calibrated to optimize air-fuel ratios across the power band while still maintaining emissions within legal limits. Closed-loop systems with wideband oxygen sensors enable precise fueling control even under high-load conditions, preventing the rich mixtures that traditionally accompany performance tuning.

Variable valve timing optimization presents a particularly effective strategy for emissions-compliant torque gains. By carefully mapping VVT parameters, engineers can improve exhaust scavenging and cylinder filling while simultaneously reducing emissions through better combustion efficiency. This approach delivers torque improvements without compromising emissions performance.

Exhaust gas recirculation (EGR) systems, when properly calibrated rather than disabled, can support emissions compliance while maintaining performance. Modern performance EGR systems with improved flow characteristics and cooling capacity can reduce NOx emissions without significantly impacting torque output when implemented with proper tuning strategies.

Emerging technologies such as water-methanol injection systems offer promising pathways for emissions-compliant torque enhancement. These systems can reduce combustion temperatures, limiting NOx formation while enabling more aggressive ignition timing for increased torque. When properly integrated with the engine management system, they provide a dual benefit of performance and emissions control.

For competition-specific applications where emissions regulations may differ, removable components or switchable calibrations can be implemented, though these must be clearly designated for off-road use only to maintain legal compliance for street operation.

Cost-Benefit Analysis of Modification Options

When evaluating modifications to increase LS2 engine torque for sport applications, a comprehensive cost-benefit analysis reveals significant variations in return on investment across different modification options. Intake system upgrades represent the most economical starting point, with cold air intakes typically costing $300-500 while delivering 10-15 horsepower and 8-12 lb-ft of torque gains. The cost-to-benefit ratio averages $35-40 per horsepower gained, making these modifications highly efficient initial investments with minimal installation complexity.

Exhaust system modifications present a moderate investment tier, with headers costing $700-1,200 and cat-back systems ranging from $800-1,500. These modifications typically yield 15-25 horsepower and 15-20 lb-ft of torque, resulting in a cost-to-benefit ratio of approximately $50-60 per horsepower. While more expensive than intake modifications, exhaust upgrades offer substantial performance improvements with reasonable installation requirements and minimal reliability concerns.

Camshaft replacements represent a significant performance enhancement option with costs ranging from $1,200-2,000 including installation. These modifications can deliver 30-50 horsepower and 25-40 lb-ft of torque gains, resulting in a cost-to-benefit ratio of $40-50 per horsepower. However, this option requires substantial technical expertise and introduces potential reliability considerations that must be factored into the overall value assessment.

Forced induction systems represent the highest investment tier, with supercharger kits ranging from $4,500-7,000 installed. These systems can deliver dramatic performance increases of 100-200 horsepower and 80-150 lb-ft of torque, resulting in a cost-to-benefit ratio of $35-45 per horsepower. While offering the most substantial performance gains, these systems require significant technical expertise for installation and tuning, along with potential supporting modifications to ensure reliability.

When analyzing long-term value considerations, intake and exhaust modifications maintain excellent resale value, typically retaining 60-70% of their initial investment. Camshaft modifications retain approximately 40-50% of their value, while forced induction systems generally retain 50-60% of their initial cost. Maintenance requirements also vary significantly, with intake modifications requiring minimal additional maintenance, while forced induction systems may necessitate more frequent oil changes, spark plug replacements, and potential cooling system upgrades.

Exhaust system modifications present a moderate investment tier, with headers costing $700-1,200 and cat-back systems ranging from $800-1,500. These modifications typically yield 15-25 horsepower and 15-20 lb-ft of torque, resulting in a cost-to-benefit ratio of approximately $50-60 per horsepower. While more expensive than intake modifications, exhaust upgrades offer substantial performance improvements with reasonable installation requirements and minimal reliability concerns.

Camshaft replacements represent a significant performance enhancement option with costs ranging from $1,200-2,000 including installation. These modifications can deliver 30-50 horsepower and 25-40 lb-ft of torque gains, resulting in a cost-to-benefit ratio of $40-50 per horsepower. However, this option requires substantial technical expertise and introduces potential reliability considerations that must be factored into the overall value assessment.

Forced induction systems represent the highest investment tier, with supercharger kits ranging from $4,500-7,000 installed. These systems can deliver dramatic performance increases of 100-200 horsepower and 80-150 lb-ft of torque, resulting in a cost-to-benefit ratio of $35-45 per horsepower. While offering the most substantial performance gains, these systems require significant technical expertise for installation and tuning, along with potential supporting modifications to ensure reliability.

When analyzing long-term value considerations, intake and exhaust modifications maintain excellent resale value, typically retaining 60-70% of their initial investment. Camshaft modifications retain approximately 40-50% of their value, while forced induction systems generally retain 50-60% of their initial cost. Maintenance requirements also vary significantly, with intake modifications requiring minimal additional maintenance, while forced induction systems may necessitate more frequent oil changes, spark plug replacements, and potential cooling system upgrades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!