How to Optimize Alkyl Chemistry for Greater Scalability?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Chemistry Background and Objectives

Alkyl chemistry has been a cornerstone of organic synthesis for over a century, playing a crucial role in the production of numerous industrial chemicals, pharmaceuticals, and materials. The field has evolved significantly since its inception, with continuous advancements in reaction methodologies, catalysts, and process technologies. As the demand for more efficient and sustainable chemical processes grows, the optimization of alkyl chemistry for greater scalability has become a paramount objective in both academic and industrial research.

The historical development of alkyl chemistry can be traced back to the early 20th century, with pioneering work on organometallic reagents and carbon-carbon bond formation. Over the decades, the field has witnessed remarkable progress, including the development of transition metal-catalyzed cross-coupling reactions, which revolutionized synthetic organic chemistry. However, as the complexity of target molecules increases and environmental concerns become more pressing, there is a growing need to enhance the scalability and efficiency of alkyl chemistry processes.

The primary goal of optimizing alkyl chemistry for greater scalability is to develop robust, cost-effective, and environmentally friendly methodologies that can be readily implemented in large-scale industrial settings. This objective encompasses several key aspects, including improving reaction yields, enhancing selectivity, reducing waste generation, and minimizing energy consumption. Additionally, there is a strong focus on developing more sustainable approaches, such as utilizing renewable feedstocks and implementing green chemistry principles.

One of the major challenges in scaling up alkyl chemistry processes is maintaining reaction efficiency and selectivity while increasing reaction volumes. This often requires careful consideration of heat and mass transfer issues, as well as the development of novel reactor designs and process control strategies. Furthermore, the optimization of catalyst systems plays a critical role in achieving greater scalability, with emphasis on improving catalyst stability, recyclability, and turnover numbers.

Another important aspect of the optimization process is the development of more atom-efficient and step-economical synthetic routes. This involves exploring new reaction pathways, designing multifunctional catalysts, and implementing cascade or tandem reactions to minimize the number of intermediate steps and purification processes. Such approaches not only enhance scalability but also contribute to reducing the overall environmental footprint of chemical production.

As we look towards the future of alkyl chemistry, emerging technologies such as flow chemistry, automated synthesis platforms, and artificial intelligence-driven reaction optimization are expected to play increasingly important roles in achieving greater scalability. These innovative approaches offer the potential to revolutionize traditional batch processes, enabling more efficient and flexible production methods that can readily adapt to changing market demands and regulatory requirements.

The historical development of alkyl chemistry can be traced back to the early 20th century, with pioneering work on organometallic reagents and carbon-carbon bond formation. Over the decades, the field has witnessed remarkable progress, including the development of transition metal-catalyzed cross-coupling reactions, which revolutionized synthetic organic chemistry. However, as the complexity of target molecules increases and environmental concerns become more pressing, there is a growing need to enhance the scalability and efficiency of alkyl chemistry processes.

The primary goal of optimizing alkyl chemistry for greater scalability is to develop robust, cost-effective, and environmentally friendly methodologies that can be readily implemented in large-scale industrial settings. This objective encompasses several key aspects, including improving reaction yields, enhancing selectivity, reducing waste generation, and minimizing energy consumption. Additionally, there is a strong focus on developing more sustainable approaches, such as utilizing renewable feedstocks and implementing green chemistry principles.

One of the major challenges in scaling up alkyl chemistry processes is maintaining reaction efficiency and selectivity while increasing reaction volumes. This often requires careful consideration of heat and mass transfer issues, as well as the development of novel reactor designs and process control strategies. Furthermore, the optimization of catalyst systems plays a critical role in achieving greater scalability, with emphasis on improving catalyst stability, recyclability, and turnover numbers.

Another important aspect of the optimization process is the development of more atom-efficient and step-economical synthetic routes. This involves exploring new reaction pathways, designing multifunctional catalysts, and implementing cascade or tandem reactions to minimize the number of intermediate steps and purification processes. Such approaches not only enhance scalability but also contribute to reducing the overall environmental footprint of chemical production.

As we look towards the future of alkyl chemistry, emerging technologies such as flow chemistry, automated synthesis platforms, and artificial intelligence-driven reaction optimization are expected to play increasingly important roles in achieving greater scalability. These innovative approaches offer the potential to revolutionize traditional batch processes, enabling more efficient and flexible production methods that can readily adapt to changing market demands and regulatory requirements.

Market Demand for Scalable Alkyl Processes

The market demand for scalable alkyl processes has been steadily increasing in recent years, driven by the growing need for efficient and cost-effective chemical production across various industries. Alkyl chemistry plays a crucial role in the synthesis of numerous compounds used in pharmaceuticals, agrochemicals, polymers, and specialty chemicals. As these sectors continue to expand, the pressure to optimize alkyl processes for greater scalability has become more pronounced.

In the pharmaceutical industry, the demand for scalable alkyl processes is particularly high due to the increasing complexity of drug molecules and the need for large-scale production of active pharmaceutical ingredients (APIs). The ability to efficiently scale up alkyl reactions can significantly reduce production costs and time-to-market for new drugs, making it a key focus area for pharmaceutical companies.

The agrochemical sector also presents a substantial market for scalable alkyl processes. With the global population growth and the need for increased food production, there is a rising demand for more effective and environmentally friendly crop protection chemicals. Optimized alkyl chemistry can lead to the development of more potent and selective agrochemicals, which can be produced at scale with reduced environmental impact.

In the polymer industry, scalable alkyl processes are essential for the production of various monomers and polymer additives. As the demand for high-performance and specialty polymers continues to grow, manufacturers are seeking more efficient ways to produce alkyl-based intermediates and end products. This trend is particularly evident in the development of sustainable and bio-based polymers, where optimized alkyl chemistry can play a crucial role in improving production efficiency and reducing costs.

The specialty chemicals market also shows a strong demand for scalable alkyl processes. From surfactants to lubricants, many specialty chemical products rely on alkyl chemistry. As industries such as personal care, electronics, and automotive continue to evolve, there is an increasing need for customized alkyl-based chemicals that can be produced at scale to meet specific performance requirements.

Furthermore, the push towards more sustainable and environmentally friendly chemical processes has created additional market demand for optimized alkyl chemistry. Companies are seeking ways to reduce waste, improve atom economy, and minimize the use of hazardous reagents in alkyl reactions. Scalable processes that can achieve these goals while maintaining or improving product quality are highly sought after in the current market landscape.

The global market size for products and intermediates relying on alkyl chemistry is substantial, with estimates suggesting it accounts for a significant portion of the overall chemical industry. As industries continue to innovate and expand, the demand for scalable alkyl processes is expected to grow further, driving research and development efforts in this area.

In the pharmaceutical industry, the demand for scalable alkyl processes is particularly high due to the increasing complexity of drug molecules and the need for large-scale production of active pharmaceutical ingredients (APIs). The ability to efficiently scale up alkyl reactions can significantly reduce production costs and time-to-market for new drugs, making it a key focus area for pharmaceutical companies.

The agrochemical sector also presents a substantial market for scalable alkyl processes. With the global population growth and the need for increased food production, there is a rising demand for more effective and environmentally friendly crop protection chemicals. Optimized alkyl chemistry can lead to the development of more potent and selective agrochemicals, which can be produced at scale with reduced environmental impact.

In the polymer industry, scalable alkyl processes are essential for the production of various monomers and polymer additives. As the demand for high-performance and specialty polymers continues to grow, manufacturers are seeking more efficient ways to produce alkyl-based intermediates and end products. This trend is particularly evident in the development of sustainable and bio-based polymers, where optimized alkyl chemistry can play a crucial role in improving production efficiency and reducing costs.

The specialty chemicals market also shows a strong demand for scalable alkyl processes. From surfactants to lubricants, many specialty chemical products rely on alkyl chemistry. As industries such as personal care, electronics, and automotive continue to evolve, there is an increasing need for customized alkyl-based chemicals that can be produced at scale to meet specific performance requirements.

Furthermore, the push towards more sustainable and environmentally friendly chemical processes has created additional market demand for optimized alkyl chemistry. Companies are seeking ways to reduce waste, improve atom economy, and minimize the use of hazardous reagents in alkyl reactions. Scalable processes that can achieve these goals while maintaining or improving product quality are highly sought after in the current market landscape.

The global market size for products and intermediates relying on alkyl chemistry is substantial, with estimates suggesting it accounts for a significant portion of the overall chemical industry. As industries continue to innovate and expand, the demand for scalable alkyl processes is expected to grow further, driving research and development efforts in this area.

Current Challenges in Alkyl Chemistry Scalability

Alkyl chemistry scalability faces several significant challenges that hinder its widespread industrial application. One of the primary obstacles is the inherent reactivity of alkyl compounds, which often leads to side reactions and unwanted by-products. This reactivity makes it difficult to control and predict reaction outcomes, especially when scaling up from laboratory to industrial levels.

Another major challenge is the sensitivity of many alkyl reactions to environmental factors such as temperature, pressure, and the presence of impurities. These sensitivities can result in inconsistent product quality and yield when transitioning from small-scale to large-scale production. Maintaining precise control over reaction conditions becomes increasingly complex and costly as the scale of production increases.

The use of expensive or hazardous reagents in alkyl chemistry also poses significant challenges for scalability. Many reactions require stoichiometric amounts of organometallic compounds or other costly materials, which can make large-scale production economically unfeasible. Additionally, the handling and disposal of these reagents at an industrial scale present safety and environmental concerns that must be carefully addressed.

Purification and separation processes represent another hurdle in scaling up alkyl chemistry. The similarity in physical properties between desired products and by-products often necessitates complex and energy-intensive separation techniques. These processes can be particularly challenging when dealing with large volumes of material, leading to increased production costs and reduced overall efficiency.

Furthermore, the limited availability of certain raw materials used in alkyl chemistry can constrain scalability. Some key starting materials may be derived from non-renewable resources or require extensive processing, making them unsuitable for large-scale applications. This scarcity can lead to supply chain vulnerabilities and price volatility, which are significant concerns for industrial-scale production.

Regulatory compliance and safety considerations also present challenges in scaling up alkyl chemistry. Many alkyl compounds and their intermediates are classified as hazardous materials, requiring stringent safety protocols and specialized equipment for handling and storage. Meeting these regulatory requirements at an industrial scale can be complex and costly, potentially limiting the feasibility of large-scale production for certain alkyl chemistry processes.

Lastly, the development of sustainable and environmentally friendly alkyl chemistry processes remains a significant challenge. As industries face increasing pressure to reduce their environmental impact, finding ways to minimize waste, improve atom economy, and reduce the use of harmful solvents in alkyl reactions becomes crucial for long-term scalability and market acceptance.

Another major challenge is the sensitivity of many alkyl reactions to environmental factors such as temperature, pressure, and the presence of impurities. These sensitivities can result in inconsistent product quality and yield when transitioning from small-scale to large-scale production. Maintaining precise control over reaction conditions becomes increasingly complex and costly as the scale of production increases.

The use of expensive or hazardous reagents in alkyl chemistry also poses significant challenges for scalability. Many reactions require stoichiometric amounts of organometallic compounds or other costly materials, which can make large-scale production economically unfeasible. Additionally, the handling and disposal of these reagents at an industrial scale present safety and environmental concerns that must be carefully addressed.

Purification and separation processes represent another hurdle in scaling up alkyl chemistry. The similarity in physical properties between desired products and by-products often necessitates complex and energy-intensive separation techniques. These processes can be particularly challenging when dealing with large volumes of material, leading to increased production costs and reduced overall efficiency.

Furthermore, the limited availability of certain raw materials used in alkyl chemistry can constrain scalability. Some key starting materials may be derived from non-renewable resources or require extensive processing, making them unsuitable for large-scale applications. This scarcity can lead to supply chain vulnerabilities and price volatility, which are significant concerns for industrial-scale production.

Regulatory compliance and safety considerations also present challenges in scaling up alkyl chemistry. Many alkyl compounds and their intermediates are classified as hazardous materials, requiring stringent safety protocols and specialized equipment for handling and storage. Meeting these regulatory requirements at an industrial scale can be complex and costly, potentially limiting the feasibility of large-scale production for certain alkyl chemistry processes.

Lastly, the development of sustainable and environmentally friendly alkyl chemistry processes remains a significant challenge. As industries face increasing pressure to reduce their environmental impact, finding ways to minimize waste, improve atom economy, and reduce the use of harmful solvents in alkyl reactions becomes crucial for long-term scalability and market acceptance.

Existing Scalable Alkyl Chemistry Solutions

01 Scalable alkyl chemistry processes

Developing scalable processes for alkyl chemistry reactions is crucial for industrial applications. This involves optimizing reaction conditions, improving catalyst efficiency, and designing continuous flow systems to increase production capacity while maintaining product quality and yield.- Scalable alkyl chemistry processes: Developing scalable processes for alkyl chemistry reactions is crucial for industrial applications. This involves optimizing reaction conditions, improving catalyst efficiency, and designing continuous flow systems to increase production capacity while maintaining product quality and yield.

- Computational modeling for alkyl reactions: Utilizing advanced computational modeling techniques to predict and optimize alkyl chemistry reactions at scale. These models can simulate reaction kinetics, thermodynamics, and mass transfer effects, enabling more efficient process design and scale-up strategies.

- Innovative reactor designs for alkyl chemistry: Developing novel reactor designs specifically tailored for alkyl chemistry reactions at industrial scale. This includes microreactor technology, modular reactor systems, and advanced mixing techniques to improve heat and mass transfer, resulting in better control and efficiency of large-scale alkyl reactions.

- Sustainable alkyl chemistry processes: Implementing sustainable practices in large-scale alkyl chemistry, focusing on green solvents, renewable feedstocks, and energy-efficient processes. This approach aims to reduce environmental impact while maintaining or improving process scalability and economic viability.

- Process analytical technology for alkyl chemistry: Integrating advanced process analytical technology (PAT) into alkyl chemistry manufacturing processes. This involves real-time monitoring and control of critical process parameters, enabling rapid adjustments and optimizations to maintain product quality and consistency at industrial scale.

02 Computational modeling for alkyl reactions

Utilizing computational modeling and simulation techniques to predict and optimize alkyl chemistry reactions at scale. This approach helps in understanding reaction mechanisms, identifying potential bottlenecks, and designing more efficient processes for large-scale production.Expand Specific Solutions03 Continuous flow alkylation systems

Implementing continuous flow systems for alkylation reactions to improve scalability and efficiency. These systems allow for better control of reaction parameters, enhanced heat and mass transfer, and increased productivity compared to batch processes.Expand Specific Solutions04 Catalyst optimization for large-scale alkylation

Developing and optimizing catalysts specifically for large-scale alkylation processes. This includes improving catalyst stability, selectivity, and recyclability to enhance overall process efficiency and reduce production costs in industrial settings.Expand Specific Solutions05 Process intensification for alkyl chemistry

Applying process intensification techniques to alkyl chemistry reactions for improved scalability. This involves integrating multiple unit operations, utilizing novel reactor designs, and optimizing heat and mass transfer to achieve higher throughput and energy efficiency in large-scale production.Expand Specific Solutions

Key Players in Industrial Alkyl Chemistry

The optimization of alkyl chemistry for greater scalability is currently in a growth phase, with increasing market demand driven by various industries. The global market size for alkyl chemicals is expanding, fueled by applications in petrochemicals, pharmaceuticals, and materials science. Technologically, the field is advancing rapidly, with key players like China Petroleum & Chemical Corp., BASF Corp., and Henkel AG & Co. KGaA leading innovation efforts. These companies are investing in research to improve process efficiency and product yield. Emerging technologies from research institutions like Sinopec Research Institute of Petroleum Processing and East China University of Science & Technology are also contributing to the field's maturation. However, challenges in scalability and sustainability remain, indicating that the technology is not yet fully mature and offers significant potential for further optimization and growth.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced alkylation technologies to optimize alkyl chemistry for greater scalability. Their approach involves using ionic liquid catalysts in alkylation processes, which offers several advantages over traditional sulfuric acid catalysts. This technology allows for continuous operation, reducing downtime and increasing overall efficiency. Sinopec has also implemented a proprietary solid acid catalyst system that enhances the alkylation of light olefins, resulting in improved product quality and yield[1][3]. The company has invested in large-scale pilot plants to demonstrate the commercial viability of these technologies, with reported alkylate production capacities reaching up to 100,000 tons per year[2].

Strengths: Improved catalyst efficiency, reduced environmental impact, and increased process safety. Weaknesses: High initial investment costs and potential challenges in scaling up to very large production volumes.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative approaches to optimize alkyl chemistry scalability through their proprietary OASE® gas treatment technology. This technology utilizes specialized alkyl-substituted amines as solvents for selective gas absorption, particularly in the removal of acid gases from natural gas and synthesis gas streams. BASF's continuous research has led to the development of new amine formulations that offer improved absorption capacity and energy efficiency[4]. Additionally, BASF has introduced advanced process designs that incorporate heat integration and optimized regeneration cycles, significantly reducing the overall energy consumption of alkylation processes. The company has also made strides in the field of alkyl polyglycosides (APGs), developing scalable production methods for these biodegradable surfactants derived from renewable resources[5].

Strengths: High selectivity in gas treatment, reduced energy consumption, and focus on sustainable chemistry. Weaknesses: Potential limitations in adapting the technology to diverse industrial applications beyond gas treatment.

Innovative Approaches in Alkyl Reaction Optimization

Methods for preparing alkali cellulose and cellulose ether

PatentInactiveEP1734055A2

Innovation

- Simultaneously feeding pulp powder and an aqueous alkali solution into a high-speed disperser to achieve uniform alkali distribution in alkali cellulose, allowing for continuous processing and improved control over alkali concentration, thereby preventing the formation of undissolved cellulose ether portions.

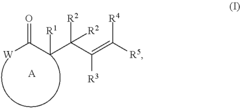

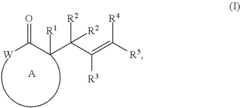

Asymmetric catalytic decarboxylative alkyl alkylation using low catalyst concentrations and a robust precatalyst

PatentInactiveUS20190055182A1

Innovation

- A scalable and enantioselective catalytic decarboxylative allylic alkylation reaction using a robust Pd(II) catalyst and chiral ligands, allowing for the synthesis of cyclic cycloalkanone and lactam products with an α-stereocenter, reducing catalyst loadings from 5.0-10.0 mol% to as low as 0.01-0.15 mol% and optimizing reaction conditions for improved efficiency and scalability.

Green Chemistry Considerations in Alkyl Processes

Green chemistry principles are increasingly crucial in optimizing alkyl processes for greater scalability. These principles focus on reducing environmental impact, improving efficiency, and enhancing safety in chemical processes. In the context of alkyl chemistry, several key considerations emerge.

Firstly, the use of safer solvents and reaction conditions is paramount. Traditional alkyl processes often rely on hazardous organic solvents, which pose environmental and health risks. Shifting towards aqueous systems or using ionic liquids as alternative reaction media can significantly reduce these risks while maintaining or even improving reaction efficiency.

Atom economy is another critical aspect of green alkyl chemistry. Designing reactions that incorporate most of the starting materials into the final product minimizes waste generation. This approach not only reduces environmental impact but also improves cost-effectiveness, a key factor in scalability.

Energy efficiency is a major consideration in scaling up alkyl processes. Developing reactions that can proceed at ambient temperature and pressure, or utilizing renewable energy sources for necessary heating or cooling, can dramatically reduce the energy footprint of these processes. Catalysis plays a crucial role here, with the development of more efficient catalysts enabling lower energy barriers and faster reaction rates.

Waste reduction is integral to green chemistry and scalability. Implementing continuous flow processes can lead to better control over reaction parameters, reducing side product formation and improving overall yield. Additionally, exploring opportunities for in-situ product separation can minimize post-reaction processing steps and associated waste.

The use of renewable feedstocks is gaining traction in alkyl chemistry. Replacing petroleum-based starting materials with bio-derived alternatives not only reduces reliance on finite resources but also often leads to more biodegradable end products. This shift aligns with circular economy principles and can enhance the long-term sustainability of alkyl processes.

Real-time analysis and process monitoring are becoming increasingly important in optimizing green alkyl processes. Advanced analytical techniques allow for rapid adjustment of reaction conditions, ensuring optimal performance and minimizing waste generation. This approach is particularly valuable in scaling up processes, where small inefficiencies can translate to significant losses.

Lastly, considering the entire lifecycle of alkyl products is essential. Designing molecules that are easier to recycle or biodegrade at the end of their useful life can significantly reduce the overall environmental impact of these processes. This holistic approach to green chemistry ensures that the benefits of optimization extend beyond the production phase.

Firstly, the use of safer solvents and reaction conditions is paramount. Traditional alkyl processes often rely on hazardous organic solvents, which pose environmental and health risks. Shifting towards aqueous systems or using ionic liquids as alternative reaction media can significantly reduce these risks while maintaining or even improving reaction efficiency.

Atom economy is another critical aspect of green alkyl chemistry. Designing reactions that incorporate most of the starting materials into the final product minimizes waste generation. This approach not only reduces environmental impact but also improves cost-effectiveness, a key factor in scalability.

Energy efficiency is a major consideration in scaling up alkyl processes. Developing reactions that can proceed at ambient temperature and pressure, or utilizing renewable energy sources for necessary heating or cooling, can dramatically reduce the energy footprint of these processes. Catalysis plays a crucial role here, with the development of more efficient catalysts enabling lower energy barriers and faster reaction rates.

Waste reduction is integral to green chemistry and scalability. Implementing continuous flow processes can lead to better control over reaction parameters, reducing side product formation and improving overall yield. Additionally, exploring opportunities for in-situ product separation can minimize post-reaction processing steps and associated waste.

The use of renewable feedstocks is gaining traction in alkyl chemistry. Replacing petroleum-based starting materials with bio-derived alternatives not only reduces reliance on finite resources but also often leads to more biodegradable end products. This shift aligns with circular economy principles and can enhance the long-term sustainability of alkyl processes.

Real-time analysis and process monitoring are becoming increasingly important in optimizing green alkyl processes. Advanced analytical techniques allow for rapid adjustment of reaction conditions, ensuring optimal performance and minimizing waste generation. This approach is particularly valuable in scaling up processes, where small inefficiencies can translate to significant losses.

Lastly, considering the entire lifecycle of alkyl products is essential. Designing molecules that are easier to recycle or biodegrade at the end of their useful life can significantly reduce the overall environmental impact of these processes. This holistic approach to green chemistry ensures that the benefits of optimization extend beyond the production phase.

Economic Impact of Scaled Alkyl Chemistry

The economic impact of scaled alkyl chemistry is profound and far-reaching, affecting multiple industries and global markets. As alkyl chemistry processes become more scalable and efficient, the potential for cost reduction and increased production capacity grows significantly. This scalability directly translates to improved economic viability for a wide range of products that rely on alkyl compounds, from pharmaceuticals to advanced materials.

One of the primary economic benefits of scaled alkyl chemistry is the reduction in production costs. As processes become more efficient and can be implemented on a larger scale, the cost per unit of alkyl compounds decreases. This cost reduction cascades through the supply chain, potentially lowering prices for end consumers and increasing profit margins for manufacturers. Industries such as petrochemicals, polymers, and specialty chemicals stand to benefit greatly from these economies of scale.

The increased scalability of alkyl chemistry also opens up new market opportunities. Products that were previously economically unfeasible due to high production costs may now become viable. This can lead to the development of new materials and applications, driving innovation across various sectors. For instance, more affordable and abundant alkyl compounds could enable the creation of novel polymers with enhanced properties, revolutionizing industries like automotive manufacturing or consumer electronics.

Furthermore, the ability to scale alkyl chemistry processes can have significant implications for global trade and economic competitiveness. Regions or countries that can effectively implement and optimize these scaled processes may gain a competitive advantage in the chemical industry. This could lead to shifts in global supply chains and potentially influence economic policies and trade relationships.

The environmental impact of scaled alkyl chemistry also has economic ramifications. As processes become more efficient, there is potential for reduced energy consumption and waste generation per unit of product. This not only aligns with increasingly stringent environmental regulations but can also result in cost savings and improved corporate sustainability profiles. Companies that can demonstrate environmentally friendly alkyl chemistry processes may gain a market advantage and attract environmentally conscious consumers and investors.

Lastly, the scaling of alkyl chemistry processes can stimulate job creation and economic growth in related sectors. As production capacities increase, there may be a need for expanded infrastructure, logistics, and support services. This can lead to the development of specialized chemical industry clusters, fostering innovation and attracting investment. The ripple effect of this growth can extend to education and research institutions, as demand for skilled workers and advanced research in alkyl chemistry increases.

One of the primary economic benefits of scaled alkyl chemistry is the reduction in production costs. As processes become more efficient and can be implemented on a larger scale, the cost per unit of alkyl compounds decreases. This cost reduction cascades through the supply chain, potentially lowering prices for end consumers and increasing profit margins for manufacturers. Industries such as petrochemicals, polymers, and specialty chemicals stand to benefit greatly from these economies of scale.

The increased scalability of alkyl chemistry also opens up new market opportunities. Products that were previously economically unfeasible due to high production costs may now become viable. This can lead to the development of new materials and applications, driving innovation across various sectors. For instance, more affordable and abundant alkyl compounds could enable the creation of novel polymers with enhanced properties, revolutionizing industries like automotive manufacturing or consumer electronics.

Furthermore, the ability to scale alkyl chemistry processes can have significant implications for global trade and economic competitiveness. Regions or countries that can effectively implement and optimize these scaled processes may gain a competitive advantage in the chemical industry. This could lead to shifts in global supply chains and potentially influence economic policies and trade relationships.

The environmental impact of scaled alkyl chemistry also has economic ramifications. As processes become more efficient, there is potential for reduced energy consumption and waste generation per unit of product. This not only aligns with increasingly stringent environmental regulations but can also result in cost savings and improved corporate sustainability profiles. Companies that can demonstrate environmentally friendly alkyl chemistry processes may gain a market advantage and attract environmentally conscious consumers and investors.

Lastly, the scaling of alkyl chemistry processes can stimulate job creation and economic growth in related sectors. As production capacities increase, there may be a need for expanded infrastructure, logistics, and support services. This can lead to the development of specialized chemical industry clusters, fostering innovation and attracting investment. The ripple effect of this growth can extend to education and research institutions, as demand for skilled workers and advanced research in alkyl chemistry increases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!