How to Precision-Align 5.4 Triton Engine Parts?

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Triton Engine Alignment Background and Objectives

The Triton 5.4L engine, a powerful V8 powerplant, has been a cornerstone in Ford's lineup for over two decades. Initially introduced in the late 1990s, this engine has undergone several iterations and improvements, becoming a staple in various Ford vehicles, including the F-150 pickup truck and the Expedition SUV. The engine's longevity and widespread use underscore the importance of precision alignment in its assembly and maintenance processes.

Precision alignment of Triton engine parts is crucial for optimal performance, efficiency, and longevity. As engine tolerances have become tighter over the years, the need for exact alignment has become increasingly critical. Misalignment, even by fractions of a millimeter, can lead to increased wear, reduced fuel efficiency, and potential engine failure. This heightened precision requirement has driven the evolution of alignment techniques and technologies in engine manufacturing and servicing.

The primary objective of precision alignment in the 5.4 Triton engine is to ensure that all moving parts, from the crankshaft to the camshafts, pistons, and valves, operate in perfect synchronization. This alignment is essential for maintaining proper combustion timing, minimizing friction, and ensuring even distribution of forces throughout the engine. Achieving this level of precision requires advanced measurement techniques, specialized tools, and a deep understanding of the engine's design and tolerances.

Over time, the methods for aligning Triton engine parts have evolved significantly. Early techniques relied heavily on manual measurements and adjustments, which were time-consuming and prone to human error. Modern alignment processes incorporate computerized measurement systems, laser alignment tools, and precision machining techniques. These advancements have not only improved accuracy but also increased efficiency in both production and maintenance settings.

The challenge of precision alignment extends beyond the initial assembly of the engine. As vehicles accumulate mileage, wear and tear can affect the alignment of various components. This necessitates ongoing maintenance and periodic realignment to ensure continued optimal performance. The development of non-invasive diagnostic tools and techniques for assessing engine alignment in situ has become an important focus area in recent years.

Looking forward, the trend towards even greater precision in engine manufacturing and maintenance is likely to continue. Emerging technologies such as 3D scanning, artificial intelligence-assisted alignment processes, and advanced materials with improved dimensional stability are expected to play significant roles in future alignment techniques for the Triton engine and similar powerplants. These developments aim to further enhance engine performance, reduce emissions, and extend the operational life of these critical components.

Precision alignment of Triton engine parts is crucial for optimal performance, efficiency, and longevity. As engine tolerances have become tighter over the years, the need for exact alignment has become increasingly critical. Misalignment, even by fractions of a millimeter, can lead to increased wear, reduced fuel efficiency, and potential engine failure. This heightened precision requirement has driven the evolution of alignment techniques and technologies in engine manufacturing and servicing.

The primary objective of precision alignment in the 5.4 Triton engine is to ensure that all moving parts, from the crankshaft to the camshafts, pistons, and valves, operate in perfect synchronization. This alignment is essential for maintaining proper combustion timing, minimizing friction, and ensuring even distribution of forces throughout the engine. Achieving this level of precision requires advanced measurement techniques, specialized tools, and a deep understanding of the engine's design and tolerances.

Over time, the methods for aligning Triton engine parts have evolved significantly. Early techniques relied heavily on manual measurements and adjustments, which were time-consuming and prone to human error. Modern alignment processes incorporate computerized measurement systems, laser alignment tools, and precision machining techniques. These advancements have not only improved accuracy but also increased efficiency in both production and maintenance settings.

The challenge of precision alignment extends beyond the initial assembly of the engine. As vehicles accumulate mileage, wear and tear can affect the alignment of various components. This necessitates ongoing maintenance and periodic realignment to ensure continued optimal performance. The development of non-invasive diagnostic tools and techniques for assessing engine alignment in situ has become an important focus area in recent years.

Looking forward, the trend towards even greater precision in engine manufacturing and maintenance is likely to continue. Emerging technologies such as 3D scanning, artificial intelligence-assisted alignment processes, and advanced materials with improved dimensional stability are expected to play significant roles in future alignment techniques for the Triton engine and similar powerplants. These developments aim to further enhance engine performance, reduce emissions, and extend the operational life of these critical components.

Market Demand for Precision-Aligned Engines

The market demand for precision-aligned engines, particularly in the context of the 5.4 Triton engine, has been steadily growing due to increasing consumer expectations for vehicle performance, fuel efficiency, and longevity. As automotive technologies advance, the need for precise component alignment becomes more critical, driving the demand for engines with tighter tolerances and better overall performance.

In the automotive industry, precision-aligned engines offer several advantages that appeal to both manufacturers and consumers. These engines typically demonstrate improved fuel efficiency, reduced emissions, and enhanced power output. For the 5.4 Triton engine, which has been widely used in Ford vehicles, precision alignment can address some of the historical issues associated with this engine model, such as spark plug problems and oil consumption concerns.

The aftermarket sector has also shown significant interest in precision-aligned engine parts for the 5.4 Triton. Many vehicle owners seek to upgrade or rebuild their engines to achieve better performance and reliability. This has created a substantial market for high-quality, precision-aligned replacement parts and complete engine rebuild kits.

Fleet operators and commercial vehicle users represent another significant segment driving the demand for precision-aligned engines. These customers prioritize vehicle uptime and long-term reliability, making them particularly interested in engines that offer reduced maintenance needs and extended service life. The 5.4 Triton engine's widespread use in Ford's commercial vehicle lineup makes it a prime candidate for precision alignment improvements in this sector.

Environmental regulations and fuel economy standards have further bolstered the market for precision-aligned engines. As governments worldwide implement stricter emissions controls, manufacturers are under pressure to produce engines that run more efficiently and cleanly. Precision alignment of engine components contributes to meeting these standards by optimizing combustion processes and reducing internal friction.

The racing and high-performance vehicle markets also contribute to the demand for precision-aligned engine parts. In these applications, even minor improvements in engine efficiency and power output can translate to significant competitive advantages. The 5.4 Triton engine, with its potential for high-performance applications, has a dedicated following in motorsports communities, further driving the demand for precision-aligned components.

As automotive manufacturing technologies evolve, there is an increasing focus on automated precision alignment processes. This trend is likely to accelerate the adoption of precision-aligned engines across various vehicle segments, potentially leading to economies of scale that could make these engines more accessible to a broader market.

In the automotive industry, precision-aligned engines offer several advantages that appeal to both manufacturers and consumers. These engines typically demonstrate improved fuel efficiency, reduced emissions, and enhanced power output. For the 5.4 Triton engine, which has been widely used in Ford vehicles, precision alignment can address some of the historical issues associated with this engine model, such as spark plug problems and oil consumption concerns.

The aftermarket sector has also shown significant interest in precision-aligned engine parts for the 5.4 Triton. Many vehicle owners seek to upgrade or rebuild their engines to achieve better performance and reliability. This has created a substantial market for high-quality, precision-aligned replacement parts and complete engine rebuild kits.

Fleet operators and commercial vehicle users represent another significant segment driving the demand for precision-aligned engines. These customers prioritize vehicle uptime and long-term reliability, making them particularly interested in engines that offer reduced maintenance needs and extended service life. The 5.4 Triton engine's widespread use in Ford's commercial vehicle lineup makes it a prime candidate for precision alignment improvements in this sector.

Environmental regulations and fuel economy standards have further bolstered the market for precision-aligned engines. As governments worldwide implement stricter emissions controls, manufacturers are under pressure to produce engines that run more efficiently and cleanly. Precision alignment of engine components contributes to meeting these standards by optimizing combustion processes and reducing internal friction.

The racing and high-performance vehicle markets also contribute to the demand for precision-aligned engine parts. In these applications, even minor improvements in engine efficiency and power output can translate to significant competitive advantages. The 5.4 Triton engine, with its potential for high-performance applications, has a dedicated following in motorsports communities, further driving the demand for precision-aligned components.

As automotive manufacturing technologies evolve, there is an increasing focus on automated precision alignment processes. This trend is likely to accelerate the adoption of precision-aligned engines across various vehicle segments, potentially leading to economies of scale that could make these engines more accessible to a broader market.

Current Challenges in 5.4 Triton Engine Alignment

The precision alignment of 5.4 Triton engine parts presents several significant challenges that engineers and manufacturers must overcome to ensure optimal engine performance and longevity. One of the primary difficulties lies in the complex geometry of the engine components, which requires extremely tight tolerances for proper fitment and operation. The intricate design of the 5.4 Triton engine, with its multiple cylinders and moving parts, demands a level of precision that pushes the boundaries of current manufacturing capabilities.

A major challenge in the alignment process is the management of thermal expansion. Engine components are subject to significant temperature fluctuations during operation, which can cause materials to expand and contract. This thermal cycling can lead to misalignment over time, even if parts are initially precision-aligned. Engineers must account for these thermal effects in their design and alignment processes, often necessitating the use of advanced materials with carefully matched thermal expansion coefficients.

Another obstacle is the variability in manufacturing processes. Even with state-of-the-art production techniques, minute variations can occur between individual engine parts. These variations, while small, can compound across the entire engine assembly, potentially leading to misalignment issues. Achieving consistency in part production and developing robust quality control measures are ongoing challenges in the industry.

The integration of increasingly complex electronic systems within modern engines further complicates the alignment process. Sensors, actuators, and control modules must be precisely positioned to function correctly, adding another layer of complexity to the already demanding task of mechanical alignment. Ensuring that these electronic components are accurately placed and remain so throughout the engine's lifecycle is a significant challenge.

Wear and tear during engine operation pose additional alignment challenges. Over time, engine components can shift, deform, or wear unevenly, leading to gradual misalignment. Developing materials and designs that can maintain precise alignment under the harsh conditions of engine operation, including high temperatures, pressures, and vibrations, remains an ongoing challenge for engineers.

The need for specialized tools and equipment for precision alignment is another hurdle. Many alignment procedures require custom-designed fixtures and highly accurate measurement devices. The development and implementation of these tools can be costly and time-consuming, presenting both technical and economic challenges to manufacturers.

Lastly, the human factor in the assembly and maintenance process introduces variability that can affect alignment. Even highly skilled technicians can introduce small errors during engine assembly or servicing. Developing foolproof assembly procedures and potentially incorporating more automated assembly processes to minimize human error are areas of ongoing research and development in the automotive industry.

A major challenge in the alignment process is the management of thermal expansion. Engine components are subject to significant temperature fluctuations during operation, which can cause materials to expand and contract. This thermal cycling can lead to misalignment over time, even if parts are initially precision-aligned. Engineers must account for these thermal effects in their design and alignment processes, often necessitating the use of advanced materials with carefully matched thermal expansion coefficients.

Another obstacle is the variability in manufacturing processes. Even with state-of-the-art production techniques, minute variations can occur between individual engine parts. These variations, while small, can compound across the entire engine assembly, potentially leading to misalignment issues. Achieving consistency in part production and developing robust quality control measures are ongoing challenges in the industry.

The integration of increasingly complex electronic systems within modern engines further complicates the alignment process. Sensors, actuators, and control modules must be precisely positioned to function correctly, adding another layer of complexity to the already demanding task of mechanical alignment. Ensuring that these electronic components are accurately placed and remain so throughout the engine's lifecycle is a significant challenge.

Wear and tear during engine operation pose additional alignment challenges. Over time, engine components can shift, deform, or wear unevenly, leading to gradual misalignment. Developing materials and designs that can maintain precise alignment under the harsh conditions of engine operation, including high temperatures, pressures, and vibrations, remains an ongoing challenge for engineers.

The need for specialized tools and equipment for precision alignment is another hurdle. Many alignment procedures require custom-designed fixtures and highly accurate measurement devices. The development and implementation of these tools can be costly and time-consuming, presenting both technical and economic challenges to manufacturers.

Lastly, the human factor in the assembly and maintenance process introduces variability that can affect alignment. Even highly skilled technicians can introduce small errors during engine assembly or servicing. Developing foolproof assembly procedures and potentially incorporating more automated assembly processes to minimize human error are areas of ongoing research and development in the automotive industry.

Existing Alignment Solutions for 5.4 Triton Engines

01 Precision alignment systems for engine components

Advanced alignment systems are used to ensure precise positioning of Triton engine parts. These systems may include laser-based tools, optical sensors, or computerized alignment equipment to achieve high accuracy in component placement and assembly. Proper alignment is crucial for optimal engine performance, efficiency, and longevity.- Precision alignment systems for engine parts: Advanced alignment systems are used to ensure precise positioning of Triton engine components. These systems may include laser-guided tools, computerized measurement devices, and specialized fixtures to achieve high accuracy in part alignment during assembly or maintenance.

- Automated assembly and alignment processes: Automated systems are employed for the assembly and alignment of Triton engine parts. These may include robotic arms, conveyor systems, and computer-controlled positioning equipment to ensure consistent and precise alignment of components during the manufacturing process.

- Specialized tools and fixtures for engine part alignment: Custom-designed tools and fixtures are utilized to facilitate the precise alignment of Triton engine parts. These may include alignment pins, gauges, and jigs specifically tailored to the unique geometry and requirements of the engine components.

- Quality control and inspection methods: Advanced quality control and inspection techniques are implemented to verify the precision alignment of Triton engine parts. These may include 3D scanning, coordinate measuring machines (CMM), and non-destructive testing methods to ensure components meet strict tolerances and specifications.

- Thermal management and compensation techniques: Thermal management and compensation strategies are employed to maintain precision alignment of Triton engine parts during operation. These techniques account for thermal expansion and contraction, ensuring optimal performance and longevity of the engine components under various operating conditions.

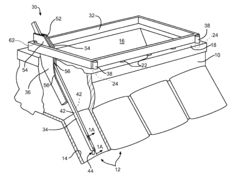

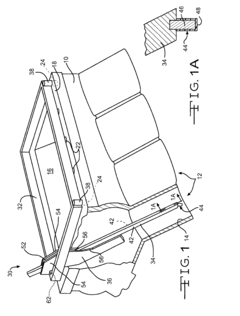

02 Specialized fixtures and jigs for engine assembly

Custom-designed fixtures and jigs are employed to hold and position Triton engine parts during the assembly process. These tools are engineered to maintain precise alignment and ensure consistent quality across production. They may incorporate adjustable features to accommodate different engine configurations or components.Expand Specific Solutions03 Automated alignment and assembly processes

Robotic systems and automated assembly lines are utilized for Triton engine parts alignment. These systems can perform high-precision movements and measurements, reducing human error and increasing production efficiency. They may incorporate machine vision technology and real-time feedback mechanisms to ensure accurate positioning.Expand Specific Solutions04 Measurement and calibration techniques

Advanced measurement and calibration methods are employed to verify and maintain the precision alignment of Triton engine parts. These may include coordinate measuring machines (CMMs), 3D scanning technology, or specialized gauges designed for specific engine components. Regular calibration ensures ongoing accuracy in the alignment process.Expand Specific Solutions05 Thermal compensation and material considerations

Precision alignment of Triton engine parts takes into account thermal expansion and contraction of materials. Techniques are employed to compensate for temperature-induced changes in dimensions, ensuring that alignment remains accurate under various operating conditions. Material selection and treatment processes may also be optimized to enhance dimensional stability.Expand Specific Solutions

Key Players in Precision Engine Alignment Industry

The precision alignment of 5.4 Triton engine parts represents a mature technology in the automotive industry, with the market in a stable growth phase. The global market for engine component precision alignment is substantial, driven by the continuous demand for high-performance engines in various sectors. Companies like GM Global Technology Operations LLC, Chery Automobile Co., Ltd., and Zhejiang Geely Holding Group Co., Ltd. have demonstrated advanced capabilities in this field. The technology's maturity is evident in the widespread adoption across major automotive manufacturers, including Toyota Motor Corp. and Honda Motor Co., Ltd., indicating a high level of technical sophistication and standardization in the industry.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive approach to precision alignment of engine parts, applicable to engines like the 5.4 Triton. Their system combines traditional mechanical alignment techniques with advanced digital technologies[7]. Key features include: 1) Use of high-precision CNC machining centers with thermal stability control for consistent part production. 2) Implementation of a digital thread that tracks each component from manufacturing through assembly, ensuring traceability and quality control. 3) Development of smart fixtures that automatically adjust to compensate for part variations[8]. 4) Utilization of AI-powered image recognition for rapid inspection and verification of alignment during assembly. 5) Integration of predictive maintenance algorithms to anticipate potential alignment issues before they occur.

Strengths: Comprehensive traceability, high adaptability to different engine designs, potential for predictive quality control. Weaknesses: Complex system integration may lead to longer setup times for new engine models.

The Boeing Co.

Technical Solution: Boeing has developed advanced precision alignment techniques for their aircraft engines, including the 5.4 Triton. They utilize a combination of laser alignment systems and computerized measurement tools to achieve micron-level precision[1]. Their process involves a multi-step approach: 1) Pre-assembly measurement and calibration of individual parts using coordinate measuring machines (CMMs). 2) Laser tracking systems for real-time alignment during assembly. 3) Optical comparators for final verification of critical dimensions. 4) Thermal compensation algorithms to account for expansion/contraction during operation[3]. This comprehensive approach ensures optimal performance and longevity of the engine components.

Strengths: Highly accurate alignment, reduced assembly time, improved engine efficiency. Weaknesses: Expensive equipment required, need for specialized training for technicians.

Core Innovations in Engine Part Alignment

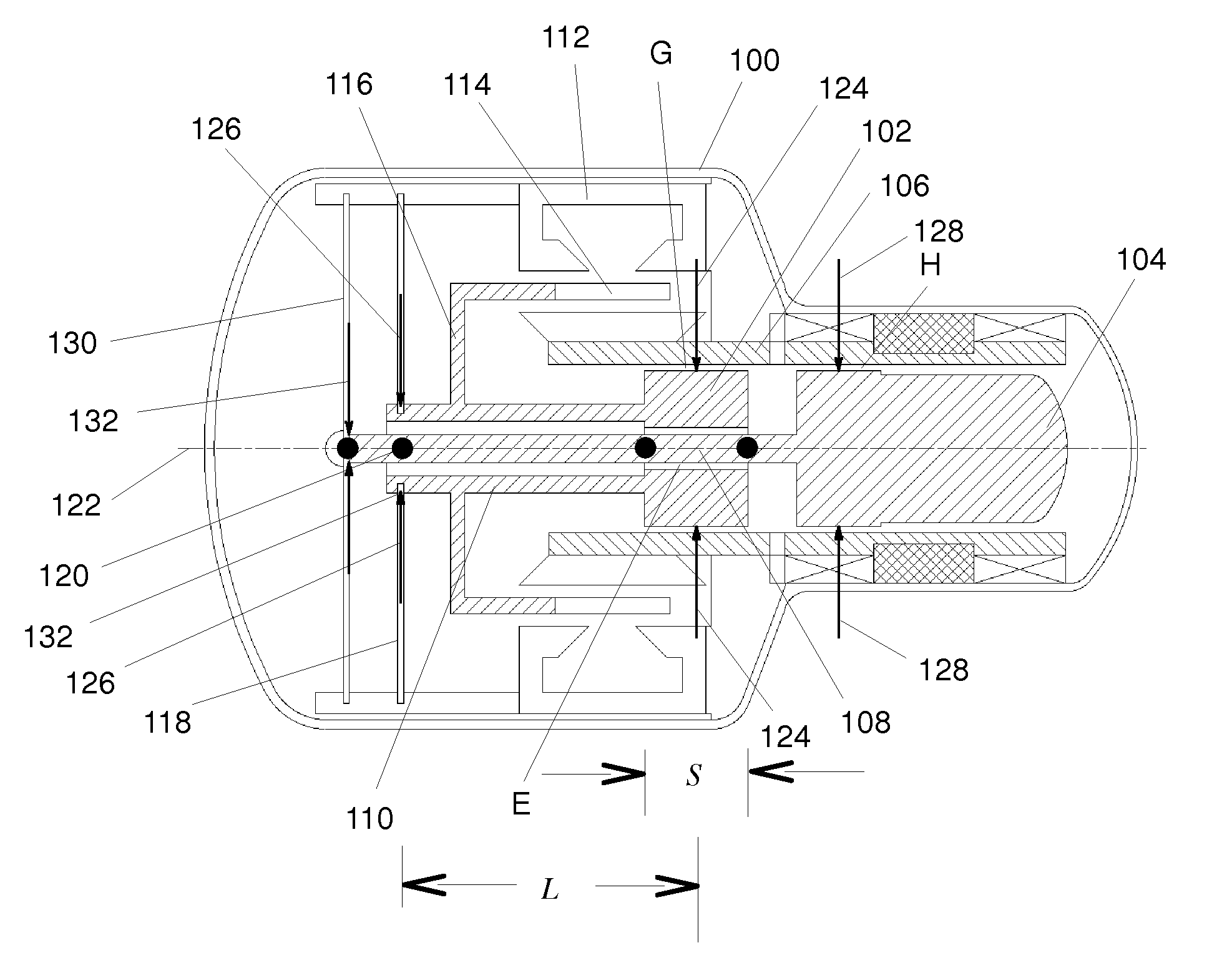

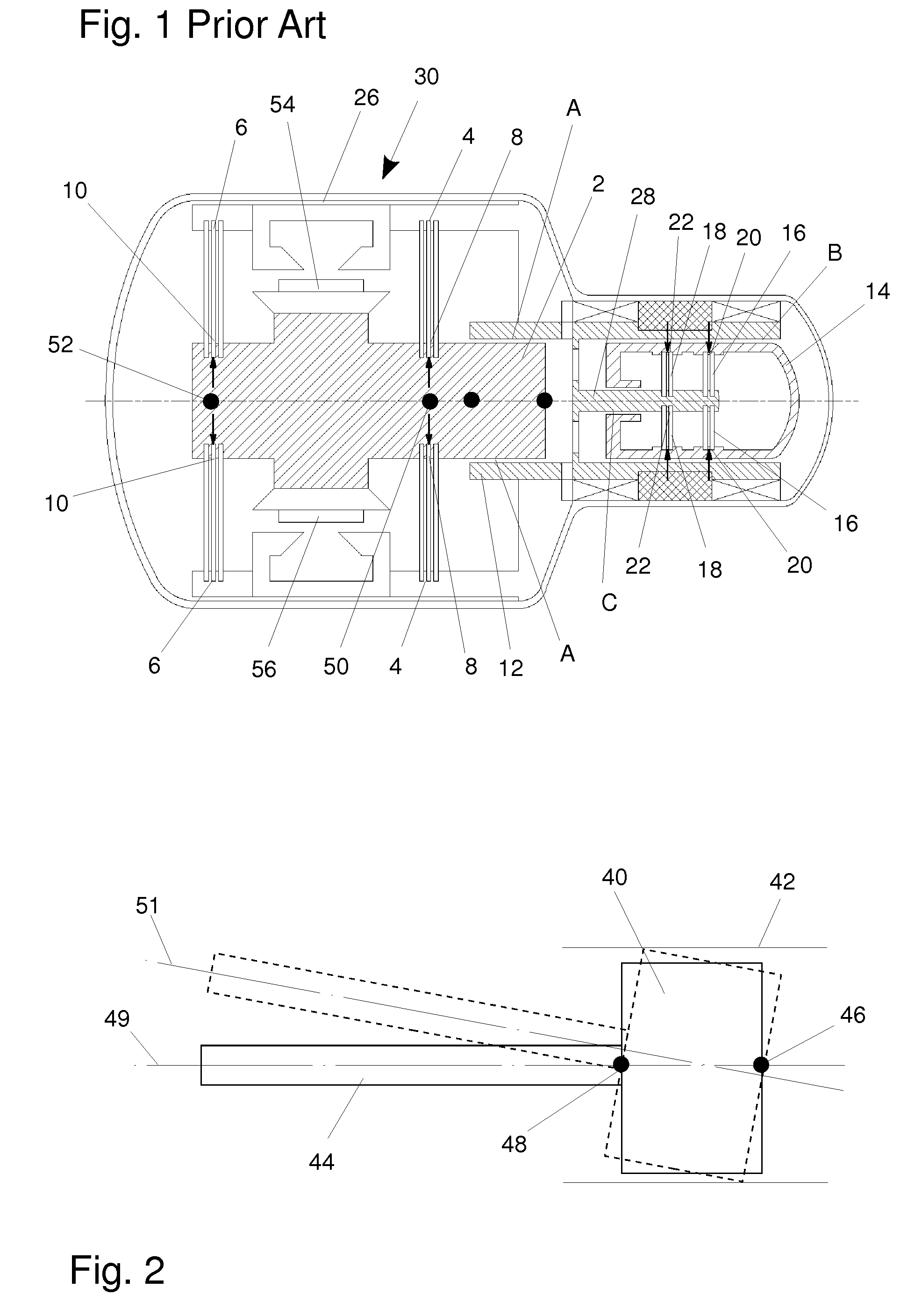

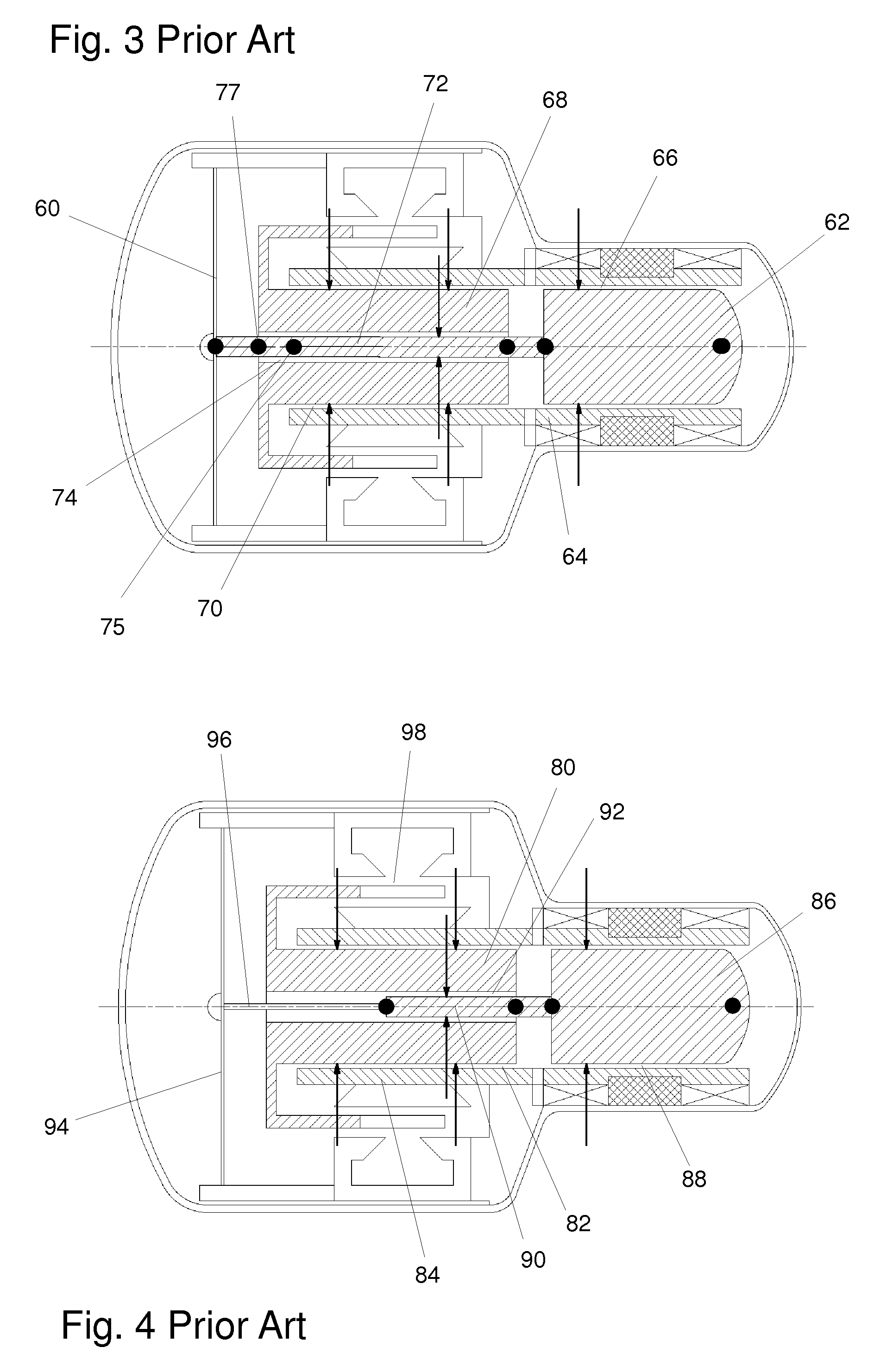

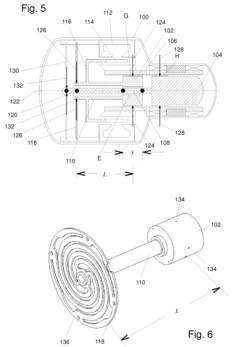

Bearing support system for free-piston stirling machines

PatentActiveUS20110056196A1

Innovation

- A bearing support system using a gas bearing at the piston and a radially acting spring bearing at the connecting rod, with a spacing that exceeds the seal length, reducing the number of alignment points and increasing tolerance for misalignment, thus simplifying the alignment process and enhancing robustness.

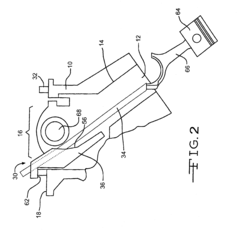

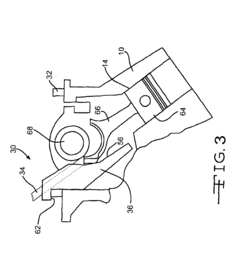

Apparatus and method for installing connecting rods

PatentInactiveUS7836571B2

Innovation

- An apparatus comprising a frame, an installation rod, and a guide with a channel, which facilitates the perpendicular alignment and secure installation of connecting rods within the engine block, maintaining them away from the cylinder wall and ensuring accurate alignment with the crankshaft, suitable for both conventional and cracked connecting rods.

Quality Control Measures for Aligned Engine Parts

Quality control measures for aligned engine parts are crucial in ensuring the precision and reliability of the 5.4 Triton engine. These measures encompass a range of techniques and processes designed to maintain the highest standards of accuracy and consistency in part alignment.

One of the primary quality control measures is the implementation of advanced measurement systems. Coordinate Measuring Machines (CMMs) are extensively used to verify the dimensional accuracy of engine parts. These machines can measure complex geometries with micron-level precision, ensuring that each component meets the stringent specifications required for proper alignment.

In addition to CMMs, optical measurement systems play a vital role in quality control. High-resolution cameras and laser scanners are employed to create detailed 3D models of engine parts. These models can be compared against CAD data to identify any deviations from the design specifications, allowing for immediate corrective action.

Statistical Process Control (SPC) is another critical quality control measure. By continuously monitoring key alignment parameters and analyzing trends, manufacturers can detect and address potential issues before they result in misaligned parts. SPC charts and software help in maintaining process stability and reducing variability in alignment processes.

Automated inspection systems are increasingly being integrated into production lines. These systems use a combination of sensors, cameras, and artificial intelligence to perform real-time inspections of engine parts as they move through the assembly process. This approach allows for immediate detection and rejection of non-conforming parts, minimizing the risk of misaligned components reaching later stages of production.

Torque monitoring and control systems are essential for ensuring proper tightening of bolts and fasteners. These systems use precision torque wrenches and electronic monitoring devices to apply and verify the correct torque values, which is critical for maintaining alignment during engine operation.

Environmental control is another crucial aspect of quality control for aligned engine parts. Temperature-controlled assembly areas and precision-controlled storage facilities help prevent thermal expansion or contraction that could affect part dimensions and alignment.

Regular calibration and maintenance of alignment tools and fixtures are also vital quality control measures. This includes periodic verification of alignment jigs, assembly fixtures, and measurement equipment to ensure they maintain their accuracy over time.

Lastly, comprehensive training programs for assembly technicians and quality control personnel are implemented to ensure consistent application of alignment procedures and inspection techniques. These programs often include hands-on training with alignment tools and measurement equipment, as well as instruction in interpreting quality control data and troubleshooting alignment issues.

One of the primary quality control measures is the implementation of advanced measurement systems. Coordinate Measuring Machines (CMMs) are extensively used to verify the dimensional accuracy of engine parts. These machines can measure complex geometries with micron-level precision, ensuring that each component meets the stringent specifications required for proper alignment.

In addition to CMMs, optical measurement systems play a vital role in quality control. High-resolution cameras and laser scanners are employed to create detailed 3D models of engine parts. These models can be compared against CAD data to identify any deviations from the design specifications, allowing for immediate corrective action.

Statistical Process Control (SPC) is another critical quality control measure. By continuously monitoring key alignment parameters and analyzing trends, manufacturers can detect and address potential issues before they result in misaligned parts. SPC charts and software help in maintaining process stability and reducing variability in alignment processes.

Automated inspection systems are increasingly being integrated into production lines. These systems use a combination of sensors, cameras, and artificial intelligence to perform real-time inspections of engine parts as they move through the assembly process. This approach allows for immediate detection and rejection of non-conforming parts, minimizing the risk of misaligned components reaching later stages of production.

Torque monitoring and control systems are essential for ensuring proper tightening of bolts and fasteners. These systems use precision torque wrenches and electronic monitoring devices to apply and verify the correct torque values, which is critical for maintaining alignment during engine operation.

Environmental control is another crucial aspect of quality control for aligned engine parts. Temperature-controlled assembly areas and precision-controlled storage facilities help prevent thermal expansion or contraction that could affect part dimensions and alignment.

Regular calibration and maintenance of alignment tools and fixtures are also vital quality control measures. This includes periodic verification of alignment jigs, assembly fixtures, and measurement equipment to ensure they maintain their accuracy over time.

Lastly, comprehensive training programs for assembly technicians and quality control personnel are implemented to ensure consistent application of alignment procedures and inspection techniques. These programs often include hands-on training with alignment tools and measurement equipment, as well as instruction in interpreting quality control data and troubleshooting alignment issues.

Environmental Impact of Precision-Aligned Engines

The precision alignment of 5.4 Triton engine parts not only enhances engine performance but also significantly impacts environmental sustainability. By ensuring optimal fit and function of engine components, precision alignment reduces friction, minimizes energy loss, and improves overall engine efficiency. This translates to lower fuel consumption and reduced emissions, contributing to a smaller carbon footprint.

Precision-aligned engines exhibit improved combustion efficiency, leading to more complete fuel burning and fewer unburned hydrocarbons released into the atmosphere. This reduction in pollutants helps mitigate air quality issues and lessens the environmental impact of vehicle emissions. Additionally, the enhanced durability of precision-aligned parts extends engine life, reducing the frequency of replacements and the associated environmental costs of manufacturing new components.

The manufacturing process for precision-aligned parts itself can be more environmentally friendly. Advanced manufacturing techniques, such as 3D printing and computer-controlled machining, allow for more precise production with less material waste. This reduction in raw material consumption and scrap contributes to resource conservation and reduced industrial waste.

Moreover, precision alignment enables the use of lighter materials in engine construction without compromising structural integrity. Lighter engines contribute to overall vehicle weight reduction, further improving fuel efficiency and reducing the environmental impact of transportation. This aligns with global efforts to decrease greenhouse gas emissions from the automotive sector.

The improved efficiency of precision-aligned engines also has indirect environmental benefits. As these engines require less frequent maintenance and have longer operational lifespans, there is a reduction in the consumption of lubricants, coolants, and other maintenance fluids. This decrease in fluid usage and disposal positively impacts water and soil quality by reducing the potential for contamination.

Furthermore, the enhanced performance of precision-aligned engines can facilitate the adoption of alternative fuels and hybrid technologies. These engines are better equipped to handle the specific requirements of biofuels or electric-hybrid systems, potentially accelerating the transition to more sustainable transportation solutions.

In conclusion, the environmental impact of precision-aligned 5.4 Triton engine parts extends beyond immediate performance improvements. It encompasses reduced emissions, improved resource efficiency, extended component lifespan, and support for cleaner energy technologies, collectively contributing to a more sustainable automotive industry and a healthier environment.

Precision-aligned engines exhibit improved combustion efficiency, leading to more complete fuel burning and fewer unburned hydrocarbons released into the atmosphere. This reduction in pollutants helps mitigate air quality issues and lessens the environmental impact of vehicle emissions. Additionally, the enhanced durability of precision-aligned parts extends engine life, reducing the frequency of replacements and the associated environmental costs of manufacturing new components.

The manufacturing process for precision-aligned parts itself can be more environmentally friendly. Advanced manufacturing techniques, such as 3D printing and computer-controlled machining, allow for more precise production with less material waste. This reduction in raw material consumption and scrap contributes to resource conservation and reduced industrial waste.

Moreover, precision alignment enables the use of lighter materials in engine construction without compromising structural integrity. Lighter engines contribute to overall vehicle weight reduction, further improving fuel efficiency and reducing the environmental impact of transportation. This aligns with global efforts to decrease greenhouse gas emissions from the automotive sector.

The improved efficiency of precision-aligned engines also has indirect environmental benefits. As these engines require less frequent maintenance and have longer operational lifespans, there is a reduction in the consumption of lubricants, coolants, and other maintenance fluids. This decrease in fluid usage and disposal positively impacts water and soil quality by reducing the potential for contamination.

Furthermore, the enhanced performance of precision-aligned engines can facilitate the adoption of alternative fuels and hybrid technologies. These engines are better equipped to handle the specific requirements of biofuels or electric-hybrid systems, potentially accelerating the transition to more sustainable transportation solutions.

In conclusion, the environmental impact of precision-aligned 5.4 Triton engine parts extends beyond immediate performance improvements. It encompasses reduced emissions, improved resource efficiency, extended component lifespan, and support for cleaner energy technologies, collectively contributing to a more sustainable automotive industry and a healthier environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!