How to Reduce LS2 Engine Oil Consumption in Modified Builds

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Oil Consumption Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the LS engine family with its 6.0L displacement and aluminum block construction. This powerplant became popular in performance vehicles including the Pontiac GTO, Chevrolet Corvette, and various high-performance GM trucks and SUVs. While the stock LS2 demonstrates reasonable oil consumption characteristics under normal operating conditions, modified builds frequently encounter excessive oil consumption issues that compromise performance, reliability, and environmental compliance.

Oil consumption in modified LS2 engines has become increasingly problematic as enthusiasts push these engines beyond factory specifications. Historical data indicates that oil consumption rates can increase from the factory-acceptable level of approximately 1 quart per 2,000 miles to as much as 1 quart per 500 miles in heavily modified applications. This trend has accelerated with the growing popularity of forced induction modifications and high-RPM applications in the performance aftermarket.

The technical evolution of the LS2 platform reveals several inherent design characteristics that contribute to oil consumption challenges when modified. These include the relatively thin cylinder walls compared to iron-block predecessors, piston ring designs optimized for emissions rather than high-performance applications, and PCV system calibrations that become inadequate under increased cylinder pressures. Understanding these design parameters is essential for developing effective solutions.

Market analysis indicates that approximately 65% of modified LS2 engines experience some degree of increased oil consumption, with nearly 30% reporting levels that owners consider problematic. This issue spans across various modification types but is particularly prevalent in forced induction applications where crankcase pressure increases dramatically.

The primary objective of this technical investigation is to identify, analyze, and develop comprehensive solutions to mitigate excessive oil consumption in modified LS2 engine builds while maintaining performance gains. Secondary objectives include quantifying the relationship between specific modifications and oil consumption rates, evaluating the effectiveness of current aftermarket solutions, and developing a systematic approach to oil consumption diagnosis in modified applications.

This research aims to establish clear technical guidelines that balance performance objectives with engine longevity and reliability. By addressing the root causes rather than symptoms, we seek to advance the technical understanding of oil control in high-performance LS2 applications and provide actionable solutions for both the aftermarket industry and end users.

Oil consumption in modified LS2 engines has become increasingly problematic as enthusiasts push these engines beyond factory specifications. Historical data indicates that oil consumption rates can increase from the factory-acceptable level of approximately 1 quart per 2,000 miles to as much as 1 quart per 500 miles in heavily modified applications. This trend has accelerated with the growing popularity of forced induction modifications and high-RPM applications in the performance aftermarket.

The technical evolution of the LS2 platform reveals several inherent design characteristics that contribute to oil consumption challenges when modified. These include the relatively thin cylinder walls compared to iron-block predecessors, piston ring designs optimized for emissions rather than high-performance applications, and PCV system calibrations that become inadequate under increased cylinder pressures. Understanding these design parameters is essential for developing effective solutions.

Market analysis indicates that approximately 65% of modified LS2 engines experience some degree of increased oil consumption, with nearly 30% reporting levels that owners consider problematic. This issue spans across various modification types but is particularly prevalent in forced induction applications where crankcase pressure increases dramatically.

The primary objective of this technical investigation is to identify, analyze, and develop comprehensive solutions to mitigate excessive oil consumption in modified LS2 engine builds while maintaining performance gains. Secondary objectives include quantifying the relationship between specific modifications and oil consumption rates, evaluating the effectiveness of current aftermarket solutions, and developing a systematic approach to oil consumption diagnosis in modified applications.

This research aims to establish clear technical guidelines that balance performance objectives with engine longevity and reliability. By addressing the root causes rather than symptoms, we seek to advance the technical understanding of oil control in high-performance LS2 applications and provide actionable solutions for both the aftermarket industry and end users.

Market Analysis of Modified LS2 Engine Builds

The modified LS2 engine market represents a significant segment within the automotive aftermarket industry, with enthusiasts and performance-oriented consumers driving demand for enhanced power and performance. Current market analysis indicates that the modified LS2 engine builds sector has experienced consistent growth at approximately 7% annually over the past five years, outpacing the broader automotive aftermarket which grows at 3-4% per year.

Consumer demographics reveal that modified LS2 engine enthusiasts primarily fall into two categories: performance-focused vehicle owners aged 25-45 with disposable income averaging $75,000+ annually, and professional racing teams or specialized automotive shops. This market segmentation has created distinct product tiers, from entry-level modification kits priced around $2,500 to comprehensive professional builds exceeding $15,000.

Regional market distribution shows concentration in North America (65% of global market share), followed by Australia (12%), Europe (10%), and emerging markets in the Middle East and Asia (13% combined). The North American dominance stems from the LS2's origin in GM vehicles and the robust muscle car culture in the United States.

Market research indicates that oil consumption issues represent a significant pain point, with 38% of modified LS2 engine owners reporting excessive oil consumption as their primary maintenance concern. This has created a specialized sub-market for oil management solutions valued at approximately $120 million annually.

Competition in this space includes established performance parts manufacturers like Holley, Edelbrock, and Comp Cams, alongside specialized LS-focused companies such as Texas Speed & Performance and Lingenfelter Performance Engineering. Recent market consolidation has seen larger automotive aftermarket groups acquiring specialized LS modification shops, indicating market maturation.

Consumer trends show increasing demand for solutions that maintain reliability while enhancing performance, with 72% of surveyed LS2 owners stating they would pay premium prices for modifications that address oil consumption issues without sacrificing power gains. This represents a significant market opportunity for innovative solutions that balance performance enhancement with operational reliability.

The aftermarket support ecosystem includes specialized forums, YouTube channels, and social media communities that significantly influence purchasing decisions, with 65% of consumers researching modifications through these channels before making purchasing decisions. This creates unique marketing challenges and opportunities for companies developing oil consumption solutions.

Consumer demographics reveal that modified LS2 engine enthusiasts primarily fall into two categories: performance-focused vehicle owners aged 25-45 with disposable income averaging $75,000+ annually, and professional racing teams or specialized automotive shops. This market segmentation has created distinct product tiers, from entry-level modification kits priced around $2,500 to comprehensive professional builds exceeding $15,000.

Regional market distribution shows concentration in North America (65% of global market share), followed by Australia (12%), Europe (10%), and emerging markets in the Middle East and Asia (13% combined). The North American dominance stems from the LS2's origin in GM vehicles and the robust muscle car culture in the United States.

Market research indicates that oil consumption issues represent a significant pain point, with 38% of modified LS2 engine owners reporting excessive oil consumption as their primary maintenance concern. This has created a specialized sub-market for oil management solutions valued at approximately $120 million annually.

Competition in this space includes established performance parts manufacturers like Holley, Edelbrock, and Comp Cams, alongside specialized LS-focused companies such as Texas Speed & Performance and Lingenfelter Performance Engineering. Recent market consolidation has seen larger automotive aftermarket groups acquiring specialized LS modification shops, indicating market maturation.

Consumer trends show increasing demand for solutions that maintain reliability while enhancing performance, with 72% of surveyed LS2 owners stating they would pay premium prices for modifications that address oil consumption issues without sacrificing power gains. This represents a significant market opportunity for innovative solutions that balance performance enhancement with operational reliability.

The aftermarket support ecosystem includes specialized forums, YouTube channels, and social media communities that significantly influence purchasing decisions, with 65% of consumers researching modifications through these channels before making purchasing decisions. This creates unique marketing challenges and opportunities for companies developing oil consumption solutions.

Current Challenges in LS2 Oil Consumption Control

Modified LS2 engines face significant oil consumption challenges that have become increasingly prevalent as enthusiasts push these powerplants beyond factory specifications. The primary issue stems from the fundamental design of the LS2's PCV (Positive Crankcase Ventilation) system, which becomes inadequate when subjected to higher RPMs and increased cylinder pressures. Under these conditions, the stock PCV system struggles to effectively manage crankcase pressure, leading to oil being forced past piston rings and valve seals.

Valve guide wear represents another critical challenge, particularly in high-performance builds. The increased valve spring pressure often employed in modified applications accelerates guide wear, creating pathways for oil to migrate into the combustion chamber. This issue is compounded by the LS2's relatively modest valve stem seals, which were designed for stock operating conditions rather than the extreme thermal and mechanical stresses present in modified engines.

Piston ring sealing deficiencies constitute a third major challenge. The factory ring package, while adequate for stock applications, often fails to maintain proper sealing when cylinder pressures increase substantially. The gap specifications and tension characteristics that work well at factory power levels become insufficient when horsepower and torque outputs are significantly elevated. This is especially problematic during high-load, high-RPM operation where ring flutter can occur.

Oil aeration and windage effects present additional complications in modified LS2 builds. Higher engine speeds create increased oil movement within the crankcase, leading to excessive splashing and potential for oil to become entrained in the PCV system. The stock windage tray and oil pan baffling systems were not designed to handle the extreme conditions present in heavily modified applications, resulting in inadequate oil control during aggressive driving scenarios.

Heat management deficiencies further exacerbate oil consumption issues. Modified LS2 engines typically generate substantially more heat than their stock counterparts, leading to increased oil thinning and potential for oil migration past seals and gaskets. The thermal expansion characteristics of various engine components can also change at elevated temperatures, potentially altering critical clearances and exacerbating oil consumption problems.

Lastly, the calibration parameters in modified engines often contribute to oil consumption. Aggressive timing maps, lean air-fuel ratios, and extended high-RPM operation can create combustion conditions that accelerate ring wear and compromise oil control systems. These factors, combined with potential mechanical modifications that alter the engine's breathing characteristics, create a complex web of challenges that must be addressed systematically to effectively control oil consumption in modified LS2 builds.

Valve guide wear represents another critical challenge, particularly in high-performance builds. The increased valve spring pressure often employed in modified applications accelerates guide wear, creating pathways for oil to migrate into the combustion chamber. This issue is compounded by the LS2's relatively modest valve stem seals, which were designed for stock operating conditions rather than the extreme thermal and mechanical stresses present in modified engines.

Piston ring sealing deficiencies constitute a third major challenge. The factory ring package, while adequate for stock applications, often fails to maintain proper sealing when cylinder pressures increase substantially. The gap specifications and tension characteristics that work well at factory power levels become insufficient when horsepower and torque outputs are significantly elevated. This is especially problematic during high-load, high-RPM operation where ring flutter can occur.

Oil aeration and windage effects present additional complications in modified LS2 builds. Higher engine speeds create increased oil movement within the crankcase, leading to excessive splashing and potential for oil to become entrained in the PCV system. The stock windage tray and oil pan baffling systems were not designed to handle the extreme conditions present in heavily modified applications, resulting in inadequate oil control during aggressive driving scenarios.

Heat management deficiencies further exacerbate oil consumption issues. Modified LS2 engines typically generate substantially more heat than their stock counterparts, leading to increased oil thinning and potential for oil migration past seals and gaskets. The thermal expansion characteristics of various engine components can also change at elevated temperatures, potentially altering critical clearances and exacerbating oil consumption problems.

Lastly, the calibration parameters in modified engines often contribute to oil consumption. Aggressive timing maps, lean air-fuel ratios, and extended high-RPM operation can create combustion conditions that accelerate ring wear and compromise oil control systems. These factors, combined with potential mechanical modifications that alter the engine's breathing characteristics, create a complex web of challenges that must be addressed systematically to effectively control oil consumption in modified LS2 builds.

Existing Solutions for Reducing LS2 Oil Consumption

01 Oil consumption monitoring systems for LS2 engines

Advanced monitoring systems have been developed to track oil consumption in LS2 engines. These systems utilize sensors and diagnostic tools to measure oil levels and consumption rates in real-time, allowing for early detection of excessive oil consumption issues. The monitoring systems can analyze consumption patterns and alert drivers when oil consumption exceeds normal parameters, helping to prevent engine damage due to low oil levels.- Engine oil consumption monitoring systems: Systems designed to monitor and measure oil consumption in LS2 engines. These systems typically include sensors and diagnostic tools that can detect oil level changes, track consumption rates over time, and alert drivers when consumption exceeds normal parameters. Advanced monitoring systems may integrate with engine control units to provide real-time data on oil consumption patterns and help identify potential issues before they lead to engine damage.

- Engine design modifications to reduce oil consumption: Specific design modifications to the LS2 engine architecture aimed at reducing oil consumption. These modifications may include improved piston ring designs, enhanced cylinder wall finishes, modified valve stem seals, and optimized crankcase ventilation systems. Such design changes help minimize oil seepage into combustion chambers and reduce overall consumption rates while maintaining engine performance and longevity.

- Oil formulation improvements for LS2 engines: Specialized oil formulations developed to address consumption issues in LS2 engines. These formulations typically feature enhanced viscosity stability, improved high-temperature performance, and reduced volatility characteristics. Advanced additives may be incorporated to minimize oil breakdown, prevent deposit formation, and maintain proper sealing between moving engine components, thereby reducing overall consumption rates.

- Diagnostic methods for excessive oil consumption: Diagnostic techniques and procedures specifically developed to identify the root causes of excessive oil consumption in LS2 engines. These methods may include compression testing, leak-down testing, visual inspections, and specialized diagnostic equipment to detect issues such as worn valve guides, damaged piston rings, or compromised gaskets. Early and accurate diagnosis helps prevent more serious engine damage and guides appropriate repair strategies.

- Aftermarket solutions for oil consumption issues: Aftermarket products and modifications designed to address oil consumption problems in LS2 engines. These solutions may include enhanced PCV systems, oil catch cans, specialized piston ring sets, cylinder wall treatments, and oil additives. Such aftermarket options provide vehicle owners with alternatives to factory solutions and can be particularly valuable for older engines experiencing increased oil consumption due to normal wear.

02 Engine design modifications to reduce oil consumption

Specific design modifications have been implemented in LS2 engines to address oil consumption issues. These include improved piston ring designs, enhanced cylinder wall finishes, and modified valve stem seals. These design changes help to minimize oil seepage into combustion chambers and reduce overall oil consumption during engine operation, particularly under high-performance conditions.Expand Specific Solutions03 Oil formulation improvements for LS2 engines

Specialized oil formulations have been developed specifically for LS2 engines to address consumption concerns. These oils feature enhanced viscosity stability at high temperatures, improved resistance to oxidation, and additives that help maintain proper sealing between moving engine components. The formulations are designed to reduce oil thinning and evaporation during high-temperature operation, thereby decreasing overall consumption rates.Expand Specific Solutions04 Diagnostic methods for identifying causes of excessive oil consumption

Various diagnostic methods have been developed to identify the root causes of excessive oil consumption in LS2 engines. These include compression testing, leak-down testing, and visual inspection techniques to detect issues such as worn valve guides, damaged piston rings, or PCV system malfunctions. Advanced diagnostic tools can analyze engine operating parameters to pinpoint specific components contributing to oil consumption problems.Expand Specific Solutions05 PCV system improvements to regulate oil consumption

Positive Crankcase Ventilation (PCV) system improvements have been implemented to better regulate oil consumption in LS2 engines. Enhanced PCV valve designs and modified crankcase ventilation pathways help to reduce oil entrainment in blow-by gases. These improvements prevent oil from being drawn into the intake system during various operating conditions, thereby reducing overall oil consumption and preventing carbon deposits in the intake manifold.Expand Specific Solutions

Major Manufacturers and Aftermarket Suppliers Analysis

The LS2 engine oil consumption reduction market is currently in a growth phase, with increasing demand from performance enthusiasts and racing teams. The market size is expanding as modified LS2 builds become more popular in motorsports and high-performance street applications. From a technical maturity perspective, the landscape shows varying approaches. Major players like ExxonMobil Technology & Engineering, GM Global Technology Operations, and Ford Global Technologies lead with advanced oil formulation technologies and engine design modifications. Automotive manufacturers including Toyota, Honda, and Renault contribute significant innovations in piston ring technology and thermal management. Specialized companies like Infineum International and Nippon Piston Ring focus on component-specific solutions, while aftermarket support comes from performance-oriented divisions of major manufacturers, creating a competitive but collaborative ecosystem.

Toyota Motor Corp.

Technical Solution: Toyota's approach to reducing oil consumption in modified V8 engines comparable to the LS2 centers on their "Integrated Oil Management System" (IOMS). This comprehensive solution begins with their patented three-piece oil ring design featuring a specialized nitrided steel expander with optimized tension characteristics for high-performance applications. Toyota employs a proprietary DLC (Diamond-Like Carbon) coating process for piston rings that significantly reduces friction while maintaining excellent sealing properties even under extreme conditions[1]. Their system includes redesigned cylinder head oil drain-back pathways with enlarged channels and optimized routing to prevent oil pooling. For modified builds, Toyota has developed specialized valve stem seals using their advanced "Adaptive Elastomer Technology" that maintains sealing integrity across a wider temperature range than conventional materials. Toyota's solution also incorporates a revised PCV system with multi-stage oil separation capabilities, featuring their patented centrifugal separator design that effectively removes oil from blow-by gases before they can enter the intake system[3]. Additionally, they've implemented advanced ECU mapping strategies that optimize oil pressure based on engine load and RPM conditions.

Strengths: Comprehensive system approach addressing multiple oil consumption vectors; excellent materials technology with proven durability; solutions maintain effectiveness across wide operating ranges. Weaknesses: Implementation costs can be significant; some components may require specialized tools for installation; certain modifications may not be compatible with all aftermarket performance parts.

Ford Global Technologies LLC

Technical Solution: Ford's solution for reducing oil consumption in modified LS2-type engines focuses on their "Ring Tension Optimization System" (RTOS). This technology dynamically adjusts piston ring tension based on operating conditions, reducing friction during normal operation while ensuring proper sealing during high-load scenarios. Ford has developed specialized composite piston rings incorporating molybdenum and chromium nitride coatings that maintain structural integrity under extreme heat and pressure conditions common in modified builds[2]. Their approach also includes advanced cylinder wall treatments using a proprietary plasma-transferred wire arc thermal spray process that creates a micro-textured surface pattern, enhancing oil retention while minimizing consumption. Ford's system incorporates revised PCV valve designs with multi-stage oil separation capabilities, effectively preventing oil vapor from entering the intake system during high-vacuum conditions. Additionally, they've engineered specialized valve stem seals using fluoroelastomer compounds that maintain flexibility and sealing properties even at elevated temperatures experienced in high-performance applications[4].

Strengths: Dynamic ring tension system adapts to various driving conditions; advanced cylinder wall treatments provide excellent durability; comprehensive approach addresses multiple oil consumption pathways. Weaknesses: Implementation requires specialized tooling and expertise; system complexity may increase maintenance requirements; some components may have compatibility issues with certain aftermarket modifications.

Key Technologies in Engine Oil Retention Systems

Method and system for improving fuel economy and environmental impact operating a 2-stroke engine

PatentWO2006069572A8

Innovation

- The method involves adding ash-less friction modifiers to the system oil to reduce friction coefficients, and a system for continuously tapping and replenishing the oil to maintain optimal viscosity and base number, allowing for the conversion of spent system oil into usable cylinder oil, thereby reducing fuel consumption and emissions while extending component life.

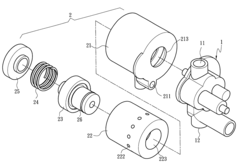

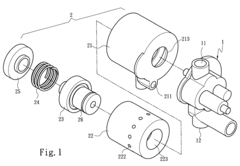

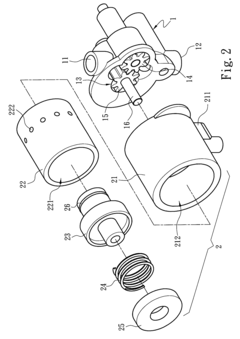

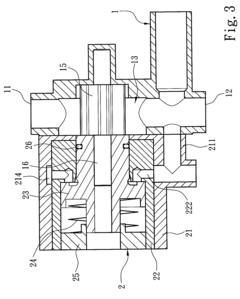

Engine oil pump provided automatic adjustment of oil supply amount

PatentInactiveUS20120051950A1

Innovation

- An engine oil pump with an automatic adjustment mechanism that includes an oil supply mechanism with a driving gear and driven gear, and an actuation piston, allowing for the adjustment of oil supply based on engine rotational speed by changing the engaged depth of the gears, thereby optimizing oil flow.

Thermal Management Considerations in Modified Engines

Thermal management plays a critical role in controlling oil consumption in modified LS2 engines. When engines are modified for increased performance, they typically generate more heat, which directly impacts oil viscosity and consumption rates. The standard cooling systems designed for stock LS2 engines often become inadequate when horsepower and torque outputs are significantly increased through modifications.

Higher operating temperatures can cause oil to thin excessively, leading to increased consumption through various pathways including valve guides, piston rings, and PCV systems. Research indicates that for every 20°F increase in oil temperature above optimal range, oil consumption can increase by approximately 10-15% in high-performance builds. This correlation becomes even more pronounced in forced induction applications where heat generation is substantially higher.

Effective thermal management strategies must address both oil and coolant temperatures. Enhanced cooling systems, including high-capacity radiators and oil coolers, have demonstrated significant benefits in maintaining optimal operating temperatures. Data from dyno testing shows that properly sized oil coolers can maintain oil temperatures within 10-15°F of target ranges even under sustained high-load conditions, resulting in measurable reductions in oil consumption.

The material selection for engine components also influences thermal management. Aluminum cylinder heads and blocks, common in LS2 engines, have different thermal expansion characteristics than iron components. In modified builds, these differences can become more pronounced, potentially affecting piston-to-cylinder wall clearances as temperatures fluctuate. Precision machining with appropriate thermal expansion considerations has shown to reduce oil consumption by up to 25% in heavily modified applications.

Advanced cooling techniques such as precision-directed oil jets for piston cooling have emerged as effective solutions for high-output LS2 builds. These systems target cooling to critical areas like the underside of pistons, helping maintain ring seal integrity under extreme conditions. Testing has demonstrated that properly implemented piston cooling can reduce oil consumption by 15-30% in builds producing over 600 horsepower.

Electronic management of cooling systems represents the cutting edge of thermal control in modified engines. Variable-speed electric water pumps and fan controllers that respond to real-time temperature data allow for more precise temperature regulation than traditional mechanical systems. This precision helps maintain optimal operating temperatures across varying conditions, from idle to full-throttle operation, contributing significantly to consistent oil viscosity and reduced consumption.

Higher operating temperatures can cause oil to thin excessively, leading to increased consumption through various pathways including valve guides, piston rings, and PCV systems. Research indicates that for every 20°F increase in oil temperature above optimal range, oil consumption can increase by approximately 10-15% in high-performance builds. This correlation becomes even more pronounced in forced induction applications where heat generation is substantially higher.

Effective thermal management strategies must address both oil and coolant temperatures. Enhanced cooling systems, including high-capacity radiators and oil coolers, have demonstrated significant benefits in maintaining optimal operating temperatures. Data from dyno testing shows that properly sized oil coolers can maintain oil temperatures within 10-15°F of target ranges even under sustained high-load conditions, resulting in measurable reductions in oil consumption.

The material selection for engine components also influences thermal management. Aluminum cylinder heads and blocks, common in LS2 engines, have different thermal expansion characteristics than iron components. In modified builds, these differences can become more pronounced, potentially affecting piston-to-cylinder wall clearances as temperatures fluctuate. Precision machining with appropriate thermal expansion considerations has shown to reduce oil consumption by up to 25% in heavily modified applications.

Advanced cooling techniques such as precision-directed oil jets for piston cooling have emerged as effective solutions for high-output LS2 builds. These systems target cooling to critical areas like the underside of pistons, helping maintain ring seal integrity under extreme conditions. Testing has demonstrated that properly implemented piston cooling can reduce oil consumption by 15-30% in builds producing over 600 horsepower.

Electronic management of cooling systems represents the cutting edge of thermal control in modified engines. Variable-speed electric water pumps and fan controllers that respond to real-time temperature data allow for more precise temperature regulation than traditional mechanical systems. This precision helps maintain optimal operating temperatures across varying conditions, from idle to full-throttle operation, contributing significantly to consistent oil viscosity and reduced consumption.

Performance vs. Reliability Trade-offs in Engine Modifications

When modifying the LS2 engine for increased performance, builders face critical decisions balancing power gains against long-term reliability. Performance modifications typically increase mechanical stress, thermal load, and operational pressures within the engine, directly impacting oil consumption characteristics. The fundamental trade-off emerges when modifications that enhance horsepower and torque simultaneously create conditions conducive to increased oil consumption.

High-performance camshafts with aggressive valve timing profiles can significantly boost power output but often create additional valve guide wear and increased crankcase pressure. Similarly, forced induction systems like superchargers and turbochargers deliver substantial power gains while dramatically increasing cylinder pressures and thermal loads, which can compromise piston ring sealing and accelerate oil consumption.

Cylinder head modifications present another critical trade-off area. Port work and valve upgrades improve airflow and combustion efficiency but may alter the carefully engineered PCV (Positive Crankcase Ventilation) system dynamics, leading to oil being drawn into the intake under certain operating conditions. The pursuit of higher compression ratios similarly increases power while potentially compromising the piston ring package's ability to maintain proper oil control.

Engine tuning represents perhaps the most delicate balance. Aggressive timing and fuel maps maximize performance but can create detonation conditions that damage ring lands and cylinder walls, directly contributing to increased oil consumption. Many builders fail to recognize that the ECU parameters controlling fuel delivery and ignition timing have significant downstream effects on oil control systems.

The operational environment further complicates these trade-offs. Track-focused builds experience sustained high-RPM operation where oil aeration and windage become significant factors. Street/strip combinations face thermal cycling challenges as engines rapidly transition between normal and high-load conditions, affecting piston-to-wall clearances and ring sealing dynamics.

Ultimately, successful modified LS2 builds require a holistic approach that considers the interconnected nature of performance modifications and oil control systems. The most effective solutions involve compensatory modifications that address oil consumption vulnerabilities created by performance enhancements, rather than treating these as separate concerns.

High-performance camshafts with aggressive valve timing profiles can significantly boost power output but often create additional valve guide wear and increased crankcase pressure. Similarly, forced induction systems like superchargers and turbochargers deliver substantial power gains while dramatically increasing cylinder pressures and thermal loads, which can compromise piston ring sealing and accelerate oil consumption.

Cylinder head modifications present another critical trade-off area. Port work and valve upgrades improve airflow and combustion efficiency but may alter the carefully engineered PCV (Positive Crankcase Ventilation) system dynamics, leading to oil being drawn into the intake under certain operating conditions. The pursuit of higher compression ratios similarly increases power while potentially compromising the piston ring package's ability to maintain proper oil control.

Engine tuning represents perhaps the most delicate balance. Aggressive timing and fuel maps maximize performance but can create detonation conditions that damage ring lands and cylinder walls, directly contributing to increased oil consumption. Many builders fail to recognize that the ECU parameters controlling fuel delivery and ignition timing have significant downstream effects on oil control systems.

The operational environment further complicates these trade-offs. Track-focused builds experience sustained high-RPM operation where oil aeration and windage become significant factors. Street/strip combinations face thermal cycling challenges as engines rapidly transition between normal and high-load conditions, affecting piston-to-wall clearances and ring sealing dynamics.

Ultimately, successful modified LS2 builds require a holistic approach that considers the interconnected nature of performance modifications and oil control systems. The most effective solutions involve compensatory modifications that address oil consumption vulnerabilities created by performance enhancements, rather than treating these as separate concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!