How to Safeguard Against Isocyanate Exposure Risks?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Exposure Risks and Protection Goals

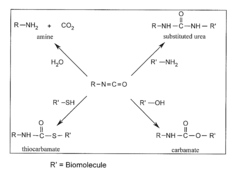

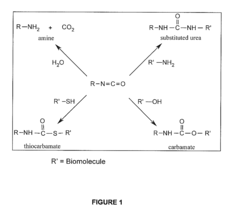

Isocyanates are highly reactive chemicals widely used in various industries, particularly in the production of polyurethane products. However, exposure to these compounds poses significant health risks, including respiratory irritation, sensitization, and occupational asthma. The primary goal of safeguarding against isocyanate exposure is to protect workers and the environment from these potential hazards.

The evolution of isocyanate safety measures has been driven by increasing awareness of their health impacts and stringent regulatory requirements. Early protective measures focused on basic personal protective equipment (PPE) and ventilation systems. As research advanced, more sophisticated engineering controls and monitoring technologies were developed to minimize exposure risks.

Current protection goals encompass a multi-faceted approach, addressing exposure prevention, detection, and response. Key objectives include reducing airborne isocyanate concentrations in workplaces, implementing robust exposure monitoring systems, and enhancing worker education and training programs. Additionally, there is a growing emphasis on developing safer alternatives and improving product formulations to reduce overall isocyanate use.

Technological advancements play a crucial role in achieving these protection goals. Real-time monitoring devices, improved PPE designs, and automated application systems are being developed to provide more effective safeguards. Furthermore, research is ongoing to create isocyanate-free or low-isocyanate alternatives that maintain desired product properties while reducing exposure risks.

The regulatory landscape surrounding isocyanate exposure has also evolved, with organizations such as OSHA and the EPA implementing stricter guidelines and exposure limits. These regulations drive industry compliance and innovation in safety measures. International collaboration and knowledge sharing have become increasingly important in establishing best practices for isocyanate handling and exposure prevention.

Looking ahead, future protection goals are likely to focus on further reducing exposure limits, developing more sensitive detection methods, and advancing towards safer chemical alternatives. The integration of artificial intelligence and machine learning in exposure prediction and risk assessment is an emerging trend that may revolutionize isocyanate safety protocols.

In conclusion, safeguarding against isocyanate exposure risks requires a comprehensive approach that combines technological innovation, regulatory compliance, and ongoing research. The ultimate goal is to create safer work environments and products while maintaining the benefits of isocyanate-based materials in various applications.

The evolution of isocyanate safety measures has been driven by increasing awareness of their health impacts and stringent regulatory requirements. Early protective measures focused on basic personal protective equipment (PPE) and ventilation systems. As research advanced, more sophisticated engineering controls and monitoring technologies were developed to minimize exposure risks.

Current protection goals encompass a multi-faceted approach, addressing exposure prevention, detection, and response. Key objectives include reducing airborne isocyanate concentrations in workplaces, implementing robust exposure monitoring systems, and enhancing worker education and training programs. Additionally, there is a growing emphasis on developing safer alternatives and improving product formulations to reduce overall isocyanate use.

Technological advancements play a crucial role in achieving these protection goals. Real-time monitoring devices, improved PPE designs, and automated application systems are being developed to provide more effective safeguards. Furthermore, research is ongoing to create isocyanate-free or low-isocyanate alternatives that maintain desired product properties while reducing exposure risks.

The regulatory landscape surrounding isocyanate exposure has also evolved, with organizations such as OSHA and the EPA implementing stricter guidelines and exposure limits. These regulations drive industry compliance and innovation in safety measures. International collaboration and knowledge sharing have become increasingly important in establishing best practices for isocyanate handling and exposure prevention.

Looking ahead, future protection goals are likely to focus on further reducing exposure limits, developing more sensitive detection methods, and advancing towards safer chemical alternatives. The integration of artificial intelligence and machine learning in exposure prediction and risk assessment is an emerging trend that may revolutionize isocyanate safety protocols.

In conclusion, safeguarding against isocyanate exposure risks requires a comprehensive approach that combines technological innovation, regulatory compliance, and ongoing research. The ultimate goal is to create safer work environments and products while maintaining the benefits of isocyanate-based materials in various applications.

Market Demand for Isocyanate Safety Solutions

The market demand for isocyanate safety solutions has been steadily increasing due to growing awareness of the health risks associated with isocyanate exposure and stricter regulatory requirements across industries. Isocyanates are widely used in the production of polyurethanes, which find applications in various sectors including automotive, construction, furniture, and electronics.

In the automotive industry, there is a significant demand for isocyanate safety solutions due to the extensive use of polyurethane-based materials in vehicle interiors, seats, and insulation. As vehicle production continues to rise globally, the need for effective safety measures in manufacturing processes has become paramount.

The construction sector represents another major market for isocyanate safety solutions. With the growing use of spray polyurethane foam insulation in buildings, there is an increased focus on protecting workers and occupants from potential exposure risks. This has led to a surge in demand for personal protective equipment, ventilation systems, and monitoring devices specifically designed for isocyanate handling.

The furniture industry, particularly in the production of foam cushions and mattresses, has also seen a rise in demand for isocyanate safety solutions. Manufacturers are investing in advanced safety equipment and training programs to mitigate exposure risks during production processes.

In the electronics sector, where isocyanates are used in the production of circuit boards and other components, there is a growing market for specialized safety solutions tailored to the unique requirements of clean room environments.

The healthcare sector has emerged as a new market for isocyanate safety solutions, driven by the increasing use of polyurethane-based medical devices and equipment. Hospitals and medical device manufacturers are seeking advanced safety measures to protect both workers and patients from potential isocyanate exposure.

Market analysts project that the global market for isocyanate safety solutions will continue to expand at a compound annual growth rate of over 5% in the coming years. This growth is attributed to factors such as increasing industrialization in developing countries, stricter occupational safety regulations, and growing awareness of the long-term health effects of isocyanate exposure.

The demand for innovative safety solutions, such as real-time monitoring systems, smart personal protective equipment, and advanced filtration technologies, is expected to drive market growth. Additionally, there is a rising interest in developing alternative materials and processes that could reduce or eliminate the use of isocyanates in certain applications, creating new opportunities for safety solution providers.

In the automotive industry, there is a significant demand for isocyanate safety solutions due to the extensive use of polyurethane-based materials in vehicle interiors, seats, and insulation. As vehicle production continues to rise globally, the need for effective safety measures in manufacturing processes has become paramount.

The construction sector represents another major market for isocyanate safety solutions. With the growing use of spray polyurethane foam insulation in buildings, there is an increased focus on protecting workers and occupants from potential exposure risks. This has led to a surge in demand for personal protective equipment, ventilation systems, and monitoring devices specifically designed for isocyanate handling.

The furniture industry, particularly in the production of foam cushions and mattresses, has also seen a rise in demand for isocyanate safety solutions. Manufacturers are investing in advanced safety equipment and training programs to mitigate exposure risks during production processes.

In the electronics sector, where isocyanates are used in the production of circuit boards and other components, there is a growing market for specialized safety solutions tailored to the unique requirements of clean room environments.

The healthcare sector has emerged as a new market for isocyanate safety solutions, driven by the increasing use of polyurethane-based medical devices and equipment. Hospitals and medical device manufacturers are seeking advanced safety measures to protect both workers and patients from potential isocyanate exposure.

Market analysts project that the global market for isocyanate safety solutions will continue to expand at a compound annual growth rate of over 5% in the coming years. This growth is attributed to factors such as increasing industrialization in developing countries, stricter occupational safety regulations, and growing awareness of the long-term health effects of isocyanate exposure.

The demand for innovative safety solutions, such as real-time monitoring systems, smart personal protective equipment, and advanced filtration technologies, is expected to drive market growth. Additionally, there is a rising interest in developing alternative materials and processes that could reduce or eliminate the use of isocyanates in certain applications, creating new opportunities for safety solution providers.

Current Challenges in Isocyanate Exposure Prevention

Despite significant advancements in occupational safety, isocyanate exposure prevention remains a critical challenge in various industries. The primary difficulty lies in the ubiquitous nature of isocyanates, which are widely used in the production of polyurethanes, foams, coatings, and adhesives. Their versatility and essential role in manufacturing processes make complete elimination impractical, necessitating robust prevention strategies.

One of the key challenges is the detection and monitoring of isocyanate levels in workplace environments. Current technologies often lack the sensitivity and real-time capabilities required for immediate hazard identification. Many existing detection methods are time-consuming, requiring laboratory analysis, which delays response times and potentially prolongs worker exposure.

Personal protective equipment (PPE) presents another significant hurdle. While essential, the effectiveness of PPE is often compromised by improper use, fit, or maintenance. Ensuring consistent and correct usage across diverse work environments and job roles remains an ongoing challenge for safety managers and industrial hygienists.

The variability in isocyanate formulations and applications further complicates prevention efforts. Different isocyanate compounds exhibit varying levels of reactivity and volatility, necessitating tailored prevention strategies. This diversity makes it difficult to implement standardized safety protocols across industries and even within individual facilities.

Engineering controls, such as ventilation systems and enclosed processes, while effective, often require significant capital investment and ongoing maintenance. Balancing the cost of implementation with the need for comprehensive worker protection is a persistent challenge, particularly for smaller businesses or in industries with tight profit margins.

Another critical issue is the lack of comprehensive understanding regarding the long-term health effects of low-level, chronic isocyanate exposure. This knowledge gap hampers the development of evidence-based exposure limits and prevention strategies, potentially leaving workers vulnerable to cumulative health risks over time.

Worker education and training present ongoing challenges. Effectively communicating the risks associated with isocyanate exposure and ensuring compliance with safety protocols across diverse workforce demographics, including language barriers and varying educational backgrounds, remains a complex task for many organizations.

Lastly, the regulatory landscape surrounding isocyanate exposure prevention is often fragmented and inconsistent across jurisdictions. This lack of uniformity can lead to confusion and disparities in worker protection standards, making it difficult for multinational corporations to implement cohesive safety programs across their global operations.

One of the key challenges is the detection and monitoring of isocyanate levels in workplace environments. Current technologies often lack the sensitivity and real-time capabilities required for immediate hazard identification. Many existing detection methods are time-consuming, requiring laboratory analysis, which delays response times and potentially prolongs worker exposure.

Personal protective equipment (PPE) presents another significant hurdle. While essential, the effectiveness of PPE is often compromised by improper use, fit, or maintenance. Ensuring consistent and correct usage across diverse work environments and job roles remains an ongoing challenge for safety managers and industrial hygienists.

The variability in isocyanate formulations and applications further complicates prevention efforts. Different isocyanate compounds exhibit varying levels of reactivity and volatility, necessitating tailored prevention strategies. This diversity makes it difficult to implement standardized safety protocols across industries and even within individual facilities.

Engineering controls, such as ventilation systems and enclosed processes, while effective, often require significant capital investment and ongoing maintenance. Balancing the cost of implementation with the need for comprehensive worker protection is a persistent challenge, particularly for smaller businesses or in industries with tight profit margins.

Another critical issue is the lack of comprehensive understanding regarding the long-term health effects of low-level, chronic isocyanate exposure. This knowledge gap hampers the development of evidence-based exposure limits and prevention strategies, potentially leaving workers vulnerable to cumulative health risks over time.

Worker education and training present ongoing challenges. Effectively communicating the risks associated with isocyanate exposure and ensuring compliance with safety protocols across diverse workforce demographics, including language barriers and varying educational backgrounds, remains a complex task for many organizations.

Lastly, the regulatory landscape surrounding isocyanate exposure prevention is often fragmented and inconsistent across jurisdictions. This lack of uniformity can lead to confusion and disparities in worker protection standards, making it difficult for multinational corporations to implement cohesive safety programs across their global operations.

Existing Isocyanate Exposure Control Methods

01 Health and safety monitoring systems for isocyanate exposure

Advanced monitoring systems are being developed to detect and measure isocyanate exposure in real-time. These systems can alert workers and supervisors to potential hazards, helping to prevent overexposure and related health risks. The technology may include wearable sensors, environmental monitors, and data analytics to track exposure levels and patterns over time.- Health and safety monitoring systems for isocyanate exposure: Advanced monitoring systems are being developed to detect and measure isocyanate exposure in real-time. These systems can alert workers to potential hazards and help prevent overexposure. They may include wearable devices, environmental sensors, and data analytics to track exposure levels and patterns over time.

- Risk assessment and management strategies: Comprehensive risk assessment methodologies are being implemented to identify potential isocyanate exposure risks in various industrial settings. These strategies involve analyzing workplace conditions, processes, and materials to develop targeted prevention and mitigation measures. Risk management approaches may include engineering controls, administrative controls, and personal protective equipment recommendations.

- Personal protective equipment (PPE) innovations: Advancements in PPE design and materials are improving protection against isocyanate exposure. New respirator technologies, chemical-resistant clothing, and gloves are being developed to provide better barriers against isocyanate compounds. These innovations focus on enhancing comfort, breathability, and durability while maintaining high levels of protection.

- Training and education programs: Specialized training programs are being developed to educate workers about isocyanate exposure risks and proper handling procedures. These programs may incorporate virtual reality simulations, interactive modules, and hands-on exercises to improve understanding and retention of safety protocols. Continuous education and certification processes are also being implemented to ensure ongoing awareness and compliance.

- Exposure prediction and prevention systems: Advanced predictive models and AI-driven systems are being developed to anticipate potential isocyanate exposure risks before they occur. These systems analyze historical data, environmental factors, and work processes to identify high-risk scenarios and recommend preventive measures. They may also integrate with existing safety management systems to provide comprehensive risk mitigation strategies.

02 Risk assessment and management strategies

Comprehensive risk assessment methodologies are being implemented to identify potential isocyanate exposure risks in various industrial settings. These strategies involve analyzing workplace processes, evaluating control measures, and developing tailored risk management plans. The approach may include regular audits, employee training programs, and the implementation of best practices to minimize exposure risks.Expand Specific Solutions03 Personal protective equipment (PPE) innovations

Advancements in PPE design and materials are enhancing protection against isocyanate exposure. New respirator technologies, chemical-resistant clothing, and gloves are being developed to provide improved barriers against isocyanate compounds. These innovations focus on comfort, durability, and effectiveness to encourage consistent use by workers in high-risk environments.Expand Specific Solutions04 Exposure prediction and prevention models

Sophisticated predictive models are being created to forecast potential isocyanate exposure scenarios in various industrial processes. These models utilize machine learning algorithms and historical data to identify high-risk activities and environmental conditions. By anticipating exposure risks, preventive measures can be implemented proactively, reducing the likelihood of harmful incidents.Expand Specific Solutions05 Regulatory compliance and reporting systems

Automated systems are being developed to streamline regulatory compliance and reporting related to isocyanate exposure. These systems can track exposure incidents, maintain documentation, and generate reports for regulatory bodies. By simplifying the compliance process, organizations can better focus on implementing safety measures and reducing exposure risks.Expand Specific Solutions

Key Players in Isocyanate Safety Industry

The isocyanate exposure risk mitigation market is in a mature stage, with established safety protocols and technologies. The global market size for isocyanate safety equipment and solutions is estimated to be in the billions of dollars, driven by stringent regulations and growing awareness of occupational health risks. Technologically, the field is well-developed, with companies like Wanhua Chemical Group, BASF, and Henkel offering advanced protective equipment and exposure monitoring systems. However, there is ongoing research and innovation, particularly in areas of safer isocyanate alternatives and more effective personal protective equipment, led by institutions such as Johns Hopkins University and industry leaders like Evonik Operations GmbH.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate handling systems that incorporate multiple safety measures. Their approach includes closed-loop transfer systems to minimize exposure during handling and transportation. They have implemented real-time monitoring systems using advanced sensors to detect even trace amounts of isocyanates in the air[1]. Additionally, Wanhua has developed specialized personal protective equipment (PPE) with enhanced resistance to isocyanate permeation, including full-body suits and respiratory protection with extended service life[2]. Their facilities are equipped with state-of-the-art ventilation systems that maintain negative pressure in production areas to prevent isocyanate vapors from escaping[3].

Strengths: Comprehensive approach combining engineering controls, PPE, and monitoring. Weaknesses: High implementation costs, potential for over-reliance on PPE.

BASF Corp.

Technical Solution: BASF has pioneered a multi-faceted approach to isocyanate safety. They have developed low-emission isocyanate formulations that reduce vapor release during application[4]. BASF's safety strategy includes the use of robotics and automation in high-risk handling areas to minimize human exposure. They have also implemented a comprehensive training program, utilizing virtual reality simulations to prepare workers for potential exposure scenarios[5]. BASF's research has led to the development of rapid-response decontamination solutions specifically designed for isocyanate exposure, which can be quickly deployed in case of accidental contact[6].

Strengths: Innovative use of technology in training and handling, focus on reducing emissions at source. Weaknesses: Dependence on specialized equipment may limit applicability in smaller operations.

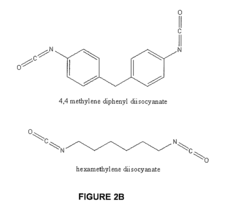

Innovative Approaches to Isocyanate Risk Mitigation

Methods and compositions relating to isocyanate conjugates

PatentActiveUS20100099201A1

Innovation

- Development of monoclonal antibodies and antigen binding fragments with specificity for diisocyanate-protein conjugates, allowing for the isolation, detection, and characterization of these conjugates in samples from exposed individuals, independent of the protein moiety identity, using techniques such as Western blots and ELISA.

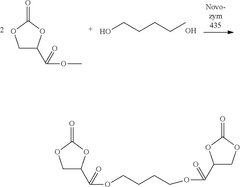

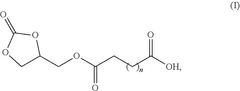

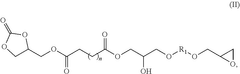

Method for producing functionalized polyesters

PatentActiveUS12122871B2

Innovation

- A method involving the reaction of glycerine carbonate with an anhydride, followed by a polyepoxide compound, and then a polycarboxylic acid, under mild conditions to form cyclic carbonate functional polyesters with high functionality and molecular weight, avoiding the use of toxic substances and high temperatures.

Regulatory Framework for Isocyanate Handling

The regulatory framework for isocyanate handling is a critical component in safeguarding against exposure risks. Governments and international organizations have established comprehensive guidelines and regulations to ensure the safe use, storage, and disposal of isocyanates across various industries.

In the United States, the Occupational Safety and Health Administration (OSHA) has set stringent standards for isocyanate handling. These include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE). OSHA's Hazard Communication Standard mandates that employers provide workers with information and training on isocyanate hazards and proper handling procedures.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating isocyanates under the Toxic Substances Control Act (TSCA). The EPA has implemented reporting requirements for manufacturers and importers of isocyanates, ensuring proper documentation and risk assessment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety data sheets. The EU has also introduced specific restrictions on the use of diisocyanates in industrial and professional applications.

The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication for isocyanates. This system ensures consistent labeling and safety data sheet formats across different countries, facilitating international trade and improving worker safety.

Many countries have adopted national standards for isocyanate handling. For instance, Australia's Safe Work Australia has developed a Code of Practice for managing risks associated with spray painting and powder coating, which includes specific guidelines for isocyanate use.

Industry-specific regulations also exist, such as those in the automotive and construction sectors. These regulations often focus on ventilation requirements, spray booth designs, and waste disposal procedures tailored to the unique challenges of isocyanate use in these industries.

Compliance with these regulatory frameworks is essential for organizations working with isocyanates. Regular audits, employee training programs, and up-to-date safety protocols are necessary to ensure adherence to these regulations. Companies must also stay informed about evolving regulatory landscapes, as new research and emerging risks may lead to updates in isocyanate handling requirements.

In the United States, the Occupational Safety and Health Administration (OSHA) has set stringent standards for isocyanate handling. These include permissible exposure limits (PELs) and requirements for personal protective equipment (PPE). OSHA's Hazard Communication Standard mandates that employers provide workers with information and training on isocyanate hazards and proper handling procedures.

The Environmental Protection Agency (EPA) also plays a crucial role in regulating isocyanates under the Toxic Substances Control Act (TSCA). The EPA has implemented reporting requirements for manufacturers and importers of isocyanates, ensuring proper documentation and risk assessment.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of isocyanates. REACH requires manufacturers and importers to register substances and provide safety data sheets. The EU has also introduced specific restrictions on the use of diisocyanates in industrial and professional applications.

The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to hazard communication for isocyanates. This system ensures consistent labeling and safety data sheet formats across different countries, facilitating international trade and improving worker safety.

Many countries have adopted national standards for isocyanate handling. For instance, Australia's Safe Work Australia has developed a Code of Practice for managing risks associated with spray painting and powder coating, which includes specific guidelines for isocyanate use.

Industry-specific regulations also exist, such as those in the automotive and construction sectors. These regulations often focus on ventilation requirements, spray booth designs, and waste disposal procedures tailored to the unique challenges of isocyanate use in these industries.

Compliance with these regulatory frameworks is essential for organizations working with isocyanates. Regular audits, employee training programs, and up-to-date safety protocols are necessary to ensure adherence to these regulations. Companies must also stay informed about evolving regulatory landscapes, as new research and emerging risks may lead to updates in isocyanate handling requirements.

Environmental Impact of Isocyanate Use and Control

The use of isocyanates in various industries has significant environmental implications that require careful consideration and control measures. Isocyanates are highly reactive chemicals widely used in the production of polyurethanes, which find applications in foam insulation, coatings, adhesives, and elastomers. While these materials offer valuable properties, their production and disposal can pose risks to ecosystems and human health if not properly managed.

One of the primary environmental concerns associated with isocyanate use is air pollution. During manufacturing processes, isocyanate vapors can be released into the atmosphere, contributing to the formation of ground-level ozone and particulate matter. These pollutants can have detrimental effects on air quality, leading to respiratory issues in both humans and wildlife. Additionally, the release of isocyanates into the air can result in the formation of secondary organic aerosols, which can impact climate patterns and contribute to global warming.

Water contamination is another critical environmental issue related to isocyanate use. Improper disposal of isocyanate-containing materials or accidental spills can lead to the leaching of these chemicals into groundwater and surface water bodies. This contamination can have severe consequences for aquatic ecosystems, potentially causing harm to fish, plants, and other organisms. Furthermore, the presence of isocyanates in water sources can pose risks to human health if the contaminated water is used for drinking or agricultural purposes.

To mitigate these environmental impacts, stringent control measures must be implemented throughout the lifecycle of isocyanate-containing products. This includes the adoption of closed-loop manufacturing systems to minimize emissions, the use of advanced air filtration technologies to capture and treat isocyanate vapors, and the implementation of proper waste management protocols to prevent environmental contamination. Additionally, the development of more environmentally friendly alternatives to traditional isocyanate-based products is an area of ongoing research and innovation.

Regulatory frameworks play a crucial role in controlling the environmental impact of isocyanate use. Many countries have established strict guidelines for the handling, storage, and disposal of isocyanates and related materials. These regulations often require companies to implement comprehensive environmental management systems, conduct regular monitoring and reporting of emissions, and develop emergency response plans for potential spills or releases.

The long-term environmental persistence of isocyanates and their degradation products is an area of ongoing study. While isocyanates themselves are generally reactive and do not persist in the environment for extended periods, some of their breakdown products may have longer-lasting effects. Research into the environmental fate and ecotoxicology of these compounds is essential for developing more effective control strategies and assessing the overall environmental impact of isocyanate use.

One of the primary environmental concerns associated with isocyanate use is air pollution. During manufacturing processes, isocyanate vapors can be released into the atmosphere, contributing to the formation of ground-level ozone and particulate matter. These pollutants can have detrimental effects on air quality, leading to respiratory issues in both humans and wildlife. Additionally, the release of isocyanates into the air can result in the formation of secondary organic aerosols, which can impact climate patterns and contribute to global warming.

Water contamination is another critical environmental issue related to isocyanate use. Improper disposal of isocyanate-containing materials or accidental spills can lead to the leaching of these chemicals into groundwater and surface water bodies. This contamination can have severe consequences for aquatic ecosystems, potentially causing harm to fish, plants, and other organisms. Furthermore, the presence of isocyanates in water sources can pose risks to human health if the contaminated water is used for drinking or agricultural purposes.

To mitigate these environmental impacts, stringent control measures must be implemented throughout the lifecycle of isocyanate-containing products. This includes the adoption of closed-loop manufacturing systems to minimize emissions, the use of advanced air filtration technologies to capture and treat isocyanate vapors, and the implementation of proper waste management protocols to prevent environmental contamination. Additionally, the development of more environmentally friendly alternatives to traditional isocyanate-based products is an area of ongoing research and innovation.

Regulatory frameworks play a crucial role in controlling the environmental impact of isocyanate use. Many countries have established strict guidelines for the handling, storage, and disposal of isocyanates and related materials. These regulations often require companies to implement comprehensive environmental management systems, conduct regular monitoring and reporting of emissions, and develop emergency response plans for potential spills or releases.

The long-term environmental persistence of isocyanates and their degradation products is an area of ongoing study. While isocyanates themselves are generally reactive and do not persist in the environment for extended periods, some of their breakdown products may have longer-lasting effects. Research into the environmental fate and ecotoxicology of these compounds is essential for developing more effective control strategies and assessing the overall environmental impact of isocyanate use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!