How to Test Load Distribution in Lithium Phosphate Infrastructure

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Testing Background and Objectives

Lithium phosphate batteries have emerged as a critical component in modern energy storage systems, particularly in renewable energy infrastructure and electric vehicle applications. The evolution of this technology can be traced back to the early 1990s when researchers first identified the potential of lithium iron phosphate (LiFePO₄) as a cathode material. Over the subsequent decades, significant advancements have been made in improving energy density, cycle life, and safety characteristics of these batteries.

The testing of load distribution in lithium phosphate infrastructure represents a crucial aspect of ensuring optimal performance and longevity of these energy storage systems. Historically, testing methodologies have evolved from simple voltage and current measurements to sophisticated real-time monitoring systems that can analyze multiple parameters simultaneously across complex battery arrays.

The primary technical objective in this domain is to develop comprehensive testing protocols that can accurately assess how electrical loads are distributed across lithium phosphate battery cells and modules under various operational conditions. This includes evaluating performance during peak demand periods, rapid charging scenarios, and under extreme environmental conditions that may affect battery chemistry and electrical characteristics.

Current testing objectives focus on several key areas: identifying potential points of thermal runaway, detecting early signs of cell degradation, optimizing charge/discharge cycles to maximize battery lifespan, and ensuring balanced load distribution across parallel and series configurations. Additionally, there is growing emphasis on developing predictive testing models that can anticipate system behavior under future load scenarios.

The technological trajectory indicates a shift toward more integrated testing approaches that combine electrical, thermal, and chemical analysis in real-time. This holistic testing paradigm aims to provide a more complete understanding of lithium phosphate infrastructure performance under diverse operational conditions.

Industry standards for lithium phosphate testing continue to evolve, with organizations such as IEEE, IEC, and UL developing increasingly sophisticated protocols. These standards seek to establish uniform testing methodologies that enable meaningful comparisons between different battery systems and configurations while ensuring safety and reliability.

As lithium phosphate technology continues to mature and find wider application in grid-scale energy storage and transportation sectors, the importance of advanced load distribution testing becomes increasingly critical to ensuring system reliability, safety, and optimal performance throughout the expected service life of these installations.

The testing of load distribution in lithium phosphate infrastructure represents a crucial aspect of ensuring optimal performance and longevity of these energy storage systems. Historically, testing methodologies have evolved from simple voltage and current measurements to sophisticated real-time monitoring systems that can analyze multiple parameters simultaneously across complex battery arrays.

The primary technical objective in this domain is to develop comprehensive testing protocols that can accurately assess how electrical loads are distributed across lithium phosphate battery cells and modules under various operational conditions. This includes evaluating performance during peak demand periods, rapid charging scenarios, and under extreme environmental conditions that may affect battery chemistry and electrical characteristics.

Current testing objectives focus on several key areas: identifying potential points of thermal runaway, detecting early signs of cell degradation, optimizing charge/discharge cycles to maximize battery lifespan, and ensuring balanced load distribution across parallel and series configurations. Additionally, there is growing emphasis on developing predictive testing models that can anticipate system behavior under future load scenarios.

The technological trajectory indicates a shift toward more integrated testing approaches that combine electrical, thermal, and chemical analysis in real-time. This holistic testing paradigm aims to provide a more complete understanding of lithium phosphate infrastructure performance under diverse operational conditions.

Industry standards for lithium phosphate testing continue to evolve, with organizations such as IEEE, IEC, and UL developing increasingly sophisticated protocols. These standards seek to establish uniform testing methodologies that enable meaningful comparisons between different battery systems and configurations while ensuring safety and reliability.

As lithium phosphate technology continues to mature and find wider application in grid-scale energy storage and transportation sectors, the importance of advanced load distribution testing becomes increasingly critical to ensuring system reliability, safety, and optimal performance throughout the expected service life of these installations.

Market Analysis for Lithium Phosphate Energy Storage

The global energy storage market is experiencing unprecedented growth, with lithium phosphate (LFP) technology emerging as a frontrunner due to its safety profile, longer cycle life, and cost advantages compared to other lithium-ion chemistries. Current market valuations place the LFP energy storage sector at approximately $7.5 billion in 2023, with projections indicating a compound annual growth rate of 18-20% through 2030, potentially reaching $25 billion by decade's end.

Demand drivers for lithium phosphate energy storage systems span multiple sectors. The utility-scale segment currently dominates, accounting for roughly 60% of deployments, as grid operators increasingly rely on battery storage to integrate intermittent renewable energy sources and provide grid stabilization services. Commercial and industrial applications represent about 25% of the market, driven by peak shaving capabilities and resilience requirements.

Residential energy storage, while smaller at 15% market share, is experiencing the fastest growth rate at 25-30% annually as homeowners seek energy independence and backup power solutions. This segment is particularly strong in regions with high electricity costs, frequent power outages, or favorable net metering policies.

Geographically, China leads LFP production and deployment with approximately 70% of global manufacturing capacity, though North America and Europe are rapidly expanding their market presence through substantial investments in domestic manufacturing capabilities. The Asia-Pacific region collectively represents about 45% of global demand, with North America at 30% and Europe at 20%.

Price trends show encouraging developments for market expansion, with LFP battery pack costs declining from above $300/kWh in 2018 to approximately $135-150/kWh in 2023. Industry analysts project further reductions to below $100/kWh by 2025-2026, representing the threshold at which energy storage achieves broad economic viability across most applications without subsidies.

Regulatory landscapes are increasingly favorable, with policies supporting energy storage deployment in major markets. The Inflation Reduction Act in the United States provides investment tax credits for standalone storage projects, while the European Union's REPowerEU plan emphasizes storage as critical infrastructure for energy security and decarbonization goals.

Market challenges persist in supply chain constraints, particularly for key materials like phosphorus and iron phosphate. Additionally, testing and certification standards for load distribution in large-scale LFP installations remain fragmented across different markets, creating barriers to rapid deployment and technology validation.

Demand drivers for lithium phosphate energy storage systems span multiple sectors. The utility-scale segment currently dominates, accounting for roughly 60% of deployments, as grid operators increasingly rely on battery storage to integrate intermittent renewable energy sources and provide grid stabilization services. Commercial and industrial applications represent about 25% of the market, driven by peak shaving capabilities and resilience requirements.

Residential energy storage, while smaller at 15% market share, is experiencing the fastest growth rate at 25-30% annually as homeowners seek energy independence and backup power solutions. This segment is particularly strong in regions with high electricity costs, frequent power outages, or favorable net metering policies.

Geographically, China leads LFP production and deployment with approximately 70% of global manufacturing capacity, though North America and Europe are rapidly expanding their market presence through substantial investments in domestic manufacturing capabilities. The Asia-Pacific region collectively represents about 45% of global demand, with North America at 30% and Europe at 20%.

Price trends show encouraging developments for market expansion, with LFP battery pack costs declining from above $300/kWh in 2018 to approximately $135-150/kWh in 2023. Industry analysts project further reductions to below $100/kWh by 2025-2026, representing the threshold at which energy storage achieves broad economic viability across most applications without subsidies.

Regulatory landscapes are increasingly favorable, with policies supporting energy storage deployment in major markets. The Inflation Reduction Act in the United States provides investment tax credits for standalone storage projects, while the European Union's REPowerEU plan emphasizes storage as critical infrastructure for energy security and decarbonization goals.

Market challenges persist in supply chain constraints, particularly for key materials like phosphorus and iron phosphate. Additionally, testing and certification standards for load distribution in large-scale LFP installations remain fragmented across different markets, creating barriers to rapid deployment and technology validation.

Current Load Distribution Testing Challenges

Testing load distribution in lithium phosphate energy storage infrastructure presents several significant challenges that impede accurate performance assessment and system optimization. The complexity of these challenges has increased as lithium phosphate battery systems have scaled from small applications to grid-level implementations.

One primary challenge is the lack of standardized testing protocols specifically designed for lithium phosphate systems. While general battery testing standards exist, they often fail to address the unique characteristics of lithium phosphate chemistry, particularly regarding load distribution behavior under varying operational conditions. This absence of tailored methodologies creates inconsistencies in test results across different facilities and research institutions.

Real-time monitoring of load distribution presents another substantial hurdle. Current sensor technologies struggle to provide high-resolution data across large battery arrays without introducing significant measurement errors or system interference. The trade-off between measurement accuracy and system performance impact remains problematic, especially when attempting to capture transient load distribution phenomena that occur within milliseconds.

Environmental factors significantly complicate testing procedures. Lithium phosphate systems exhibit different load distribution patterns under varying temperature and humidity conditions. Creating controlled testing environments that can accurately simulate real-world operational scenarios while maintaining experimental consistency requires sophisticated climate control systems that many testing facilities lack.

Scale-related challenges are particularly pronounced in grid-level applications. Laboratory tests often fail to replicate the complex load distribution dynamics that emerge in large-scale deployments. The extrapolation of small-scale test results to predict large-scale performance has proven unreliable, creating a significant gap between laboratory findings and field performance.

Data interpretation presents yet another challenge. The massive datasets generated during comprehensive load distribution testing require advanced analytical tools and expertise. Current analytical frameworks often struggle to identify subtle patterns and anomalies that may indicate potential system inefficiencies or failure modes.

Accelerated life testing methodologies for load distribution assessment remain underdeveloped. The industry lacks reliable methods to simulate years of operational load distribution patterns within reasonable testing timeframes. This limitation hinders accurate long-term performance predictions and lifetime assessments.

Lastly, the economic constraints of comprehensive load distribution testing cannot be overlooked. High-precision testing equipment, specialized facilities, and expert personnel represent significant investments that many organizations find prohibitive, leading to compromises in testing scope and accuracy that ultimately affect system reliability and performance optimization.

One primary challenge is the lack of standardized testing protocols specifically designed for lithium phosphate systems. While general battery testing standards exist, they often fail to address the unique characteristics of lithium phosphate chemistry, particularly regarding load distribution behavior under varying operational conditions. This absence of tailored methodologies creates inconsistencies in test results across different facilities and research institutions.

Real-time monitoring of load distribution presents another substantial hurdle. Current sensor technologies struggle to provide high-resolution data across large battery arrays without introducing significant measurement errors or system interference. The trade-off between measurement accuracy and system performance impact remains problematic, especially when attempting to capture transient load distribution phenomena that occur within milliseconds.

Environmental factors significantly complicate testing procedures. Lithium phosphate systems exhibit different load distribution patterns under varying temperature and humidity conditions. Creating controlled testing environments that can accurately simulate real-world operational scenarios while maintaining experimental consistency requires sophisticated climate control systems that many testing facilities lack.

Scale-related challenges are particularly pronounced in grid-level applications. Laboratory tests often fail to replicate the complex load distribution dynamics that emerge in large-scale deployments. The extrapolation of small-scale test results to predict large-scale performance has proven unreliable, creating a significant gap between laboratory findings and field performance.

Data interpretation presents yet another challenge. The massive datasets generated during comprehensive load distribution testing require advanced analytical tools and expertise. Current analytical frameworks often struggle to identify subtle patterns and anomalies that may indicate potential system inefficiencies or failure modes.

Accelerated life testing methodologies for load distribution assessment remain underdeveloped. The industry lacks reliable methods to simulate years of operational load distribution patterns within reasonable testing timeframes. This limitation hinders accurate long-term performance predictions and lifetime assessments.

Lastly, the economic constraints of comprehensive load distribution testing cannot be overlooked. High-precision testing equipment, specialized facilities, and expert personnel represent significant investments that many organizations find prohibitive, leading to compromises in testing scope and accuracy that ultimately affect system reliability and performance optimization.

Existing Load Distribution Testing Solutions

01 Lithium phosphate battery management systems for load distribution

Advanced battery management systems are essential for optimizing load distribution in lithium phosphate battery infrastructures. These systems monitor and control the charging and discharging processes, balance loads across multiple cells, and ensure optimal performance under varying demand conditions. By implementing sophisticated algorithms, these management systems can extend battery life, improve energy efficiency, and prevent overloading of specific components within the infrastructure.- Lithium phosphate battery management systems for load distribution: Advanced battery management systems are essential for optimizing load distribution in lithium phosphate battery infrastructures. These systems monitor and control the charging and discharging processes, ensuring balanced load across battery cells and extending battery life. They incorporate algorithms that dynamically adjust power distribution based on demand patterns and battery conditions, preventing overloading of specific cells or modules within the battery system.

- Grid integration technologies for lithium phosphate energy storage: Technologies for integrating lithium phosphate battery systems into existing power grids enable efficient load distribution across infrastructure. These solutions include power conversion systems, grid-tie inverters, and smart controllers that facilitate bidirectional power flow between batteries and the grid. Advanced grid integration technologies allow lithium phosphate systems to provide grid services such as peak shaving, frequency regulation, and load balancing, enhancing overall grid stability while optimizing battery utilization.

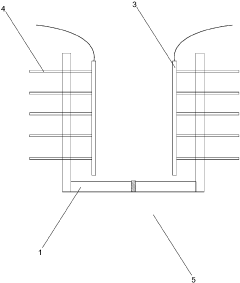

- Thermal management systems for lithium phosphate infrastructure: Thermal management is critical for maintaining optimal performance and safety in lithium phosphate battery installations. Systems designed for effective heat distribution and dissipation prevent thermal runaway and ensure consistent performance across battery modules. These solutions incorporate cooling channels, phase-change materials, or liquid cooling systems that maintain uniform temperature distribution throughout the battery infrastructure, allowing for higher charging and discharging rates while preserving battery longevity.

- Distributed energy storage architectures using lithium phosphate batteries: Distributed energy storage architectures leverage lithium phosphate batteries placed strategically throughout power networks to optimize load distribution. These systems use modular battery units that can be deployed at various points in the grid, from utility-scale installations to local microgrids. By distributing storage capacity closer to points of generation or consumption, these architectures reduce transmission losses, improve resilience against outages, and enable more efficient management of intermittent renewable energy sources.

- Load prediction and adaptive control systems for lithium phosphate infrastructure: Advanced prediction algorithms and adaptive control systems optimize load distribution in lithium phosphate battery infrastructures. These systems analyze historical usage patterns, weather forecasts, and real-time grid conditions to anticipate demand fluctuations and preemptively adjust battery charging or discharging schedules. Machine learning techniques continuously improve prediction accuracy, while adaptive controllers dynamically balance loads across the battery infrastructure to maximize efficiency, minimize degradation, and ensure power availability during peak demand periods.

02 Grid integration technologies for lithium phosphate energy storage

Technologies for integrating lithium phosphate energy storage systems into existing power grids enable efficient load distribution across infrastructure networks. These solutions include power conversion systems, grid-tie inverters, and smart controllers that facilitate bidirectional energy flow between batteries and the grid. Such integration technologies allow for peak shaving, frequency regulation, and load balancing, which are critical for maintaining grid stability while maximizing the utilization of lithium phosphate storage capacity.Expand Specific Solutions03 Thermal management systems for lithium phosphate infrastructure

Thermal management is crucial for maintaining optimal performance and safety in lithium phosphate energy storage infrastructures. Systems designed for heat dissipation, temperature monitoring, and thermal load distribution help prevent hotspots and ensure uniform temperature across battery arrays. Advanced cooling technologies, including liquid cooling circuits and phase-change materials, enable high-power applications while maintaining battery health and extending operational lifespans under varying load conditions.Expand Specific Solutions04 Distributed energy resource management for lithium phosphate systems

Distributed energy resource management systems optimize the deployment and operation of lithium phosphate batteries across multiple locations. These systems coordinate energy flow between various storage points, renewable generation sources, and consumption centers to balance loads effectively. By leveraging cloud computing, IoT connectivity, and predictive analytics, these management platforms enable real-time decision-making for load distribution, demand response, and energy arbitrage, maximizing the economic and technical benefits of lithium phosphate infrastructure.Expand Specific Solutions05 Material innovations for enhanced load capacity in lithium phosphate batteries

Advanced material formulations and structural designs improve the load-bearing capacity of lithium phosphate battery components. Innovations include doped cathode materials, composite electrodes, and novel electrolyte formulations that enhance ionic conductivity and structural stability under high-load conditions. These material advancements enable higher energy density, faster charging rates, and improved cycle life, allowing lithium phosphate infrastructure to handle greater load variations while maintaining performance and safety standards.Expand Specific Solutions

Key Industry Players in Lithium Phosphate Technology

The lithium phosphate infrastructure load distribution testing market is in a growth phase, characterized by increasing demand for reliable energy storage solutions. The market size is expanding rapidly due to global energy transition initiatives and electrification trends. From a technical maturity perspective, the landscape shows varying degrees of advancement. State Grid Corporation of China and LG Energy Solution lead with comprehensive testing frameworks, while companies like Hubei Yiwei Power and SinoHytec are developing specialized testing protocols for their applications. Research institutions including China Electric Power Research Institute and Xi'an Jiaotong University contribute significant innovations in testing methodologies. Toyota and Dongfeng Motor are advancing automotive-specific load distribution testing, particularly for electric vehicle applications, creating a competitive ecosystem balancing established players and emerging specialists.

China Electric Power Research Institute Ltd.

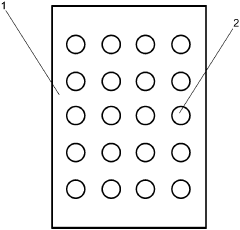

Technical Solution: China Electric Power Research Institute has developed a multi-dimensional load distribution testing framework specifically for lithium phosphate battery systems in grid infrastructure. Their methodology combines electrochemical performance testing with structural integrity evaluation under various load conditions. The institute employs advanced Battery Management System (BMS) validation techniques that stress-test load balancing algorithms under asymmetric discharge scenarios. Their testing protocols include precision current distribution analysis across parallel-connected cells using Hall effect sensors with accuracy to ±0.1%, enabling the detection of subtle imbalances. The institute has pioneered non-invasive testing methods using ultrasonic and thermal imaging to map internal structural changes during cycling without disrupting battery operation. Their approach incorporates real-time impedance tracking during charge-discharge cycles to identify cells with abnormal behavior that might indicate uneven load distribution.

Strengths: Comprehensive integration of electrical, thermal, and mechanical testing methodologies; strong focus on standardization of testing protocols; extensive experience with grid-scale implementations. Weaknesses: Testing equipment requires significant technical expertise to operate effectively; some methodologies are time-intensive and difficult to scale for high-throughput testing; limited commercial availability of their proprietary testing systems.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has pioneered grid-scale lithium phosphate infrastructure testing methodologies focused on load distribution across massive energy storage installations. Their approach combines physical testing with digital twin modeling to simulate various load scenarios before actual deployment. The company has developed specialized high-power testing equipment capable of simulating grid fluctuations up to 10MW to evaluate battery response under extreme conditions. Their testing protocol includes thermal gradient mapping using infrared imaging to identify hotspots that may indicate uneven load distribution. State Grid's methodology incorporates long-duration cycling tests (1000+ cycles) under variable load conditions that mimic real-world grid demands, including frequency regulation, peak shaving, and renewable integration scenarios. Their testing facilities can simultaneously evaluate multiple battery racks to ensure uniform performance across large installations.

Strengths: Unparalleled scale of testing capabilities; direct integration with actual grid operations data; comprehensive simulation capabilities for diverse operational scenarios. Weaknesses: Testing methodologies sometimes prioritize grid stability over battery longevity; limited transparency in sharing detailed testing protocols with international partners; high capital requirements for implementing similar testing approaches.

Critical Testing Technologies and Patents

Test method and test device for distribution of electrolyte in vanadium battery stack

PatentActiveCN109461953A

Innovation

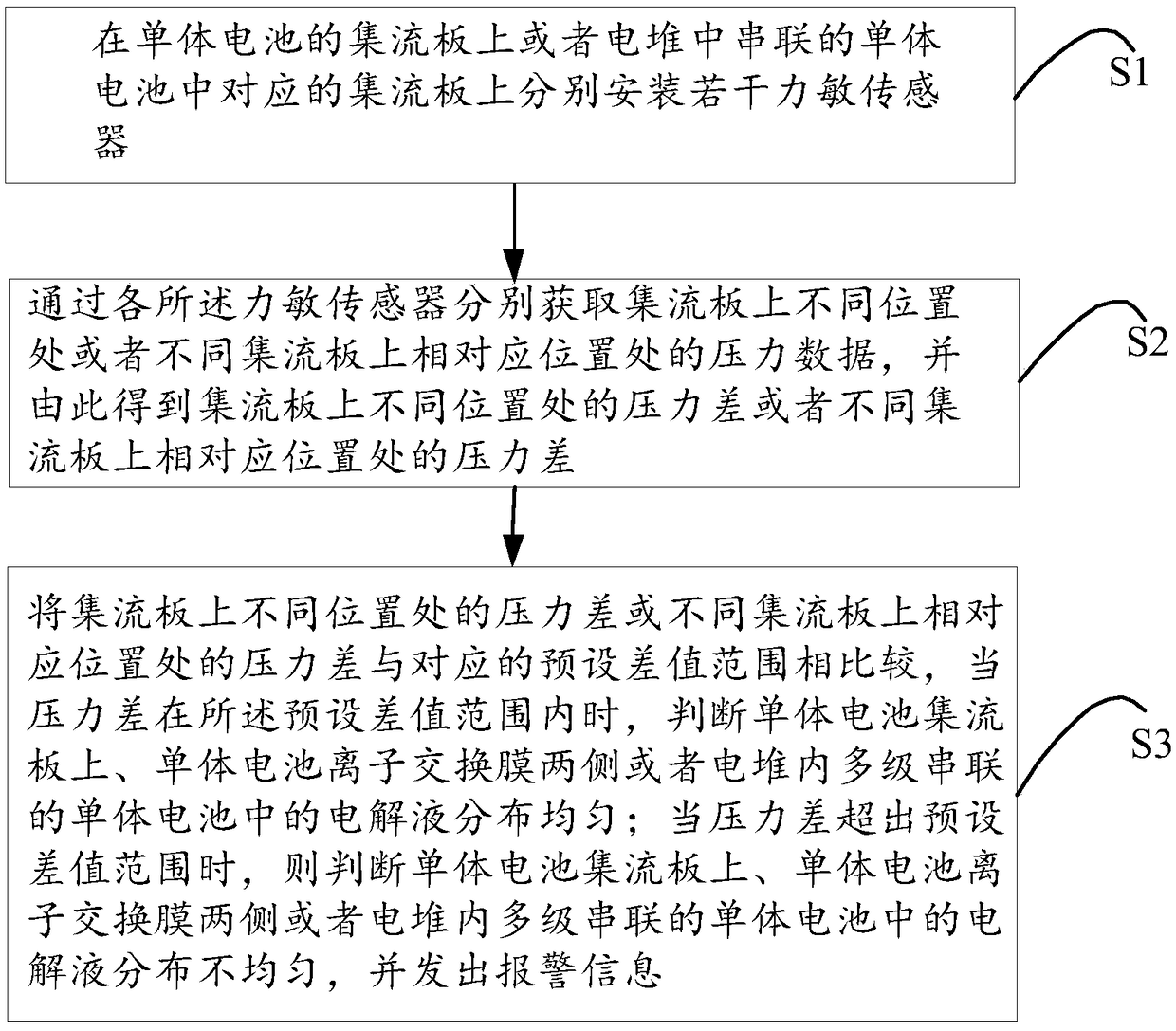

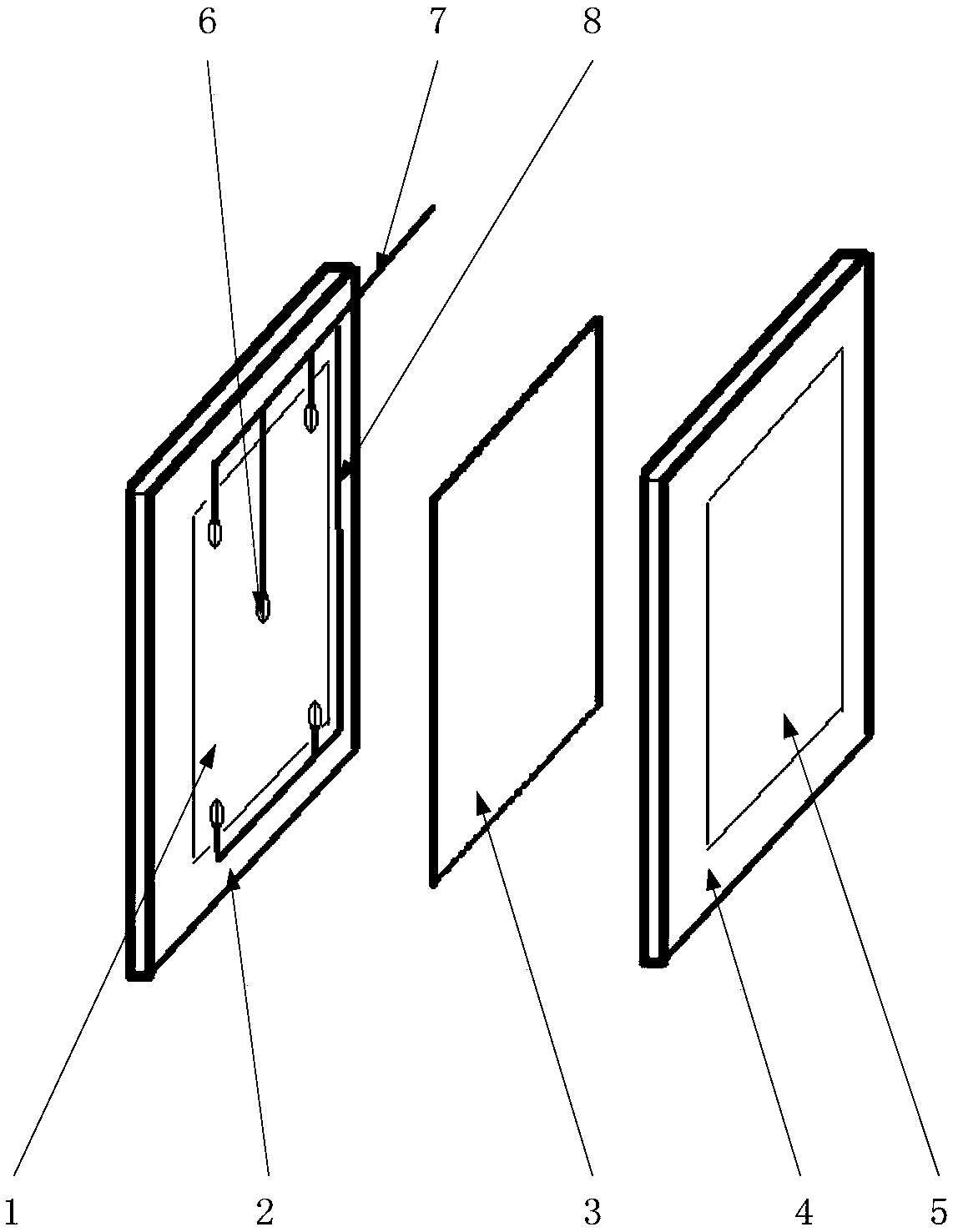

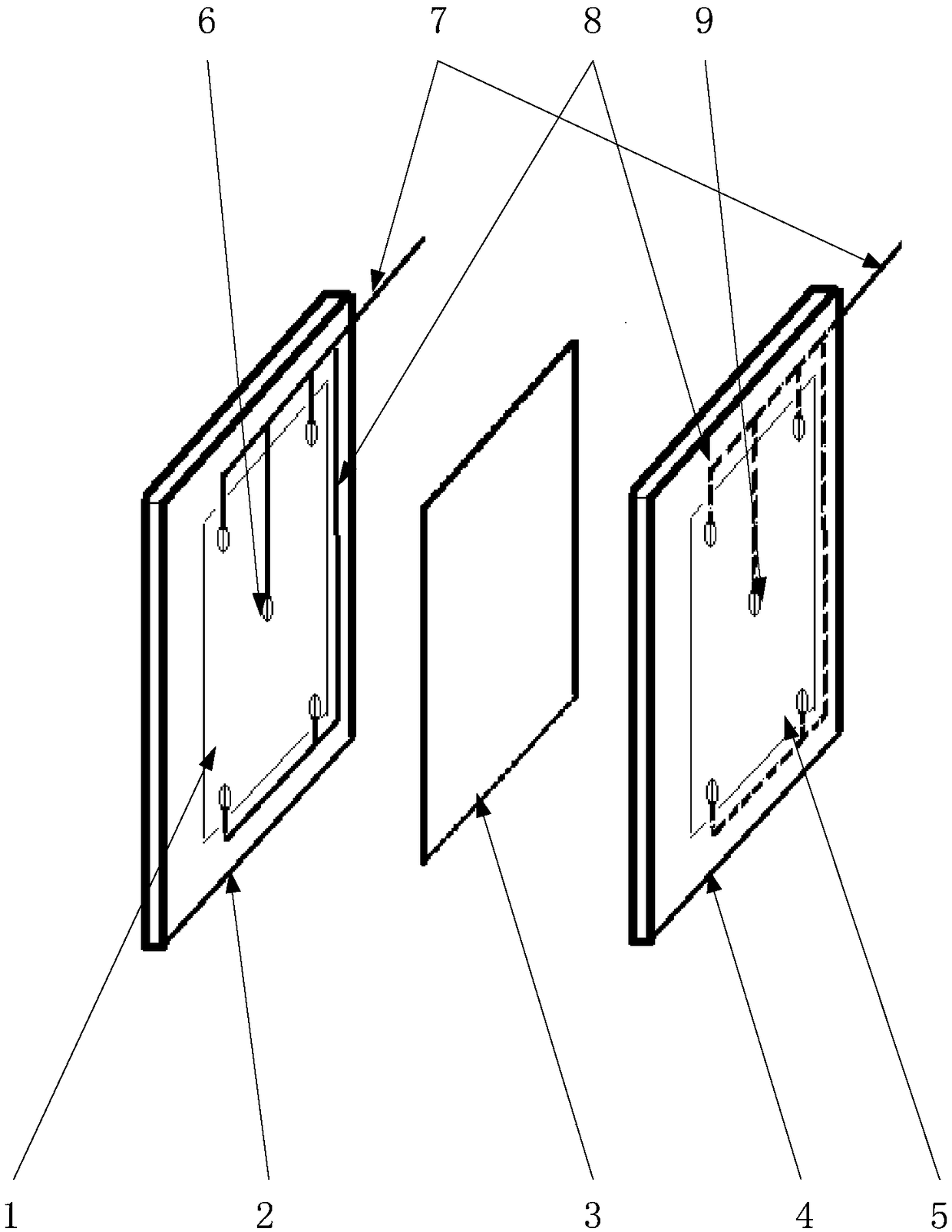

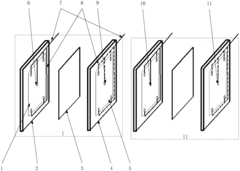

- Install several force-sensitive sensors on the current collector plate of a single cell or in the single cells connected in series in the stack to obtain pressure difference data at different locations on the current collector plate, and determine the electrolyte distribution by comparing it with the preset difference range. Uniform or uneven, and an alarm message is issued.

Test method for voltage distribution of lead-acid storage battery grid

PatentActiveCN107942252A

Innovation

- By drilling holes for the horizontal ribs in the half-shell of the container, welding the horizontal ribs to the grid to be tested to form a corresponding plug-in structure, injecting sulfuric acid solution, and using a data recorder to record the voltage values on the horizontal ribs, the voltage distribution trend can be obtained , providing rib layout design reference.

Safety Standards and Compliance Requirements

Testing load distribution in lithium phosphate infrastructure requires strict adherence to comprehensive safety standards and compliance requirements established by international and regional regulatory bodies. The International Electrotechnical Commission (IEC) has developed specific standards such as IEC 62619 for secondary lithium cells and batteries for industrial applications, which outlines safety requirements for testing, including load distribution assessments. Similarly, UL 1642 and UL 2054 provide critical guidelines for lithium battery testing in North America, with particular emphasis on electrical load distribution parameters.

The European Union's Battery Directive (2006/66/EC) and its amendments mandate specific safety testing protocols for energy storage systems, requiring manufacturers to demonstrate proper load distribution across cells to prevent thermal runaway scenarios. These regulations are complemented by UN 38.3 requirements for transportation safety, which include vibration and shock tests that directly impact load distribution characteristics in lithium phosphate systems.

NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems) provides essential guidelines for testing load distribution in larger infrastructure implementations, specifying minimum separation distances and maximum allowable energy capacities based on load distribution test results. This standard is particularly relevant for grid-scale lithium phosphate installations where uneven load distribution can create significant safety hazards.

Testing protocols must also comply with IEEE 1625 and IEEE 1725 standards, which establish criteria for rechargeable batteries in portable computing and cellular telephone applications respectively. These standards define specific test methodologies for evaluating load distribution under various operational conditions, including temperature extremes and charge/discharge cycles.

ISO 13849 requirements for functional safety of control systems must be incorporated into testing procedures, particularly when evaluating automated load management systems in lithium phosphate infrastructure. This includes validation of safety integrity levels (SIL) for components that monitor and adjust load distribution during operation.

Compliance with IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) is mandatory when testing load distribution management systems, requiring documented risk assessment and mitigation strategies. This standard emphasizes the importance of redundancy in monitoring systems to ensure reliable detection of load distribution anomalies.

Regional variations in compliance requirements necessitate tailored testing approaches, with China's GB/T 36276 standard imposing additional requirements for lithium battery safety testing that specifically address load distribution concerns in high-density energy storage applications. Similarly, Japan's JIS C8715 standard provides market-specific guidelines that must be incorporated into comprehensive testing protocols.

The European Union's Battery Directive (2006/66/EC) and its amendments mandate specific safety testing protocols for energy storage systems, requiring manufacturers to demonstrate proper load distribution across cells to prevent thermal runaway scenarios. These regulations are complemented by UN 38.3 requirements for transportation safety, which include vibration and shock tests that directly impact load distribution characteristics in lithium phosphate systems.

NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems) provides essential guidelines for testing load distribution in larger infrastructure implementations, specifying minimum separation distances and maximum allowable energy capacities based on load distribution test results. This standard is particularly relevant for grid-scale lithium phosphate installations where uneven load distribution can create significant safety hazards.

Testing protocols must also comply with IEEE 1625 and IEEE 1725 standards, which establish criteria for rechargeable batteries in portable computing and cellular telephone applications respectively. These standards define specific test methodologies for evaluating load distribution under various operational conditions, including temperature extremes and charge/discharge cycles.

ISO 13849 requirements for functional safety of control systems must be incorporated into testing procedures, particularly when evaluating automated load management systems in lithium phosphate infrastructure. This includes validation of safety integrity levels (SIL) for components that monitor and adjust load distribution during operation.

Compliance with IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) is mandatory when testing load distribution management systems, requiring documented risk assessment and mitigation strategies. This standard emphasizes the importance of redundancy in monitoring systems to ensure reliable detection of load distribution anomalies.

Regional variations in compliance requirements necessitate tailored testing approaches, with China's GB/T 36276 standard imposing additional requirements for lithium battery safety testing that specifically address load distribution concerns in high-density energy storage applications. Similarly, Japan's JIS C8715 standard provides market-specific guidelines that must be incorporated into comprehensive testing protocols.

Environmental Impact Assessment

The environmental impact of lithium phosphate battery infrastructure testing procedures represents a critical consideration in sustainable energy development. Testing load distribution in these systems generates multiple environmental concerns that must be systematically evaluated and mitigated. Primary environmental impacts include energy consumption during testing processes, which can be substantial when simulating real-world load scenarios across large-scale battery installations.

Waste generation presents another significant environmental challenge, as testing procedures may produce chemical waste from electrolyte sampling, damaged battery components, and testing materials that require specialized disposal protocols. Many of these materials contain potentially hazardous substances that demand careful handling to prevent soil and water contamination.

Water usage in cooling systems during high-load testing scenarios represents a resource consumption concern, particularly in water-stressed regions where battery infrastructure may be deployed. The water footprint of comprehensive testing regimes can be substantial when scaled to industrial levels, necessitating water recycling systems and efficiency measures.

Carbon emissions associated with testing operations must also be quantified, especially when testing relies on grid electricity from non-renewable sources. The environmental assessment should include both direct emissions from testing equipment and indirect emissions from energy consumption, providing a complete carbon footprint analysis of the testing lifecycle.

Local ecosystem impacts require evaluation when testing facilities are located in environmentally sensitive areas. This includes potential effects on wildlife, vegetation, and habitat disruption from testing infrastructure, noise pollution, and electromagnetic emissions during high-load testing scenarios.

Regulatory compliance frameworks vary significantly across jurisdictions, with testing protocols needing to meet increasingly stringent environmental standards. A comprehensive assessment must address compliance with local, national, and international environmental regulations governing battery testing, including specific requirements for hazardous materials handling and disposal.

Mitigation strategies should incorporate renewable energy integration for testing operations, closed-loop testing systems that minimize waste generation, and advanced monitoring technologies to detect and prevent environmental contamination. The implementation of ISO 14001 environmental management systems can provide a structured approach to continuous improvement in environmental performance throughout the testing lifecycle.

Waste generation presents another significant environmental challenge, as testing procedures may produce chemical waste from electrolyte sampling, damaged battery components, and testing materials that require specialized disposal protocols. Many of these materials contain potentially hazardous substances that demand careful handling to prevent soil and water contamination.

Water usage in cooling systems during high-load testing scenarios represents a resource consumption concern, particularly in water-stressed regions where battery infrastructure may be deployed. The water footprint of comprehensive testing regimes can be substantial when scaled to industrial levels, necessitating water recycling systems and efficiency measures.

Carbon emissions associated with testing operations must also be quantified, especially when testing relies on grid electricity from non-renewable sources. The environmental assessment should include both direct emissions from testing equipment and indirect emissions from energy consumption, providing a complete carbon footprint analysis of the testing lifecycle.

Local ecosystem impacts require evaluation when testing facilities are located in environmentally sensitive areas. This includes potential effects on wildlife, vegetation, and habitat disruption from testing infrastructure, noise pollution, and electromagnetic emissions during high-load testing scenarios.

Regulatory compliance frameworks vary significantly across jurisdictions, with testing protocols needing to meet increasingly stringent environmental standards. A comprehensive assessment must address compliance with local, national, and international environmental regulations governing battery testing, including specific requirements for hazardous materials handling and disposal.

Mitigation strategies should incorporate renewable energy integration for testing operations, closed-loop testing systems that minimize waste generation, and advanced monitoring technologies to detect and prevent environmental contamination. The implementation of ISO 14001 environmental management systems can provide a structured approach to continuous improvement in environmental performance throughout the testing lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!