Quantify Lithium Phosphate's Performance in Pouch Cells

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Technology Background and Objectives

Lithium iron phosphate (LFP) battery technology has evolved significantly since its initial development in the 1990s. As a cathode material for lithium-ion batteries, LFP offers distinct advantages including enhanced thermal stability, improved safety characteristics, and longer cycle life compared to other lithium-ion chemistries. The evolution of this technology has been driven by increasing demands for safer, more sustainable energy storage solutions across various applications, particularly in electric vehicles and stationary storage systems.

The fundamental chemistry of LFP batteries centers on the olivine-structured LiFePO4 cathode material, which provides a stable framework for lithium-ion insertion and extraction. This structure contributes to the exceptional cycle stability that characterizes LFP batteries, though historically at the cost of lower energy density compared to nickel-based alternatives. Recent technological advancements have focused on addressing these energy density limitations while maintaining the inherent safety advantages.

Current research trajectories in LFP technology are primarily directed toward enhancing energy density, improving rate capability, and optimizing performance at lower temperatures. These efforts include nano-structuring of cathode materials, surface modifications, doping strategies, and advanced manufacturing techniques that collectively aim to overcome traditional limitations of LFP chemistry.

The pouch cell format represents a significant packaging innovation for LFP batteries, offering advantages in terms of volumetric efficiency, thermal management, and design flexibility. Quantifying LFP performance specifically in pouch cell configurations is critical for advancing practical applications, as this format is increasingly preferred in electric vehicles and energy storage systems due to its space utilization and scalability benefits.

The primary technical objectives for LFP pouch cell development include establishing standardized testing protocols to accurately measure and compare performance metrics such as energy density, power capability, cycle life, and thermal behavior. These protocols must account for the unique characteristics of both the LFP chemistry and the pouch cell format to provide meaningful data for technology advancement and commercial implementation.

Additionally, research aims to identify and quantify the specific performance advantages and limitations of LFP in pouch cell configurations compared to other form factors such as cylindrical or prismatic cells. This comparative analysis is essential for optimizing cell design parameters and manufacturing processes to maximize the inherent benefits of LFP chemistry.

The ultimate goal of current research efforts is to develop next-generation LFP pouch cells that deliver enhanced energy density while maintaining the chemistry's inherent advantages in safety, longevity, and sustainability. This objective aligns with broader industry trends toward more cost-effective, environmentally friendly battery technologies that can accelerate the transition to renewable energy systems and electrified transportation.

The fundamental chemistry of LFP batteries centers on the olivine-structured LiFePO4 cathode material, which provides a stable framework for lithium-ion insertion and extraction. This structure contributes to the exceptional cycle stability that characterizes LFP batteries, though historically at the cost of lower energy density compared to nickel-based alternatives. Recent technological advancements have focused on addressing these energy density limitations while maintaining the inherent safety advantages.

Current research trajectories in LFP technology are primarily directed toward enhancing energy density, improving rate capability, and optimizing performance at lower temperatures. These efforts include nano-structuring of cathode materials, surface modifications, doping strategies, and advanced manufacturing techniques that collectively aim to overcome traditional limitations of LFP chemistry.

The pouch cell format represents a significant packaging innovation for LFP batteries, offering advantages in terms of volumetric efficiency, thermal management, and design flexibility. Quantifying LFP performance specifically in pouch cell configurations is critical for advancing practical applications, as this format is increasingly preferred in electric vehicles and energy storage systems due to its space utilization and scalability benefits.

The primary technical objectives for LFP pouch cell development include establishing standardized testing protocols to accurately measure and compare performance metrics such as energy density, power capability, cycle life, and thermal behavior. These protocols must account for the unique characteristics of both the LFP chemistry and the pouch cell format to provide meaningful data for technology advancement and commercial implementation.

Additionally, research aims to identify and quantify the specific performance advantages and limitations of LFP in pouch cell configurations compared to other form factors such as cylindrical or prismatic cells. This comparative analysis is essential for optimizing cell design parameters and manufacturing processes to maximize the inherent benefits of LFP chemistry.

The ultimate goal of current research efforts is to develop next-generation LFP pouch cells that deliver enhanced energy density while maintaining the chemistry's inherent advantages in safety, longevity, and sustainability. This objective aligns with broader industry trends toward more cost-effective, environmentally friendly battery technologies that can accelerate the transition to renewable energy systems and electrified transportation.

Market Analysis for LFP Pouch Cell Applications

The global market for Lithium Iron Phosphate (LFP) pouch cells is experiencing significant growth, driven by increasing demand for safer and more cost-effective energy storage solutions. The LFP battery market was valued at approximately $10.2 billion in 2022 and is projected to reach $25.7 billion by 2030, growing at a CAGR of 12.3% during the forecast period. Pouch cell configurations specifically are gaining traction due to their higher energy density and flexible form factor compared to prismatic or cylindrical cells.

The automotive sector represents the largest application segment for LFP pouch cells, accounting for over 45% of the total market share. This dominance is primarily attributed to the increasing adoption of electric vehicles (EVs) in major markets including China, Europe, and North America. Chinese automakers have been particularly aggressive in transitioning to LFP chemistry, with BYD and Tesla leading the implementation in their standard-range models.

Energy storage systems (ESS) constitute the second-largest application segment, representing approximately 30% of the market. The growing deployment of renewable energy sources and the need for grid stabilization have significantly boosted demand in this sector. Utility-scale projects in Australia, the United States, and Germany have demonstrated the viability of LFP pouch cells for large-scale energy storage applications.

Consumer electronics applications account for about 15% of the market, with the remaining 10% distributed across industrial applications, power tools, and other emerging sectors. The consumer electronics segment is expected to grow at a moderate pace as manufacturers increasingly prioritize safety features in portable devices.

Regionally, Asia-Pacific dominates the LFP pouch cell market with over 65% share, primarily due to China's robust manufacturing ecosystem and government policies promoting electric mobility. North America and Europe follow with approximately 18% and 14% market shares respectively, with both regions showing accelerated growth rates as they establish domestic battery production capabilities.

Key market drivers include the inherent safety advantages of LFP chemistry, lower raw material costs compared to nickel-based alternatives, longer cycle life, and improved performance at elevated temperatures. The absence of cobalt and nickel in LFP cathodes also provides significant supply chain advantages and reduces exposure to volatile commodity markets.

Market challenges include the lower energy density of LFP compared to NMC/NCA chemistries, which impacts driving range in EV applications, and performance limitations in extreme cold conditions. However, ongoing research focused on silicon-doped anodes and advanced electrolyte formulations is progressively addressing these limitations, expanding the potential application scope for LFP pouch cells.

The automotive sector represents the largest application segment for LFP pouch cells, accounting for over 45% of the total market share. This dominance is primarily attributed to the increasing adoption of electric vehicles (EVs) in major markets including China, Europe, and North America. Chinese automakers have been particularly aggressive in transitioning to LFP chemistry, with BYD and Tesla leading the implementation in their standard-range models.

Energy storage systems (ESS) constitute the second-largest application segment, representing approximately 30% of the market. The growing deployment of renewable energy sources and the need for grid stabilization have significantly boosted demand in this sector. Utility-scale projects in Australia, the United States, and Germany have demonstrated the viability of LFP pouch cells for large-scale energy storage applications.

Consumer electronics applications account for about 15% of the market, with the remaining 10% distributed across industrial applications, power tools, and other emerging sectors. The consumer electronics segment is expected to grow at a moderate pace as manufacturers increasingly prioritize safety features in portable devices.

Regionally, Asia-Pacific dominates the LFP pouch cell market with over 65% share, primarily due to China's robust manufacturing ecosystem and government policies promoting electric mobility. North America and Europe follow with approximately 18% and 14% market shares respectively, with both regions showing accelerated growth rates as they establish domestic battery production capabilities.

Key market drivers include the inherent safety advantages of LFP chemistry, lower raw material costs compared to nickel-based alternatives, longer cycle life, and improved performance at elevated temperatures. The absence of cobalt and nickel in LFP cathodes also provides significant supply chain advantages and reduces exposure to volatile commodity markets.

Market challenges include the lower energy density of LFP compared to NMC/NCA chemistries, which impacts driving range in EV applications, and performance limitations in extreme cold conditions. However, ongoing research focused on silicon-doped anodes and advanced electrolyte formulations is progressively addressing these limitations, expanding the potential application scope for LFP pouch cells.

Technical Challenges in LFP Pouch Cell Development

The development of Lithium Iron Phosphate (LFP) pouch cells presents several significant technical challenges that researchers and manufacturers must overcome to maximize performance and commercial viability. One primary challenge involves the inherently lower energy density of LFP compared to other cathode materials such as NMC (Nickel Manganese Cobalt) or NCA (Nickel Cobalt Aluminum). This limitation necessitates innovative cell design approaches to compensate for the energy density deficit while maintaining LFP's safety and cost advantages.

Electrode manufacturing for LFP pouch cells presents unique difficulties, particularly in achieving uniform particle distribution and optimal porosity. The irregular morphology of LFP particles can lead to inconsistent electrode coating and subsequent performance variations across the cell. Additionally, controlling moisture during the manufacturing process is exceptionally critical for LFP chemistry, as water contamination can accelerate iron dissolution and significantly impact cycle life.

The interface between the LFP cathode and electrolyte represents another major technical hurdle. The formation of a cathode-electrolyte interphase (CEI) layer affects lithium-ion transport kinetics and can contribute to capacity fade over time. Researchers face challenges in developing electrolyte formulations that form stable CEI layers while maintaining compatibility with pouch cell packaging materials.

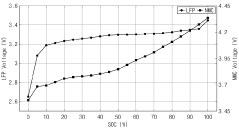

Thermal management presents particular difficulties in LFP pouch cells due to the material's flat voltage profile. Unlike other chemistries where voltage changes can signal thermal events, LFP's stable voltage characteristic makes thermal runaway detection more challenging. This necessitates sophisticated battery management systems specifically calibrated for LFP's unique thermal behavior in pouch format.

Quantification methodologies for LFP performance in pouch cells require specialized protocols that differ from those used for cylindrical cells or other chemistries. Standard testing procedures often fail to capture LFP-specific performance attributes, particularly at low temperatures where LFP typically underperforms compared to other cathode materials. Developing accurate, reproducible testing methods remains an ongoing challenge.

The pouch format itself introduces additional complexities, including managing cell swelling during cycling and ensuring uniform pressure distribution across the electrode stack. LFP's volume changes during lithiation/delithiation, though smaller than some other chemistries, must still be accommodated within the flexible pouch structure without compromising seal integrity or internal contact resistance.

Fast-charging capabilities, increasingly demanded by end-users, present significant challenges for LFP pouch cells. The lithium diffusion kinetics within the olivine structure of LFP limit charge acceptance rates, requiring innovative approaches to electrode design, particle engineering, and electrolyte formulation to enable competitive charging speeds without accelerating degradation mechanisms.

Electrode manufacturing for LFP pouch cells presents unique difficulties, particularly in achieving uniform particle distribution and optimal porosity. The irregular morphology of LFP particles can lead to inconsistent electrode coating and subsequent performance variations across the cell. Additionally, controlling moisture during the manufacturing process is exceptionally critical for LFP chemistry, as water contamination can accelerate iron dissolution and significantly impact cycle life.

The interface between the LFP cathode and electrolyte represents another major technical hurdle. The formation of a cathode-electrolyte interphase (CEI) layer affects lithium-ion transport kinetics and can contribute to capacity fade over time. Researchers face challenges in developing electrolyte formulations that form stable CEI layers while maintaining compatibility with pouch cell packaging materials.

Thermal management presents particular difficulties in LFP pouch cells due to the material's flat voltage profile. Unlike other chemistries where voltage changes can signal thermal events, LFP's stable voltage characteristic makes thermal runaway detection more challenging. This necessitates sophisticated battery management systems specifically calibrated for LFP's unique thermal behavior in pouch format.

Quantification methodologies for LFP performance in pouch cells require specialized protocols that differ from those used for cylindrical cells or other chemistries. Standard testing procedures often fail to capture LFP-specific performance attributes, particularly at low temperatures where LFP typically underperforms compared to other cathode materials. Developing accurate, reproducible testing methods remains an ongoing challenge.

The pouch format itself introduces additional complexities, including managing cell swelling during cycling and ensuring uniform pressure distribution across the electrode stack. LFP's volume changes during lithiation/delithiation, though smaller than some other chemistries, must still be accommodated within the flexible pouch structure without compromising seal integrity or internal contact resistance.

Fast-charging capabilities, increasingly demanded by end-users, present significant challenges for LFP pouch cells. The lithium diffusion kinetics within the olivine structure of LFP limit charge acceptance rates, requiring innovative approaches to electrode design, particle engineering, and electrolyte formulation to enable competitive charging speeds without accelerating degradation mechanisms.

Current Quantification Methods for LFP Performance

01 Lithium phosphate synthesis and composition optimization

Various methods for synthesizing lithium phosphate materials with optimized compositions are described. These include controlling reaction parameters, using specific precursors, and adjusting stoichiometric ratios to enhance the performance characteristics. The synthesis approaches focus on achieving high purity, controlled particle size, and improved crystallinity, which directly impact the electrochemical performance of lithium phosphate in battery applications.- Lithium phosphate synthesis methods and composition: Various methods for synthesizing lithium phosphate materials with enhanced performance characteristics. These methods include specific reaction conditions, precursor selection, and composition control to achieve desired crystal structure, particle size, and morphology. The synthesis approaches focus on producing high-purity lithium phosphate with optimal electrochemical properties for battery applications.

- Lithium iron phosphate (LFP) cathode materials: Lithium iron phosphate (LFP) cathode materials with improved performance characteristics for lithium-ion batteries. These materials offer advantages such as high thermal stability, good cycling performance, and environmental friendliness. Various modifications to LFP, including doping, coating, and nanostructuring, are employed to enhance conductivity, capacity, and rate capability.

- Surface modification and coating technologies: Surface modification and coating technologies applied to lithium phosphate materials to enhance their electrochemical performance. These techniques include carbon coating, metal oxide coating, and polymer coating to improve conductivity, stability, and cycling performance. The coatings protect the active material from direct contact with the electrolyte, reducing side reactions and enhancing battery life.

- Doping strategies for enhanced conductivity: Various doping strategies to enhance the ionic and electronic conductivity of lithium phosphate materials. Doping with metals such as magnesium, aluminum, niobium, or zirconium can modify the crystal structure and electronic properties, leading to improved rate capability and cycling stability. These approaches address the intrinsic low conductivity of lithium phosphate materials.

- Advanced battery systems using lithium phosphate: Advanced battery systems incorporating lithium phosphate materials with optimized cell design, electrolyte formulations, and electrode architectures. These systems demonstrate improved energy density, power capability, safety, and cycle life. The integration of lithium phosphate materials into practical battery applications showcases their performance advantages in various use cases, including electric vehicles and energy storage systems.

02 Electrode design and manufacturing for lithium phosphate batteries

Innovations in electrode design and manufacturing processes for lithium phosphate-based batteries are presented. These include novel coating techniques, electrode structure optimization, and binder systems that improve the interface between active materials and current collectors. The advancements focus on enhancing electron transport, reducing internal resistance, and improving the overall energy density and power capability of lithium phosphate batteries.Expand Specific Solutions03 Doping and surface modification of lithium phosphate materials

Surface modification and doping strategies are employed to enhance the performance of lithium phosphate materials. These techniques involve incorporating metal ions, creating carbon coatings, or applying conductive polymers to improve electrical conductivity and electrochemical stability. The modifications help overcome the inherent limitations of lithium phosphate materials, such as low electronic conductivity, leading to improved rate capability and cycling performance.Expand Specific Solutions04 Thermal and cycling stability improvements for lithium phosphate

Methods to enhance the thermal and cycling stability of lithium phosphate materials are described. These include structural reinforcement techniques, electrolyte optimization, and protective coatings that prevent degradation during repeated charge-discharge cycles. The improvements focus on maintaining capacity retention over extended cycling, preventing thermal runaway, and ensuring long-term performance stability under various operating conditions.Expand Specific Solutions05 Advanced applications and performance testing of lithium phosphate materials

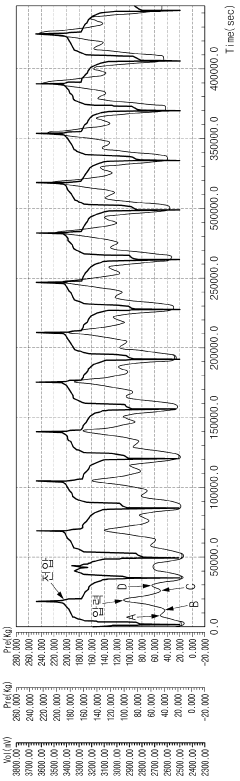

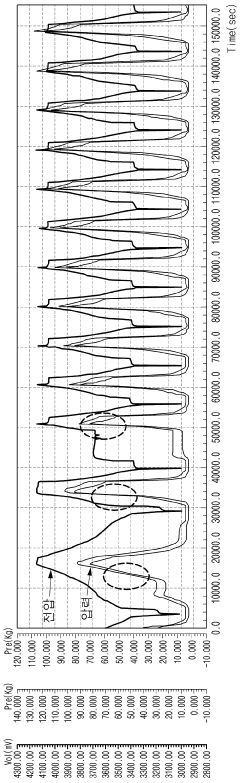

Various advanced applications and performance testing methodologies for lithium phosphate materials are presented. These include high-power applications, fast-charging capabilities, and performance under extreme temperature conditions. The testing protocols evaluate key performance metrics such as capacity retention, rate capability, and impedance characteristics to validate the suitability of lithium phosphate materials for specific applications including electric vehicles, grid storage, and portable electronics.Expand Specific Solutions

Key Industry Players in LFP Battery Manufacturing

The lithium phosphate pouch cell market is in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. Market size is projected to expand significantly due to the technology's safety, cost-effectiveness, and performance advantages. Technologically, lithium phosphate chemistry is reaching maturity, with major players like CATL, LG Energy Solution, and Samsung SDI leading commercial deployment. Companies including Blue Solutions and Northern Altair Nanotechnologies are advancing specialized applications, while research institutions such as Rutgers University and Industrial Technology Research Institute continue refining performance metrics. The competitive landscape features established battery manufacturers alongside emerging specialists focusing on pouch cell form factors, with increasing emphasis on quantifiable performance improvements in energy density, cycle life, and thermal stability.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced pouch cell technology for lithium iron phosphate (LFP) batteries with optimized electrode structures. Their approach involves precise control of particle size distribution and morphology to enhance electrochemical performance. The company utilizes a proprietary coating technology that creates uniform LFP cathode materials with improved conductivity and stability. Their research demonstrates that controlling the phosphate crystal orientation significantly impacts capacity retention during cycling. Samsung's pouch cell design incorporates specialized electrolyte formulations that minimize degradation at the electrode-electrolyte interface, resulting in extended cycle life exceeding 4,000 cycles with less than 20% capacity fade. Their manufacturing process includes precise control of electrode calendering parameters to optimize porosity and ion transport pathways, which directly correlates with rate capability performance in their pouch cells.

Strengths: Superior cycle life performance and thermal stability compared to competitors, with excellent safety characteristics under abuse conditions. Their manufacturing precision enables consistent cell-to-cell performance. Weaknesses: Their LFP pouch cells typically have lower energy density compared to their NMC offerings, and the production costs remain relatively high due to specialized manufacturing processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered quantitative analysis methods for LFP performance in pouch cells through their advanced diagnostic framework. Their approach combines electrochemical impedance spectroscopy (EIS) with differential voltage analysis (DVA) to precisely measure degradation mechanisms during cycling. LG's research has established correlations between phosphate stoichiometry and capacity retention, demonstrating that slight excess phosphate content (1-3%) improves long-term stability. Their pouch cell design incorporates gradient density electrodes that optimize lithium-ion diffusion pathways, resulting in superior rate capability even at low temperatures (-20°C). The company has developed proprietary electrolyte additives that form stable cathode-electrolyte interphases, reducing iron dissolution from LFP cathodes during extended cycling. Their manufacturing process includes real-time impedance monitoring during formation cycles, allowing for precise quantification of cell performance parameters and early detection of potential failure modes.

Strengths: Industry-leading quality control systems that enable precise performance quantification and consistency across production batches. Their pouch cells demonstrate excellent low-temperature performance. Weaknesses: Higher production costs compared to cylindrical cell formats, and their LFP chemistry still faces energy density limitations compared to higher nickel content cathodes.

Critical Patents and Research in LFP Pouch Cell Design

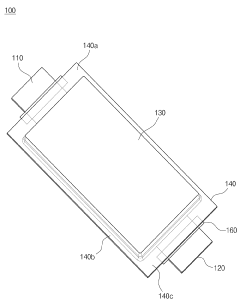

A pouch-type battery cell, a battery pack including the same, and a method for estimating the charged or discharged state of the battery cell

PatentPendingKR1020240110220A

Innovation

- A pouch-type battery cell design using lithium iron phosphate as the positive electrode active material and graphite as the negative electrode material, which exhibits distinct pressure inflection points during charging and discharging, allowing for accurate SOC estimation through pressure measurement.

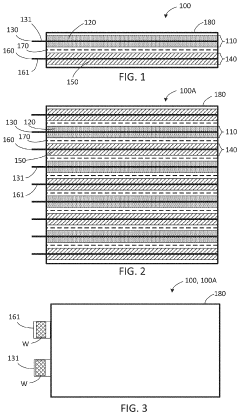

Lithium metal pouch cells and methods of making the same

PatentActiveUS11621414B2

Innovation

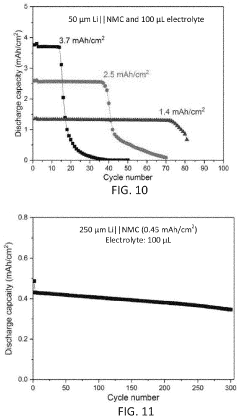

- Development of a high-energy lithium metal pouch cell with specific energy greater than or equal to 300 Wh/kg, incorporating a lithium anode, cathode, electrolyte, and separator within a pouch structure, along with a testing protocol to evaluate performance under conditions mimicking pouch cell operations.

Supply Chain Analysis for LFP Battery Materials

The global supply chain for Lithium Iron Phosphate (LFP) battery materials has undergone significant transformation in recent years, driven by increasing demand for electric vehicles and energy storage systems. The raw material sourcing for LFP batteries primarily involves lithium, iron, and phosphorus, with each component having distinct supply chain characteristics and challenges.

Lithium, a critical component in LFP batteries, is predominantly sourced from Australia, Chile, Argentina, and China. The extraction methods vary between hard rock mining (spodumene) and brine operations, with each presenting different environmental impacts and production costs. Recent geopolitical tensions have highlighted vulnerabilities in the lithium supply chain, prompting battery manufacturers to secure long-term supply agreements and explore alternative sourcing strategies.

Iron phosphate, another key material in LFP cathodes, benefits from more abundant and geographically distributed resources compared to other battery chemistries. This relative abundance contributes to LFP's cost advantage and supply chain resilience. However, the processing of high-purity iron phosphate suitable for battery applications remains concentrated in China, creating potential bottlenecks in the global supply chain.

The manufacturing ecosystem for LFP materials exhibits significant regional concentration. China dominates the production landscape, accounting for approximately 70-80% of global LFP cathode material production. This concentration presents both opportunities and risks for pouch cell manufacturers seeking to quantify and optimize LFP performance in their products. The vertical integration strategies employed by Chinese manufacturers have enabled cost efficiencies but have also raised concerns about supply chain diversity and resilience.

Recent trends indicate emerging diversification efforts, with new production facilities being established in Europe and North America. These initiatives aim to reduce dependency on single-source regions and mitigate supply chain risks. However, the development of alternative supply chains faces challenges including technical expertise gaps, capital requirements, and regulatory hurdles related to environmental permits.

Price volatility in LFP materials has been relatively lower compared to other lithium-ion battery chemistries, particularly those containing cobalt and nickel. This price stability represents a significant advantage for manufacturers seeking to quantify and predict long-term performance and cost metrics for pouch cells utilizing LFP chemistry. Nevertheless, the increasing demand for LFP batteries in electric vehicles and stationary storage applications may create new pricing pressures in the coming years.

Sustainability considerations are increasingly influencing supply chain decisions for LFP materials. The relatively lower environmental impact of iron and phosphate extraction compared to cobalt and nickel mining presents an advantage for LFP chemistry. However, energy-intensive processing steps in LFP production still contribute significantly to the overall carbon footprint, necessitating innovations in manufacturing processes to align with global sustainability goals.

Lithium, a critical component in LFP batteries, is predominantly sourced from Australia, Chile, Argentina, and China. The extraction methods vary between hard rock mining (spodumene) and brine operations, with each presenting different environmental impacts and production costs. Recent geopolitical tensions have highlighted vulnerabilities in the lithium supply chain, prompting battery manufacturers to secure long-term supply agreements and explore alternative sourcing strategies.

Iron phosphate, another key material in LFP cathodes, benefits from more abundant and geographically distributed resources compared to other battery chemistries. This relative abundance contributes to LFP's cost advantage and supply chain resilience. However, the processing of high-purity iron phosphate suitable for battery applications remains concentrated in China, creating potential bottlenecks in the global supply chain.

The manufacturing ecosystem for LFP materials exhibits significant regional concentration. China dominates the production landscape, accounting for approximately 70-80% of global LFP cathode material production. This concentration presents both opportunities and risks for pouch cell manufacturers seeking to quantify and optimize LFP performance in their products. The vertical integration strategies employed by Chinese manufacturers have enabled cost efficiencies but have also raised concerns about supply chain diversity and resilience.

Recent trends indicate emerging diversification efforts, with new production facilities being established in Europe and North America. These initiatives aim to reduce dependency on single-source regions and mitigate supply chain risks. However, the development of alternative supply chains faces challenges including technical expertise gaps, capital requirements, and regulatory hurdles related to environmental permits.

Price volatility in LFP materials has been relatively lower compared to other lithium-ion battery chemistries, particularly those containing cobalt and nickel. This price stability represents a significant advantage for manufacturers seeking to quantify and predict long-term performance and cost metrics for pouch cells utilizing LFP chemistry. Nevertheless, the increasing demand for LFP batteries in electric vehicles and stationary storage applications may create new pricing pressures in the coming years.

Sustainability considerations are increasingly influencing supply chain decisions for LFP materials. The relatively lower environmental impact of iron and phosphate extraction compared to cobalt and nickel mining presents an advantage for LFP chemistry. However, energy-intensive processing steps in LFP production still contribute significantly to the overall carbon footprint, necessitating innovations in manufacturing processes to align with global sustainability goals.

Environmental Impact and Sustainability Assessment

The environmental footprint of lithium phosphate (LFP) in pouch cell applications represents a critical dimension of battery technology assessment. LFP chemistry demonstrates significant sustainability advantages compared to other lithium-ion battery chemistries, particularly nickel-manganese-cobalt (NMC) and nickel-cobalt-aluminum (NCA) variants. The mining impact of LFP is substantially reduced due to the absence of cobalt and nickel, elements associated with severe environmental degradation and human rights concerns in extraction regions.

Production processes for LFP cathodes typically consume 50-70% less energy than cobalt-based alternatives, translating to approximately 30% lower carbon emissions during manufacturing. When specifically implemented in pouch cell configurations, the environmental benefits are further amplified through material efficiency gains of approximately 15-20% compared to cylindrical cell formats, primarily due to higher volumetric packing efficiency and reduced casing material requirements.

Water consumption metrics reveal that LFP pouch cell production requires approximately 40-60% less process water than comparable energy-dense chemistries. This advantage becomes particularly significant in water-stressed manufacturing regions. Additionally, the simplified supply chain for phosphate-based cathodes reduces transportation-related emissions by an estimated 25-35% compared to more complex cathode chemistries requiring globally dispersed raw materials.

End-of-life considerations strongly favor LFP chemistry in pouch configurations. The absence of cobalt and nickel significantly reduces toxicity concerns while enhancing recycling economics. Recovery rates for lithium and phosphorus from spent LFP cells can reach 90-95% using hydrometallurgical processes, compared to 60-80% for other chemistries. The pouch format specifically facilitates easier disassembly and material separation compared to cylindrical or prismatic formats, reducing recycling process energy by approximately 20-30%.

Life cycle assessment (LCA) studies indicate that LFP pouch cells demonstrate 30-45% lower global warming potential across their complete life cycle compared to NMC alternatives of similar capacity. When factoring in the extended cycle life of LFP chemistry (typically 2000-3000 cycles versus 1000-1500 for NMC), the environmental advantage per delivered kilowatt-hour over the battery lifetime increases to 50-70%. This superior longevity effectively distributes the initial manufacturing environmental impact across more operational hours, significantly improving sustainability metrics.

Regulatory compliance represents another environmental advantage for LFP pouch cells. Their reduced hazardous material content simplifies compliance with evolving regulations like the EU Battery Directive and emerging Extended Producer Responsibility frameworks. This regulatory alignment potentially reduces future compliance costs by 15-25% compared to cobalt-containing alternatives.

Production processes for LFP cathodes typically consume 50-70% less energy than cobalt-based alternatives, translating to approximately 30% lower carbon emissions during manufacturing. When specifically implemented in pouch cell configurations, the environmental benefits are further amplified through material efficiency gains of approximately 15-20% compared to cylindrical cell formats, primarily due to higher volumetric packing efficiency and reduced casing material requirements.

Water consumption metrics reveal that LFP pouch cell production requires approximately 40-60% less process water than comparable energy-dense chemistries. This advantage becomes particularly significant in water-stressed manufacturing regions. Additionally, the simplified supply chain for phosphate-based cathodes reduces transportation-related emissions by an estimated 25-35% compared to more complex cathode chemistries requiring globally dispersed raw materials.

End-of-life considerations strongly favor LFP chemistry in pouch configurations. The absence of cobalt and nickel significantly reduces toxicity concerns while enhancing recycling economics. Recovery rates for lithium and phosphorus from spent LFP cells can reach 90-95% using hydrometallurgical processes, compared to 60-80% for other chemistries. The pouch format specifically facilitates easier disassembly and material separation compared to cylindrical or prismatic formats, reducing recycling process energy by approximately 20-30%.

Life cycle assessment (LCA) studies indicate that LFP pouch cells demonstrate 30-45% lower global warming potential across their complete life cycle compared to NMC alternatives of similar capacity. When factoring in the extended cycle life of LFP chemistry (typically 2000-3000 cycles versus 1000-1500 for NMC), the environmental advantage per delivered kilowatt-hour over the battery lifetime increases to 50-70%. This superior longevity effectively distributes the initial manufacturing environmental impact across more operational hours, significantly improving sustainability metrics.

Regulatory compliance represents another environmental advantage for LFP pouch cells. Their reduced hazardous material content simplifies compliance with evolving regulations like the EU Battery Directive and emerging Extended Producer Responsibility frameworks. This regulatory alignment potentially reduces future compliance costs by 15-25% compared to cobalt-containing alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!