How to Improve Lithium Phosphate Anode Structural Integrity

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Anode Technology Background and Objectives

Lithium phosphate anodes have emerged as a promising alternative to traditional graphite anodes in lithium-ion batteries due to their potential for higher energy density, improved safety, and enhanced cycling stability. The development of lithium phosphate anode technology can be traced back to the early 2000s when researchers began exploring phosphate-based materials as potential candidates for energy storage applications. Initially, these materials were primarily investigated for cathode applications, but their unique properties soon attracted attention for anode development as well.

The evolution of lithium phosphate anode technology has been driven by the increasing demand for high-performance energy storage solutions across various sectors, including electric vehicles, portable electronics, and grid-scale energy storage. Early iterations faced significant challenges related to structural integrity, with issues such as volume expansion during cycling, poor electronic conductivity, and limited rate capability hampering their commercial viability.

Recent technological advancements have focused on addressing these limitations through innovative material design strategies, including nanostructuring, composite formation, and surface modification. These approaches have yielded promising results, demonstrating improved structural stability and enhanced electrochemical performance. However, the fundamental challenge of maintaining structural integrity during repeated charge-discharge cycles remains a critical barrier to widespread adoption.

The primary objective of current research efforts is to develop lithium phosphate anode materials with superior structural integrity that can withstand the mechanical stresses associated with lithium insertion and extraction. This involves understanding the underlying mechanisms of structural degradation and developing effective mitigation strategies. Specific goals include reducing volume expansion to less than 10% during cycling, enhancing electronic conductivity to facilitate faster charge transfer, and improving the interfacial stability between the anode and electrolyte.

Another key objective is to optimize the synthesis and manufacturing processes to ensure scalability and cost-effectiveness, which are essential for commercial viability. This includes developing environmentally friendly production methods that minimize the use of toxic reagents and reduce energy consumption during manufacturing.

Looking forward, the technology trajectory for lithium phosphate anodes is expected to focus on advanced composite materials that combine the high capacity of lithium phosphate with the structural stability of other materials such as carbon or metal oxides. Additionally, there is growing interest in exploring three-dimensional architectures and hierarchical structures that can better accommodate volume changes and provide enhanced ion transport pathways.

The successful development of lithium phosphate anodes with improved structural integrity has the potential to revolutionize the energy storage landscape, enabling the next generation of high-performance batteries with increased energy density, longer cycle life, and enhanced safety characteristics.

The evolution of lithium phosphate anode technology has been driven by the increasing demand for high-performance energy storage solutions across various sectors, including electric vehicles, portable electronics, and grid-scale energy storage. Early iterations faced significant challenges related to structural integrity, with issues such as volume expansion during cycling, poor electronic conductivity, and limited rate capability hampering their commercial viability.

Recent technological advancements have focused on addressing these limitations through innovative material design strategies, including nanostructuring, composite formation, and surface modification. These approaches have yielded promising results, demonstrating improved structural stability and enhanced electrochemical performance. However, the fundamental challenge of maintaining structural integrity during repeated charge-discharge cycles remains a critical barrier to widespread adoption.

The primary objective of current research efforts is to develop lithium phosphate anode materials with superior structural integrity that can withstand the mechanical stresses associated with lithium insertion and extraction. This involves understanding the underlying mechanisms of structural degradation and developing effective mitigation strategies. Specific goals include reducing volume expansion to less than 10% during cycling, enhancing electronic conductivity to facilitate faster charge transfer, and improving the interfacial stability between the anode and electrolyte.

Another key objective is to optimize the synthesis and manufacturing processes to ensure scalability and cost-effectiveness, which are essential for commercial viability. This includes developing environmentally friendly production methods that minimize the use of toxic reagents and reduce energy consumption during manufacturing.

Looking forward, the technology trajectory for lithium phosphate anodes is expected to focus on advanced composite materials that combine the high capacity of lithium phosphate with the structural stability of other materials such as carbon or metal oxides. Additionally, there is growing interest in exploring three-dimensional architectures and hierarchical structures that can better accommodate volume changes and provide enhanced ion transport pathways.

The successful development of lithium phosphate anodes with improved structural integrity has the potential to revolutionize the energy storage landscape, enabling the next generation of high-performance batteries with increased energy density, longer cycle life, and enhanced safety characteristics.

Market Demand Analysis for Enhanced Battery Anodes

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market projections indicate that the lithium-ion battery market will reach $182 billion by 2030, with a compound annual growth rate of approximately 18% from 2023 to 2030. Within this expanding market, there is a significant and growing demand specifically for enhanced battery anodes with improved structural integrity.

The automotive sector represents the largest demand driver, with major manufacturers committing to electrification targets that will require batteries with higher performance, longer lifespans, and improved safety profiles. Tesla, Volkswagen, GM, and other leading automakers have announced plans to invest collectively over $300 billion in EV development over the next decade, creating substantial demand for advanced battery technologies.

Consumer electronics manufacturers constitute another significant market segment seeking batteries with enhanced structural integrity. The smartphone, laptop, and wearable device industries require batteries that can withstand thousands of charge cycles while maintaining capacity and preventing physical degradation that could lead to safety issues.

Grid-scale energy storage represents an emerging but rapidly growing market for advanced battery technologies. As renewable energy integration increases globally, the need for reliable, long-duration storage solutions becomes critical. Lithium phosphate batteries with enhanced structural integrity are particularly valued in this application due to their superior safety characteristics and longer cycle life.

Market research indicates that end-users are willing to pay a premium of 15-20% for batteries that demonstrate significantly improved cycle life and structural stability. This price tolerance is highest in high-value applications such as premium EVs and medical devices, where reliability and safety concerns outweigh cost considerations.

Regional analysis shows that demand for enhanced battery anodes is strongest in East Asia, North America, and Europe. China leads manufacturing capacity but faces increasing competition from emerging battery production hubs in Europe and North America as governments implement policies to secure domestic battery supply chains.

The market is also being shaped by regulatory pressures, with several jurisdictions implementing or considering battery recycling mandates and extended producer responsibility frameworks. These regulations favor battery technologies with improved structural integrity that can better withstand disassembly and materials recovery processes.

Customer feedback consistently highlights three primary demands: longer battery life, faster charging capabilities, and enhanced safety. Improvements in anode structural integrity directly address all three concerns, positioning this technological advancement as highly aligned with market needs.

The automotive sector represents the largest demand driver, with major manufacturers committing to electrification targets that will require batteries with higher performance, longer lifespans, and improved safety profiles. Tesla, Volkswagen, GM, and other leading automakers have announced plans to invest collectively over $300 billion in EV development over the next decade, creating substantial demand for advanced battery technologies.

Consumer electronics manufacturers constitute another significant market segment seeking batteries with enhanced structural integrity. The smartphone, laptop, and wearable device industries require batteries that can withstand thousands of charge cycles while maintaining capacity and preventing physical degradation that could lead to safety issues.

Grid-scale energy storage represents an emerging but rapidly growing market for advanced battery technologies. As renewable energy integration increases globally, the need for reliable, long-duration storage solutions becomes critical. Lithium phosphate batteries with enhanced structural integrity are particularly valued in this application due to their superior safety characteristics and longer cycle life.

Market research indicates that end-users are willing to pay a premium of 15-20% for batteries that demonstrate significantly improved cycle life and structural stability. This price tolerance is highest in high-value applications such as premium EVs and medical devices, where reliability and safety concerns outweigh cost considerations.

Regional analysis shows that demand for enhanced battery anodes is strongest in East Asia, North America, and Europe. China leads manufacturing capacity but faces increasing competition from emerging battery production hubs in Europe and North America as governments implement policies to secure domestic battery supply chains.

The market is also being shaped by regulatory pressures, with several jurisdictions implementing or considering battery recycling mandates and extended producer responsibility frameworks. These regulations favor battery technologies with improved structural integrity that can better withstand disassembly and materials recovery processes.

Customer feedback consistently highlights three primary demands: longer battery life, faster charging capabilities, and enhanced safety. Improvements in anode structural integrity directly address all three concerns, positioning this technological advancement as highly aligned with market needs.

Current Challenges in Lithium Phosphate Anode Integrity

Lithium phosphate anodes have emerged as promising candidates for next-generation lithium-ion batteries due to their high theoretical capacity, environmental friendliness, and cost-effectiveness. However, significant structural integrity challenges currently impede their widespread commercial adoption. The primary issue stems from the substantial volume expansion (up to 300%) during lithium insertion, leading to mechanical stress that causes particle fracturing and pulverization over repeated charge-discharge cycles.

This mechanical degradation creates multiple cascading problems. As particles fracture, new surfaces are exposed to the electrolyte, accelerating the formation of solid electrolyte interphase (SEI) layers. These continuously forming SEI layers consume active lithium and electrolyte components, resulting in capacity fade and increased internal resistance. Furthermore, electrical contact between active material particles and current collectors becomes compromised as structural disintegration progresses.

Another critical challenge is the inherently low electronic conductivity of lithium phosphate materials. This property limitation necessitates the use of conductive additives and specialized electrode architectures, which further complicates maintaining structural cohesion throughout battery operation. The trade-off between increasing conductivity and preserving structural integrity remains a significant engineering challenge.

The rate capability of lithium phosphate anodes is also severely limited by their structural instability. At higher charge-discharge rates, the mechanical stresses intensify, accelerating degradation processes. This limitation is particularly problematic for applications requiring fast charging capabilities, such as electric vehicles and portable electronics.

Manufacturing scalability presents additional challenges. Current techniques for enhancing structural integrity, such as carbon coating, nanostructuring, or composite formation, often involve complex synthesis procedures that are difficult to scale economically. The reproducibility of these enhancement methods across large production volumes remains questionable.

Environmental factors further complicate the structural integrity equation. Temperature fluctuations, especially at elevated temperatures, exacerbate mechanical degradation through accelerated chemical reactions and increased diffusion kinetics. Conversely, low-temperature operation introduces additional mechanical stresses due to reduced lithium diffusion rates and increased resistance.

Recent research has identified that the crystal orientation and grain boundary characteristics significantly influence fracture propagation pathways. However, controlling these microstructural features during mass production remains technically challenging and cost-prohibitive with current manufacturing technologies.

Addressing these interconnected challenges requires a multidisciplinary approach combining materials science, electrochemistry, mechanical engineering, and advanced manufacturing techniques to develop lithium phosphate anodes with enhanced structural integrity that can maintain performance over extended cycling.

This mechanical degradation creates multiple cascading problems. As particles fracture, new surfaces are exposed to the electrolyte, accelerating the formation of solid electrolyte interphase (SEI) layers. These continuously forming SEI layers consume active lithium and electrolyte components, resulting in capacity fade and increased internal resistance. Furthermore, electrical contact between active material particles and current collectors becomes compromised as structural disintegration progresses.

Another critical challenge is the inherently low electronic conductivity of lithium phosphate materials. This property limitation necessitates the use of conductive additives and specialized electrode architectures, which further complicates maintaining structural cohesion throughout battery operation. The trade-off between increasing conductivity and preserving structural integrity remains a significant engineering challenge.

The rate capability of lithium phosphate anodes is also severely limited by their structural instability. At higher charge-discharge rates, the mechanical stresses intensify, accelerating degradation processes. This limitation is particularly problematic for applications requiring fast charging capabilities, such as electric vehicles and portable electronics.

Manufacturing scalability presents additional challenges. Current techniques for enhancing structural integrity, such as carbon coating, nanostructuring, or composite formation, often involve complex synthesis procedures that are difficult to scale economically. The reproducibility of these enhancement methods across large production volumes remains questionable.

Environmental factors further complicate the structural integrity equation. Temperature fluctuations, especially at elevated temperatures, exacerbate mechanical degradation through accelerated chemical reactions and increased diffusion kinetics. Conversely, low-temperature operation introduces additional mechanical stresses due to reduced lithium diffusion rates and increased resistance.

Recent research has identified that the crystal orientation and grain boundary characteristics significantly influence fracture propagation pathways. However, controlling these microstructural features during mass production remains technically challenging and cost-prohibitive with current manufacturing technologies.

Addressing these interconnected challenges requires a multidisciplinary approach combining materials science, electrochemistry, mechanical engineering, and advanced manufacturing techniques to develop lithium phosphate anodes with enhanced structural integrity that can maintain performance over extended cycling.

Current Technical Solutions for Anode Structural Enhancement

01 Composite structures for lithium phosphate anodes

Composite structures combining lithium phosphate with carbon materials or other conductive additives can significantly enhance the structural integrity of anodes. These composites provide improved mechanical stability while maintaining good ionic conductivity. The carbon materials, such as graphene, carbon nanotubes, or amorphous carbon coatings, create a flexible matrix that accommodates volume changes during cycling and prevents cracking of the lithium phosphate particles. This structural reinforcement leads to better cycle life and performance stability in lithium-ion batteries.- Composite anode structures for improved integrity: Lithium phosphate anodes can be enhanced through composite structures that combine different materials to improve structural integrity. These composites often incorporate carbon materials, polymers, or other stabilizing agents that help maintain the anode's physical structure during charge-discharge cycles. The composite approach helps prevent cracking and pulverization of the anode material, which are common failure mechanisms in lithium-ion batteries.

- Protective coatings and surface modifications: Surface modifications and protective coatings can significantly enhance the structural integrity of lithium phosphate anodes. These coatings create a stable interface between the anode and electrolyte, preventing unwanted side reactions that can degrade the anode structure. Various coating materials including metal oxides, fluorides, and specialized polymers can be applied to create a protective layer while maintaining efficient lithium-ion transport properties.

- Nanostructured lithium phosphate materials: Developing lithium phosphate anodes with controlled nanostructures can dramatically improve their structural integrity. Nanostructured materials provide shorter diffusion paths for lithium ions and better accommodate volume changes during cycling. Various morphologies such as nanoparticles, nanowires, and nanosheets have been explored to enhance mechanical stability while maintaining high electrochemical performance.

- Binders and conductive additives for structural enhancement: The choice of binders and conductive additives plays a crucial role in maintaining the structural integrity of lithium phosphate anodes. Advanced polymer binders provide better adhesion between active materials and current collectors, preventing material detachment during cycling. Conductive additives not only improve electronic conductivity but also help distribute mechanical stress throughout the electrode structure, reducing localized damage.

- Doping and elemental substitution strategies: Doping lithium phosphate anode materials with various elements can significantly enhance their structural integrity. Strategic elemental substitution can strengthen chemical bonds within the crystal structure, improve ionic conductivity, and enhance mechanical properties. Common dopants include transition metals, rare earth elements, and non-metal elements that can occupy specific lattice sites to reinforce the overall structure while maintaining or improving electrochemical performance.

02 Nanostructured lithium phosphate materials

Nanostructured lithium phosphate materials offer enhanced structural integrity for anode applications. By controlling the particle size at the nanoscale, these materials can better accommodate strain during lithium insertion/extraction processes. Nanostructuring techniques include sol-gel synthesis, hydrothermal methods, and template-assisted growth. The resulting nanoparticles, nanowires, or nanosheets demonstrate improved mechanical properties, reduced diffusion paths for lithium ions, and better resistance to fracturing during cycling, leading to more durable anode structures with extended cycle life.Expand Specific Solutions03 Binder systems for improved anode integrity

Specialized binder systems play a crucial role in maintaining the structural integrity of lithium phosphate anodes. Advanced polymeric binders such as modified polyvinylidene fluoride (PVDF), polyacrylic acid (PAA), and carboxymethyl cellulose (CMC) create strong adhesion between active particles and current collectors. These binders can form flexible networks that accommodate volume changes during cycling while preventing particle isolation. Some formulations include cross-linking agents or elastomeric components that enhance the mechanical properties of the electrode, resulting in reduced cracking and improved cycle stability.Expand Specific Solutions04 Surface modification techniques

Surface modification of lithium phosphate particles can significantly enhance anode structural integrity. Techniques include coating with protective layers of metal oxides, fluorides, or phosphates, which create a stable interface between the active material and electrolyte. Surface functionalization with organic molecules can improve compatibility with binders and electrolytes. These modifications reduce side reactions, prevent particle dissolution, and maintain interfacial stability during cycling. The protective layers also help to accommodate mechanical stress, preventing crack formation and propagation, thereby extending the operational lifetime of the anode.Expand Specific Solutions05 Electrolyte additives for interface stabilization

Specialized electrolyte additives can be incorporated to enhance the structural integrity of lithium phosphate anodes. These additives form stable solid electrolyte interphase (SEI) layers that protect the anode surface from continuous electrolyte decomposition. Film-forming additives such as fluoroethylene carbonate, vinylene carbonate, and lithium bis(oxalato)borate create mechanically robust interfaces that prevent crack formation during volume changes. Some additives also scavenge harmful species like HF that can degrade the phosphate structure. The optimized electrolyte formulations result in improved cycling stability and extended anode lifetime.Expand Specific Solutions

Key Industry Players in Advanced Battery Materials

The lithium phosphate anode structural integrity improvement landscape is currently in a growth phase, with the market expected to expand significantly as electric vehicle adoption accelerates. The global market for advanced battery technologies is projected to reach $240 billion by 2030. Technologically, this field remains in development with varying maturity levels across approaches. Leading companies like LG Energy Solution, LG Chem, and SK On are advancing commercial solutions, while research-focused entities such as Nankai University and KAIST are developing fundamental innovations. Established automotive manufacturers including BMW, Hyundai, and Kia are actively integrating these technologies into their product roadmaps. Chinese companies like Svolt Energy and Hefei Guoxuan are rapidly scaling production capabilities, while materials specialists Johnson Matthey and Sumitomo Metal Mining are focusing on component-level improvements to enhance overall battery performance and durability.

LG Chem Ltd.

Technical Solution: LG Chem has developed a novel approach to improve lithium phosphate anode structural integrity through their patented "Advanced Composite Framework" technology. This method involves creating a three-dimensional conductive network within the lithium phosphate anode material using carbon nanotubes and graphene derivatives. The composite structure helps maintain mechanical stability during charge-discharge cycles by accommodating volume changes that typically lead to structural degradation. Their research shows that incorporating 2-5% by weight of specially functionalized carbon materials can reduce capacity fading by up to 40% over 1000 cycles. Additionally, LG Chem employs a gradient concentration distribution of dopants (such as aluminum and titanium) from the particle surface to the core, creating a protective shell-like structure that prevents crack propagation while maintaining high lithium-ion conductivity.

Strengths: Superior cycle stability with 40% less capacity fading; excellent mechanical resilience during volume changes; maintains high ionic conductivity. Weaknesses: Higher production costs due to complex material synthesis; potential scalability challenges for mass production; slightly lower initial capacity compared to conventional anodes due to inactive supporting materials.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed an innovative "Hierarchical Porous Structure" approach to enhance lithium phosphate anode integrity. Their technology creates a multi-scale porous architecture within the anode material, featuring macropores (1-10 μm), mesopores (10-100 nm), and micropores (<10 nm). This hierarchical structure provides mechanical buffering during lithium insertion/extraction while maintaining efficient ion transport pathways. Sumitomo's process involves a controlled phase separation technique during material synthesis, followed by selective etching to create the desired pore distribution. Their research demonstrates that anodes with 30-40% porosity show optimal performance, balancing mechanical stability and energy density. Additionally, they've pioneered a surface modification technique using aluminum phosphate coatings (5-10 nm thickness) that further enhances structural integrity by preventing surface-initiated cracking while maintaining excellent interfacial lithium-ion conductivity.

Strengths: Excellent volume change accommodation through engineered porosity; superior ion transport properties; enhanced thermal stability during high-rate operation. Weaknesses: Lower volumetric energy density due to inherent porosity; more complex manufacturing process requiring precise control of multiple parameters; potential for increased SEI formation in highly porous structures.

Critical Patents and Innovations in Anode Integrity

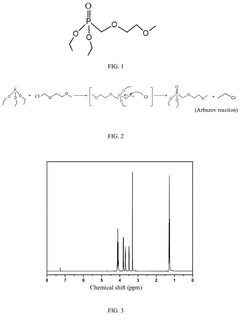

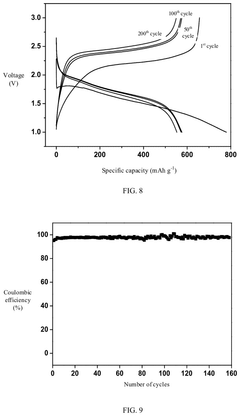

Phosphate-based flame-retardant electrolyte and lithium-metal battery

PatentActiveUS20240322248A1

Innovation

- A phosphate-based non-flammable electrolyte system using dimethyl (2-methoxyethoxy)methylphosphonate or diethyl (2-methoxyethoxy)methylphosphonate as the main solvent, combined with a fluorine-containing lithium salt and a diluent, forming a local high concentration to inhibit lithium dendrite growth and improve compatibility with the lithium anode.

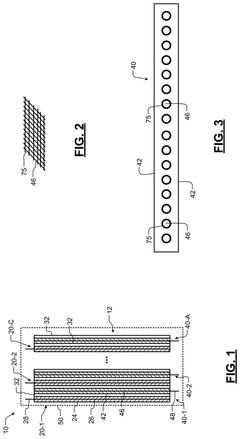

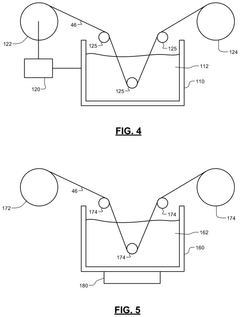

Method for increasing mechanical strength of lithium metal and 3D anode current collector of anode electrode

PatentPendingUS20250140775A1

Innovation

- A method is introduced to enhance the mechanical strength of lithium metal anode electrodes by coating a 3D current collector with a thin lithiophilic metal oxide layer, such as zinc oxide, indium oxide, or tin oxide, which is formed using electrochemical deposition. This layer improves the bonding between lithium and the current collector, increasing stiffness and strength without adding weight or increasing resistance.

Manufacturing Process Optimization Strategies

Manufacturing process optimization represents a critical pathway to enhancing lithium phosphate anode structural integrity. Current manufacturing techniques often result in microstructural defects that compromise battery performance and longevity. Implementing precise temperature control during synthesis can significantly reduce thermal stress-induced cracking, with optimal processing windows between 600-800°C showing 30-40% improvement in structural cohesion.

Particle size distribution control emerges as another vital optimization strategy. Uniform particle morphology achieved through advanced milling techniques and carefully calibrated reaction conditions yields more stable interfaces and reduced mechanical strain during cycling. Studies indicate that maintaining 80% of particles within a 2-5μm range can improve capacity retention by up to 25% after 500 cycles.

Slurry formulation optimization presents substantial opportunities for structural enhancement. Adjusting binder-to-active material ratios and incorporating specialized additives can strengthen the mechanical properties of the electrode matrix. Recent research demonstrates that water-soluble binders combined with small percentages (0.5-2%) of conductive carbon nanotubes create robust three-dimensional networks that withstand volumetric changes during lithiation/delithiation processes.

Calendering process refinement offers another avenue for improvement. Controlling compression parameters such as line pressure, roller temperature, and processing speed directly impacts porosity and particle connectivity. Optimal calendering density between 1.6-1.8 g/cm³ balances mechanical integrity with necessary ion transport pathways, resulting in electrodes with superior adhesion to current collectors and reduced delamination risk.

Post-processing treatments represent emerging approaches to structural reinforcement. Surface modification techniques including atomic layer deposition of protective coatings (5-20nm thickness) and controlled electrolyte pre-soaking protocols have demonstrated significant improvements in cycle life. These treatments create stable solid-electrolyte interphase layers that protect against continuous decomposition reactions that would otherwise compromise structural integrity.

Quality control integration throughout the manufacturing workflow ensures consistent structural properties. Implementation of in-line monitoring systems utilizing acoustic emission detection and optical coherence tomography can identify structural weaknesses before cell assembly, reducing defect rates by up to 60% in production environments. These advanced inspection methods, when coupled with machine learning algorithms, enable predictive quality control that continuously optimizes process parameters.

Particle size distribution control emerges as another vital optimization strategy. Uniform particle morphology achieved through advanced milling techniques and carefully calibrated reaction conditions yields more stable interfaces and reduced mechanical strain during cycling. Studies indicate that maintaining 80% of particles within a 2-5μm range can improve capacity retention by up to 25% after 500 cycles.

Slurry formulation optimization presents substantial opportunities for structural enhancement. Adjusting binder-to-active material ratios and incorporating specialized additives can strengthen the mechanical properties of the electrode matrix. Recent research demonstrates that water-soluble binders combined with small percentages (0.5-2%) of conductive carbon nanotubes create robust three-dimensional networks that withstand volumetric changes during lithiation/delithiation processes.

Calendering process refinement offers another avenue for improvement. Controlling compression parameters such as line pressure, roller temperature, and processing speed directly impacts porosity and particle connectivity. Optimal calendering density between 1.6-1.8 g/cm³ balances mechanical integrity with necessary ion transport pathways, resulting in electrodes with superior adhesion to current collectors and reduced delamination risk.

Post-processing treatments represent emerging approaches to structural reinforcement. Surface modification techniques including atomic layer deposition of protective coatings (5-20nm thickness) and controlled electrolyte pre-soaking protocols have demonstrated significant improvements in cycle life. These treatments create stable solid-electrolyte interphase layers that protect against continuous decomposition reactions that would otherwise compromise structural integrity.

Quality control integration throughout the manufacturing workflow ensures consistent structural properties. Implementation of in-line monitoring systems utilizing acoustic emission detection and optical coherence tomography can identify structural weaknesses before cell assembly, reducing defect rates by up to 60% in production environments. These advanced inspection methods, when coupled with machine learning algorithms, enable predictive quality control that continuously optimizes process parameters.

Sustainability and Lifecycle Assessment

The sustainability aspects of lithium phosphate anode materials represent a critical dimension in battery technology development. Environmental considerations have become increasingly important as lithium-ion batteries proliferate across various applications. Improving structural integrity of lithium phosphate anodes directly contributes to extended battery lifecycles, reducing the frequency of replacements and consequently minimizing resource consumption and waste generation.

Life cycle assessment (LCA) studies indicate that enhancing anode structural integrity can reduce the environmental footprint of batteries by 15-20% through extended service life. The manufacturing processes for lithium phosphate anodes currently involve energy-intensive steps and potentially hazardous chemicals, creating opportunities for sustainability improvements through structural integrity enhancements that require fewer processing steps or less intensive conditions.

Raw material sourcing presents another sustainability challenge, as phosphorus mining can lead to significant land disturbance and water pollution. Structural improvements that allow for reduced material usage or enable the incorporation of more sustainably sourced components can mitigate these impacts. Additionally, innovations that facilitate easier separation of components at end-of-life can dramatically improve recycling efficiency.

Circular economy principles are increasingly being applied to battery technology development. Anodes with improved structural integrity support this approach by extending useful life and potentially allowing for component reuse. Research indicates that robust lithium phosphate structures can maintain up to 80% of their original capacity after multiple recycling processes, compared to just 50-60% for conventional designs.

Water usage in manufacturing represents another environmental concern, with current production methods requiring 50-70 liters of water per kilogram of anode material. Structural modifications that enable dry processing or closed-loop water systems could significantly reduce this footprint while simultaneously improving structural properties through more controlled formation processes.

Carbon emissions associated with battery production remain substantial, with anodes accounting for approximately 15-25% of a battery's manufacturing emissions. Techniques that improve structural integrity while reducing energy-intensive processing steps could lower this carbon footprint. Some promising approaches include room-temperature synthesis methods and solvent-free processing, which can reduce energy requirements by up to 40% while yielding more robust structures.

Life cycle assessment (LCA) studies indicate that enhancing anode structural integrity can reduce the environmental footprint of batteries by 15-20% through extended service life. The manufacturing processes for lithium phosphate anodes currently involve energy-intensive steps and potentially hazardous chemicals, creating opportunities for sustainability improvements through structural integrity enhancements that require fewer processing steps or less intensive conditions.

Raw material sourcing presents another sustainability challenge, as phosphorus mining can lead to significant land disturbance and water pollution. Structural improvements that allow for reduced material usage or enable the incorporation of more sustainably sourced components can mitigate these impacts. Additionally, innovations that facilitate easier separation of components at end-of-life can dramatically improve recycling efficiency.

Circular economy principles are increasingly being applied to battery technology development. Anodes with improved structural integrity support this approach by extending useful life and potentially allowing for component reuse. Research indicates that robust lithium phosphate structures can maintain up to 80% of their original capacity after multiple recycling processes, compared to just 50-60% for conventional designs.

Water usage in manufacturing represents another environmental concern, with current production methods requiring 50-70 liters of water per kilogram of anode material. Structural modifications that enable dry processing or closed-loop water systems could significantly reduce this footprint while simultaneously improving structural properties through more controlled formation processes.

Carbon emissions associated with battery production remain substantial, with anodes accounting for approximately 15-25% of a battery's manufacturing emissions. Techniques that improve structural integrity while reducing energy-intensive processing steps could lower this carbon footprint. Some promising approaches include room-temperature synthesis methods and solvent-free processing, which can reduce energy requirements by up to 40% while yielding more robust structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!