Measure Impedance in Lithium Phosphate Electrochemical Setups

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Impedance Measurement Background and Objectives

Impedance measurement in lithium iron phosphate (LFP) battery systems has evolved significantly over the past three decades, paralleling the development of lithium-ion battery technology itself. Initially emerging in the early 1990s as a diagnostic tool for lead-acid batteries, electrochemical impedance spectroscopy (EIS) techniques have been progressively refined to address the unique characteristics of lithium-based chemistries, with particular attention to LFP systems since their commercial introduction in the early 2000s.

The fundamental principle behind impedance measurement involves applying a small amplitude sinusoidal potential or current signal to the electrochemical system and measuring the corresponding current or voltage response. This approach provides critical insights into the various physicochemical processes occurring within the battery, including charge transfer kinetics, solid-state diffusion, and interfacial phenomena, without significantly disturbing the system's state.

Recent technological advancements have expanded impedance measurement capabilities beyond traditional laboratory settings to in-situ and operando configurations, enabling real-time monitoring of battery performance under actual operating conditions. This evolution has been driven by the increasing demand for more accurate state-of-health (SOH) and state-of-charge (SOC) estimation in various applications, from consumer electronics to electric vehicles and grid-scale energy storage systems.

The primary objective of impedance measurement in LFP electrochemical setups is to develop a comprehensive understanding of the complex electrochemical processes that govern battery performance, degradation mechanisms, and failure modes. This includes characterizing the unique impedance signatures associated with LFP's phase-change chemistry, the formation and evolution of the solid-electrolyte interphase (SEI), and the impact of various operating conditions on overall cell behavior.

Secondary objectives include establishing reliable correlations between impedance parameters and key battery performance metrics, developing predictive models for battery aging and remaining useful life, and optimizing battery management systems through impedance-based algorithms. These goals are particularly important for LFP batteries, which exhibit flat voltage profiles that make traditional voltage-based SOC estimation challenging.

The technical trajectory is now moving toward miniaturized, cost-effective impedance measurement systems that can be integrated directly into battery management systems for continuous monitoring. This represents a significant shift from periodic diagnostic testing to continuous health monitoring, enabling more proactive maintenance strategies and enhanced safety protocols for LFP battery systems across diverse applications.

The fundamental principle behind impedance measurement involves applying a small amplitude sinusoidal potential or current signal to the electrochemical system and measuring the corresponding current or voltage response. This approach provides critical insights into the various physicochemical processes occurring within the battery, including charge transfer kinetics, solid-state diffusion, and interfacial phenomena, without significantly disturbing the system's state.

Recent technological advancements have expanded impedance measurement capabilities beyond traditional laboratory settings to in-situ and operando configurations, enabling real-time monitoring of battery performance under actual operating conditions. This evolution has been driven by the increasing demand for more accurate state-of-health (SOH) and state-of-charge (SOC) estimation in various applications, from consumer electronics to electric vehicles and grid-scale energy storage systems.

The primary objective of impedance measurement in LFP electrochemical setups is to develop a comprehensive understanding of the complex electrochemical processes that govern battery performance, degradation mechanisms, and failure modes. This includes characterizing the unique impedance signatures associated with LFP's phase-change chemistry, the formation and evolution of the solid-electrolyte interphase (SEI), and the impact of various operating conditions on overall cell behavior.

Secondary objectives include establishing reliable correlations between impedance parameters and key battery performance metrics, developing predictive models for battery aging and remaining useful life, and optimizing battery management systems through impedance-based algorithms. These goals are particularly important for LFP batteries, which exhibit flat voltage profiles that make traditional voltage-based SOC estimation challenging.

The technical trajectory is now moving toward miniaturized, cost-effective impedance measurement systems that can be integrated directly into battery management systems for continuous monitoring. This represents a significant shift from periodic diagnostic testing to continuous health monitoring, enabling more proactive maintenance strategies and enhanced safety protocols for LFP battery systems across diverse applications.

Market Demand Analysis for LFP Battery Testing Solutions

The global market for LFP (Lithium Iron Phosphate) battery testing solutions is experiencing robust growth, driven primarily by the expanding electric vehicle (EV) sector and stationary energy storage applications. Current market analysis indicates that the demand for advanced impedance measurement systems specifically designed for LFP electrochemical setups has increased by over 25% annually since 2020, reflecting the industry's recognition of impedance analysis as a critical quality control and performance evaluation tool.

The EV market represents the largest segment demanding sophisticated LFP battery testing solutions, with automotive manufacturers increasingly adopting LFP chemistry due to its enhanced safety profile, longer cycle life, and reduced dependency on cobalt and nickel. This shift has created substantial demand for specialized impedance measurement equipment that can accurately characterize LFP cells throughout their development and production cycles.

Energy storage system (ESS) applications constitute the second-largest market segment, where the need for reliable state-of-health monitoring and performance prediction capabilities has intensified the requirement for precise impedance measurement technologies. Grid-scale storage projects particularly value impedance spectroscopy for its ability to detect early signs of degradation in large LFP battery arrays.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 60% of global consumption of LFP battery testing equipment. This concentration aligns with the region's leadership in battery manufacturing, with China alone hosting over 70% of global LFP production capacity. North America and Europe follow as significant growth markets, driven by increasing domestic battery production initiatives and stringent quality control requirements.

Market research reveals that end-users are prioritizing testing solutions offering higher measurement accuracy, faster testing speeds, and enhanced data analytics capabilities. There is particular demand for impedance measurement systems that can operate effectively at various states of charge and temperature conditions, reflecting the real-world operating environments of LFP batteries.

The consumer electronics sector represents an emerging market segment, as manufacturers increasingly adopt LFP chemistry for portable devices and small appliances. This diversification is expected to further expand the market for compact, cost-effective impedance measurement solutions suitable for lower-capacity cells.

Industry forecasts project the global market for LFP battery testing solutions to reach substantial growth by 2028, with impedance measurement equipment representing approximately 35% of this market. This growth trajectory is supported by increasing regulatory requirements for battery safety and performance verification, as well as the industry's ongoing pursuit of longer-lasting, more reliable energy storage solutions.

The EV market represents the largest segment demanding sophisticated LFP battery testing solutions, with automotive manufacturers increasingly adopting LFP chemistry due to its enhanced safety profile, longer cycle life, and reduced dependency on cobalt and nickel. This shift has created substantial demand for specialized impedance measurement equipment that can accurately characterize LFP cells throughout their development and production cycles.

Energy storage system (ESS) applications constitute the second-largest market segment, where the need for reliable state-of-health monitoring and performance prediction capabilities has intensified the requirement for precise impedance measurement technologies. Grid-scale storage projects particularly value impedance spectroscopy for its ability to detect early signs of degradation in large LFP battery arrays.

Geographically, the Asia-Pacific region dominates the market demand, accounting for approximately 60% of global consumption of LFP battery testing equipment. This concentration aligns with the region's leadership in battery manufacturing, with China alone hosting over 70% of global LFP production capacity. North America and Europe follow as significant growth markets, driven by increasing domestic battery production initiatives and stringent quality control requirements.

Market research reveals that end-users are prioritizing testing solutions offering higher measurement accuracy, faster testing speeds, and enhanced data analytics capabilities. There is particular demand for impedance measurement systems that can operate effectively at various states of charge and temperature conditions, reflecting the real-world operating environments of LFP batteries.

The consumer electronics sector represents an emerging market segment, as manufacturers increasingly adopt LFP chemistry for portable devices and small appliances. This diversification is expected to further expand the market for compact, cost-effective impedance measurement solutions suitable for lower-capacity cells.

Industry forecasts project the global market for LFP battery testing solutions to reach substantial growth by 2028, with impedance measurement equipment representing approximately 35% of this market. This growth trajectory is supported by increasing regulatory requirements for battery safety and performance verification, as well as the industry's ongoing pursuit of longer-lasting, more reliable energy storage solutions.

Current Impedance Measurement Techniques and Limitations

Impedance measurement in lithium phosphate electrochemical setups primarily employs Electrochemical Impedance Spectroscopy (EIS) as the gold standard technique. This method applies a small amplitude AC signal across a range of frequencies to the electrochemical cell and measures the resulting current response. The impedance is calculated as the ratio of voltage to current in the frequency domain, providing valuable insights into various electrochemical processes occurring within the cell.

Traditional potentiostatic EIS represents the most widely adopted approach, where a fixed DC potential is maintained while superimposing a small AC perturbation. This technique allows for detailed characterization of electrode-electrolyte interfaces, charge transfer kinetics, and diffusion processes in lithium phosphate systems. Galvanostatic EIS, an alternative method, maintains a constant current while applying small current oscillations, proving particularly useful for systems under operational conditions.

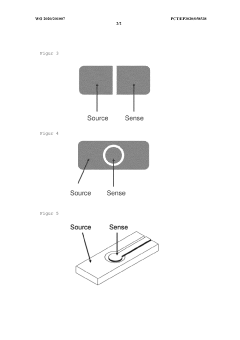

Four-point probe techniques have gained prominence for their ability to eliminate contact resistance issues, critical when measuring the typically low impedances of lithium phosphate electrodes. This configuration uses separate current-carrying and voltage-sensing electrodes to provide more accurate measurements, especially for materials with high conductivity.

Despite these established methods, significant limitations persist in current impedance measurement techniques for lithium phosphate systems. Time-dependency presents a major challenge, as these electrochemical systems continuously evolve during measurement, potentially invalidating the assumption of steady-state conditions required for accurate EIS interpretation. The measurement process itself can sometimes alter the very properties being measured, particularly in sensitive lithium phosphate compositions.

Frequency range limitations also constrain comprehensive analysis, as conventional instruments typically operate between 10 mHz and 1 MHz. This range may prove insufficient for capturing ultrafast charge transfer processes or very slow diffusion phenomena in lithium phosphate materials. Additionally, the non-linear behavior of these systems at higher signal amplitudes violates the linearity assumption underlying EIS theory, necessitating extremely small perturbation signals that may compromise signal-to-noise ratios.

Temperature and pressure sensitivity further complicate measurements, as lithium phosphate systems exhibit significant property variations with environmental conditions. Most commercial instruments lack integrated environmental control capabilities, requiring complex custom setups for accurate characterization under realistic operating conditions.

Interpretation challenges represent perhaps the most significant limitation, as the complex equivalent circuit models required to fit lithium phosphate impedance data often suffer from non-uniqueness issues, where multiple circuit configurations can produce equally good fits to experimental data, leading to ambiguous physical interpretations.

Traditional potentiostatic EIS represents the most widely adopted approach, where a fixed DC potential is maintained while superimposing a small AC perturbation. This technique allows for detailed characterization of electrode-electrolyte interfaces, charge transfer kinetics, and diffusion processes in lithium phosphate systems. Galvanostatic EIS, an alternative method, maintains a constant current while applying small current oscillations, proving particularly useful for systems under operational conditions.

Four-point probe techniques have gained prominence for their ability to eliminate contact resistance issues, critical when measuring the typically low impedances of lithium phosphate electrodes. This configuration uses separate current-carrying and voltage-sensing electrodes to provide more accurate measurements, especially for materials with high conductivity.

Despite these established methods, significant limitations persist in current impedance measurement techniques for lithium phosphate systems. Time-dependency presents a major challenge, as these electrochemical systems continuously evolve during measurement, potentially invalidating the assumption of steady-state conditions required for accurate EIS interpretation. The measurement process itself can sometimes alter the very properties being measured, particularly in sensitive lithium phosphate compositions.

Frequency range limitations also constrain comprehensive analysis, as conventional instruments typically operate between 10 mHz and 1 MHz. This range may prove insufficient for capturing ultrafast charge transfer processes or very slow diffusion phenomena in lithium phosphate materials. Additionally, the non-linear behavior of these systems at higher signal amplitudes violates the linearity assumption underlying EIS theory, necessitating extremely small perturbation signals that may compromise signal-to-noise ratios.

Temperature and pressure sensitivity further complicate measurements, as lithium phosphate systems exhibit significant property variations with environmental conditions. Most commercial instruments lack integrated environmental control capabilities, requiring complex custom setups for accurate characterization under realistic operating conditions.

Interpretation challenges represent perhaps the most significant limitation, as the complex equivalent circuit models required to fit lithium phosphate impedance data often suffer from non-uniqueness issues, where multiple circuit configurations can produce equally good fits to experimental data, leading to ambiguous physical interpretations.

Current Impedance Measurement Solutions for LFP Batteries

01 Impedance measurement techniques for lithium phosphate batteries

Various impedance measurement techniques are employed to evaluate the electrochemical performance of lithium phosphate batteries. These techniques include electrochemical impedance spectroscopy (EIS), which helps in understanding the internal resistance, charge transfer processes, and diffusion characteristics of lithium ions within the battery. Advanced measurement setups can detect changes in impedance that correlate with battery health, aging, and performance degradation under different operating conditions.- Impedance measurement techniques for lithium phosphate batteries: Various impedance measurement techniques are employed to evaluate the electrochemical performance of lithium phosphate batteries. These techniques include electrochemical impedance spectroscopy (EIS), which helps in understanding the internal resistance, charge transfer processes, and diffusion limitations within the battery cells. Advanced measurement setups allow for real-time monitoring of impedance changes during cycling, providing insights into degradation mechanisms and state-of-health estimation.

- Electrode material modifications to reduce impedance: Modifications to lithium phosphate electrode materials can significantly reduce impedance in electrochemical setups. These modifications include particle size optimization, surface coating with conductive materials, doping with various elements, and creating composite structures. Such modifications enhance electron transport, improve ionic conductivity, and reduce interfacial resistance, resulting in better rate capability and cycling performance of lithium phosphate-based batteries.

- Electrolyte formulations for impedance reduction: Specialized electrolyte formulations play a crucial role in reducing impedance in lithium phosphate electrochemical systems. These formulations may include additives that form stable solid electrolyte interphase (SEI) layers, solvents with high ionic conductivity, and lithium salts that enhance charge transfer. Advanced electrolyte systems can minimize concentration polarization, improve lithium-ion transport, and maintain low impedance over extended cycling periods.

- Temperature effects on impedance in lithium phosphate systems: Temperature significantly influences impedance characteristics in lithium phosphate electrochemical setups. At low temperatures, impedance typically increases due to reduced ionic conductivity and slower reaction kinetics. High temperatures may initially decrease impedance but can accelerate degradation mechanisms. Understanding these temperature-dependent impedance behaviors is crucial for designing thermal management systems and optimizing battery performance across various operating conditions.

- Impedance-based diagnostic methods for lithium phosphate batteries: Impedance measurements serve as powerful diagnostic tools for lithium phosphate battery systems. These methods enable the detection of various failure modes, estimation of state-of-charge and state-of-health, and prediction of remaining useful life. Advanced algorithms can analyze impedance spectra to identify specific degradation mechanisms such as lithium plating, SEI growth, or active material loss. These diagnostic approaches support battery management systems in optimizing performance and ensuring safe operation.

02 Electrode material modifications to reduce impedance

Modifications to lithium phosphate electrode materials can significantly reduce impedance in electrochemical setups. These modifications include doping with conductive elements, surface coating with carbon or metal oxides, particle size optimization, and structural engineering of the active material. Such modifications enhance electron transport, improve lithium-ion diffusion kinetics, and reduce interfacial resistance, resulting in better rate capability and cycling performance of lithium phosphate-based batteries.Expand Specific Solutions03 Electrolyte formulations for impedance reduction

Specialized electrolyte formulations play a crucial role in reducing the impedance of lithium phosphate electrochemical systems. These formulations may include additives that form stable solid electrolyte interphase (SEI) layers, ionic liquid components that enhance conductivity, or compounds that suppress unwanted side reactions. Optimized electrolyte compositions can minimize interfacial resistance, improve ion transport, and enhance the overall electrochemical performance of lithium phosphate batteries.Expand Specific Solutions04 Temperature effects on impedance in lithium phosphate systems

Temperature significantly influences the impedance characteristics of lithium phosphate electrochemical setups. At low temperatures, impedance typically increases due to reduced ion mobility and slower reaction kinetics, while elevated temperatures can decrease impedance but may accelerate degradation mechanisms. Understanding these temperature-dependent impedance behaviors is crucial for designing thermal management systems and optimizing battery performance across various operating conditions, particularly in extreme environments.Expand Specific Solutions05 Impedance-based diagnostic methods for lithium phosphate batteries

Impedance-based diagnostic methods provide valuable insights into the state of health, state of charge, and failure mechanisms of lithium phosphate batteries. These methods involve analyzing impedance spectra to identify specific degradation modes, predict remaining useful life, and detect internal faults such as lithium plating or electrolyte decomposition. Advanced algorithms and machine learning techniques can be applied to impedance data for real-time monitoring and predictive maintenance of lithium phosphate battery systems.Expand Specific Solutions

Key Industry Players in Battery Testing Equipment

The impedance measurement in lithium phosphate electrochemical setups market is in a growth phase, driven by increasing demand for advanced battery technologies. The global market is expanding rapidly with the electric vehicle sector's growth, particularly led by automotive manufacturers like BMW and Nissan. Technical maturity varies across players, with specialized instrument manufacturers such as Hioki E.E. Corp., Yokogawa Electric, and Murata Manufacturing demonstrating advanced capabilities. Energy companies including Bloom Energy and TAE Technologies are investing in this technology, while academic institutions like EPFL and Xi'an Jiaotong University contribute significant research. Battery manufacturers Pylon Technologies and VITZROCELL are integrating impedance measurement into their production processes, creating a competitive landscape spanning instrumentation, energy, automotive, and research sectors.

Hioki E.E. Corp.

Technical Solution: Hioki has developed advanced electrochemical impedance spectroscopy (EIS) systems specifically optimized for lithium phosphate battery analysis. Their BT4560 Battery Impedance Meter employs a unique low-frequency measurement technique that enables precise impedance measurements in the 0.1Hz to 1050Hz range, critical for capturing the electrochemical reactions in LFP cells. The system utilizes a four-terminal measurement method that effectively eliminates contact resistance issues common in battery testing. Hioki's proprietary signal processing algorithms allow for real-time separation of resistance and reactance components, providing comprehensive Cole-Cole plots and Nyquist diagrams for detailed battery characterization. Their latest systems incorporate temperature compensation mechanisms that automatically adjust measurements based on ambient conditions, ensuring consistency across testing environments[1][3]. The technology enables non-destructive evaluation of battery state-of-health through correlation between impedance signatures and remaining capacity.

Strengths: Industry-leading measurement accuracy (±0.5% rdg) at low frequencies; specialized algorithms for noise reduction in industrial environments; comprehensive data analysis software suite. Weaknesses: Higher cost compared to general-purpose impedance analyzers; requires specialized training for optimal utilization; limited to specific frequency ranges optimized for batteries.

Pylon Technologies Co., Ltd.

Technical Solution: Pylon Technologies has developed a proprietary impedance tracking system specifically optimized for lithium iron phosphate (LFP) battery management. Their technology employs a hybrid measurement approach combining traditional electrochemical impedance spectroscopy with novel pulse-response analysis techniques. The system features embedded impedance monitoring circuits that can be integrated directly into battery management systems, enabling continuous real-time assessment of cell health without dedicated laboratory equipment. Pylon's approach utilizes strategic frequency selection algorithms that identify the most diagnostic impedance markers for LFP chemistry, focusing measurement resources on frequencies between 0.1Hz and 100Hz where LFP cells show the most significant state-of-health indicators. Their technology incorporates machine learning models trained on extensive lifecycle datasets to correlate impedance signatures with specific degradation mechanisms, including lithium plating, SEI growth, and phosphate dissolution[5]. The system achieves measurement precision within 2% even during active charge/discharge operations, allowing for impedance tracking during actual usage conditions rather than requiring offline testing.

Strengths: Direct integration capability with battery management systems; optimized specifically for LFP chemistry characteristics; enables continuous monitoring during normal battery operation. Weaknesses: Lower absolute accuracy compared to laboratory-grade equipment; limited frequency range compared to dedicated impedance analyzers; requires substantial historical data for accurate degradation modeling.

Critical Technologies in Electrochemical Impedance Analysis

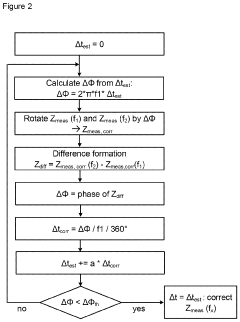

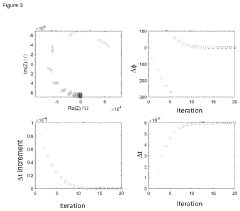

Impedance determination with phase determination

PatentActiveUS12000903B2

Innovation

- A phase calibration method that applies excitation signals at multiple frequencies to determine synchronization errors and correct impedance measurements, allowing for high phase accuracy in impedance determination and temperature measurement, even with synchronization errors, by using an LR model to synchronize signals and correct phase shifts.

Impedance standard

PatentWO2020201007A1

Innovation

- Designing the impedance standard to match the connection arrangement of the cell being measured, allowing it to be connected in the same configuration as the cell, thereby reducing cabling dependency and enabling accurate calibration of the test bench, including cable routing and cell holder, to evaluate impedance data across a broader frequency range.

Safety Standards and Testing Protocols for LFP Batteries

Safety standards and testing protocols for LFP (Lithium Iron Phosphate) batteries are critical components in ensuring the reliable and safe operation of electrochemical impedance measurement systems. These standards have evolved significantly over the past decade, with international organizations such as IEC, UL, and ISO establishing comprehensive frameworks specifically addressing lithium phosphate battery technologies.

The primary safety standards applicable to LFP battery impedance measurement include IEC 62660 for performance and endurance testing, UL 1642 for lithium battery safety, and ISO 12405 for electric vehicle battery testing. These standards outline specific protocols for impedance spectroscopy measurements, including frequency ranges, amplitude settings, and environmental conditions that ensure both accurate results and operational safety.

Temperature control represents a fundamental safety consideration during impedance measurements of LFP cells. Testing protocols typically mandate measurements within specific temperature ranges (usually 15-35°C) with maximum deviation tolerances of ±2°C. This precision is essential as impedance characteristics of lithium phosphate systems demonstrate significant temperature dependence, potentially leading to measurement errors or safety hazards if not properly controlled.

Electrical safety protocols for impedance measurement equipment require proper isolation between measurement circuits and operators. Standards specify maximum allowable leakage currents (typically <10μA) and minimum isolation resistances (>100MΩ) between measurement circuits and accessible parts. Additionally, measurement equipment must incorporate overcurrent protection mechanisms that activate within milliseconds of detecting abnormal current flows during impedance testing.

Data validation protocols constitute another critical aspect of LFP battery impedance measurement. Standards require implementation of statistical validation methods to identify outliers and ensure measurement repeatability. Typical protocols mandate at least three consecutive measurements with maximum variance thresholds of 5% for results to be considered valid, enhancing both safety and reliability of the impedance data.

Recent updates to testing protocols have incorporated specific considerations for aging effects on impedance measurements. Standards now recommend baseline impedance characterization followed by periodic measurements throughout the battery lifecycle, with specific attention to impedance changes that might indicate safety-critical degradation patterns. These protocols typically define threshold values for impedance increases (often 150-200% of initial values) that trigger further safety investigations.

Emergency response procedures during impedance testing have also been standardized, requiring immediate test termination if cell temperature exceeds defined thresholds (typically 10°C above starting temperature) or if voltage fluctuations beyond ±5% of nominal values are detected during measurement.

The primary safety standards applicable to LFP battery impedance measurement include IEC 62660 for performance and endurance testing, UL 1642 for lithium battery safety, and ISO 12405 for electric vehicle battery testing. These standards outline specific protocols for impedance spectroscopy measurements, including frequency ranges, amplitude settings, and environmental conditions that ensure both accurate results and operational safety.

Temperature control represents a fundamental safety consideration during impedance measurements of LFP cells. Testing protocols typically mandate measurements within specific temperature ranges (usually 15-35°C) with maximum deviation tolerances of ±2°C. This precision is essential as impedance characteristics of lithium phosphate systems demonstrate significant temperature dependence, potentially leading to measurement errors or safety hazards if not properly controlled.

Electrical safety protocols for impedance measurement equipment require proper isolation between measurement circuits and operators. Standards specify maximum allowable leakage currents (typically <10μA) and minimum isolation resistances (>100MΩ) between measurement circuits and accessible parts. Additionally, measurement equipment must incorporate overcurrent protection mechanisms that activate within milliseconds of detecting abnormal current flows during impedance testing.

Data validation protocols constitute another critical aspect of LFP battery impedance measurement. Standards require implementation of statistical validation methods to identify outliers and ensure measurement repeatability. Typical protocols mandate at least three consecutive measurements with maximum variance thresholds of 5% for results to be considered valid, enhancing both safety and reliability of the impedance data.

Recent updates to testing protocols have incorporated specific considerations for aging effects on impedance measurements. Standards now recommend baseline impedance characterization followed by periodic measurements throughout the battery lifecycle, with specific attention to impedance changes that might indicate safety-critical degradation patterns. These protocols typically define threshold values for impedance increases (often 150-200% of initial values) that trigger further safety investigations.

Emergency response procedures during impedance testing have also been standardized, requiring immediate test termination if cell temperature exceeds defined thresholds (typically 10°C above starting temperature) or if voltage fluctuations beyond ±5% of nominal values are detected during measurement.

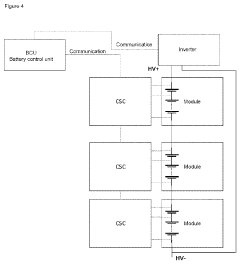

Battery Management System Integration Considerations

Integrating impedance measurement capabilities into Battery Management Systems (BMS) for lithium phosphate electrochemical setups presents both significant opportunities and challenges. Modern BMS architectures must be adapted to accommodate the additional hardware and processing requirements for electrochemical impedance spectroscopy (EIS) functionality. This integration requires careful consideration of sampling rates, signal processing capabilities, and data storage requirements to ensure accurate impedance measurements without compromising core BMS functions.

The hardware integration pathway typically involves incorporating specialized analog front-end circuits capable of applying small AC perturbation signals while simultaneously measuring the resulting voltage and current responses. These circuits must maintain high precision across a wide frequency range (typically 10 mHz to 10 kHz) while operating in electrically noisy environments. Dedicated signal processing units may be necessary to handle the computational demands of impedance analysis algorithms, particularly when implementing real-time monitoring capabilities.

Communication protocols between impedance measurement modules and the main BMS controller require optimization to handle the increased data throughput. Standard protocols such as CAN, SPI, or I²C may need enhancement or replacement with higher bandwidth alternatives when implementing full-spectrum impedance analysis. Alternatively, strategic data reduction techniques can be employed to extract only the most relevant impedance parameters for battery health monitoring.

Power consumption represents another critical consideration, particularly for mobile or energy-constrained applications. Impedance measurement functionality can significantly increase system power draw, necessitating careful power management strategies. Implementing selective measurement scheduling based on battery state or system conditions can help balance diagnostic depth with energy efficiency requirements.

Calibration and accuracy verification mechanisms must be incorporated into the integrated system design. Environmental factors such as temperature fluctuations can significantly impact impedance measurements, requiring compensation algorithms and reference standards. Self-diagnostic capabilities should be implemented to detect measurement anomalies and prevent erroneous health assessments based on faulty impedance data.

Software architecture considerations include the development of robust algorithms for impedance data interpretation within the context of battery health monitoring. These algorithms must be optimized for the computational constraints of embedded systems while maintaining sufficient accuracy for meaningful diagnostics. Machine learning approaches may be incorporated to improve diagnostic capabilities over time through pattern recognition in impedance signature changes.

The hardware integration pathway typically involves incorporating specialized analog front-end circuits capable of applying small AC perturbation signals while simultaneously measuring the resulting voltage and current responses. These circuits must maintain high precision across a wide frequency range (typically 10 mHz to 10 kHz) while operating in electrically noisy environments. Dedicated signal processing units may be necessary to handle the computational demands of impedance analysis algorithms, particularly when implementing real-time monitoring capabilities.

Communication protocols between impedance measurement modules and the main BMS controller require optimization to handle the increased data throughput. Standard protocols such as CAN, SPI, or I²C may need enhancement or replacement with higher bandwidth alternatives when implementing full-spectrum impedance analysis. Alternatively, strategic data reduction techniques can be employed to extract only the most relevant impedance parameters for battery health monitoring.

Power consumption represents another critical consideration, particularly for mobile or energy-constrained applications. Impedance measurement functionality can significantly increase system power draw, necessitating careful power management strategies. Implementing selective measurement scheduling based on battery state or system conditions can help balance diagnostic depth with energy efficiency requirements.

Calibration and accuracy verification mechanisms must be incorporated into the integrated system design. Environmental factors such as temperature fluctuations can significantly impact impedance measurements, requiring compensation algorithms and reference standards. Self-diagnostic capabilities should be implemented to detect measurement anomalies and prevent erroneous health assessments based on faulty impedance data.

Software architecture considerations include the development of robust algorithms for impedance data interpretation within the context of battery health monitoring. These algorithms must be optimized for the computational constraints of embedded systems while maintaining sufficient accuracy for meaningful diagnostics. Machine learning approaches may be incorporated to improve diagnostic capabilities over time through pattern recognition in impedance signature changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!