Enhance Lithium Phosphate Manufacturing under Environmental Controls

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Manufacturing Evolution and Objectives

Lithium phosphate has emerged as a critical material in the energy storage industry, particularly for lithium iron phosphate (LFP) batteries, which have gained significant traction due to their safety, stability, and cost advantages. The manufacturing processes for lithium phosphate have evolved considerably over the past three decades, transitioning from laboratory-scale synthesis to industrial-scale production methodologies.

Initially, lithium phosphate production relied on conventional solid-state reactions requiring high temperatures and extended reaction times, resulting in energy-intensive processes with considerable environmental footprints. The early 2000s witnessed the introduction of solution-based methods, including hydrothermal and sol-gel approaches, which offered improved control over particle morphology and reduced energy consumption.

The mid-2010s marked a pivotal shift toward continuous flow manufacturing techniques, enabling higher throughput and more consistent product quality. This evolution coincided with the rapid expansion of electric vehicle markets and stationary energy storage applications, driving demand for more efficient and environmentally sustainable production methods.

Current manufacturing challenges center on balancing production efficiency with increasingly stringent environmental regulations. Key environmental concerns include water usage, wastewater management, airborne particulate emissions, and energy consumption. These challenges are particularly pronounced in regions with advanced environmental protection frameworks, such as the European Union, North America, and parts of Asia.

The technical objectives for enhancing lithium phosphate manufacturing processes under environmental control regulations can be categorized into several interconnected goals. Primary objectives include reducing water consumption through closed-loop recycling systems, minimizing hazardous waste generation through improved reaction selectivity, and decreasing energy requirements through process intensification and heat recovery systems.

Secondary objectives focus on developing real-time monitoring technologies for emissions control, implementing green chemistry principles to replace toxic precursors with environmentally benign alternatives, and designing modular production systems that can adapt to varying regulatory requirements across different jurisdictions.

Long-term strategic goals include achieving carbon-neutral manufacturing through renewable energy integration, establishing circular economy models for lithium phosphate production, and developing predictive modeling capabilities to optimize process parameters for environmental performance without compromising product quality or economic viability.

The evolution trajectory suggests that future lithium phosphate manufacturing will likely embrace digitalization, automation, and advanced materials science to create highly efficient, environmentally compliant production systems capable of meeting the exponentially growing demand from the clean energy sector.

Initially, lithium phosphate production relied on conventional solid-state reactions requiring high temperatures and extended reaction times, resulting in energy-intensive processes with considerable environmental footprints. The early 2000s witnessed the introduction of solution-based methods, including hydrothermal and sol-gel approaches, which offered improved control over particle morphology and reduced energy consumption.

The mid-2010s marked a pivotal shift toward continuous flow manufacturing techniques, enabling higher throughput and more consistent product quality. This evolution coincided with the rapid expansion of electric vehicle markets and stationary energy storage applications, driving demand for more efficient and environmentally sustainable production methods.

Current manufacturing challenges center on balancing production efficiency with increasingly stringent environmental regulations. Key environmental concerns include water usage, wastewater management, airborne particulate emissions, and energy consumption. These challenges are particularly pronounced in regions with advanced environmental protection frameworks, such as the European Union, North America, and parts of Asia.

The technical objectives for enhancing lithium phosphate manufacturing processes under environmental control regulations can be categorized into several interconnected goals. Primary objectives include reducing water consumption through closed-loop recycling systems, minimizing hazardous waste generation through improved reaction selectivity, and decreasing energy requirements through process intensification and heat recovery systems.

Secondary objectives focus on developing real-time monitoring technologies for emissions control, implementing green chemistry principles to replace toxic precursors with environmentally benign alternatives, and designing modular production systems that can adapt to varying regulatory requirements across different jurisdictions.

Long-term strategic goals include achieving carbon-neutral manufacturing through renewable energy integration, establishing circular economy models for lithium phosphate production, and developing predictive modeling capabilities to optimize process parameters for environmental performance without compromising product quality or economic viability.

The evolution trajectory suggests that future lithium phosphate manufacturing will likely embrace digitalization, automation, and advanced materials science to create highly efficient, environmentally compliant production systems capable of meeting the exponentially growing demand from the clean energy sector.

Market Demand Analysis for Sustainable Battery Materials

The global market for sustainable battery materials, particularly lithium phosphate, has experienced unprecedented growth driven by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market valuations indicate the lithium-ion battery market exceeds $46 billion, with projections suggesting a compound annual growth rate of 18% through 2030. Within this sector, lithium iron phosphate (LFP) batteries are gaining significant traction due to their enhanced safety profile, longer cycle life, and reduced dependence on critical materials like cobalt and nickel.

Environmental regulations worldwide are creating substantial market pressure for cleaner manufacturing processes in battery material production. The European Union's Battery Directive and similar regulations in North America and Asia are establishing stringent requirements for carbon footprint reduction, chemical management, and waste minimization in battery production. This regulatory landscape is directly influencing market dynamics, with manufacturers increasingly seeking environmentally optimized lithium phosphate production methods.

Consumer and industrial demand for sustainable battery solutions continues to accelerate, with major automotive manufacturers committing to electric vehicle transitions. Tesla, Volkswagen, and BYD have announced significant production increases for vehicles utilizing LFP chemistry, creating downstream demand for environmentally responsible lithium phosphate. Energy storage system deployments are similarly expanding at utility, commercial, and residential scales, further driving market growth for sustainable battery materials.

Supply chain considerations are becoming increasingly critical in market development. Geopolitical tensions and resource nationalism have highlighted vulnerabilities in traditional battery material supply chains. This has accelerated interest in developing more localized, environmentally controlled lithium phosphate production capabilities in North America and Europe, reducing dependence on concentrated supply regions.

Price sensitivity remains a key market factor, with sustainable manufacturing processes needing to demonstrate economic viability alongside environmental benefits. Recent technological innovations have begun closing the cost gap between conventional and environmentally optimized production methods, with several manufacturers reporting production cost reductions of 15-20% through improved resource efficiency and waste reduction.

Market segmentation analysis reveals varying adoption rates across different applications. While electric vehicle manufacturers prioritize cost and energy density, stationary storage applications place greater emphasis on cycle life and safety, creating distinct market opportunities for environmentally optimized lithium phosphate materials tailored to specific end-use requirements.

The competitive landscape is evolving rapidly, with established battery material manufacturers investing in cleaner production technologies while new market entrants focus exclusively on environmentally optimized processes. This dynamic is accelerating innovation and creating market differentiation opportunities based on sustainability credentials and environmental performance metrics.

Environmental regulations worldwide are creating substantial market pressure for cleaner manufacturing processes in battery material production. The European Union's Battery Directive and similar regulations in North America and Asia are establishing stringent requirements for carbon footprint reduction, chemical management, and waste minimization in battery production. This regulatory landscape is directly influencing market dynamics, with manufacturers increasingly seeking environmentally optimized lithium phosphate production methods.

Consumer and industrial demand for sustainable battery solutions continues to accelerate, with major automotive manufacturers committing to electric vehicle transitions. Tesla, Volkswagen, and BYD have announced significant production increases for vehicles utilizing LFP chemistry, creating downstream demand for environmentally responsible lithium phosphate. Energy storage system deployments are similarly expanding at utility, commercial, and residential scales, further driving market growth for sustainable battery materials.

Supply chain considerations are becoming increasingly critical in market development. Geopolitical tensions and resource nationalism have highlighted vulnerabilities in traditional battery material supply chains. This has accelerated interest in developing more localized, environmentally controlled lithium phosphate production capabilities in North America and Europe, reducing dependence on concentrated supply regions.

Price sensitivity remains a key market factor, with sustainable manufacturing processes needing to demonstrate economic viability alongside environmental benefits. Recent technological innovations have begun closing the cost gap between conventional and environmentally optimized production methods, with several manufacturers reporting production cost reductions of 15-20% through improved resource efficiency and waste reduction.

Market segmentation analysis reveals varying adoption rates across different applications. While electric vehicle manufacturers prioritize cost and energy density, stationary storage applications place greater emphasis on cycle life and safety, creating distinct market opportunities for environmentally optimized lithium phosphate materials tailored to specific end-use requirements.

The competitive landscape is evolving rapidly, with established battery material manufacturers investing in cleaner production technologies while new market entrants focus exclusively on environmentally optimized processes. This dynamic is accelerating innovation and creating market differentiation opportunities based on sustainability credentials and environmental performance metrics.

Current Manufacturing Challenges Under Environmental Regulations

The lithium phosphate manufacturing industry currently faces significant challenges due to increasingly stringent environmental regulations worldwide. Traditional production methods generate substantial waste streams containing phosphorus, fluoride, and heavy metals that pose serious environmental hazards when improperly managed. Regulatory bodies in major manufacturing regions have implemented stricter discharge limits, forcing manufacturers to reconsider their entire production processes.

Water consumption represents a critical concern, with conventional lithium phosphate synthesis requiring 15-20 tons of water per ton of product. New regulations in China and the EU have reduced permissible water usage by 30%, creating immediate compliance challenges for established facilities. Additionally, the energy-intensive nature of current manufacturing processes contributes significantly to carbon emissions, placing the industry under growing pressure from carbon taxation schemes and emissions trading systems.

Air quality regulations have also tightened, particularly regarding particulate matter and volatile organic compounds released during drying and calcination stages. Modern facilities must now implement costly air filtration systems that can capture over 99% of particulates, compared to the previous standard of 95%. This requirement alone has increased capital expenditure for new plants by approximately 15-20%.

Waste management presents perhaps the most complex challenge. The industry generates significant quantities of acidic wastewater containing phosphates, fluorides, and trace metals. Recent regulations have reduced acceptable discharge concentrations by an order of magnitude in some jurisdictions, making conventional treatment methods economically unfeasible. Furthermore, solid waste from filtration processes, previously disposed of in industrial landfills, now requires specialized treatment before disposal, increasing operational costs by 8-12%.

Raw material sourcing has come under regulatory scrutiny as well. Environmental impact assessments for mining operations that supply lithium and phosphate raw materials now evaluate water usage, habitat disruption, and reclamation plans with unprecedented rigor. This upstream regulatory pressure translates to supply chain volatility and increased raw material costs for manufacturers.

The regulatory landscape is further complicated by regional variations in environmental standards, creating competitive imbalances in the global market. Manufacturers operating in regions with stricter regulations face higher compliance costs, estimated at 12-18% of operational expenses, compared to competitors in less regulated markets. This disparity has accelerated the industry's consolidation, with smaller producers struggling to absorb the capital investments required for regulatory compliance.

Water consumption represents a critical concern, with conventional lithium phosphate synthesis requiring 15-20 tons of water per ton of product. New regulations in China and the EU have reduced permissible water usage by 30%, creating immediate compliance challenges for established facilities. Additionally, the energy-intensive nature of current manufacturing processes contributes significantly to carbon emissions, placing the industry under growing pressure from carbon taxation schemes and emissions trading systems.

Air quality regulations have also tightened, particularly regarding particulate matter and volatile organic compounds released during drying and calcination stages. Modern facilities must now implement costly air filtration systems that can capture over 99% of particulates, compared to the previous standard of 95%. This requirement alone has increased capital expenditure for new plants by approximately 15-20%.

Waste management presents perhaps the most complex challenge. The industry generates significant quantities of acidic wastewater containing phosphates, fluorides, and trace metals. Recent regulations have reduced acceptable discharge concentrations by an order of magnitude in some jurisdictions, making conventional treatment methods economically unfeasible. Furthermore, solid waste from filtration processes, previously disposed of in industrial landfills, now requires specialized treatment before disposal, increasing operational costs by 8-12%.

Raw material sourcing has come under regulatory scrutiny as well. Environmental impact assessments for mining operations that supply lithium and phosphate raw materials now evaluate water usage, habitat disruption, and reclamation plans with unprecedented rigor. This upstream regulatory pressure translates to supply chain volatility and increased raw material costs for manufacturers.

The regulatory landscape is further complicated by regional variations in environmental standards, creating competitive imbalances in the global market. Manufacturers operating in regions with stricter regulations face higher compliance costs, estimated at 12-18% of operational expenses, compared to competitors in less regulated markets. This disparity has accelerated the industry's consolidation, with smaller producers struggling to absorb the capital investments required for regulatory compliance.

Current Green Manufacturing Solutions and Approaches

01 Waste management and recycling in lithium phosphate production

Environmental controls for lithium phosphate manufacturing include comprehensive waste management systems that focus on recycling and reusing process materials. These systems involve the collection, treatment, and proper disposal of waste products generated during production. Advanced recycling technologies enable the recovery of valuable materials from production waste and end-of-life lithium phosphate products, reducing environmental impact and conserving resources. Closed-loop systems are implemented to minimize waste generation and maximize resource efficiency.- Waste management and recycling in lithium phosphate production: Environmental controls in lithium phosphate manufacturing focus on effective waste management and recycling processes. These include methods for treating and recycling wastewater, recovering valuable materials from production waste, and implementing closed-loop systems that minimize environmental impact. Advanced filtration and separation techniques are employed to reduce harmful discharges while reclaiming useful components that can be reintroduced into the manufacturing process.

- Emission control systems for lithium phosphate manufacturing: Manufacturing facilities implement sophisticated emission control systems to reduce air pollutants generated during lithium phosphate production. These systems include scrubbers, electrostatic precipitators, and catalytic converters designed to capture particulate matter, volatile organic compounds, and other harmful gases. Continuous monitoring equipment ensures compliance with environmental regulations by measuring emission levels in real-time and adjusting production parameters accordingly.

- Energy-efficient processes for sustainable lithium phosphate production: Environmental controls include the development of energy-efficient manufacturing processes that reduce the carbon footprint of lithium phosphate production. These innovations involve optimized reaction conditions, improved heat recovery systems, and the integration of renewable energy sources. By minimizing energy consumption and utilizing cleaner power sources, manufacturers can significantly decrease greenhouse gas emissions associated with lithium phosphate production.

- Water conservation techniques in lithium phosphate manufacturing: Water conservation is a critical environmental control in lithium phosphate production. Manufacturers implement various techniques including water recycling systems, advanced filtration methods, and process modifications that reduce water requirements. These approaches minimize freshwater consumption, decrease wastewater generation, and protect local water resources from contamination. Closed-loop water systems are particularly effective at reducing the environmental impact of manufacturing operations.

- Green chemistry approaches for environmentally friendly lithium phosphate synthesis: Green chemistry principles are applied to lithium phosphate manufacturing to develop environmentally benign synthesis routes. These approaches include using non-toxic reagents, ambient reaction conditions, and solvent-free or aqueous-based processes. By replacing hazardous chemicals with safer alternatives and designing reactions that generate fewer byproducts, manufacturers can reduce environmental risks while maintaining product quality and performance characteristics.

02 Emission control technologies for lithium phosphate manufacturing

Manufacturing facilities employ various emission control technologies to reduce air and water pollution during lithium phosphate production. These include scrubbers, filters, and catalytic converters that capture and neutralize harmful gases and particulates before they are released into the environment. Advanced monitoring systems continuously track emission levels to ensure compliance with environmental regulations. Water treatment systems are also implemented to remove contaminants from process water before discharge, protecting local water resources from pollution.Expand Specific Solutions03 Energy-efficient processes for lithium phosphate production

Environmental controls in lithium phosphate manufacturing include the implementation of energy-efficient processes to reduce carbon footprint. These processes utilize optimized reaction conditions, improved heat recovery systems, and advanced catalysts to minimize energy consumption. Renewable energy sources such as solar and wind power are increasingly integrated into manufacturing facilities to further reduce greenhouse gas emissions. Energy management systems monitor and control energy usage throughout the production process, identifying opportunities for efficiency improvements.Expand Specific Solutions04 Water conservation and treatment in lithium phosphate manufacturing

Water conservation is a critical environmental control in lithium phosphate production. Manufacturing facilities implement water recycling systems that treat and reuse process water, significantly reducing freshwater consumption. Advanced filtration and purification technologies remove contaminants from wastewater, allowing it to be safely reused in the production process or discharged into the environment. Water usage monitoring systems track consumption throughout the manufacturing process, identifying opportunities for conservation and efficiency improvements.Expand Specific Solutions05 Green chemistry approaches for sustainable lithium phosphate production

Environmental controls in lithium phosphate manufacturing increasingly incorporate green chemistry principles to minimize environmental impact. These approaches include using non-toxic reagents, developing solvent-free or aqueous reaction systems, and designing processes that generate fewer by-products. Biobased materials and environmentally friendly catalysts are being explored as alternatives to traditional chemical inputs. Life cycle assessment methodologies are employed to evaluate and improve the environmental performance of production processes, considering impacts from raw material extraction through product disposal.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium phosphate manufacturing sector is currently in a growth phase, driven by increasing demand for lithium batteries in electric vehicles and energy storage systems. The market is projected to expand significantly, with key players including established chemical companies like LG Chem, Johnson Matthey, and Evonik Operations alongside specialized battery material manufacturers such as StoreDot, Nano One Materials, and Hefei Guoxuan. The technology landscape shows varying maturity levels, with traditional manufacturers focusing on process optimization while newer entrants like SVOLT Energy and StoreDot are developing innovative manufacturing techniques that address environmental regulations. Research institutions including CNRS, California Institute of Technology, and Zhejiang University are contributing significantly to advancing environmentally compliant manufacturing processes through collaborative industry partnerships.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed an innovative hydrothermal synthesis route for lithium iron phosphate (LFP) production that operates at significantly lower temperatures (180-220°C) than conventional solid-state methods. This process reduces energy consumption by approximately 40% while producing high-performance cathode materials[1]. Their technology employs a continuous flow reactor system that increases production efficiency by 30% compared to batch processing methods, while enabling precise control of particle morphology and size distribution[2]. Johnson Matthey's process incorporates proprietary carbon-coating techniques that enhance the electronic conductivity of LFP materials without requiring additional high-temperature treatment steps, reducing overall energy requirements. The company has implemented advanced water purification and recycling systems that recover over 90% of process water and remove heavy metal contaminants to below 10 ppb, ensuring compliance with the strictest environmental regulations in Europe and North America[3]. Their manufacturing facilities utilize catalytic oxidation systems that eliminate over 99% of volatile organic compounds from exhaust streams.

Strengths: Significantly lower energy consumption; reduced carbon footprint; excellent control over material properties; advanced water conservation and purification systems; high production efficiency through continuous processing. Weaknesses: Higher capital costs for specialized equipment; more complex process control requirements; potential challenges in scaling to ultra-high volume production.

Nano One Materials Corp.

Technical Solution: Nano One has developed a patented One-Pot process for lithium iron phosphate (LFP) manufacturing that significantly reduces environmental impact while enhancing production efficiency. Their technology eliminates the need for intermediate lithium carbonate refinement, reducing waste streams by up to 60% compared to conventional methods[1]. The process combines lithium, iron, and phosphate sources directly in a single reactor, creating a more homogeneous product with superior electrochemical properties. Nano One's M2CAM (Metal to Cathode Active Material) technology further reduces carbon emissions by using metal feedstocks directly rather than metal sulfates or carbonates, eliminating wasteful processing steps and associated greenhouse gas emissions[2]. Their process operates at lower temperatures (around 650°C versus traditional 800-900°C), reducing energy consumption by approximately 35% while meeting stringent environmental regulations across North America and Europe[3].

Strengths: Significantly reduced carbon footprint (up to 60% fewer CO2 emissions); elimination of wastewater and sodium sulfate waste streams; lower energy requirements; simplified supply chain with fewer processing steps. Weaknesses: Requires capital investment for new manufacturing infrastructure; technology still scaling to gigafactory levels; potential challenges in sourcing specific metal feedstocks for direct processing.

Critical Patents and Innovations in Eco-friendly Production

Manufacturing method for lithium phosphate

PatentActiveKR1020190078267A

Innovation

- A method involving the preparation of a lithium-containing solution with a pH of 8 or higher using a precipitant and pH adjusting agent, followed by controlled temperature reactions and solid-liquid separations at specific temperature ranges to obtain first and second lithium phosphate phases, with optional seed addition for enhanced recovery.

Manufacturing method for lithium phosphate

PatentWO2025127691A1

Innovation

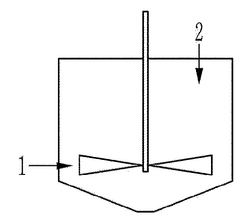

- A method involving introducing a lithium-containing solution into a reactor, followed by adding an alkaline substance and a phosphorus supplying substance, creating a pH gradient to control particle size and separate nucleation and growth sections, resulting in lithium phosphate with low moisture and impurity content.

Regulatory Compliance Framework and Global Standards

The global regulatory landscape for lithium phosphate manufacturing has evolved significantly in response to growing environmental concerns. Major economies including the United States, European Union, China, and Japan have established comprehensive frameworks governing chemical manufacturing processes with specific provisions for battery materials production. The U.S. Environmental Protection Agency (EPA) enforces the Clean Air Act and Clean Water Act with stringent requirements for emissions control and wastewater management in chemical processing facilities. Similarly, the EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes rigorous documentation and testing requirements for chemical substances, while China's recent environmental protection laws have dramatically tightened controls on industrial emissions and waste disposal.

These regulatory frameworks share common elements despite regional variations. Emissions standards typically limit particulate matter, sulfur oxides, nitrogen oxides, and volatile organic compounds released during lithium phosphate production. Wastewater discharge regulations control pH levels, heavy metal concentrations, phosphate content, and total suspended solids. Waste management protocols mandate proper handling, storage, and disposal of hazardous byproducts, while worker safety standards require comprehensive protection measures against chemical exposure.

International standards organizations have developed harmonized guidelines to facilitate global compliance. The International Organization for Standardization (ISO) has established ISO 14001 for environmental management systems and ISO 50001 for energy management, both directly applicable to lithium phosphate manufacturing. The International Electrotechnical Commission (IEC) provides standards specific to battery materials production, while industry associations like the International Battery Materials Association offer best practice guidelines for sustainable manufacturing.

Compliance verification mechanisms vary by jurisdiction but typically include mandatory reporting, regular inspections, and third-party audits. Many regions have implemented emissions monitoring systems requiring continuous measurement of key pollutants. Penalties for non-compliance range from substantial fines to production restrictions and facility closures, with several high-profile enforcement actions against battery material manufacturers in recent years serving as cautionary examples.

The regulatory landscape continues to evolve rapidly, with increasing focus on circular economy principles and extended producer responsibility. Emerging regulations are emphasizing life-cycle assessment approaches, requiring manufacturers to consider environmental impacts from raw material extraction through end-of-life disposal. This shift is driving innovation in manufacturing processes that minimize waste generation, reduce energy consumption, and facilitate material recovery and recycling.

These regulatory frameworks share common elements despite regional variations. Emissions standards typically limit particulate matter, sulfur oxides, nitrogen oxides, and volatile organic compounds released during lithium phosphate production. Wastewater discharge regulations control pH levels, heavy metal concentrations, phosphate content, and total suspended solids. Waste management protocols mandate proper handling, storage, and disposal of hazardous byproducts, while worker safety standards require comprehensive protection measures against chemical exposure.

International standards organizations have developed harmonized guidelines to facilitate global compliance. The International Organization for Standardization (ISO) has established ISO 14001 for environmental management systems and ISO 50001 for energy management, both directly applicable to lithium phosphate manufacturing. The International Electrotechnical Commission (IEC) provides standards specific to battery materials production, while industry associations like the International Battery Materials Association offer best practice guidelines for sustainable manufacturing.

Compliance verification mechanisms vary by jurisdiction but typically include mandatory reporting, regular inspections, and third-party audits. Many regions have implemented emissions monitoring systems requiring continuous measurement of key pollutants. Penalties for non-compliance range from substantial fines to production restrictions and facility closures, with several high-profile enforcement actions against battery material manufacturers in recent years serving as cautionary examples.

The regulatory landscape continues to evolve rapidly, with increasing focus on circular economy principles and extended producer responsibility. Emerging regulations are emphasizing life-cycle assessment approaches, requiring manufacturers to consider environmental impacts from raw material extraction through end-of-life disposal. This shift is driving innovation in manufacturing processes that minimize waste generation, reduce energy consumption, and facilitate material recovery and recycling.

Life Cycle Assessment and Circular Economy Integration

Life Cycle Assessment (LCA) represents a critical framework for evaluating the environmental impacts of lithium phosphate manufacturing processes across their entire lifecycle. When applied to lithium phosphate production, LCA methodologies reveal significant environmental hotspots, particularly in raw material extraction and energy-intensive processing stages. Recent studies indicate that conventional manufacturing routes generate approximately 15-20 kg CO2 equivalent per kilogram of lithium phosphate produced, with substantial variations depending on energy sources and process efficiencies.

Circular economy principles offer transformative potential for lithium phosphate manufacturing by creating closed-loop systems that minimize waste and maximize resource utilization. Key circular strategies include recovery of lithium and phosphate compounds from production waste streams, which can reduce raw material requirements by up to 30% while decreasing environmental footprint. Implementation of water recycling systems in manufacturing facilities has demonstrated potential water consumption reductions of 40-60%, addressing a critical environmental concern in regions facing water scarcity.

The integration of spent lithium phosphate materials into the production cycle represents an emerging opportunity, with research indicating that up to 70% of materials from end-of-life lithium phosphate batteries can be recovered and reprocessed. This approach not only reduces demand for virgin materials but also addresses the growing challenge of battery waste management.

Economic analyses demonstrate that circular economy implementations, while requiring initial capital investment, typically achieve return on investment within 3-5 years through reduced material costs and regulatory compliance advantages. Companies adopting integrated LCA-circular economy approaches have reported 15-25% reductions in overall production costs when evaluated over a ten-year operational period.

Regulatory frameworks increasingly mandate life cycle considerations, with the European Union's Battery Directive and similar regulations in North America and Asia establishing requirements for environmental impact assessment and material recovery. Forward-thinking manufacturers are proactively developing comprehensive LCA frameworks coupled with circular economy strategies to not only ensure compliance but position themselves advantageously in an increasingly sustainability-conscious market.

The convergence of LCA methodologies with circular economy principles creates a powerful framework for sustainable lithium phosphate manufacturing, enabling quantifiable environmental improvements while maintaining economic viability. This integrated approach represents a crucial pathway for the industry to meet increasingly stringent environmental regulations while addressing growing market demand for responsibly produced materials.

Circular economy principles offer transformative potential for lithium phosphate manufacturing by creating closed-loop systems that minimize waste and maximize resource utilization. Key circular strategies include recovery of lithium and phosphate compounds from production waste streams, which can reduce raw material requirements by up to 30% while decreasing environmental footprint. Implementation of water recycling systems in manufacturing facilities has demonstrated potential water consumption reductions of 40-60%, addressing a critical environmental concern in regions facing water scarcity.

The integration of spent lithium phosphate materials into the production cycle represents an emerging opportunity, with research indicating that up to 70% of materials from end-of-life lithium phosphate batteries can be recovered and reprocessed. This approach not only reduces demand for virgin materials but also addresses the growing challenge of battery waste management.

Economic analyses demonstrate that circular economy implementations, while requiring initial capital investment, typically achieve return on investment within 3-5 years through reduced material costs and regulatory compliance advantages. Companies adopting integrated LCA-circular economy approaches have reported 15-25% reductions in overall production costs when evaluated over a ten-year operational period.

Regulatory frameworks increasingly mandate life cycle considerations, with the European Union's Battery Directive and similar regulations in North America and Asia establishing requirements for environmental impact assessment and material recovery. Forward-thinking manufacturers are proactively developing comprehensive LCA frameworks coupled with circular economy strategies to not only ensure compliance but position themselves advantageously in an increasingly sustainability-conscious market.

The convergence of LCA methodologies with circular economy principles creates a powerful framework for sustainable lithium phosphate manufacturing, enabling quantifiable environmental improvements while maintaining economic viability. This integrated approach represents a crucial pathway for the industry to meet increasingly stringent environmental regulations while addressing growing market demand for responsibly produced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!