Benchmarking the Energy Density of Lithium Phosphate Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Evolution and Research Objectives

Lithium Iron Phosphate (LFP) battery technology has evolved significantly since its initial development in the late 1990s. First commercialized in the early 2000s, LFP batteries emerged as a safer alternative to traditional lithium-ion batteries using cobalt-based cathodes. The technology was pioneered by researchers at the University of Texas and further developed by various institutions globally, with significant contributions from Chinese research entities that have propelled China to become the dominant producer of LFP cells today.

The evolution of LFP batteries has been characterized by incremental improvements in energy density, which historically has been their primary limitation. Early LFP cells delivered energy densities of approximately 90-100 Wh/kg, significantly lower than competing lithium-ion chemistries. However, recent advancements have pushed these figures to 160-180 Wh/kg for commercial cells, with laboratory prototypes achieving even higher values.

Key milestones in LFP development include the introduction of nano-scale particle engineering around 2005-2010, which improved electron and ion transport properties; the development of carbon-coating techniques to enhance conductivity; and more recently, cell design innovations such as cell-to-pack technologies that optimize packaging efficiency and increase system-level energy density by up to 15-20%.

The current technological trajectory suggests continued improvements in energy density through materials engineering and manufacturing process refinements. Industry projections indicate potential for LFP cells to reach 200-220 Wh/kg in commercial applications within the next 3-5 years, narrowing the gap with nickel-based chemistries while maintaining their inherent safety and cost advantages.

Our research objectives for benchmarking LFP energy density are multifaceted. First, we aim to establish a comprehensive baseline of current commercial LFP cell performance across different manufacturers and form factors. This will include standardized testing protocols to ensure comparable results across diverse cell designs and manufacturing processes.

Second, we intend to identify the key technological factors that differentiate high-performing LFP cells from average performers, with particular focus on cathode material composition, particle morphology, electrode design, and electrolyte formulations. This analysis will help isolate the most promising pathways for further energy density improvements.

Third, we will evaluate the practical trade-offs between energy density and other critical performance parameters including cycle life, rate capability, temperature performance, and manufacturing cost. This holistic assessment will provide a more nuanced understanding of the true value proposition of different LFP cell designs in various application contexts.

Finally, we aim to develop predictive models for LFP energy density evolution based on identified technology trends and innovation pathways, providing strategic guidance for future research and development investments in this increasingly important battery chemistry.

The evolution of LFP batteries has been characterized by incremental improvements in energy density, which historically has been their primary limitation. Early LFP cells delivered energy densities of approximately 90-100 Wh/kg, significantly lower than competing lithium-ion chemistries. However, recent advancements have pushed these figures to 160-180 Wh/kg for commercial cells, with laboratory prototypes achieving even higher values.

Key milestones in LFP development include the introduction of nano-scale particle engineering around 2005-2010, which improved electron and ion transport properties; the development of carbon-coating techniques to enhance conductivity; and more recently, cell design innovations such as cell-to-pack technologies that optimize packaging efficiency and increase system-level energy density by up to 15-20%.

The current technological trajectory suggests continued improvements in energy density through materials engineering and manufacturing process refinements. Industry projections indicate potential for LFP cells to reach 200-220 Wh/kg in commercial applications within the next 3-5 years, narrowing the gap with nickel-based chemistries while maintaining their inherent safety and cost advantages.

Our research objectives for benchmarking LFP energy density are multifaceted. First, we aim to establish a comprehensive baseline of current commercial LFP cell performance across different manufacturers and form factors. This will include standardized testing protocols to ensure comparable results across diverse cell designs and manufacturing processes.

Second, we intend to identify the key technological factors that differentiate high-performing LFP cells from average performers, with particular focus on cathode material composition, particle morphology, electrode design, and electrolyte formulations. This analysis will help isolate the most promising pathways for further energy density improvements.

Third, we will evaluate the practical trade-offs between energy density and other critical performance parameters including cycle life, rate capability, temperature performance, and manufacturing cost. This holistic assessment will provide a more nuanced understanding of the true value proposition of different LFP cell designs in various application contexts.

Finally, we aim to develop predictive models for LFP energy density evolution based on identified technology trends and innovation pathways, providing strategic guidance for future research and development investments in this increasingly important battery chemistry.

Market Analysis of LFP Energy Storage Solutions

The global market for Lithium Iron Phosphate (LFP) energy storage solutions has experienced remarkable growth in recent years, driven primarily by increasing demand for sustainable energy solutions and the declining costs of battery technology. The market value of LFP batteries reached approximately $10.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 15.3% through 2030, potentially reaching $30.5 billion by the end of the decade.

The electric vehicle (EV) sector represents the largest application segment for LFP batteries, accounting for roughly 65% of total market demand. This dominance stems from LFP's superior safety profile and longer cycle life compared to other lithium-ion chemistries, despite its lower energy density. Tesla's strategic shift to incorporate LFP cells in its standard-range vehicles has significantly boosted market adoption and visibility.

Stationary energy storage systems constitute the second-largest market segment at approximately 25% of total demand. Utility-scale projects, commercial and industrial applications, and residential energy storage systems are driving growth in this segment. The remaining 10% is distributed across consumer electronics, power tools, and emerging applications such as electric marine vessels and aviation.

Geographically, China dominates the LFP market with approximately 70% of global production capacity. This concentration results from early investments in LFP technology and a robust supply chain for raw materials. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts to develop LFP manufacturing capabilities in North America and Europe, with several multi-billion-dollar investments announced in the past two years.

Price trends show a consistent decline, with LFP battery pack costs decreasing from approximately $180/kWh in 2018 to around $115/kWh in 2023. This price reduction has significantly improved the competitive position of LFP against other battery chemistries, particularly in applications where energy density is not the primary concern.

Customer demand patterns indicate growing preference for LFP in mid-range EVs and stationary storage applications, while high-energy-density applications like premium EVs continue to favor nickel-based chemistries. However, ongoing improvements in LFP energy density are gradually expanding its potential application range.

Market forecasts suggest that LFP will continue gaining market share against NMC (Nickel Manganese Cobalt) batteries in the coming years, potentially capturing up to 40% of the total lithium-ion battery market by 2030, compared to approximately 25% in 2022. This growth trajectory is supported by LFP's compelling value proposition in terms of cost, safety, and sustainability.

The electric vehicle (EV) sector represents the largest application segment for LFP batteries, accounting for roughly 65% of total market demand. This dominance stems from LFP's superior safety profile and longer cycle life compared to other lithium-ion chemistries, despite its lower energy density. Tesla's strategic shift to incorporate LFP cells in its standard-range vehicles has significantly boosted market adoption and visibility.

Stationary energy storage systems constitute the second-largest market segment at approximately 25% of total demand. Utility-scale projects, commercial and industrial applications, and residential energy storage systems are driving growth in this segment. The remaining 10% is distributed across consumer electronics, power tools, and emerging applications such as electric marine vessels and aviation.

Geographically, China dominates the LFP market with approximately 70% of global production capacity. This concentration results from early investments in LFP technology and a robust supply chain for raw materials. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated efforts to develop LFP manufacturing capabilities in North America and Europe, with several multi-billion-dollar investments announced in the past two years.

Price trends show a consistent decline, with LFP battery pack costs decreasing from approximately $180/kWh in 2018 to around $115/kWh in 2023. This price reduction has significantly improved the competitive position of LFP against other battery chemistries, particularly in applications where energy density is not the primary concern.

Customer demand patterns indicate growing preference for LFP in mid-range EVs and stationary storage applications, while high-energy-density applications like premium EVs continue to favor nickel-based chemistries. However, ongoing improvements in LFP energy density are gradually expanding its potential application range.

Market forecasts suggest that LFP will continue gaining market share against NMC (Nickel Manganese Cobalt) batteries in the coming years, potentially capturing up to 40% of the total lithium-ion battery market by 2030, compared to approximately 25% in 2022. This growth trajectory is supported by LFP's compelling value proposition in terms of cost, safety, and sustainability.

Technical Challenges in LFP Cell Energy Density

Lithium iron phosphate (LFP) batteries face significant energy density limitations compared to other lithium-ion chemistries. The fundamental challenge stems from LFP's inherently lower theoretical specific capacity (170 mAh/g) and operating voltage (3.2V) versus alternatives like NMC (nickel-manganese-cobalt) which can achieve 200+ mAh/g at higher voltages. This intrinsic limitation creates a ceiling effect that requires innovative approaches to overcome.

Material-level challenges further complicate energy density improvements. LFP's lower electronic conductivity necessitates additional conductive additives and specialized carbon coating processes, which add inactive weight to cells. The material's relatively low tap density also results in electrodes that occupy more volume per unit mass, directly impacting volumetric energy density metrics critical for space-constrained applications.

Manufacturing processes present additional hurdles. Current electrode coating technologies struggle to achieve the ultra-thick electrode designs that could potentially boost energy density. When manufacturers attempt to increase active material loading, issues with mechanical integrity, electrolyte wetting, and lithium-ion transport kinetics emerge, creating a practical ceiling for electrode thickness optimization.

Cell design constraints further limit energy density improvements. The need for robust mechanical support structures, current collectors, separators, and electrolyte volume all contribute to "dead weight" that doesn't directly store energy. While these components are essential for safety and performance, they represent a significant portion of cell mass and volume that cannot be easily reduced without compromising other performance metrics.

Thermal management requirements add another layer of complexity. LFP cells with higher energy density generate more heat during operation, necessitating more sophisticated cooling systems that add weight and volume to battery packs. This creates a challenging optimization problem where gains in cell-level energy density may be partially offset by additional thermal management requirements at the pack level.

Market and economic factors also influence technical development paths. The cost pressure on LFP technology often limits the implementation of advanced materials or manufacturing processes that could boost energy density. The industry faces difficult trade-offs between maintaining LFP's cost advantage while simultaneously pushing energy density boundaries.

Benchmarking efforts are further complicated by inconsistent testing protocols across the industry. Different cycling conditions, temperature ranges, and end-of-life definitions make direct comparisons challenging. Standardized testing frameworks are needed to accurately assess incremental improvements in energy density across different cell designs and manufacturing approaches.

Material-level challenges further complicate energy density improvements. LFP's lower electronic conductivity necessitates additional conductive additives and specialized carbon coating processes, which add inactive weight to cells. The material's relatively low tap density also results in electrodes that occupy more volume per unit mass, directly impacting volumetric energy density metrics critical for space-constrained applications.

Manufacturing processes present additional hurdles. Current electrode coating technologies struggle to achieve the ultra-thick electrode designs that could potentially boost energy density. When manufacturers attempt to increase active material loading, issues with mechanical integrity, electrolyte wetting, and lithium-ion transport kinetics emerge, creating a practical ceiling for electrode thickness optimization.

Cell design constraints further limit energy density improvements. The need for robust mechanical support structures, current collectors, separators, and electrolyte volume all contribute to "dead weight" that doesn't directly store energy. While these components are essential for safety and performance, they represent a significant portion of cell mass and volume that cannot be easily reduced without compromising other performance metrics.

Thermal management requirements add another layer of complexity. LFP cells with higher energy density generate more heat during operation, necessitating more sophisticated cooling systems that add weight and volume to battery packs. This creates a challenging optimization problem where gains in cell-level energy density may be partially offset by additional thermal management requirements at the pack level.

Market and economic factors also influence technical development paths. The cost pressure on LFP technology often limits the implementation of advanced materials or manufacturing processes that could boost energy density. The industry faces difficult trade-offs between maintaining LFP's cost advantage while simultaneously pushing energy density boundaries.

Benchmarking efforts are further complicated by inconsistent testing protocols across the industry. Different cycling conditions, temperature ranges, and end-of-life definitions make direct comparisons challenging. Standardized testing frameworks are needed to accurately assess incremental improvements in energy density across different cell designs and manufacturing approaches.

Current Benchmarking Methodologies for LFP Cells

01 Composition modifications to enhance energy density

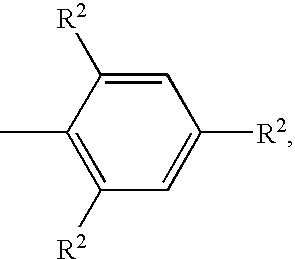

Various compositional modifications can be made to lithium phosphate cells to enhance their energy density. These include doping with elements like nickel, manganese, or cobalt, creating composite materials with carbon or other conductive additives, and optimizing the ratio of active materials. These modifications improve the electrochemical performance, conductivity, and capacity of the cells, resulting in higher energy density.- Improving energy density through electrode material optimization: Lithium phosphate cells can achieve higher energy density through optimization of electrode materials. This includes using nano-sized lithium iron phosphate particles, doping with elements like manganese or cobalt, and creating composite cathode materials. These modifications enhance the electrochemical performance, increase specific capacity, and improve the overall energy density of the cells.

- Electrolyte formulations for enhanced energy density: Specialized electrolyte formulations can significantly improve the energy density of lithium phosphate cells. These formulations may include additives that form stable solid electrolyte interphases, ionic liquids that enhance lithium ion transport, and compounds that prevent electrolyte decomposition at high voltages. Such electrolyte innovations enable higher operating voltages and better capacity retention, directly contributing to increased energy density.

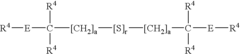

- Cell design and structural innovations: Structural innovations in lithium phosphate cell design can lead to improved energy density. These include thinner separators, optimized electrode stacking or winding techniques, reduced inactive components, and novel cell geometries. Advanced packaging methods and higher compression of cell components also contribute to volumetric energy density improvements while maintaining safety characteristics.

- Carbon coating and conductive additives: Carbon coating of lithium phosphate particles and incorporation of conductive additives significantly enhances energy density. These techniques improve electronic conductivity, reduce internal resistance, and enable faster charge/discharge rates without sacrificing capacity. Various carbon sources including graphene, carbon nanotubes, and amorphous carbon can be used to create uniform conductive networks throughout the electrode material.

- Multi-component cathode systems: Multi-component cathode systems that combine lithium phosphate with other cathode materials can achieve higher energy density. These hybrid approaches leverage the safety of lithium phosphate while incorporating higher-capacity materials like lithium-rich manganese oxides or nickel-based compounds. The resulting composite cathodes deliver improved energy density while maintaining thermal stability and cycle life advantages of lithium phosphate.

02 Structural design improvements for lithium phosphate cells

Innovative structural designs can significantly improve the energy density of lithium phosphate cells. These include developing nano-structured materials, creating porous electrode structures, implementing core-shell architectures, and designing hierarchical structures. These structural modifications increase the surface area for electrochemical reactions, improve ion transport, and enhance the utilization of active materials, leading to higher energy density.Expand Specific Solutions03 Manufacturing process optimization

Optimizing manufacturing processes can lead to lithium phosphate cells with higher energy density. Advanced synthesis methods such as hydrothermal synthesis, sol-gel processing, and spray pyrolysis can produce materials with controlled morphology and improved electrochemical properties. Additionally, optimized coating techniques, calendering processes, and electrode formulation can increase the loading density of active materials and improve cell performance.Expand Specific Solutions04 Electrolyte and interface engineering

Engineering the electrolyte composition and electrode-electrolyte interfaces can enhance the energy density of lithium phosphate cells. This includes developing advanced electrolyte formulations with additives that form stable solid-electrolyte interfaces, using ionic liquid electrolytes, and implementing surface coatings on electrode materials. These approaches reduce interfacial resistance, improve ion transport, and enhance the cycling stability of the cells.Expand Specific Solutions05 Cell design and packaging innovations

Innovations in cell design and packaging can maximize the energy density of lithium phosphate cells. These include developing high-density electrode stacking techniques, reducing the thickness of inactive components like separators and current collectors, implementing space-efficient cell formats, and optimizing the cell casing design. These approaches increase the volumetric proportion of active materials in the cell, resulting in higher energy density.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The lithium phosphate cell energy density benchmarking landscape is currently in a growth phase, with the market expanding rapidly due to increasing electric vehicle and energy storage demands. The global market size for LFP batteries is projected to reach $10-15 billion by 2025, growing at 15-20% annually. Leading players demonstrate varying technological maturity: A123 Systems and Guoxuan High-Tech have established commercial-scale production with energy densities around 140-160 Wh/kg, while newer entrants like Factorial and Sion Power are developing next-generation technologies targeting 200+ Wh/kg. Research institutions including MIT and Northeastern University are advancing fundamental innovations, while major manufacturers like Panasonic Energy, LG Energy Solution, and BASF are investing heavily in manufacturing scale and process improvements to enhance performance-to-cost ratios.

Jiangsu Haiji New Energy Co Ltd.

Technical Solution: Jiangsu Haiji has developed a systematic benchmarking approach for their LFP cells that evaluates performance across multiple dimensions including gravimetric energy density (150-165 Wh/kg), volumetric energy density (300-330 Wh/L), and cycle life (2000+ cycles to 80% capacity). Their proprietary manufacturing process includes precise control of cathode stoichiometry and carbon coating thickness to optimize electronic conductivity while minimizing parasitic reactions. The company employs advanced electrolyte formulations with film-forming additives that create stable solid-electrolyte interphase layers, reducing capacity fade during cycling. Their benchmarking methodology includes comprehensive testing under various temperature conditions (-20°C to 55°C) and discharge rates (0.2C to 5C), with standardized protocols for measuring capacity retention after extended cycling. Jiangsu Haiji has implemented automated production lines with in-line quality control that ensures consistent cell performance[9][10].

Strengths: Highly competitive manufacturing costs through economies of scale; good thermal stability with minimal heat generation during fast charging; established supply chain with secured raw material sources. Weaknesses: Less advanced R&D capabilities compared to global leaders; limited international certification and compliance documentation; less sophisticated battery management system integration.

Hefei Guoxuan High-Tech Power Energy Co., Ltd.

Technical Solution: Guoxuan has developed a comprehensive benchmarking system for their LFP cells that incorporates multi-dimensional performance metrics including energy density, power capability, cycle life, and temperature adaptability. Their latest generation LFP cells achieve energy densities of 160-175 Wh/kg through optimized particle engineering and electrode design. The company employs a proprietary doping strategy for their cathode materials, incorporating trace amounts of manganese and vanadium to enhance electronic conductivity and structural stability. Their benchmarking protocol includes calendar life testing under various temperature and state-of-charge conditions, with extrapolation models to predict 10+ year performance. Guoxuan has pioneered high-loading electrode manufacturing techniques that increase active material content while maintaining mechanical integrity, contributing to higher energy density[7][8].

Strengths: Cost-effective manufacturing with vertically integrated supply chain; excellent safety performance with no thermal runaway in nail penetration tests; competitive energy density approaching 175 Wh/kg. Weaknesses: Less established quality control compared to tier-one global manufacturers; limited low-temperature performance optimization; less advanced battery management system integration capabilities.

Critical Patents and Innovations in LFP Chemistry

Safer high energy battery

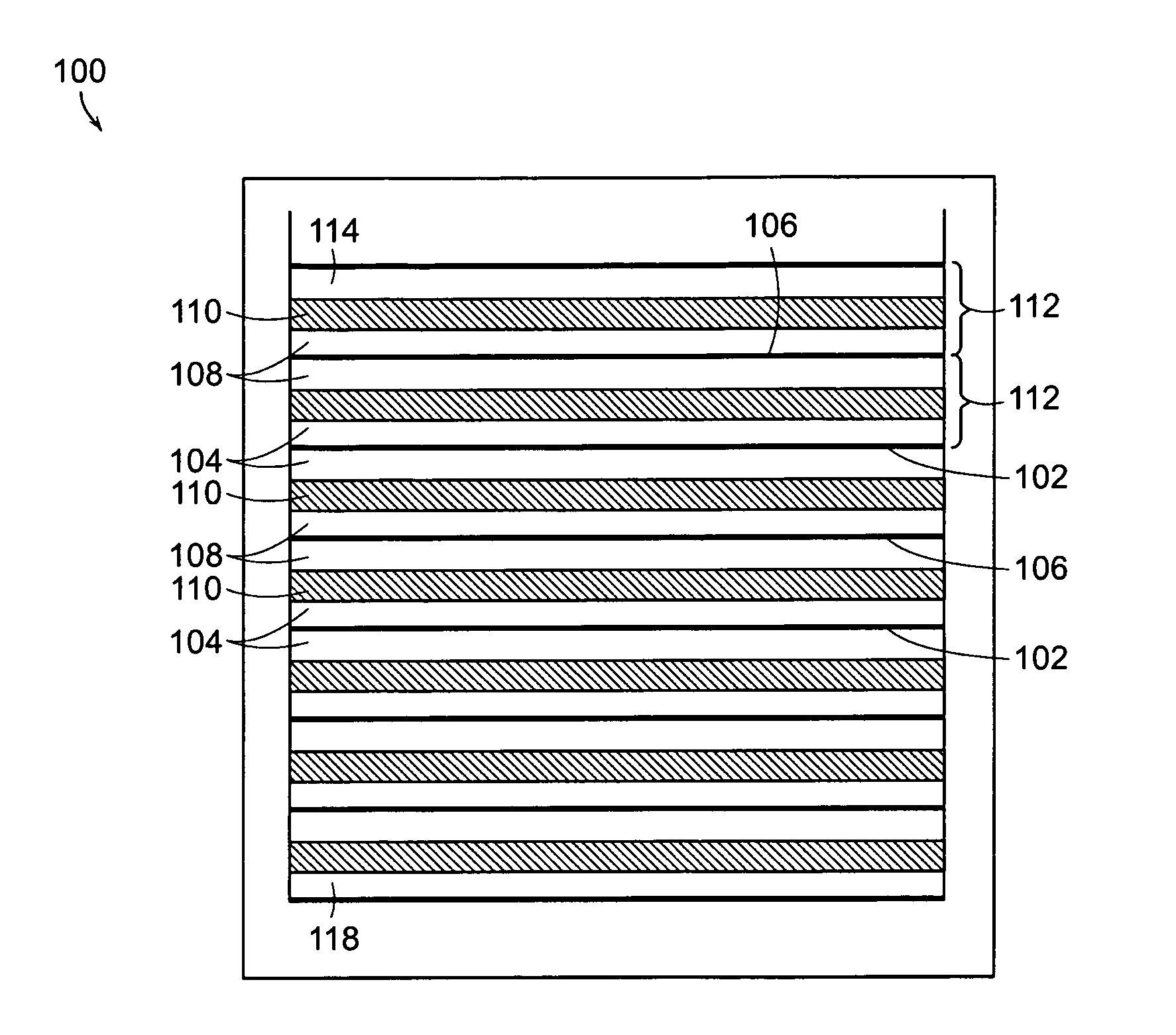

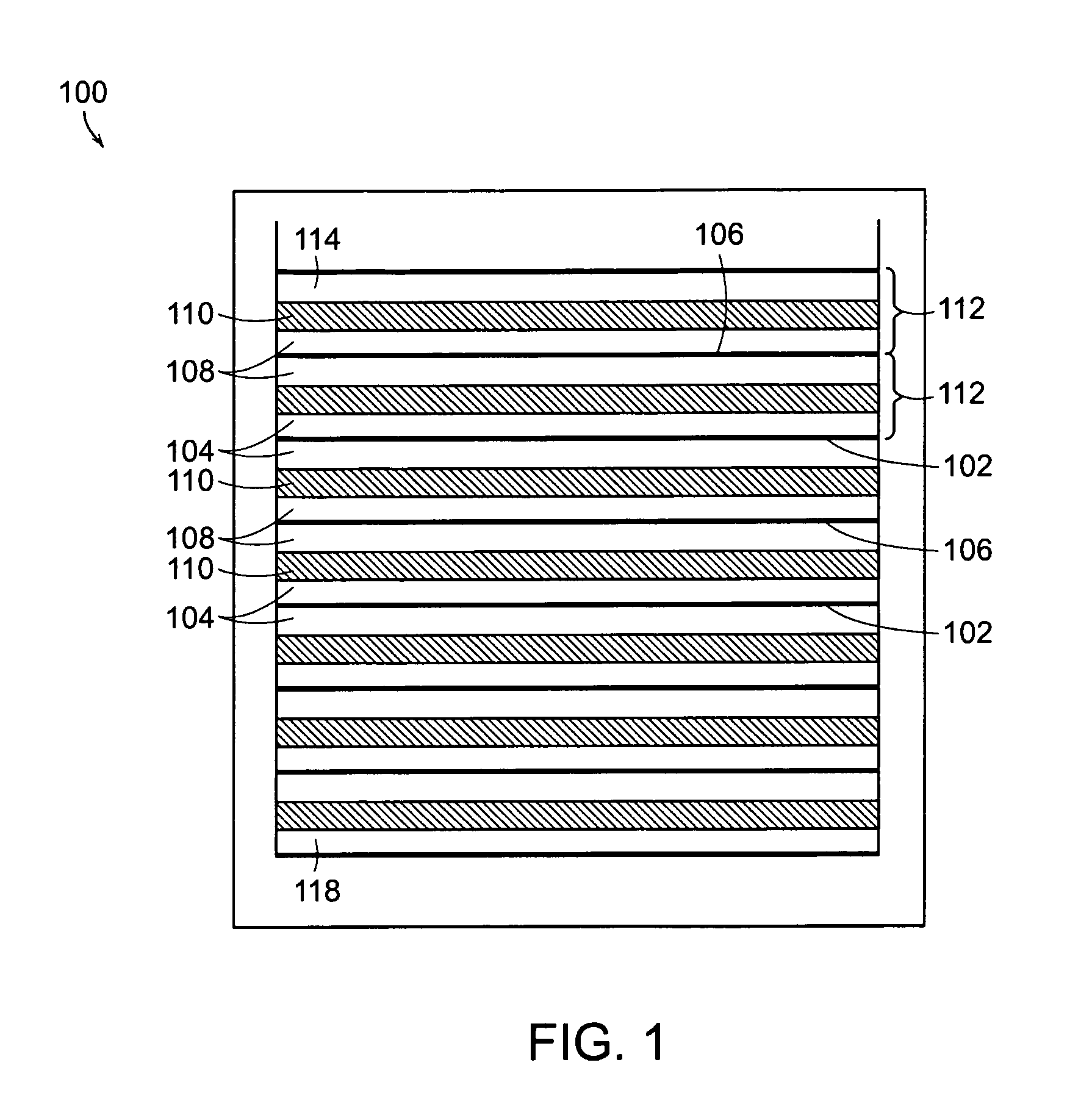

PatentInactiveUS20080199764A1

Innovation

- A lithium-ion secondary battery design featuring stacked layers with a positive electrode thickness of at least 200 μm, a low-reactive anode, and a non-bonded electrode stack configuration, which reduces the rate of discharge during failure events and prevents catastrophic failure by limiting heat generation and allowing the electrode stack to separate, thereby maintaining the cell enclosure integrity.

Lithium batteries

PatentInactiveUS6936382B2

Innovation

- A lithium electrochemical cell design featuring a solid lithium anode, a solid cathode with an electroactive sulfur-containing material, and a non-aqueous electrolyte comprising lithium salts, non-aqueous solvents, and capacity-enhancing reactive components such as anion receptors and electron transfer mediators, which enhance energy density and cycle life.

Sustainability and Environmental Impact Assessment

The environmental impact of lithium phosphate (LFP) battery cells represents a critical dimension in evaluating their overall viability as an energy storage solution. When benchmarking the energy density of these cells, sustainability considerations must be integrated into the assessment framework to provide a comprehensive understanding of their true cost and benefit.

LFP cells demonstrate significant environmental advantages compared to other lithium-ion chemistries. The absence of cobalt and nickel in their cathode composition substantially reduces the ecological footprint associated with mining these critical materials, which often involves habitat destruction, water pollution, and human rights concerns in certain regions. This composition advantage translates to approximately 30% lower carbon emissions during the manufacturing phase compared to nickel-manganese-cobalt (NMC) alternatives.

The extended cycle life of LFP cells—typically 2,000-3,000 cycles versus 1,000-1,500 for other lithium-ion variants—further enhances their sustainability profile by reducing the frequency of replacement and associated waste generation. This longevity effectively amortizes the initial environmental impact of production over a longer operational period.

Water consumption during LFP cell manufacturing presents another important metric, with recent advancements reducing process water requirements by up to 25% compared to previous generation technologies. However, the phosphate mining necessary for cathode materials continues to pose environmental challenges, including potential for water eutrophication if mining effluents are improperly managed.

End-of-life considerations reveal additional sustainability advantages for LFP cells. Their chemistry facilitates more efficient recycling processes, with recovery rates for lithium and phosphate reaching 90% in advanced recycling facilities. This circular economy potential significantly reduces the need for virgin material extraction and associated environmental impacts.

Temperature stability of LFP cells contributes to their safety profile and reduces the risk of thermal runaway events that could result in fires or release of toxic substances. This inherent safety characteristic minimizes the potential for acute environmental contamination incidents during operation or disposal phases.

When evaluating the complete lifecycle environmental impact, LFP cells demonstrate approximately 20-30% lower global warming potential compared to higher energy density alternatives when normalized for equivalent energy storage capacity. This advantage must be weighed against their lower energy density, which may require more materials per kWh of storage capacity in certain applications.

Future sustainability improvements for LFP technology will likely focus on reducing energy intensity during manufacturing, developing water-free processing techniques, and enhancing material recovery systems to further close the loop on resource utilization.

LFP cells demonstrate significant environmental advantages compared to other lithium-ion chemistries. The absence of cobalt and nickel in their cathode composition substantially reduces the ecological footprint associated with mining these critical materials, which often involves habitat destruction, water pollution, and human rights concerns in certain regions. This composition advantage translates to approximately 30% lower carbon emissions during the manufacturing phase compared to nickel-manganese-cobalt (NMC) alternatives.

The extended cycle life of LFP cells—typically 2,000-3,000 cycles versus 1,000-1,500 for other lithium-ion variants—further enhances their sustainability profile by reducing the frequency of replacement and associated waste generation. This longevity effectively amortizes the initial environmental impact of production over a longer operational period.

Water consumption during LFP cell manufacturing presents another important metric, with recent advancements reducing process water requirements by up to 25% compared to previous generation technologies. However, the phosphate mining necessary for cathode materials continues to pose environmental challenges, including potential for water eutrophication if mining effluents are improperly managed.

End-of-life considerations reveal additional sustainability advantages for LFP cells. Their chemistry facilitates more efficient recycling processes, with recovery rates for lithium and phosphate reaching 90% in advanced recycling facilities. This circular economy potential significantly reduces the need for virgin material extraction and associated environmental impacts.

Temperature stability of LFP cells contributes to their safety profile and reduces the risk of thermal runaway events that could result in fires or release of toxic substances. This inherent safety characteristic minimizes the potential for acute environmental contamination incidents during operation or disposal phases.

When evaluating the complete lifecycle environmental impact, LFP cells demonstrate approximately 20-30% lower global warming potential compared to higher energy density alternatives when normalized for equivalent energy storage capacity. This advantage must be weighed against their lower energy density, which may require more materials per kWh of storage capacity in certain applications.

Future sustainability improvements for LFP technology will likely focus on reducing energy intensity during manufacturing, developing water-free processing techniques, and enhancing material recovery systems to further close the loop on resource utilization.

Cost-Performance Analysis of LFP vs Alternative Chemistries

When evaluating lithium iron phosphate (LFP) batteries against alternative chemistries, cost-performance analysis reveals significant economic advantages that have driven their widespread adoption in certain market segments. LFP cells typically cost 20-30% less per kWh than nickel manganese cobalt (NMC) or nickel cobalt aluminum (NCA) alternatives, primarily due to the absence of expensive metals like cobalt and nickel. This cost advantage becomes particularly pronounced at scale, with large manufacturers reporting production costs below $80/kWh for LFP cells compared to $100-120/kWh for comparable NMC variants.

The total cost of ownership (TCO) calculations further favor LFP chemistry when considering the full lifecycle. With demonstrated cycle life often exceeding 3,000 full cycles at 80% depth of discharge—approximately double that of many NMC formulations—the amortized cost per cycle shows LFP cells outperforming higher energy density alternatives in applications where longevity is prioritized over volumetric constraints.

Performance trade-offs must be acknowledged in this economic equation. The 30-40% lower gravimetric energy density of LFP cells (typically 140-160 Wh/kg versus 200-260 Wh/kg for NMC/NCA) necessitates larger, heavier battery packs to achieve equivalent range in electric vehicles or runtime in stationary applications. This translates to increased structural costs and potential efficiency losses that partially offset the cell-level cost advantages.

Market segmentation has emerged based on these cost-performance characteristics. Budget-conscious electric vehicles, particularly in price-sensitive markets like China, have embraced LFP chemistry, with manufacturers reporting 15-25% lower battery pack costs enabling more competitive vehicle pricing. Conversely, premium automotive segments continue favoring higher energy density chemistries despite the cost premium, as the performance benefits justify the increased expense for their target demographics.

Supply chain resilience represents another economic dimension favoring LFP cells. The relative abundance of iron and phosphate compared to cobalt and nickel results in more stable pricing and reduced geopolitical supply risks. Historical price volatility analysis shows LFP raw material costs fluctuating within a 15% band over five years, while cobalt prices for NMC production have experienced swings exceeding 400% during the same period, creating significant challenges for long-term cost forecasting and business planning.

The total cost of ownership (TCO) calculations further favor LFP chemistry when considering the full lifecycle. With demonstrated cycle life often exceeding 3,000 full cycles at 80% depth of discharge—approximately double that of many NMC formulations—the amortized cost per cycle shows LFP cells outperforming higher energy density alternatives in applications where longevity is prioritized over volumetric constraints.

Performance trade-offs must be acknowledged in this economic equation. The 30-40% lower gravimetric energy density of LFP cells (typically 140-160 Wh/kg versus 200-260 Wh/kg for NMC/NCA) necessitates larger, heavier battery packs to achieve equivalent range in electric vehicles or runtime in stationary applications. This translates to increased structural costs and potential efficiency losses that partially offset the cell-level cost advantages.

Market segmentation has emerged based on these cost-performance characteristics. Budget-conscious electric vehicles, particularly in price-sensitive markets like China, have embraced LFP chemistry, with manufacturers reporting 15-25% lower battery pack costs enabling more competitive vehicle pricing. Conversely, premium automotive segments continue favoring higher energy density chemistries despite the cost premium, as the performance benefits justify the increased expense for their target demographics.

Supply chain resilience represents another economic dimension favoring LFP cells. The relative abundance of iron and phosphate compared to cobalt and nickel results in more stable pricing and reduced geopolitical supply risks. Historical price volatility analysis shows LFP raw material costs fluctuating within a 15% band over five years, while cobalt prices for NMC production have experienced swings exceeding 400% during the same period, creating significant challenges for long-term cost forecasting and business planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!