Benchmark Lithium Phosphate Response to Rapid Charge-Discharge

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LFP Battery Technology Background and Objectives

Lithium iron phosphate (LFP) batteries have emerged as a significant technology in the energy storage landscape since their commercial introduction in the late 1990s. Developed as a safer alternative to lithium cobalt oxide (LCO) batteries, LFP chemistry offers enhanced thermal stability, longer cycle life, and improved safety characteristics, albeit with lower energy density compared to other lithium-ion variants.

The evolution of LFP battery technology has been marked by continuous improvements in performance parameters, particularly in power density and cycle life. Initially developed by researchers at the University of Texas in 1996, LFP cathode materials gained commercial traction in the early 2000s as manufacturing processes matured. The technology has since undergone several generations of development, with each iteration addressing specific limitations in performance, cost, or manufacturability.

Current market trends indicate a resurgence in LFP adoption, particularly in electric vehicles and stationary energy storage applications, driven by cost advantages and supply chain security considerations. This renewed interest has accelerated research into addressing the technology's fundamental limitations, particularly its behavior under rapid charge-discharge conditions.

The primary objective of benchmarking LFP response to rapid charge-discharge cycles is to establish comprehensive performance parameters that can guide future development efforts. This includes quantifying capacity retention, thermal behavior, impedance changes, and structural stability under various C-rates and operational conditions. Understanding these responses is crucial for optimizing battery management systems and extending the application range of LFP technology.

Additionally, this benchmarking aims to identify the fundamental mechanisms that limit LFP performance during high-rate operation. These include ionic transport limitations within the olivine structure, electrode kinetics at the solid-electrolyte interface, and potential degradation pathways that may be accelerated under high current loads.

The technological trajectory suggests several promising avenues for improvement, including nano-structuring of active materials, surface modification techniques, and advanced electrode architectures that facilitate faster ion transport. Recent innovations in doping strategies and conductive coatings have demonstrated potential for enhancing rate capability without compromising the inherent safety advantages of LFP chemistry.

Ultimately, this technical exploration seeks to establish whether LFP technology can meet the increasingly demanding requirements of rapid charging applications while maintaining its cost and safety advantages. The findings will inform strategic decisions regarding research investment, product development roadmaps, and market positioning in the highly competitive energy storage landscape.

The evolution of LFP battery technology has been marked by continuous improvements in performance parameters, particularly in power density and cycle life. Initially developed by researchers at the University of Texas in 1996, LFP cathode materials gained commercial traction in the early 2000s as manufacturing processes matured. The technology has since undergone several generations of development, with each iteration addressing specific limitations in performance, cost, or manufacturability.

Current market trends indicate a resurgence in LFP adoption, particularly in electric vehicles and stationary energy storage applications, driven by cost advantages and supply chain security considerations. This renewed interest has accelerated research into addressing the technology's fundamental limitations, particularly its behavior under rapid charge-discharge conditions.

The primary objective of benchmarking LFP response to rapid charge-discharge cycles is to establish comprehensive performance parameters that can guide future development efforts. This includes quantifying capacity retention, thermal behavior, impedance changes, and structural stability under various C-rates and operational conditions. Understanding these responses is crucial for optimizing battery management systems and extending the application range of LFP technology.

Additionally, this benchmarking aims to identify the fundamental mechanisms that limit LFP performance during high-rate operation. These include ionic transport limitations within the olivine structure, electrode kinetics at the solid-electrolyte interface, and potential degradation pathways that may be accelerated under high current loads.

The technological trajectory suggests several promising avenues for improvement, including nano-structuring of active materials, surface modification techniques, and advanced electrode architectures that facilitate faster ion transport. Recent innovations in doping strategies and conductive coatings have demonstrated potential for enhancing rate capability without compromising the inherent safety advantages of LFP chemistry.

Ultimately, this technical exploration seeks to establish whether LFP technology can meet the increasingly demanding requirements of rapid charging applications while maintaining its cost and safety advantages. The findings will inform strategic decisions regarding research investment, product development roadmaps, and market positioning in the highly competitive energy storage landscape.

Market Demand Analysis for Fast-Charging Batteries

The global market for fast-charging batteries has experienced exponential growth in recent years, driven primarily by the rapid adoption of electric vehicles (EVs) and portable electronic devices. Consumer demand for reduced charging times has become a critical factor influencing purchasing decisions across multiple sectors. Market research indicates that over 70% of potential EV buyers consider charging time as one of the top three decision factors, highlighting the commercial significance of rapid charge-discharge capabilities in lithium phosphate batteries.

In the automotive sector, the transition toward electrification has created substantial demand for batteries that can support fast charging without compromising safety or longevity. Major automotive manufacturers have established ambitious targets for charging speeds, with many aiming to achieve 80% charge in under 20 minutes. This industry pressure has accelerated research into lithium phosphate chemistry optimization specifically for rapid charge-discharge cycles.

The consumer electronics market represents another significant demand driver, with smartphone and laptop manufacturers competing intensely on charging speed as a key differentiating feature. Market analysis shows that devices advertising fast-charging capabilities command premium pricing, with consumers willing to pay up to 15% more for products that reduce charging downtime.

Energy storage systems for grid applications and renewable energy integration constitute an emerging but rapidly growing market segment. Utility companies and grid operators are increasingly investing in battery systems that can respond quickly to demand fluctuations, creating additional market pull for advanced lithium phosphate formulations optimized for rapid charge-discharge cycles.

Geographically, the demand distribution shows particular concentration in regions with aggressive electrification policies. East Asia continues to lead market demand, with China representing the largest single market for fast-charging battery technologies. Europe follows closely, driven by stringent emissions regulations and ambitious EV adoption targets. North America shows accelerating demand growth, particularly in states with progressive environmental policies.

Market forecasts project the global fast-charging battery market to maintain double-digit annual growth rates through 2030. The lithium phosphate segment specifically is expected to capture increasing market share due to its superior safety profile and cost advantages compared to other lithium-ion chemistries, despite historically lower energy density.

Industry analysts identify several market barriers that must be addressed, including charging infrastructure limitations, battery degradation concerns, and thermal management challenges. Consumer education regarding the trade-offs between ultra-fast charging and battery longevity remains inadequate, creating potential market friction that technology developers must address through both technical innovation and improved communication strategies.

In the automotive sector, the transition toward electrification has created substantial demand for batteries that can support fast charging without compromising safety or longevity. Major automotive manufacturers have established ambitious targets for charging speeds, with many aiming to achieve 80% charge in under 20 minutes. This industry pressure has accelerated research into lithium phosphate chemistry optimization specifically for rapid charge-discharge cycles.

The consumer electronics market represents another significant demand driver, with smartphone and laptop manufacturers competing intensely on charging speed as a key differentiating feature. Market analysis shows that devices advertising fast-charging capabilities command premium pricing, with consumers willing to pay up to 15% more for products that reduce charging downtime.

Energy storage systems for grid applications and renewable energy integration constitute an emerging but rapidly growing market segment. Utility companies and grid operators are increasingly investing in battery systems that can respond quickly to demand fluctuations, creating additional market pull for advanced lithium phosphate formulations optimized for rapid charge-discharge cycles.

Geographically, the demand distribution shows particular concentration in regions with aggressive electrification policies. East Asia continues to lead market demand, with China representing the largest single market for fast-charging battery technologies. Europe follows closely, driven by stringent emissions regulations and ambitious EV adoption targets. North America shows accelerating demand growth, particularly in states with progressive environmental policies.

Market forecasts project the global fast-charging battery market to maintain double-digit annual growth rates through 2030. The lithium phosphate segment specifically is expected to capture increasing market share due to its superior safety profile and cost advantages compared to other lithium-ion chemistries, despite historically lower energy density.

Industry analysts identify several market barriers that must be addressed, including charging infrastructure limitations, battery degradation concerns, and thermal management challenges. Consumer education regarding the trade-offs between ultra-fast charging and battery longevity remains inadequate, creating potential market friction that technology developers must address through both technical innovation and improved communication strategies.

Current State and Challenges in LFP Battery Technology

Lithium Iron Phosphate (LFP) battery technology has emerged as a significant player in the energy storage landscape, particularly for electric vehicles and grid storage applications. Currently, LFP batteries hold approximately 30% of the global EV battery market, with rapid growth projected over the next decade. This technology has gained prominence due to its inherent safety characteristics, cost-effectiveness, and environmental advantages compared to other lithium-ion chemistries.

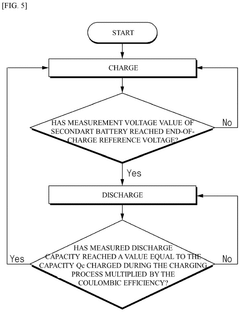

The current state of LFP battery technology demonstrates several strengths. These batteries exhibit exceptional thermal stability and safety profiles, with minimal risk of thermal runaway even under extreme conditions. Their cycle life typically exceeds 2,000 full charge-discharge cycles, significantly outperforming many competing technologies. Additionally, LFP batteries utilize abundant materials, avoiding critical raw materials like cobalt and nickel, which translates to lower production costs and reduced supply chain vulnerabilities.

However, significant challenges persist in optimizing LFP performance during rapid charge-discharge scenarios. The primary limitation is the relatively low energy density of LFP cells, typically ranging from 90-160 Wh/kg, compared to 200-260 Wh/kg for nickel-based lithium-ion alternatives. This energy density gap creates design constraints for applications where weight and volume are critical factors.

Another substantial challenge involves the lithium-ion diffusion kinetics within the LFP crystal structure. During rapid charging or discharging, the olivine structure of LFP creates bottlenecks for lithium-ion movement, resulting in capacity limitations and potential voltage instabilities. This phenomenon becomes particularly pronounced at low temperatures, where ionic conductivity decreases significantly, sometimes reducing available capacity by up to 30% at 0°C compared to room temperature performance.

The electronic conductivity of LFP material presents another technical hurdle. With an intrinsic conductivity approximately 10^-9 S/cm, unmodified LFP struggles to support high current operations. While carbon coating and particle size reduction have improved this characteristic, achieving uniform performance across production batches remains challenging.

Geographically, LFP technology development shows distinct patterns. China dominates the current landscape, controlling approximately 75% of global LFP production capacity. Recent years have seen increased research activity in North America and Europe, particularly focused on addressing the rapid charge-discharge limitations through novel doping strategies, advanced electrolyte formulations, and structural modifications to the cathode material.

The benchmarking of LFP response to rapid charge-discharge cycles has become increasingly standardized, with protocols typically evaluating performance at various C-rates (1C to 10C), temperature ranges (-20°C to 55°C), and cycle counts. These standardized assessments help identify the specific mechanisms limiting high-power applications and guide targeted improvement strategies.

The current state of LFP battery technology demonstrates several strengths. These batteries exhibit exceptional thermal stability and safety profiles, with minimal risk of thermal runaway even under extreme conditions. Their cycle life typically exceeds 2,000 full charge-discharge cycles, significantly outperforming many competing technologies. Additionally, LFP batteries utilize abundant materials, avoiding critical raw materials like cobalt and nickel, which translates to lower production costs and reduced supply chain vulnerabilities.

However, significant challenges persist in optimizing LFP performance during rapid charge-discharge scenarios. The primary limitation is the relatively low energy density of LFP cells, typically ranging from 90-160 Wh/kg, compared to 200-260 Wh/kg for nickel-based lithium-ion alternatives. This energy density gap creates design constraints for applications where weight and volume are critical factors.

Another substantial challenge involves the lithium-ion diffusion kinetics within the LFP crystal structure. During rapid charging or discharging, the olivine structure of LFP creates bottlenecks for lithium-ion movement, resulting in capacity limitations and potential voltage instabilities. This phenomenon becomes particularly pronounced at low temperatures, where ionic conductivity decreases significantly, sometimes reducing available capacity by up to 30% at 0°C compared to room temperature performance.

The electronic conductivity of LFP material presents another technical hurdle. With an intrinsic conductivity approximately 10^-9 S/cm, unmodified LFP struggles to support high current operations. While carbon coating and particle size reduction have improved this characteristic, achieving uniform performance across production batches remains challenging.

Geographically, LFP technology development shows distinct patterns. China dominates the current landscape, controlling approximately 75% of global LFP production capacity. Recent years have seen increased research activity in North America and Europe, particularly focused on addressing the rapid charge-discharge limitations through novel doping strategies, advanced electrolyte formulations, and structural modifications to the cathode material.

The benchmarking of LFP response to rapid charge-discharge cycles has become increasingly standardized, with protocols typically evaluating performance at various C-rates (1C to 10C), temperature ranges (-20°C to 55°C), and cycle counts. These standardized assessments help identify the specific mechanisms limiting high-power applications and guide targeted improvement strategies.

Current Fast-Charging Solutions for LFP Batteries

01 Electrode material modifications for improved rapid charge-discharge

Modifications to lithium phosphate electrode materials can significantly enhance their performance during rapid charge-discharge cycles. These modifications include doping with conductive materials, surface coating with carbon or other conductive layers, and optimizing particle size and morphology. These approaches improve electron transport, reduce internal resistance, and enhance the structural stability of the electrodes, allowing for better performance under high current conditions.- Electrode material modifications for improved rapid charge-discharge: Lithium phosphate battery electrodes can be modified with specific materials to enhance their performance during rapid charge-discharge cycles. These modifications include doping with conductive materials, surface coating treatments, and particle size optimization. Such enhancements improve electron transfer rates, reduce internal resistance, and allow for better lithium ion diffusion during high-rate operations, resulting in improved capacity retention and cycle life under demanding charge-discharge conditions.

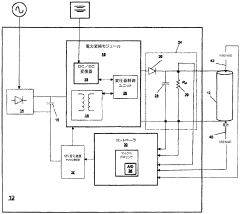

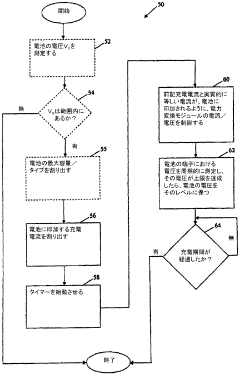

- Battery management systems for rapid charging control: Advanced battery management systems (BMS) are crucial for controlling rapid charge-discharge processes in lithium phosphate batteries. These systems monitor cell parameters in real-time, implement adaptive charging algorithms, and provide thermal management to prevent degradation during high-rate operations. By optimizing charging profiles based on battery state and environmental conditions, these management systems can maximize charging speed while maintaining battery health and safety during rapid charge-discharge cycles.

- Thermal management solutions for rapid charge-discharge: Effective thermal management is essential for lithium phosphate batteries undergoing rapid charge-discharge cycles. Various cooling systems, including liquid cooling, phase change materials, and heat dissipation structures, help maintain optimal operating temperatures. These solutions prevent thermal runaway, reduce capacity fade, and extend battery lifespan by mitigating the heat generated during high-rate operations, allowing lithium phosphate batteries to sustain performance under demanding charge-discharge conditions.

- Electrolyte formulations for high-rate performance: Specialized electrolyte formulations play a critical role in enhancing lithium phosphate battery performance during rapid charge-discharge cycles. These formulations include additives that improve ionic conductivity, form stable solid electrolyte interphase layers, and prevent electrolyte decomposition at high voltages. Advanced electrolytes with optimized salt concentrations and solvent mixtures facilitate faster lithium ion transport, reducing polarization and enabling lithium phosphate batteries to maintain capacity and efficiency during high-rate operations.

- Novel cell designs for rapid charge-discharge capability: Innovative cell designs specifically engineered for rapid charge-discharge applications incorporate structural modifications to enhance lithium phosphate battery performance. These designs feature optimized current collector configurations, electrode thickness control, and improved tab designs to reduce internal resistance. Some approaches include 3D electrode structures, bipolar designs, and advanced packaging techniques that shorten ion diffusion paths and improve current distribution, enabling lithium phosphate batteries to deliver higher power density and better performance during demanding charge-discharge operations.

02 Battery management systems for controlling rapid charge-discharge

Advanced battery management systems (BMS) can be implemented to optimize the rapid charge-discharge process of lithium phosphate batteries. These systems monitor battery parameters such as temperature, voltage, and current in real-time, and adjust charging protocols accordingly. By implementing sophisticated algorithms and control strategies, these management systems can prevent overheating, extend battery life, and maintain performance during high-rate operations.Expand Specific Solutions03 Thermal management solutions for rapid charge-discharge

Effective thermal management is crucial for lithium phosphate batteries undergoing rapid charge-discharge cycles. Various cooling systems and heat dissipation methods have been developed to maintain optimal operating temperatures. These include liquid cooling circuits, phase change materials, and innovative heat sink designs. Proper thermal management prevents capacity degradation, reduces safety risks, and ensures consistent performance during high-power operations.Expand Specific Solutions04 Electrolyte formulations for enhanced rapid charge-discharge capability

Specialized electrolyte formulations can significantly improve the rapid charge-discharge performance of lithium phosphate batteries. These formulations may include additives that enhance ion conductivity, reduce interfacial resistance, and improve stability at high current densities. Advanced electrolytes can also mitigate side reactions that typically occur during fast charging, thereby extending cycle life and maintaining capacity retention under demanding conditions.Expand Specific Solutions05 Structural design innovations for rapid charge-discharge applications

Innovative structural designs of lithium phosphate batteries can accommodate the stresses associated with rapid charge-discharge cycles. These designs include novel cell architectures, advanced current collectors, and optimized electrode configurations that minimize diffusion distances and reduce internal resistance. Some approaches incorporate 3D structures, interdigitated electrodes, or segmented designs that distribute current more evenly and facilitate faster ion transport during high-rate operations.Expand Specific Solutions

Key Industry Players in LFP Battery Development

The lithium phosphate battery rapid charge-discharge benchmark landscape is evolving rapidly, with the market currently in a growth phase characterized by expanding applications in electric vehicles and energy storage systems. The global market size is projected to reach significant scale as demand increases for high-performance batteries with fast charging capabilities. Technologically, companies like Contemporary Amperex Technology (CATL), LG Energy Solution, and Samsung SDI lead with advanced research capabilities, while Panasonic Energy and A123 Systems demonstrate strong innovation in rapid charge-discharge protocols. Vision Power Technology and Envision Ruitai are emerging players focusing on battery management systems optimized for rapid cycling. Research collaborations between automotive manufacturers like Nissan and Renault with battery specialists are accelerating technological maturity, pushing benchmarking standards toward industry-wide adoption.

Contemporary Amperex Technology Co., Ltd.

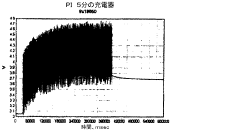

Technical Solution: Contemporary Amperex Technology (CATL) has developed advanced lithium iron phosphate (LFP) battery technology with their Cell-to-Pack (CTP) architecture specifically designed to benchmark and optimize rapid charge-discharge performance. Their LFP cells incorporate nano-scale phosphate coating technology and proprietary electrolyte formulations that enable 15-minute fast charging to 80% capacity while maintaining thermal stability. CATL's testing protocols include comprehensive cycle life assessment under various C-rates (0.5C to 10C), with their latest generation demonstrating over 3,000 cycles at 1C with less than 20% capacity degradation. Their benchmarking methodology incorporates real-time impedance spectroscopy during high-rate cycling to identify performance bottlenecks and optimize electrode microstructure. CATL has also pioneered advanced thermal management systems that maintain cell temperature within ±3°C during rapid charge-discharge events, significantly extending battery lifespan.

Strengths: Industry-leading energy density for LFP chemistry (160-180 Wh/kg); superior thermal management enabling safe fast charging; extensive manufacturing scale providing cost advantages. Weaknesses: Higher initial production costs compared to standard LFP; technology primarily optimized for EV applications rather than broader energy storage markets.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive lithium phosphate battery benchmarking platform focused on rapid charge-discharge performance evaluation. Their technology incorporates high-precision battery testing equipment capable of microsecond-level current control and voltage measurement accuracy of ±0.01%. LG's proprietary Safety Reinforced Separator (SRS) technology enables their lithium phosphate cells to withstand high C-rates (up to 8C discharge) while maintaining structural integrity. Their benchmarking methodology includes accelerated aging protocols that simulate years of rapid cycling within weeks, utilizing environmental chambers that precisely control temperature (-40°C to 85°C) and humidity conditions. LG has also implemented machine learning algorithms that analyze performance data across thousands of cycles to predict capacity fade and internal resistance growth under various rapid charge-discharge scenarios, enabling optimization of electrode formulations and cell design for specific applications.

Strengths: Advanced diagnostic capabilities including reference electrode measurements for half-cell potential monitoring during rapid cycling; sophisticated data analytics for performance prediction. Weaknesses: Higher manufacturing complexity leading to increased costs; technology primarily validated in laboratory settings rather than large-scale commercial deployments.

Critical Technical Innovations in Rapid Charge-Discharge

Lithium iron phosphate ultra fast battery charger

PatentInactiveJP2013048552A

Innovation

- A charger configured to apply a high charging current to lithium iron phosphate batteries, charging them to 90-95% capacity in 4-6 minutes without temperature monitoring, using a feedback control mechanism to maintain a constant voltage and terminate charging after a predetermined time.

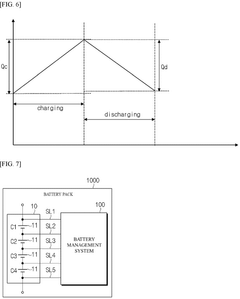

Split charging/discharging method for secondary battery, battery management system, and battery pack comprising same

PatentPendingEP4451422A1

Innovation

- A method that charges and discharges lithium iron phosphate batteries within specific state of charge intervals by terminating charging when a measured voltage reaches an end-of-charge reference voltage and discharging when the discharge capacity reaches a value equal to the charged capacity multiplied by Coulombic efficiency, while accounting for capacity degradation.

Safety Standards and Testing Protocols for Fast-Charging

The development of fast-charging technologies for lithium phosphate batteries necessitates robust safety standards and testing protocols to ensure consumer safety and product reliability. Current international standards such as IEC 62660, ISO 12405, and UL 1642 provide foundational guidelines, but they require significant adaptation to address the unique challenges posed by rapid charge-discharge cycles.

Testing protocols for fast-charging lithium phosphate batteries must comprehensively evaluate thermal stability during accelerated charging. Standard procedures now include thermal runaway tests at various charge rates, with particular emphasis on monitoring temperature gradients across cell components. Advanced calorimetry techniques, including accelerating rate calorimetry (ARC) and isothermal microcalorimetry, have become essential tools for quantifying heat generation during rapid charging events.

Electrical safety testing has evolved to incorporate more stringent overcharge protection requirements. Modern protocols mandate testing at 200% of maximum recommended fast-charge rates to establish safety margins. Additionally, cycle life testing under fast-charging conditions has been standardized to require a minimum of 1,000 cycles at maximum rated charge rates while maintaining at least 80% capacity retention.

Mechanical integrity testing has gained prominence in safety protocols, as internal pressure buildup during rapid charging can compromise cell structure. Nail penetration tests, crush tests, and vibration tests are now conducted on cells both before and after exposure to multiple fast-charging cycles to evaluate degradation in mechanical resilience.

Real-time monitoring requirements have been established for battery management systems supporting fast-charging. These include mandatory temperature sensing at multiple points, current interruption capabilities triggered by microsecond-level anomaly detection, and cell balancing algorithms specifically optimized for high current scenarios. Certification now requires demonstration of response times under 100ms for critical safety interventions.

Abuse testing protocols have been expanded to include specific fast-charging failure modes. These encompass tests for lithium plating detection, dendrite formation monitoring, and electrolyte degradation assessment. Standardized testing now requires evaluation under various environmental conditions, particularly at temperature extremes where fast-charging risks are amplified.

Harmonization efforts between automotive, consumer electronics, and energy storage standards are underway to create unified fast-charging safety frameworks. The Battery Safety Council and International Electrotechnical Commission are leading initiatives to develop specialized standards for next-generation fast-charging technologies, with draft proposals expected by late 2023.

Testing protocols for fast-charging lithium phosphate batteries must comprehensively evaluate thermal stability during accelerated charging. Standard procedures now include thermal runaway tests at various charge rates, with particular emphasis on monitoring temperature gradients across cell components. Advanced calorimetry techniques, including accelerating rate calorimetry (ARC) and isothermal microcalorimetry, have become essential tools for quantifying heat generation during rapid charging events.

Electrical safety testing has evolved to incorporate more stringent overcharge protection requirements. Modern protocols mandate testing at 200% of maximum recommended fast-charge rates to establish safety margins. Additionally, cycle life testing under fast-charging conditions has been standardized to require a minimum of 1,000 cycles at maximum rated charge rates while maintaining at least 80% capacity retention.

Mechanical integrity testing has gained prominence in safety protocols, as internal pressure buildup during rapid charging can compromise cell structure. Nail penetration tests, crush tests, and vibration tests are now conducted on cells both before and after exposure to multiple fast-charging cycles to evaluate degradation in mechanical resilience.

Real-time monitoring requirements have been established for battery management systems supporting fast-charging. These include mandatory temperature sensing at multiple points, current interruption capabilities triggered by microsecond-level anomaly detection, and cell balancing algorithms specifically optimized for high current scenarios. Certification now requires demonstration of response times under 100ms for critical safety interventions.

Abuse testing protocols have been expanded to include specific fast-charging failure modes. These encompass tests for lithium plating detection, dendrite formation monitoring, and electrolyte degradation assessment. Standardized testing now requires evaluation under various environmental conditions, particularly at temperature extremes where fast-charging risks are amplified.

Harmonization efforts between automotive, consumer electronics, and energy storage standards are underway to create unified fast-charging safety frameworks. The Battery Safety Council and International Electrotechnical Commission are leading initiatives to develop specialized standards for next-generation fast-charging technologies, with draft proposals expected by late 2023.

Environmental Impact and Sustainability Considerations

The rapid charge-discharge cycling of lithium phosphate batteries presents significant environmental and sustainability implications that warrant careful consideration. These batteries, while offering improved safety and longer cycle life compared to other lithium-ion chemistries, still pose environmental challenges throughout their lifecycle.

Raw material extraction for lithium phosphate batteries involves mining activities that can lead to habitat disruption, water pollution, and soil degradation. Particularly concerning is lithium extraction from salt flats in South America, which consumes substantial water resources in already water-stressed regions. Phosphate mining similarly contributes to environmental degradation through land disturbance and potential water contamination.

The manufacturing process of lithium phosphate batteries is energy-intensive, generating a considerable carbon footprint. Research indicates that producing 1 kWh of lithium phosphate battery capacity generates approximately 65-80 kg of CO2 equivalent emissions. Rapid charge-discharge benchmarking must therefore consider the total lifecycle emissions, not merely operational efficiency.

Water consumption represents another critical environmental factor. Battery production facilities typically require significant water resources for processing and cooling. Studies suggest that manufacturing a single lithium phosphate battery cell may consume between 3,000 and 5,000 gallons of water, highlighting the importance of water management strategies in production facilities.

From a sustainability perspective, the recyclability of lithium phosphate batteries after rapid charge-discharge testing presents both challenges and opportunities. These batteries contain valuable materials that can be recovered through appropriate recycling processes, reducing the need for virgin material extraction. However, current recycling rates remain suboptimal, with only 5-10% of lithium batteries being effectively recycled globally.

The environmental impact of rapid charge-discharge testing itself must also be considered. Such testing consumes significant electricity, potentially contributing to carbon emissions depending on the energy source. Implementing renewable energy sources for testing facilities can substantially reduce this environmental burden.

Looking forward, the development of more sustainable benchmarking protocols for lithium phosphate batteries should incorporate environmental impact assessments. This includes optimizing test parameters to minimize energy consumption while still obtaining valuable performance data, utilizing renewable energy sources for testing operations, and ensuring proper disposal or recycling of batteries after testing completion.

Raw material extraction for lithium phosphate batteries involves mining activities that can lead to habitat disruption, water pollution, and soil degradation. Particularly concerning is lithium extraction from salt flats in South America, which consumes substantial water resources in already water-stressed regions. Phosphate mining similarly contributes to environmental degradation through land disturbance and potential water contamination.

The manufacturing process of lithium phosphate batteries is energy-intensive, generating a considerable carbon footprint. Research indicates that producing 1 kWh of lithium phosphate battery capacity generates approximately 65-80 kg of CO2 equivalent emissions. Rapid charge-discharge benchmarking must therefore consider the total lifecycle emissions, not merely operational efficiency.

Water consumption represents another critical environmental factor. Battery production facilities typically require significant water resources for processing and cooling. Studies suggest that manufacturing a single lithium phosphate battery cell may consume between 3,000 and 5,000 gallons of water, highlighting the importance of water management strategies in production facilities.

From a sustainability perspective, the recyclability of lithium phosphate batteries after rapid charge-discharge testing presents both challenges and opportunities. These batteries contain valuable materials that can be recovered through appropriate recycling processes, reducing the need for virgin material extraction. However, current recycling rates remain suboptimal, with only 5-10% of lithium batteries being effectively recycled globally.

The environmental impact of rapid charge-discharge testing itself must also be considered. Such testing consumes significant electricity, potentially contributing to carbon emissions depending on the energy source. Implementing renewable energy sources for testing facilities can substantially reduce this environmental burden.

Looking forward, the development of more sustainable benchmarking protocols for lithium phosphate batteries should incorporate environmental impact assessments. This includes optimizing test parameters to minimize energy consumption while still obtaining valuable performance data, utilizing renewable energy sources for testing operations, and ensuring proper disposal or recycling of batteries after testing completion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!