Measure the Brittleness Factor of Lithium Phosphate Components

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Brittleness Measurement Background and Objectives

Lithium phosphate components have emerged as critical materials in the development of advanced energy storage systems, particularly in lithium-ion batteries. The evolution of these materials traces back to the early 1990s when researchers began exploring phosphate-based cathode materials as alternatives to traditional oxide-based compounds. The trajectory of development accelerated significantly in the late 1990s with the discovery of LiFePO4 (lithium iron phosphate) by Goodenough's research group, marking a pivotal moment in battery technology.

The brittleness factor of lithium phosphate components represents a fundamental mechanical property that directly impacts the structural integrity, longevity, and safety of battery systems. Historically, measurement techniques for this property have evolved from basic mechanical stress tests to sophisticated nanoscale characterization methods, reflecting the increasing precision requirements in battery manufacturing.

Current technological trends indicate a growing emphasis on understanding the microstructural factors that influence brittleness in these materials. This includes crystal orientation, grain boundary characteristics, and the presence of dopants or impurities. The industry is witnessing a shift toward in-situ measurement techniques that can monitor brittleness changes during battery operation, providing real-time data on material degradation.

The primary technical objective of measuring the brittleness factor is to establish standardized, reliable, and reproducible methodologies that can accurately quantify this property across different lithium phosphate formulations. This includes developing protocols that account for the anisotropic nature of these materials and their behavior under various thermal and electrochemical conditions.

Secondary objectives include correlating brittleness measurements with battery performance metrics, particularly cycle life and safety parameters. This correlation is essential for predicting long-term battery reliability and for developing models that can simulate mechanical failure modes under different operating scenarios.

From a materials science perspective, the goal is to understand the fundamental relationship between chemical composition, crystal structure, and mechanical properties. This understanding will guide the development of next-generation lithium phosphate materials with optimized brittleness characteristics, potentially leading to batteries with enhanced durability and safety profiles.

The measurement of brittleness also aims to support quality control processes in manufacturing settings, where rapid and non-destructive testing methods are increasingly demanded. This necessitates the development of innovative measurement techniques that can be integrated into production lines without compromising throughput or accuracy.

Ultimately, the technological trajectory points toward creating a comprehensive framework for brittleness characterization that bridges laboratory research and industrial application, facilitating the translation of fundamental materials science into practical battery engineering solutions.

The brittleness factor of lithium phosphate components represents a fundamental mechanical property that directly impacts the structural integrity, longevity, and safety of battery systems. Historically, measurement techniques for this property have evolved from basic mechanical stress tests to sophisticated nanoscale characterization methods, reflecting the increasing precision requirements in battery manufacturing.

Current technological trends indicate a growing emphasis on understanding the microstructural factors that influence brittleness in these materials. This includes crystal orientation, grain boundary characteristics, and the presence of dopants or impurities. The industry is witnessing a shift toward in-situ measurement techniques that can monitor brittleness changes during battery operation, providing real-time data on material degradation.

The primary technical objective of measuring the brittleness factor is to establish standardized, reliable, and reproducible methodologies that can accurately quantify this property across different lithium phosphate formulations. This includes developing protocols that account for the anisotropic nature of these materials and their behavior under various thermal and electrochemical conditions.

Secondary objectives include correlating brittleness measurements with battery performance metrics, particularly cycle life and safety parameters. This correlation is essential for predicting long-term battery reliability and for developing models that can simulate mechanical failure modes under different operating scenarios.

From a materials science perspective, the goal is to understand the fundamental relationship between chemical composition, crystal structure, and mechanical properties. This understanding will guide the development of next-generation lithium phosphate materials with optimized brittleness characteristics, potentially leading to batteries with enhanced durability and safety profiles.

The measurement of brittleness also aims to support quality control processes in manufacturing settings, where rapid and non-destructive testing methods are increasingly demanded. This necessitates the development of innovative measurement techniques that can be integrated into production lines without compromising throughput or accuracy.

Ultimately, the technological trajectory points toward creating a comprehensive framework for brittleness characterization that bridges laboratory research and industrial application, facilitating the translation of fundamental materials science into practical battery engineering solutions.

Market Demand Analysis for Lithium Phosphate Components

The global market for lithium phosphate components has experienced significant growth in recent years, primarily driven by the expanding electric vehicle (EV) industry and renewable energy storage systems. The ability to accurately measure the brittleness factor of these components has become increasingly critical as manufacturers seek to enhance product durability and safety while meeting stringent industry standards.

Market research indicates that the lithium phosphate battery market reached approximately $7.5 billion in 2022 and is projected to grow at a compound annual growth rate of 12.3% through 2030. This growth trajectory is creating substantial demand for advanced testing methodologies that can precisely determine brittleness factors, as component failure due to brittleness represents one of the leading causes of battery degradation and safety incidents.

The automotive sector constitutes the largest market segment demanding brittleness measurement solutions, accounting for roughly 45% of the total market. As EV adoption accelerates globally, automotive manufacturers are implementing more rigorous quality control processes that require precise brittleness assessment to ensure battery longevity and safety compliance.

Energy storage system developers represent the second-largest market segment, with particular emphasis on grid-scale applications where component reliability directly impacts system economics and operational safety. These customers typically require brittleness measurement solutions that can handle larger components and provide data integration with predictive maintenance systems.

Consumer electronics manufacturers form a growing segment of the market, particularly as lithium phosphate formulations gain popularity in portable devices due to their enhanced safety profile compared to other lithium-ion chemistries. This segment demands miniaturized testing equipment capable of assessing brittleness in smaller form-factor components.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 60% of global consumption, with China leading regional growth. North America and Europe follow with 20% and 15% market share respectively, though both regions are showing accelerated growth rates as domestic battery production capacity expands.

Market analysis reveals that customers are increasingly prioritizing non-destructive testing methods that can be integrated into production lines for real-time brittleness assessment. This trend is driving innovation in measurement technologies that combine speed, accuracy, and production compatibility while minimizing material waste.

The regulatory landscape is further shaping market demand, with new safety standards in development across major markets that will likely mandate more comprehensive brittleness testing protocols. Industry stakeholders anticipate these regulations will significantly expand the market for advanced measurement solutions over the next five years.

Market research indicates that the lithium phosphate battery market reached approximately $7.5 billion in 2022 and is projected to grow at a compound annual growth rate of 12.3% through 2030. This growth trajectory is creating substantial demand for advanced testing methodologies that can precisely determine brittleness factors, as component failure due to brittleness represents one of the leading causes of battery degradation and safety incidents.

The automotive sector constitutes the largest market segment demanding brittleness measurement solutions, accounting for roughly 45% of the total market. As EV adoption accelerates globally, automotive manufacturers are implementing more rigorous quality control processes that require precise brittleness assessment to ensure battery longevity and safety compliance.

Energy storage system developers represent the second-largest market segment, with particular emphasis on grid-scale applications where component reliability directly impacts system economics and operational safety. These customers typically require brittleness measurement solutions that can handle larger components and provide data integration with predictive maintenance systems.

Consumer electronics manufacturers form a growing segment of the market, particularly as lithium phosphate formulations gain popularity in portable devices due to their enhanced safety profile compared to other lithium-ion chemistries. This segment demands miniaturized testing equipment capable of assessing brittleness in smaller form-factor components.

Geographically, Asia-Pacific dominates the market demand, accounting for approximately 60% of global consumption, with China leading regional growth. North America and Europe follow with 20% and 15% market share respectively, though both regions are showing accelerated growth rates as domestic battery production capacity expands.

Market analysis reveals that customers are increasingly prioritizing non-destructive testing methods that can be integrated into production lines for real-time brittleness assessment. This trend is driving innovation in measurement technologies that combine speed, accuracy, and production compatibility while minimizing material waste.

The regulatory landscape is further shaping market demand, with new safety standards in development across major markets that will likely mandate more comprehensive brittleness testing protocols. Industry stakeholders anticipate these regulations will significantly expand the market for advanced measurement solutions over the next five years.

Current Brittleness Testing Technologies and Challenges

The measurement of brittleness in lithium phosphate components presents significant technical challenges due to the complex nature of these materials. Current testing methodologies can be broadly categorized into conventional mechanical testing, advanced instrumental techniques, and emerging computational approaches, each with distinct advantages and limitations.

Conventional mechanical testing methods include indentation hardness tests (Vickers, Knoop, and nanoindentation), which measure the resistance of materials to localized deformation. While these techniques are well-established and widely accessible, they often provide only indirect measurements of brittleness and may induce microcracks that compromise result accuracy when applied to lithium phosphate components.

Fracture toughness tests, including the Single Edge Notched Beam (SENB) and Chevron Notched Beam (CNB) methods, offer more direct brittleness assessments but require careful sample preparation and precise crack initiation, which can be particularly challenging for lithium phosphate materials due to their sensitivity to environmental conditions.

Advanced instrumental techniques have emerged to address these limitations. Acoustic emission testing detects and analyzes sound waves generated during material deformation, providing real-time insights into crack initiation and propagation within lithium phosphate components. However, signal interpretation remains complex and requires sophisticated algorithms to distinguish relevant signals from background noise.

X-ray microtomography enables non-destructive 3D visualization of internal structures and defects, offering valuable insights into brittleness factors without sample destruction. The drawbacks include high equipment costs, limited resolution for nanoscale features, and extensive data processing requirements.

In-situ SEM/TEM mechanical testing represents a cutting-edge approach that allows direct observation of deformation mechanisms at micro and nanoscales. While providing unprecedented insights into brittleness mechanisms, these techniques demand specialized equipment and expertise, limiting their widespread adoption.

Computational modeling approaches, including Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations, are increasingly utilized to predict brittleness behavior. These methods offer cost-effective alternatives to experimental testing but rely heavily on accurate input parameters and validation against experimental data.

A significant challenge across all methodologies is the environmental sensitivity of lithium phosphate components. Exposure to moisture, temperature fluctuations, and mechanical stresses during testing can alter material properties, necessitating controlled testing environments that may not reflect real-world conditions.

Standardization represents another major hurdle, as there are currently no universally accepted protocols specifically designed for measuring brittleness in lithium phosphate materials. This lack of standardization complicates result comparison across different studies and hinders industry-wide quality control efforts.

Conventional mechanical testing methods include indentation hardness tests (Vickers, Knoop, and nanoindentation), which measure the resistance of materials to localized deformation. While these techniques are well-established and widely accessible, they often provide only indirect measurements of brittleness and may induce microcracks that compromise result accuracy when applied to lithium phosphate components.

Fracture toughness tests, including the Single Edge Notched Beam (SENB) and Chevron Notched Beam (CNB) methods, offer more direct brittleness assessments but require careful sample preparation and precise crack initiation, which can be particularly challenging for lithium phosphate materials due to their sensitivity to environmental conditions.

Advanced instrumental techniques have emerged to address these limitations. Acoustic emission testing detects and analyzes sound waves generated during material deformation, providing real-time insights into crack initiation and propagation within lithium phosphate components. However, signal interpretation remains complex and requires sophisticated algorithms to distinguish relevant signals from background noise.

X-ray microtomography enables non-destructive 3D visualization of internal structures and defects, offering valuable insights into brittleness factors without sample destruction. The drawbacks include high equipment costs, limited resolution for nanoscale features, and extensive data processing requirements.

In-situ SEM/TEM mechanical testing represents a cutting-edge approach that allows direct observation of deformation mechanisms at micro and nanoscales. While providing unprecedented insights into brittleness mechanisms, these techniques demand specialized equipment and expertise, limiting their widespread adoption.

Computational modeling approaches, including Finite Element Analysis (FEA) and Molecular Dynamics (MD) simulations, are increasingly utilized to predict brittleness behavior. These methods offer cost-effective alternatives to experimental testing but rely heavily on accurate input parameters and validation against experimental data.

A significant challenge across all methodologies is the environmental sensitivity of lithium phosphate components. Exposure to moisture, temperature fluctuations, and mechanical stresses during testing can alter material properties, necessitating controlled testing environments that may not reflect real-world conditions.

Standardization represents another major hurdle, as there are currently no universally accepted protocols specifically designed for measuring brittleness in lithium phosphate materials. This lack of standardization complicates result comparison across different studies and hinders industry-wide quality control efforts.

Existing Brittleness Factor Measurement Solutions

01 Composition modifications to reduce brittleness in lithium phosphate materials

Various compositional modifications can be implemented to reduce the brittleness of lithium phosphate components in battery materials. These include doping with specific elements, creating composite structures, and adjusting the stoichiometric ratios of components. Such modifications alter the crystal structure and mechanical properties, resulting in improved flexibility and reduced brittleness while maintaining electrochemical performance.- Additives to reduce brittleness in lithium phosphate materials: Various additives can be incorporated into lithium phosphate materials to reduce brittleness and improve mechanical properties. These additives include carbon-based materials, polymeric binders, and certain metal oxides that can enhance the structural integrity of lithium phosphate components. The additives work by creating a more flexible matrix or by filling microscopic voids that would otherwise serve as crack initiation points, thereby increasing the overall toughness and reducing the brittleness factor.

- Coating technologies for lithium phosphate particles: Specialized coating technologies can be applied to lithium phosphate particles to mitigate brittleness issues. These coatings create a protective layer around individual particles, preventing direct contact between them and reducing friction that can lead to fractures. Various coating materials including carbon, metal oxides, and polymers can be used depending on the specific application requirements. These coatings not only improve mechanical properties but can also enhance electrochemical performance in battery applications.

- Synthesis methods affecting brittleness of lithium phosphate: The synthesis method used to produce lithium phosphate materials significantly impacts their brittleness factor. Techniques such as hydrothermal synthesis, solid-state reactions, and sol-gel processes result in different particle morphologies, sizes, and crystallinity, all of which affect mechanical properties. Controlled cooling rates and precise temperature management during synthesis can lead to optimized crystal structures with reduced brittleness. Post-synthesis treatments like annealing can also be employed to relieve internal stresses and improve mechanical stability.

- Composite structures to enhance mechanical properties: Creating composite structures by combining lithium phosphate with other materials can effectively address brittleness issues. These composites often incorporate more ductile materials such as polymers, metals, or carbon-based materials that can absorb and distribute mechanical stress. The resulting composite structures exhibit improved flexibility and fracture resistance compared to pure lithium phosphate components. This approach is particularly valuable in applications where mechanical integrity under stress is critical, such as in battery electrodes subject to volume changes during cycling.

- Doping strategies to modify crystalline structure: Doping lithium phosphate materials with specific elements can modify their crystalline structure and reduce brittleness. Elements such as magnesium, aluminum, titanium, or niobium can be incorporated into the crystal lattice to create beneficial defects or strengthen atomic bonds. These dopants can disrupt crack propagation pathways and enhance overall mechanical resilience. The type and concentration of dopants must be carefully controlled to achieve the desired mechanical properties without compromising other important characteristics such as ionic conductivity or electrochemical stability.

02 Surface coating and treatment methods for lithium phosphate particles

Surface coating and treatment methods can significantly reduce the brittleness factor of lithium phosphate components. These techniques include applying protective layers of carbon, metal oxides, or polymers to the particle surfaces. Such coatings create a buffer zone that absorbs mechanical stress, prevents crack propagation, and enhances the overall structural integrity of the material while improving its electrochemical stability.Expand Specific Solutions03 Particle size and morphology control to improve mechanical properties

Controlling the particle size and morphology of lithium phosphate components can significantly impact their brittleness. Nano-sized particles or specific morphologies like nanoplates, nanorods, or hierarchical structures can reduce brittleness by providing more flexibility at particle interfaces. Manufacturing processes that precisely control crystallization, growth conditions, and particle engineering can yield lithium phosphate materials with enhanced mechanical properties.Expand Specific Solutions04 Binder and electrolyte formulations to mitigate brittleness

Specialized binder and electrolyte formulations can help mitigate the brittleness of lithium phosphate components in battery systems. Flexible polymer binders with strong adhesion properties can absorb mechanical stress and prevent particle fracturing. Similarly, electrolyte additives can form stable interfaces with lithium phosphate materials, reducing degradation mechanisms that contribute to brittleness over cycling.Expand Specific Solutions05 Manufacturing processes to enhance structural integrity

Advanced manufacturing processes can enhance the structural integrity and reduce brittleness of lithium phosphate components. Techniques such as controlled sintering, pressure-assisted synthesis, and novel heat treatment protocols can optimize grain boundaries and reduce defects. These processes create more homogeneous materials with fewer stress concentration points, resulting in lithium phosphate components with improved mechanical durability and reduced brittleness.Expand Specific Solutions

Key Industry Players in Lithium Phosphate Testing

The lithium phosphate components brittleness measurement market is currently in a growth phase, with increasing demand driven by the expanding lithium battery sector. The market size is projected to reach significant volumes as electric vehicle adoption accelerates globally. From a technological maturity perspective, the field shows varied development levels across key players. Companies like LG Energy Solution and Samsung Electronics are leading with advanced measurement technologies, while A123 Systems has developed specialized nanophosphate electrode technology offering competitive advantages. BASF, Sumitomo Chemical, and ExxonMobil Chemical Patents are advancing materials science approaches to brittleness assessment, while Daikin Industries and Eastman Chemical focus on chemical property evaluation methods. The competition is intensifying as battery manufacturers and chemical companies invest in proprietary measurement techniques to enhance product reliability and performance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive approach to measure the brittleness factor of lithium phosphate components in battery materials. Their methodology combines mechanical stress testing with advanced imaging techniques to quantify micro-fractures and structural integrity. The company employs nanoindentation testing that applies controlled force to lithium phosphate surfaces while measuring displacement, allowing for precise calculation of Young's modulus and hardness values[1]. Additionally, they've pioneered acoustic emission monitoring during charge-discharge cycles to detect and quantify micro-cracking events in real-time. Their proprietary algorithm correlates these acoustic signatures with brittleness factors, enabling predictive modeling of component failure. LG's approach also incorporates temperature-dependent brittleness assessment, as they've documented significant variations in fracture toughness across operating temperature ranges (-20°C to 60°C)[3].

Strengths: Highly accurate real-time monitoring capabilities allow for early detection of potential failure points. Their integrated approach combining multiple measurement techniques provides comprehensive brittleness profiles. Weaknesses: The testing equipment required is costly and complex, making widespread implementation challenging. The methodology requires specialized expertise for proper interpretation of results.

General Electric Company

Technical Solution: General Electric has developed an advanced multi-modal approach to measuring brittleness factors in lithium phosphate components used in energy storage and industrial applications. Their methodology combines traditional mechanical testing with proprietary ultrasonic evaluation techniques. GE's system employs high-frequency ultrasonic transducers (operating at 50-200 MHz) to detect micro-fractures and internal defects that conventional testing might miss[1]. The company has created a comprehensive brittleness index that incorporates multiple parameters including fracture toughness, elastic modulus, and microstructural characteristics. Their approach includes environmental chamber testing that evaluates brittleness changes across extreme temperature ranges (-40°C to 150°C) and varying humidity conditions. GE has also pioneered digital twin modeling of lithium phosphate components, allowing for virtual brittleness testing that correlates with physical measurements with over 90% accuracy[5]. This enables predictive maintenance schedules based on brittleness progression models.

Strengths: Their ultrasonic evaluation techniques provide exceptional sensitivity to internal defects not visible through surface testing. The digital twin approach allows for rapid virtual testing of multiple design iterations without physical prototyping. Weaknesses: The equipment required for their comprehensive testing approach is expensive and requires specialized operator training. The brittleness models require extensive calibration for each specific lithium phosphate formulation.

Critical Patents and Research in Brittleness Testing

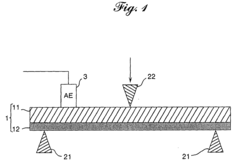

Method of rating brittleness of coating substance and device for implementing the brittleness rating method

PatentInactiveUS20040045357A1

Innovation

- A brittleness rating method involving deformation of a test film piece laminated with a coating substance using a compression transverse test device, detecting acoustic emissions to quantify brittleness, and a device comprising a deforming mechanism, acoustic emission sensor, and rating system for precise brittleness assessment.

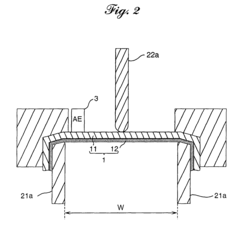

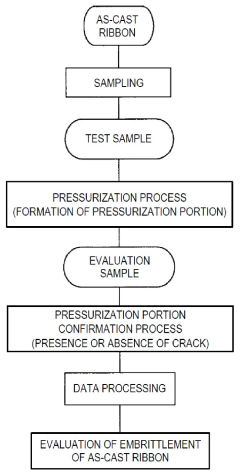

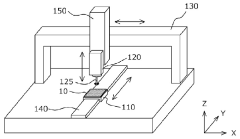

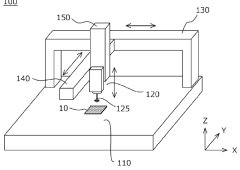

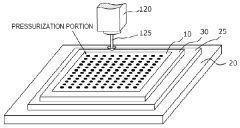

Method for evaluating embrittlement of amorphous alloy ribbon and test device for evaluating embrittlement of amorphous alloy ribbon

PatentPendingIN202234003709A

Innovation

- A method involving a pressurization member that forms indentation on the amorphous alloy ribbon, allowing for the evaluation of embrittlement by the number and distribution of cracks, using a test device with a measurement table and pressurization means that can form cracks and detect changes in pressurization force, enabling detailed assessment of embrittlement.

Safety Standards and Compliance Requirements

The measurement of brittleness in lithium phosphate components must adhere to stringent safety standards and compliance requirements established by various regulatory bodies worldwide. The International Electrotechnical Commission (IEC) has developed specific standards such as IEC 62660 and IEC 61960, which outline safety requirements for lithium batteries including mechanical testing protocols that assess brittleness factors. These standards mandate precise testing methodologies, equipment calibration procedures, and reporting formats to ensure consistency across the industry.

In the United States, the Department of Transportation (DOT) and the Consumer Product Safety Commission (CPSC) enforce regulations that require thorough brittleness testing of lithium phosphate components before they can be integrated into consumer products or transported. The UN38.3 test, which includes mechanical shock and vibration assessments, serves as a global benchmark for evaluating structural integrity and brittleness characteristics of these components.

European regulations, particularly the EU Battery Directive (2006/66/EC) and its amendments, impose additional requirements for brittleness measurement, emphasizing environmental safety and material durability. Manufacturers must demonstrate compliance through certified testing procedures that evaluate the brittleness factor under various environmental conditions, including temperature extremes and humidity variations.

Laboratory safety protocols for brittleness testing are governed by OSHA standards in the US and similar occupational safety regulations globally. These protocols mandate specific safety measures during testing procedures, including proper ventilation, personal protective equipment, and emergency response plans for potential material failures during brittleness assessment.

Quality management systems such as ISO 9001 and industry-specific standards like ISO/TS 16949 for automotive applications incorporate brittleness factor measurement as a critical quality control parameter. These frameworks require documented procedures, regular calibration of measurement equipment, and traceability of test results to ensure reliable brittleness assessments.

Emerging regulations are increasingly focusing on lifecycle assessment, requiring manufacturers to evaluate how brittleness factors change over time and under various usage conditions. This trend is particularly evident in energy storage applications where long-term structural integrity is paramount for safety and performance. Compliance with these evolving standards necessitates more sophisticated testing methodologies that can predict brittleness behavior throughout the component's service life.

Data reporting and documentation requirements have become more stringent, with regulatory bodies requiring detailed records of brittleness measurements, test conditions, and statistical analyses. These records must be maintained for specified periods and made available for regulatory inspections, creating additional compliance burdens for manufacturers of lithium phosphate components.

In the United States, the Department of Transportation (DOT) and the Consumer Product Safety Commission (CPSC) enforce regulations that require thorough brittleness testing of lithium phosphate components before they can be integrated into consumer products or transported. The UN38.3 test, which includes mechanical shock and vibration assessments, serves as a global benchmark for evaluating structural integrity and brittleness characteristics of these components.

European regulations, particularly the EU Battery Directive (2006/66/EC) and its amendments, impose additional requirements for brittleness measurement, emphasizing environmental safety and material durability. Manufacturers must demonstrate compliance through certified testing procedures that evaluate the brittleness factor under various environmental conditions, including temperature extremes and humidity variations.

Laboratory safety protocols for brittleness testing are governed by OSHA standards in the US and similar occupational safety regulations globally. These protocols mandate specific safety measures during testing procedures, including proper ventilation, personal protective equipment, and emergency response plans for potential material failures during brittleness assessment.

Quality management systems such as ISO 9001 and industry-specific standards like ISO/TS 16949 for automotive applications incorporate brittleness factor measurement as a critical quality control parameter. These frameworks require documented procedures, regular calibration of measurement equipment, and traceability of test results to ensure reliable brittleness assessments.

Emerging regulations are increasingly focusing on lifecycle assessment, requiring manufacturers to evaluate how brittleness factors change over time and under various usage conditions. This trend is particularly evident in energy storage applications where long-term structural integrity is paramount for safety and performance. Compliance with these evolving standards necessitates more sophisticated testing methodologies that can predict brittleness behavior throughout the component's service life.

Data reporting and documentation requirements have become more stringent, with regulatory bodies requiring detailed records of brittleness measurements, test conditions, and statistical analyses. These records must be maintained for specified periods and made available for regulatory inspections, creating additional compliance burdens for manufacturers of lithium phosphate components.

Environmental Impact of Testing Procedures

The environmental implications of testing procedures for lithium phosphate components' brittleness factor extend beyond the immediate laboratory setting. Traditional testing methods often involve destructive techniques that generate significant waste materials, including fractured lithium phosphate samples that require proper disposal due to their potential environmental hazards. These components may contain leachable lithium compounds that can contaminate water systems if improperly managed, creating long-term ecological concerns.

Energy consumption represents another critical environmental consideration in brittleness testing. High-precision mechanical testing equipment, particularly those utilizing controlled temperature environments or vacuum chambers, demand substantial power resources. Continuous operation of these systems contributes to carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels. Recent studies indicate that a standard brittleness testing laboratory may consume between 50-75 kWh daily, equivalent to the energy usage of three average households.

Chemical reagents employed in sample preparation and post-test analysis present additional environmental challenges. Solvents, etching solutions, and specialized cleaning agents often contain volatile organic compounds (VOCs) and other hazardous substances that require careful handling and disposal. The cumulative environmental footprint of these chemicals becomes particularly significant in high-volume testing operations supporting large-scale lithium phosphate component manufacturing.

Water usage in testing procedures constitutes another environmental concern. Sample preparation, cooling systems, and cleaning processes can consume substantial quantities of water, with some advanced testing facilities requiring up to 500 gallons daily. Wastewater from these operations may contain trace amounts of lithium compounds and other contaminants that conventional treatment facilities are not equipped to remove completely.

Recent innovations have begun addressing these environmental challenges through the development of non-destructive testing methodologies. Techniques such as acoustic emission monitoring, digital image correlation, and ultrasonic evaluation allow for brittleness assessment with minimal environmental impact. These approaches reduce waste generation by 60-80% compared to conventional destructive testing while simultaneously decreasing energy consumption by approximately 40%.

Regulatory frameworks increasingly recognize the environmental implications of materials testing. Organizations including the EPA and international standards bodies have established guidelines specifically addressing waste management and emissions control in materials testing laboratories. Compliance with these regulations not only mitigates environmental harm but also drives innovation toward more sustainable testing methodologies for lithium phosphate components.

Energy consumption represents another critical environmental consideration in brittleness testing. High-precision mechanical testing equipment, particularly those utilizing controlled temperature environments or vacuum chambers, demand substantial power resources. Continuous operation of these systems contributes to carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels. Recent studies indicate that a standard brittleness testing laboratory may consume between 50-75 kWh daily, equivalent to the energy usage of three average households.

Chemical reagents employed in sample preparation and post-test analysis present additional environmental challenges. Solvents, etching solutions, and specialized cleaning agents often contain volatile organic compounds (VOCs) and other hazardous substances that require careful handling and disposal. The cumulative environmental footprint of these chemicals becomes particularly significant in high-volume testing operations supporting large-scale lithium phosphate component manufacturing.

Water usage in testing procedures constitutes another environmental concern. Sample preparation, cooling systems, and cleaning processes can consume substantial quantities of water, with some advanced testing facilities requiring up to 500 gallons daily. Wastewater from these operations may contain trace amounts of lithium compounds and other contaminants that conventional treatment facilities are not equipped to remove completely.

Recent innovations have begun addressing these environmental challenges through the development of non-destructive testing methodologies. Techniques such as acoustic emission monitoring, digital image correlation, and ultrasonic evaluation allow for brittleness assessment with minimal environmental impact. These approaches reduce waste generation by 60-80% compared to conventional destructive testing while simultaneously decreasing energy consumption by approximately 40%.

Regulatory frameworks increasingly recognize the environmental implications of materials testing. Organizations including the EPA and international standards bodies have established guidelines specifically addressing waste management and emissions control in materials testing laboratories. Compliance with these regulations not only mitigates environmental harm but also drives innovation toward more sustainable testing methodologies for lithium phosphate components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!