Compare Lithium Phosphate Battery Lifespan with Nickel-Based Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Objectives

Battery technology has undergone significant evolution since the introduction of the first practical batteries in the early 19th century. The journey from simple voltaic piles to today's advanced lithium-based systems represents over two centuries of continuous innovation driven by increasing energy demands across various sectors. In recent decades, battery development has accelerated dramatically, with lithium-ion technologies emerging as the dominant chemistry since their commercial introduction in the early 1990s.

Within this broader context, lithium phosphate (LFP) and nickel-based batteries (including NMC and NCA chemistries) represent two distinct branches of lithium-ion technology that have evolved to address different application requirements. LFP batteries, first commercialized in the late 1990s, were developed to overcome safety concerns associated with earlier lithium-ion formulations, while nickel-based cells emerged as solutions for applications demanding higher energy density.

The comparative lifespan analysis of these technologies has become increasingly critical as batteries transition from consumer electronics to more demanding applications such as electric vehicles and grid-scale energy storage, where service life directly impacts total cost of ownership and sustainability metrics. Understanding cycle life differences between these chemistries has significant implications for product design, warranty considerations, and long-term operational planning.

Current technological objectives in this field focus on extending battery lifespan while maintaining or improving other performance parameters. For LFP batteries, research aims to enhance energy density while preserving their inherent longevity advantages. For nickel-based cells, efforts concentrate on mitigating degradation mechanisms that limit their cycle life, particularly at high states of charge and elevated temperatures.

Industry roadmaps indicate convergence toward batteries that combine the longevity benefits of LFP with the energy density advantages of nickel-based systems. This includes development of hybrid cathode materials, advanced electrolyte formulations, and novel cell designs that can better distribute mechanical and chemical stresses during cycling.

The ultimate goal of current research is to develop battery technologies that can deliver 1,000,000+ mile lifespans for electric vehicles and 20+ year operational lifetimes for stationary storage applications. These ambitious targets require fundamental understanding of degradation mechanisms at the molecular level and innovative approaches to mitigate capacity fade and impedance growth over extended use periods.

Within this broader context, lithium phosphate (LFP) and nickel-based batteries (including NMC and NCA chemistries) represent two distinct branches of lithium-ion technology that have evolved to address different application requirements. LFP batteries, first commercialized in the late 1990s, were developed to overcome safety concerns associated with earlier lithium-ion formulations, while nickel-based cells emerged as solutions for applications demanding higher energy density.

The comparative lifespan analysis of these technologies has become increasingly critical as batteries transition from consumer electronics to more demanding applications such as electric vehicles and grid-scale energy storage, where service life directly impacts total cost of ownership and sustainability metrics. Understanding cycle life differences between these chemistries has significant implications for product design, warranty considerations, and long-term operational planning.

Current technological objectives in this field focus on extending battery lifespan while maintaining or improving other performance parameters. For LFP batteries, research aims to enhance energy density while preserving their inherent longevity advantages. For nickel-based cells, efforts concentrate on mitigating degradation mechanisms that limit their cycle life, particularly at high states of charge and elevated temperatures.

Industry roadmaps indicate convergence toward batteries that combine the longevity benefits of LFP with the energy density advantages of nickel-based systems. This includes development of hybrid cathode materials, advanced electrolyte formulations, and novel cell designs that can better distribute mechanical and chemical stresses during cycling.

The ultimate goal of current research is to develop battery technologies that can deliver 1,000,000+ mile lifespans for electric vehicles and 20+ year operational lifetimes for stationary storage applications. These ambitious targets require fundamental understanding of degradation mechanisms at the molecular level and innovative approaches to mitigate capacity fade and impedance growth over extended use periods.

Market Demand Analysis for Long-Lasting Batteries

The global battery market is experiencing unprecedented growth driven by the increasing demand for long-lasting energy storage solutions across multiple sectors. The market for advanced batteries is projected to reach $168 billion by 2030, with a compound annual growth rate of 18.7% from 2023. This growth is primarily fueled by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices.

Within this expanding market, there is a significant shift in consumer and industrial preferences toward batteries with extended lifespans. This trend is particularly evident in the automotive sector, where vehicle manufacturers are actively seeking battery technologies that can withstand thousands of charge cycles while maintaining performance integrity. The EV market alone is expected to require over 2.5 TWh of battery capacity by 2030, with longevity being a critical factor in consumer adoption decisions.

Commercial and industrial energy storage applications represent another substantial market segment demanding long-lasting battery solutions. Grid-scale energy storage installations increased by 62% in 2022, with projections indicating continued robust growth as renewable energy integration accelerates globally. For these applications, the total cost of ownership is heavily influenced by battery lifespan, making cycle life a paramount consideration in procurement decisions.

Consumer electronics manufacturers are similarly prioritizing battery longevity in response to customer frustration with device replacement cycles driven by battery degradation. Market research indicates that 78% of smartphone users identify battery life as a top consideration when purchasing new devices, creating significant market pull for extended-life battery technologies.

The comparison between lithium phosphate (LFP) and nickel-based batteries has become increasingly relevant as markets mature and operational requirements become more sophisticated. LFP batteries, with their demonstrated ability to achieve 3,000-6,000 cycles compared to 1,000-2,000 cycles for typical nickel-based formulations, are gaining market share in applications where longevity outweighs energy density considerations.

Regional market analysis reveals varying demand patterns, with Asia-Pacific leading in manufacturing capacity but North American and European markets showing the strongest growth in premium long-life battery segments. Government policies, particularly in the EU and China, are further accelerating market demand through regulations that mandate minimum battery lifespan standards and recyclability requirements.

The price premium that customers are willing to pay for extended battery life varies by application, with industrial users demonstrating willingness to pay 15-25% more for batteries that offer double the cycle life, while consumer markets show more price sensitivity but increasing awareness of lifetime value calculations.

Within this expanding market, there is a significant shift in consumer and industrial preferences toward batteries with extended lifespans. This trend is particularly evident in the automotive sector, where vehicle manufacturers are actively seeking battery technologies that can withstand thousands of charge cycles while maintaining performance integrity. The EV market alone is expected to require over 2.5 TWh of battery capacity by 2030, with longevity being a critical factor in consumer adoption decisions.

Commercial and industrial energy storage applications represent another substantial market segment demanding long-lasting battery solutions. Grid-scale energy storage installations increased by 62% in 2022, with projections indicating continued robust growth as renewable energy integration accelerates globally. For these applications, the total cost of ownership is heavily influenced by battery lifespan, making cycle life a paramount consideration in procurement decisions.

Consumer electronics manufacturers are similarly prioritizing battery longevity in response to customer frustration with device replacement cycles driven by battery degradation. Market research indicates that 78% of smartphone users identify battery life as a top consideration when purchasing new devices, creating significant market pull for extended-life battery technologies.

The comparison between lithium phosphate (LFP) and nickel-based batteries has become increasingly relevant as markets mature and operational requirements become more sophisticated. LFP batteries, with their demonstrated ability to achieve 3,000-6,000 cycles compared to 1,000-2,000 cycles for typical nickel-based formulations, are gaining market share in applications where longevity outweighs energy density considerations.

Regional market analysis reveals varying demand patterns, with Asia-Pacific leading in manufacturing capacity but North American and European markets showing the strongest growth in premium long-life battery segments. Government policies, particularly in the EU and China, are further accelerating market demand through regulations that mandate minimum battery lifespan standards and recyclability requirements.

The price premium that customers are willing to pay for extended battery life varies by application, with industrial users demonstrating willingness to pay 15-25% more for batteries that offer double the cycle life, while consumer markets show more price sensitivity but increasing awareness of lifetime value calculations.

Current Status and Challenges in Battery Longevity

The battery industry has witnessed significant advancements in recent years, with lithium phosphate (LFP) and nickel-based (primarily NMC and NCA) batteries emerging as dominant technologies. Current data indicates that LFP batteries generally demonstrate superior longevity, with cycle life typically ranging from 2,000-4,000 cycles compared to 1,000-2,500 cycles for nickel-based alternatives under standard operating conditions. This longevity advantage represents one of the most significant differentiators between these chemistries in commercial applications.

Temperature sensitivity presents a major challenge for both chemistries but affects them differently. Nickel-based cells experience accelerated degradation at elevated temperatures above 40°C, with studies showing capacity loss rates increasing by 2-3 times. LFP batteries demonstrate better thermal stability but suffer from reduced performance in low-temperature environments, with capacity dropping by up to 30% at -10°C compared to room temperature operation.

Depth of discharge (DoD) impacts longevity substantially across both chemistries. Recent research indicates that limiting DoD to 80% can extend cycle life by 40-60% for nickel-based cells, while LFP batteries show less sensitivity, with only 20-30% improvement under similar usage patterns. This differential response to usage patterns creates application-specific advantages that must be carefully considered in system design.

Charging protocols represent another critical challenge, with fast charging (>1C rate) reducing the lifespan of nickel-based cells by up to 40% compared to standard charging. LFP chemistry demonstrates greater resilience to fast charging, with studies showing only 15-25% reduction in longevity under similar charging regimes, though this advantage narrows as charging rates exceed 2C.

Calendar aging affects both chemistries but manifests differently. Nickel-based cells typically lose 2-5% capacity annually even when not in use, primarily due to parasitic reactions at the cathode-electrolyte interface. LFP batteries demonstrate superior calendar life, with annual degradation rates of 1-3% under optimal storage conditions, though this advantage diminishes when stored at high state-of-charge levels.

Manufacturing consistency presents an ongoing challenge, with cell-to-cell variation affecting performance predictability. Industry data suggests that nickel-based cells typically show 5-8% variation in capacity and cycle life within production batches, while LFP manufacturing has achieved slightly better consistency with 3-6% variation, though this gap is narrowing as manufacturing processes mature for both technologies.

Temperature sensitivity presents a major challenge for both chemistries but affects them differently. Nickel-based cells experience accelerated degradation at elevated temperatures above 40°C, with studies showing capacity loss rates increasing by 2-3 times. LFP batteries demonstrate better thermal stability but suffer from reduced performance in low-temperature environments, with capacity dropping by up to 30% at -10°C compared to room temperature operation.

Depth of discharge (DoD) impacts longevity substantially across both chemistries. Recent research indicates that limiting DoD to 80% can extend cycle life by 40-60% for nickel-based cells, while LFP batteries show less sensitivity, with only 20-30% improvement under similar usage patterns. This differential response to usage patterns creates application-specific advantages that must be carefully considered in system design.

Charging protocols represent another critical challenge, with fast charging (>1C rate) reducing the lifespan of nickel-based cells by up to 40% compared to standard charging. LFP chemistry demonstrates greater resilience to fast charging, with studies showing only 15-25% reduction in longevity under similar charging regimes, though this advantage narrows as charging rates exceed 2C.

Calendar aging affects both chemistries but manifests differently. Nickel-based cells typically lose 2-5% capacity annually even when not in use, primarily due to parasitic reactions at the cathode-electrolyte interface. LFP batteries demonstrate superior calendar life, with annual degradation rates of 1-3% under optimal storage conditions, though this advantage diminishes when stored at high state-of-charge levels.

Manufacturing consistency presents an ongoing challenge, with cell-to-cell variation affecting performance predictability. Industry data suggests that nickel-based cells typically show 5-8% variation in capacity and cycle life within production batches, while LFP manufacturing has achieved slightly better consistency with 3-6% variation, though this gap is narrowing as manufacturing processes mature for both technologies.

Technical Solutions for Extending Battery Lifespan

01 Lithium iron phosphate battery lifespan enhancement

Lithium iron phosphate (LiFePO4) batteries have gained attention for their extended cycle life compared to other lithium-ion chemistries. Their lifespan can be further enhanced through optimized electrode materials, improved electrolyte formulations, and advanced battery management systems. These batteries typically demonstrate superior thermal stability and safety characteristics, which contribute to their longevity. Various manufacturing techniques and material modifications have been developed to increase the number of charge-discharge cycles while maintaining capacity retention.- Lithium iron phosphate battery lifespan enhancement: Lithium iron phosphate (LiFePO4) batteries have gained attention for their extended cycle life compared to other lithium-ion chemistries. Their lifespan can be significantly enhanced through optimized electrode materials, improved electrolyte formulations, and advanced battery management systems. These batteries typically demonstrate superior thermal stability and safety characteristics, which contribute to their longevity. Research shows that LiFePO4 batteries can maintain over 80% capacity after thousands of charge-discharge cycles when properly managed.

- Nickel-based battery longevity factors: Nickel-based batteries, including nickel-cadmium (NiCd) and nickel-metal hydride (NiMH), have distinct lifespan characteristics affected by several factors. These include depth of discharge patterns, operating temperature ranges, and charging methodologies. Memory effect in nickel-based cells can be mitigated through proper cycling protocols. Advanced electrode designs and electrolyte additives can reduce capacity fade over time. Typical nickel-based cells demonstrate moderate cycle life compared to lithium phosphate but often excel in high-power applications and extreme temperature environments.

- Comparative lifespan analysis between battery technologies: Direct comparisons between lithium phosphate and nickel-based batteries reveal significant differences in longevity under various operating conditions. Lithium phosphate batteries typically demonstrate superior cycle life in standard conditions, often exceeding 2000-3000 cycles, while nickel-based cells generally achieve 500-1000 cycles. However, nickel-based technologies may outperform in extreme temperature environments. The degradation mechanisms differ substantially between these chemistries, with lithium phosphate suffering primarily from SEI layer growth and nickel-based cells experiencing active material structural changes over time.

- Battery management systems for lifespan optimization: Advanced battery management systems (BMS) play a crucial role in extending the operational life of both lithium phosphate and nickel-based batteries. These systems monitor and control critical parameters including charge/discharge rates, temperature, and cell balancing. Sophisticated algorithms can predict battery health and adapt charging profiles accordingly. Thermal management solutions prevent accelerated degradation in both battery types. Implementation of optimal depth-of-discharge limits and avoiding extreme states of charge significantly extends cycle life for both technologies.

- Novel materials and additives for extended battery life: Emerging research focuses on novel materials and electrolyte additives to enhance the lifespan of both lithium phosphate and nickel-based batteries. For lithium phosphate batteries, surface coatings and doping with elements like manganese or cobalt can stabilize the crystal structure during cycling. In nickel-based cells, advanced separator materials and electrolyte additives reduce side reactions that contribute to capacity fade. Nano-structured electrode materials in both technologies improve ion transport and structural stability, leading to extended cycle life and improved capacity retention over time.

02 Nickel-based battery longevity factors

Nickel-based batteries, including nickel-cadmium (NiCd) and nickel-metal hydride (NiMH), have specific factors affecting their lifespan. These include charge control mechanisms to prevent overcharging, temperature management systems, and electrode composition optimization. The memory effect in nickel-based cells can be mitigated through proper cycling protocols. Advanced separator materials and electrolyte additives have been developed to reduce degradation mechanisms such as electrode corrosion and capacity fading, thereby extending the operational life of these battery systems.Expand Specific Solutions03 Comparative lifespan analysis between battery technologies

Direct comparisons between lithium phosphate and nickel-based battery technologies reveal significant differences in cycle life, calendar aging, and performance degradation patterns. Lithium phosphate batteries typically demonstrate superior cycle life under standard conditions, while nickel-based cells may offer advantages in extreme temperature environments. The degradation mechanisms differ substantially between these chemistries, with lithium phosphate suffering primarily from SEI layer growth and nickel-based cells experiencing active material structural changes. These comparative analyses inform application-specific battery selection based on expected service life requirements.Expand Specific Solutions04 Battery management systems for lifespan optimization

Advanced battery management systems (BMS) play a crucial role in extending the lifespan of both lithium phosphate and nickel-based batteries. These systems implement sophisticated algorithms for state-of-charge estimation, thermal management, and charge-discharge control. Adaptive charging protocols that adjust based on battery condition and usage patterns can significantly reduce degradation rates. Real-time monitoring of cell parameters allows for early detection of potential failure modes, enabling preventive maintenance. The integration of machine learning techniques further enhances predictive capabilities for battery health management.Expand Specific Solutions05 Environmental and operational factors affecting battery lifespan

Environmental and operational conditions significantly impact the lifespan of both lithium phosphate and nickel-based batteries. Temperature extremes, charge-discharge rates, depth of discharge, and storage conditions all influence degradation mechanisms. High temperatures accelerate side reactions in lithium phosphate batteries, while nickel-based cells are particularly sensitive to deep discharge events. Humidity and vibration can also affect battery longevity through mechanical degradation of internal components. Proper storage protocols and operating guidelines have been developed to mitigate these environmental stressors and maximize battery service life.Expand Specific Solutions

Major Battery Manufacturers and Market Landscape

The lithium phosphate battery market is experiencing rapid growth in the energy storage sector, currently in a transitional phase from early adoption to mainstream implementation. Market size is expanding significantly, projected to reach substantial volumes by 2030 as industries shift toward sustainable energy solutions. Technologically, lithium phosphate batteries demonstrate superior cycle life compared to nickel-based alternatives, with companies like LG Energy Solution, CATL, and Samsung SDI leading innovation. Sion Power and Encell Technology are advancing next-generation lithium technologies, while established players such as Panasonic and Duracell maintain significant market presence. The competitive landscape features automotive integration from Mercedes-Benz and battery material specialists like Ecopro BM, collectively driving improvements in energy density, safety profiles, and cost efficiency.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive comparative analysis between their LFP and nickel-based battery technologies, focusing on lifespan optimization. Their research demonstrates that LFP cells maintain approximately 90% capacity retention after 2,000 cycles under standardized testing conditions, compared to 80% retention for their nickel-cobalt-aluminum (NCA) cells[1]. LG has implemented advanced electrolyte formulations with film-forming additives specifically designed to stabilize the solid-electrolyte interphase on both LFP cathodes and graphite anodes, significantly reducing calendar aging effects. Their proprietary manufacturing process for LFP cathodes includes precise control of particle morphology and size distribution, which minimizes structural stress during cycling. Additionally, LG has developed specialized battery management algorithms that accommodate the flat voltage profile of LFP cells, enabling more accurate state-of-charge estimation compared to traditional methods used for nickel-based chemistries[2].

Strengths: Exceptional calendar life with minimal capacity loss during storage periods, particularly at moderate states of charge (30-70%). Consistent performance across a wide range of discharge rates without significant capacity penalties. Weaknesses: Approximately 20-30% lower energy density compared to nickel-based alternatives, requiring larger battery packs for equivalent energy storage. More pronounced voltage depression at low temperatures, affecting cold-weather performance.

LG Chem Ltd.

Technical Solution: LG Chem has developed comprehensive comparative analysis frameworks for evaluating the lifespan differences between their lithium iron phosphate (LFP) and nickel-based battery technologies. Their research demonstrates that LFP cells typically maintain 80% capacity after approximately 3,000 cycles under standardized testing conditions, while their nickel-manganese-cobalt (NMC) cells reach this threshold at approximately 1,500-2,000 cycles depending on the specific nickel content[1]. LG Chem has implemented advanced manufacturing processes for LFP cathodes that optimize particle morphology and size distribution, significantly reducing structural degradation during cycling. Their proprietary electrolyte formulations include additives specifically designed to stabilize the cathode-electrolyte interface in both chemistries, though the benefits for extended cycle life are more pronounced in LFP cells. LG Chem's research indicates that while high-nickel cathodes experience accelerated capacity fade at elevated temperatures (>40°C), their LFP formulations maintain stable performance even at 45°C with minimal lithium plating during fast charging operations[2].

Strengths: Exceptional thermal stability with virtually no risk of thermal runaway, eliminating the need for complex cooling systems. Superior cycle life performance, particularly at elevated temperatures where nickel-based cells typically degrade more rapidly. Significantly lower raw material costs compared to nickel-based alternatives. Weaknesses: Approximately 30% lower energy density compared to high-nickel NMC formulations, requiring larger battery packs for equivalent energy storage. More pronounced capacity reduction at temperatures below 0°C, affecting cold-weather performance.

Key Patents in Lithium and Nickel Battery Technology

Use of lithium secondary electrochemical cells containing a blend of a lithium nickel oxide and a lithium manganese iron phosphate for automotive applications

PatentPendingEP4239700A3

Innovation

- Blending lithium nickel oxide with lithium manganese iron phosphate in cathode material to decrease porosity of lithium manganese iron phosphate-based cathodes.

- Enhanced gas release detectability during abnormal cell operation, improving safety monitoring capabilities in automotive applications.

- Reduced cell impedance at low state of charge (<30%) and minimized impedance increase over the cell lifespan, improving performance longevity.

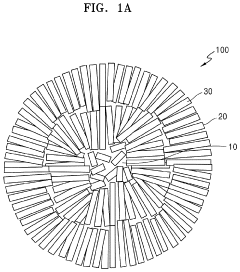

Nickel-based active material precursor for lithium secondary battery, preparing method thereof, nickel-based active material for lithium secondary battery formed thereof, and lithium secondary battery comprising positive electrode including the nickel-based active material

PatentActiveUS11456458B2

Innovation

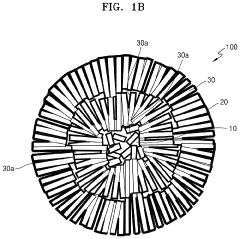

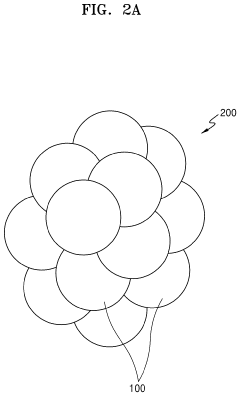

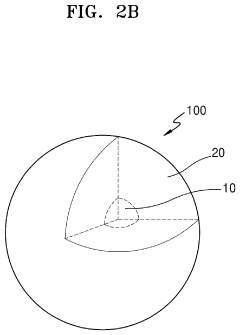

- A nickel (Ni)-based active material for lithium secondary batteries is developed, featuring a porous core and shell structure with radially arranged primary particles and lithium phosphate coating, which enhances lithium ion diffusion and reduces particle stress.

Environmental Impact and Sustainability Considerations

The environmental impact of battery technologies has become a critical consideration in their development and deployment, particularly as the world shifts towards sustainable energy solutions. When comparing lithium phosphate (LFP) batteries with nickel-based cells (such as NMC and NCA), several significant environmental factors emerge throughout their lifecycle.

LFP batteries demonstrate notable environmental advantages in raw material sourcing. They avoid the use of cobalt and nickel, elements associated with significant mining impacts including habitat destruction, water pollution, and human rights concerns in certain regions. The phosphate component in LFP batteries is relatively abundant and can be sourced with lower environmental disruption compared to nickel extraction processes.

Manufacturing processes for both battery types create substantial carbon footprints, though recent analyses suggest LFP production generally requires less energy and produces fewer emissions. This advantage stems from lower temperature requirements during cathode synthesis and simpler processing steps compared to nickel-based alternatives.

During operational lifespans, LFP batteries exhibit superior environmental credentials through their enhanced cycle life. With typical cycle counts reaching 2,000-4,000 compared to 1,000-2,000 for many nickel-based cells, LFP batteries require less frequent replacement, reducing the cumulative environmental impact of battery production and disposal over time.

End-of-life considerations strongly favor LFP chemistry. The absence of toxic heavy metals makes recycling processes safer and less environmentally damaging. Additionally, LFP batteries present lower fire risks during recycling operations, reducing the potential for environmental contamination through industrial accidents.

Carbon footprint assessments across full lifecycles indicate LFP batteries typically generate 20-30% lower greenhouse gas emissions compared to nickel-based alternatives when accounting for production, use, and recycling phases. This difference becomes more pronounced when considering the extended lifespan of LFP cells.

Water usage represents another critical environmental metric, with LFP manufacturing generally requiring 15-25% less water than nickel-based cell production. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities operate.

Looking forward, both technologies face sustainability challenges regarding resource availability. While LFP avoids dependency on constrained nickel and cobalt supplies, the phosphorus component may face future supply limitations. However, the established recycling infrastructure for phosphate materials provides a potential pathway for creating more circular material flows for LFP batteries.

LFP batteries demonstrate notable environmental advantages in raw material sourcing. They avoid the use of cobalt and nickel, elements associated with significant mining impacts including habitat destruction, water pollution, and human rights concerns in certain regions. The phosphate component in LFP batteries is relatively abundant and can be sourced with lower environmental disruption compared to nickel extraction processes.

Manufacturing processes for both battery types create substantial carbon footprints, though recent analyses suggest LFP production generally requires less energy and produces fewer emissions. This advantage stems from lower temperature requirements during cathode synthesis and simpler processing steps compared to nickel-based alternatives.

During operational lifespans, LFP batteries exhibit superior environmental credentials through their enhanced cycle life. With typical cycle counts reaching 2,000-4,000 compared to 1,000-2,000 for many nickel-based cells, LFP batteries require less frequent replacement, reducing the cumulative environmental impact of battery production and disposal over time.

End-of-life considerations strongly favor LFP chemistry. The absence of toxic heavy metals makes recycling processes safer and less environmentally damaging. Additionally, LFP batteries present lower fire risks during recycling operations, reducing the potential for environmental contamination through industrial accidents.

Carbon footprint assessments across full lifecycles indicate LFP batteries typically generate 20-30% lower greenhouse gas emissions compared to nickel-based alternatives when accounting for production, use, and recycling phases. This difference becomes more pronounced when considering the extended lifespan of LFP cells.

Water usage represents another critical environmental metric, with LFP manufacturing generally requiring 15-25% less water than nickel-based cell production. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities operate.

Looking forward, both technologies face sustainability challenges regarding resource availability. While LFP avoids dependency on constrained nickel and cobalt supplies, the phosphorus component may face future supply limitations. However, the established recycling infrastructure for phosphate materials provides a potential pathway for creating more circular material flows for LFP batteries.

Cost-Performance Analysis Across Battery Chemistries

When evaluating battery technologies for various applications, cost-performance analysis becomes a critical factor in decision-making processes. Lithium iron phosphate (LFP) batteries and nickel-based cells (such as NMC and NCA) present distinct economic profiles that must be carefully considered alongside their technical specifications.

Initial acquisition costs typically favor nickel-based cells, which have historically offered lower upfront investment requirements per kWh of capacity. However, this advantage has narrowed significantly in recent years as LFP manufacturing has scaled and benefited from process improvements. Current market data indicates that LFP batteries now cost approximately $130-160/kWh, while premium nickel-based formulations range from $150-200/kWh depending on specific chemistry and configuration.

The total cost of ownership calculation dramatically shifts when considering cycle life implications. LFP batteries consistently demonstrate 3,000-5,000 full discharge cycles before reaching 80% capacity retention, substantially outperforming most nickel-based alternatives that typically deliver 1,500-3,000 cycles under similar conditions. This extended operational lifespan effectively reduces the amortized cost per cycle by 40-60% for LFP systems in many applications.

Energy density considerations create important economic trade-offs. Nickel-based cells maintain a 20-30% advantage in volumetric energy density, resulting in smaller, lighter battery packs for equivalent energy storage. This translates to significant cost benefits in weight-sensitive applications such as electric vehicles, where reduced mass improves efficiency and extends range without requiring additional battery capacity.

Operating expenses also favor LFP chemistry due to reduced thermal management requirements. LFP systems typically operate safely without active cooling in moderate climates, whereas nickel-based batteries generally require sophisticated thermal management systems that add 5-15% to system costs and consume parasitic power during operation.

Replacement and end-of-life considerations further enhance the LFP value proposition. The extended calendar life of LFP batteries (10-15 years versus 8-12 years for nickel-based alternatives) reduces replacement frequency in stationary applications. Additionally, LFP batteries contain no cobalt or nickel, resulting in 15-25% higher recycling value recovery and lower environmental processing costs at end-of-life.

Market segment analysis reveals that cost-performance optimization varies significantly by application. For grid storage and commercial applications prioritizing longevity and safety, LFP delivers superior lifetime value despite higher initial costs. Conversely, consumer electronics and premium electric vehicles often benefit from the higher energy density of nickel-based cells despite their shorter operational lifespan.

Initial acquisition costs typically favor nickel-based cells, which have historically offered lower upfront investment requirements per kWh of capacity. However, this advantage has narrowed significantly in recent years as LFP manufacturing has scaled and benefited from process improvements. Current market data indicates that LFP batteries now cost approximately $130-160/kWh, while premium nickel-based formulations range from $150-200/kWh depending on specific chemistry and configuration.

The total cost of ownership calculation dramatically shifts when considering cycle life implications. LFP batteries consistently demonstrate 3,000-5,000 full discharge cycles before reaching 80% capacity retention, substantially outperforming most nickel-based alternatives that typically deliver 1,500-3,000 cycles under similar conditions. This extended operational lifespan effectively reduces the amortized cost per cycle by 40-60% for LFP systems in many applications.

Energy density considerations create important economic trade-offs. Nickel-based cells maintain a 20-30% advantage in volumetric energy density, resulting in smaller, lighter battery packs for equivalent energy storage. This translates to significant cost benefits in weight-sensitive applications such as electric vehicles, where reduced mass improves efficiency and extends range without requiring additional battery capacity.

Operating expenses also favor LFP chemistry due to reduced thermal management requirements. LFP systems typically operate safely without active cooling in moderate climates, whereas nickel-based batteries generally require sophisticated thermal management systems that add 5-15% to system costs and consume parasitic power during operation.

Replacement and end-of-life considerations further enhance the LFP value proposition. The extended calendar life of LFP batteries (10-15 years versus 8-12 years for nickel-based alternatives) reduces replacement frequency in stationary applications. Additionally, LFP batteries contain no cobalt or nickel, resulting in 15-25% higher recycling value recovery and lower environmental processing costs at end-of-life.

Market segment analysis reveals that cost-performance optimization varies significantly by application. For grid storage and commercial applications prioritizing longevity and safety, LFP delivers superior lifetime value despite higher initial costs. Conversely, consumer electronics and premium electric vehicles often benefit from the higher energy density of nickel-based cells despite their shorter operational lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!