Compare Lithium Phosphate's Eco-Impact with Lead-Acid Batteries

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Background and Objectives

Battery technology has evolved significantly over the past century, with various chemistries developed to meet growing energy storage demands. Lead-acid batteries, invented in 1859 by Gaston Planté, have dominated the market for decades due to their reliability and cost-effectiveness. However, the increasing focus on environmental sustainability has driven research toward alternative technologies with reduced ecological footprints.

Lithium iron phosphate (LiFePO4 or LFP) batteries emerged in the late 1990s as a promising alternative to traditional lead-acid batteries. This technology represents a significant advancement in the battery industry's pursuit of more environmentally friendly energy storage solutions. The development of LFP batteries was motivated by the need to address the environmental concerns associated with lead-acid batteries, including toxic material usage, resource depletion, and end-of-life disposal challenges.

The global battery market has experienced unprecedented growth, driven by the expansion of renewable energy systems, electric vehicles, and portable electronics. This growth trajectory has intensified scrutiny of battery technologies' environmental impacts across their entire lifecycle. Understanding the ecological footprint of different battery chemistries has become crucial for sustainable technology development and responsible resource management.

The primary objective of comparing lithium phosphate's ecological impact with lead-acid batteries is to provide a comprehensive assessment of their respective environmental performances throughout their lifecycles. This includes analyzing raw material extraction, manufacturing processes, operational efficiency, lifespan, and end-of-life management options. Such comparison aims to identify which technology offers superior environmental benefits while meeting performance requirements.

Another key goal is to evaluate the sustainability metrics of both technologies, including carbon emissions, energy consumption, water usage, land use impact, and potential for material recovery and recycling. This assessment will help determine which battery chemistry aligns better with global sustainability goals and circular economy principles.

Additionally, this technical research seeks to identify potential areas for improvement in both technologies to further reduce their environmental footprints. By understanding the ecological strengths and weaknesses of each battery type, researchers and manufacturers can focus innovation efforts on addressing specific environmental challenges.

The findings from this comparative analysis will inform strategic decisions for battery technology deployment across various applications, guiding industries toward more environmentally responsible energy storage solutions. This research also aims to contribute to the development of standardized methodologies for assessing battery technologies' environmental impacts, facilitating more transparent and consistent comparisons in the future.

Lithium iron phosphate (LiFePO4 or LFP) batteries emerged in the late 1990s as a promising alternative to traditional lead-acid batteries. This technology represents a significant advancement in the battery industry's pursuit of more environmentally friendly energy storage solutions. The development of LFP batteries was motivated by the need to address the environmental concerns associated with lead-acid batteries, including toxic material usage, resource depletion, and end-of-life disposal challenges.

The global battery market has experienced unprecedented growth, driven by the expansion of renewable energy systems, electric vehicles, and portable electronics. This growth trajectory has intensified scrutiny of battery technologies' environmental impacts across their entire lifecycle. Understanding the ecological footprint of different battery chemistries has become crucial for sustainable technology development and responsible resource management.

The primary objective of comparing lithium phosphate's ecological impact with lead-acid batteries is to provide a comprehensive assessment of their respective environmental performances throughout their lifecycles. This includes analyzing raw material extraction, manufacturing processes, operational efficiency, lifespan, and end-of-life management options. Such comparison aims to identify which technology offers superior environmental benefits while meeting performance requirements.

Another key goal is to evaluate the sustainability metrics of both technologies, including carbon emissions, energy consumption, water usage, land use impact, and potential for material recovery and recycling. This assessment will help determine which battery chemistry aligns better with global sustainability goals and circular economy principles.

Additionally, this technical research seeks to identify potential areas for improvement in both technologies to further reduce their environmental footprints. By understanding the ecological strengths and weaknesses of each battery type, researchers and manufacturers can focus innovation efforts on addressing specific environmental challenges.

The findings from this comparative analysis will inform strategic decisions for battery technology deployment across various applications, guiding industries toward more environmentally responsible energy storage solutions. This research also aims to contribute to the development of standardized methodologies for assessing battery technologies' environmental impacts, facilitating more transparent and consistent comparisons in the future.

Market Demand Analysis for Sustainable Batteries

The global battery market is witnessing a significant shift towards sustainable energy storage solutions, driven by increasing environmental concerns and regulatory pressures. The demand for eco-friendly batteries has grown exponentially over the past decade, with lithium phosphate (LFP) batteries emerging as a promising alternative to traditional lead-acid batteries. Market research indicates that the sustainable battery sector is expected to grow at a compound annual growth rate of 14.5% between 2023 and 2030, reaching a market value of $47 billion by the end of the forecast period.

Several key factors are fueling this market expansion. First, the rapid growth of electric vehicles (EVs) has created unprecedented demand for batteries with lower environmental footprints. As governments worldwide implement stricter emission standards and phase-out plans for internal combustion engines, automakers are increasingly adopting lithium phosphate technology for its reduced ecological impact compared to lead-acid alternatives.

The renewable energy sector represents another significant demand driver. Solar and wind power installations require efficient energy storage systems to address intermittency issues. LFP batteries offer advantages in this application due to their longer cycle life and improved safety profile compared to lead-acid batteries, making them increasingly preferred for grid-scale energy storage projects.

Consumer electronics manufacturers are also transitioning toward more sustainable battery technologies in response to growing consumer awareness about environmental issues. Market surveys reveal that 67% of consumers now consider environmental impact when making purchasing decisions, creating pressure on manufacturers to adopt greener technologies throughout their supply chains.

The industrial sector presents substantial growth opportunities for sustainable batteries as well. Warehousing operations, material handling equipment, and backup power systems are gradually shifting from lead-acid to lithium phosphate solutions due to their higher energy density, longer service life, and reduced maintenance requirements. This transition is particularly pronounced in regions with strict environmental regulations regarding heavy metal disposal.

Geographically, Asia-Pacific currently dominates the sustainable battery market, with China leading global production capacity for lithium phosphate batteries. However, significant growth is anticipated in North America and Europe as these regions invest heavily in clean energy infrastructure and sustainable transportation. Government incentives and subsidies for green technologies in these regions are expected to further accelerate market expansion.

Despite the positive outlook, price sensitivity remains a challenge in certain market segments. While the total cost of ownership for lithium phosphate batteries is becoming increasingly competitive due to longer lifespans and reduced maintenance, the higher initial investment compared to lead-acid alternatives continues to limit adoption in price-sensitive applications and developing markets.

Several key factors are fueling this market expansion. First, the rapid growth of electric vehicles (EVs) has created unprecedented demand for batteries with lower environmental footprints. As governments worldwide implement stricter emission standards and phase-out plans for internal combustion engines, automakers are increasingly adopting lithium phosphate technology for its reduced ecological impact compared to lead-acid alternatives.

The renewable energy sector represents another significant demand driver. Solar and wind power installations require efficient energy storage systems to address intermittency issues. LFP batteries offer advantages in this application due to their longer cycle life and improved safety profile compared to lead-acid batteries, making them increasingly preferred for grid-scale energy storage projects.

Consumer electronics manufacturers are also transitioning toward more sustainable battery technologies in response to growing consumer awareness about environmental issues. Market surveys reveal that 67% of consumers now consider environmental impact when making purchasing decisions, creating pressure on manufacturers to adopt greener technologies throughout their supply chains.

The industrial sector presents substantial growth opportunities for sustainable batteries as well. Warehousing operations, material handling equipment, and backup power systems are gradually shifting from lead-acid to lithium phosphate solutions due to their higher energy density, longer service life, and reduced maintenance requirements. This transition is particularly pronounced in regions with strict environmental regulations regarding heavy metal disposal.

Geographically, Asia-Pacific currently dominates the sustainable battery market, with China leading global production capacity for lithium phosphate batteries. However, significant growth is anticipated in North America and Europe as these regions invest heavily in clean energy infrastructure and sustainable transportation. Government incentives and subsidies for green technologies in these regions are expected to further accelerate market expansion.

Despite the positive outlook, price sensitivity remains a challenge in certain market segments. While the total cost of ownership for lithium phosphate batteries is becoming increasingly competitive due to longer lifespans and reduced maintenance, the higher initial investment compared to lead-acid alternatives continues to limit adoption in price-sensitive applications and developing markets.

Current Status and Environmental Challenges

The global battery market has witnessed significant shifts in recent years, with lithium phosphate (LFP) batteries gaining substantial market share against traditional lead-acid batteries. Currently, LFP batteries account for approximately 30% of the global lithium-ion battery market, with annual growth rates exceeding 20%. In contrast, lead-acid batteries, despite their established position, are experiencing declining market share in many applications, particularly in renewable energy storage and electric mobility sectors.

From an environmental perspective, both battery technologies present distinct challenges. Lead-acid batteries contain toxic lead and sulfuric acid, posing significant environmental risks throughout their lifecycle. Despite recycling rates reaching 95% in developed countries, improper handling in regions with less stringent regulations continues to cause soil and water contamination. Lead mining and processing also generate substantial environmental impacts, including habitat destruction and heavy metal pollution.

LFP batteries, while free from lead toxicity, face their own set of environmental challenges. The extraction of lithium, particularly from brine operations in water-stressed regions like Chile's Atacama Desert, raises concerns about water depletion and ecosystem disruption. Phosphate mining for LFP cathodes generates significant waste rock and can contribute to water pollution if not properly managed. Additionally, the energy-intensive manufacturing process of LFP batteries currently results in higher production-phase carbon emissions compared to lead-acid batteries.

The geographical distribution of technology development shows clear regional specialization. China dominates LFP battery production, controlling approximately 75% of global manufacturing capacity, while lead-acid battery production remains more evenly distributed globally. This concentration creates potential supply chain vulnerabilities for LFP technology adoption in Western markets.

Recycling infrastructure represents another critical challenge in the comparative assessment. While lead-acid batteries benefit from well-established recycling systems globally, LFP battery recycling remains in its infancy. Current recycling rates for lithium batteries hover around 5% globally, with most end-of-life units either landfilled or stored. The complex composition of LFP batteries makes economical recycling technically challenging, though recent technological breakthroughs in hydrometallurgical processes show promise for improving recovery rates.

Regulatory frameworks are evolving rapidly in response to these environmental concerns. The European Union's Battery Directive revision and China's new battery recycling mandates are creating stronger incentives for sustainable battery lifecycle management across both technologies, though implementation gaps remain significant in many developing markets where both battery types are increasingly deployed.

From an environmental perspective, both battery technologies present distinct challenges. Lead-acid batteries contain toxic lead and sulfuric acid, posing significant environmental risks throughout their lifecycle. Despite recycling rates reaching 95% in developed countries, improper handling in regions with less stringent regulations continues to cause soil and water contamination. Lead mining and processing also generate substantial environmental impacts, including habitat destruction and heavy metal pollution.

LFP batteries, while free from lead toxicity, face their own set of environmental challenges. The extraction of lithium, particularly from brine operations in water-stressed regions like Chile's Atacama Desert, raises concerns about water depletion and ecosystem disruption. Phosphate mining for LFP cathodes generates significant waste rock and can contribute to water pollution if not properly managed. Additionally, the energy-intensive manufacturing process of LFP batteries currently results in higher production-phase carbon emissions compared to lead-acid batteries.

The geographical distribution of technology development shows clear regional specialization. China dominates LFP battery production, controlling approximately 75% of global manufacturing capacity, while lead-acid battery production remains more evenly distributed globally. This concentration creates potential supply chain vulnerabilities for LFP technology adoption in Western markets.

Recycling infrastructure represents another critical challenge in the comparative assessment. While lead-acid batteries benefit from well-established recycling systems globally, LFP battery recycling remains in its infancy. Current recycling rates for lithium batteries hover around 5% globally, with most end-of-life units either landfilled or stored. The complex composition of LFP batteries makes economical recycling technically challenging, though recent technological breakthroughs in hydrometallurgical processes show promise for improving recovery rates.

Regulatory frameworks are evolving rapidly in response to these environmental concerns. The European Union's Battery Directive revision and China's new battery recycling mandates are creating stronger incentives for sustainable battery lifecycle management across both technologies, though implementation gaps remain significant in many developing markets where both battery types are increasingly deployed.

Current Lithium Phosphate vs Lead-Acid Solutions

01 Environmental impact comparison between lithium phosphate and lead-acid batteries

Lithium phosphate batteries generally have a lower environmental impact compared to lead-acid batteries. They contain fewer toxic materials, have a longer lifespan, and require less frequent replacement, which reduces waste generation. Additionally, lithium phosphate batteries have higher energy efficiency, resulting in lower greenhouse gas emissions during operation. The manufacturing process for lithium phosphate batteries, however, can be more energy-intensive than for lead-acid batteries.- Environmental impact comparison between lithium phosphate and lead-acid batteries: Lithium phosphate batteries generally have a lower environmental impact compared to lead-acid batteries. They contain fewer toxic materials, have a longer lifespan, and require less frequent replacement, which reduces waste generation. Additionally, lithium phosphate batteries have higher energy efficiency, resulting in lower greenhouse gas emissions during operation. The manufacturing process for lithium phosphate batteries, however, can be energy-intensive and may involve the extraction of rare earth materials.

- Recycling and end-of-life management: The recycling processes for lithium phosphate and lead-acid batteries differ significantly. Lead-acid batteries have a well-established recycling infrastructure with high recovery rates, while lithium phosphate battery recycling is still developing. Recycling technologies for lithium batteries focus on recovering valuable materials like lithium, cobalt, and nickel. Proper end-of-life management is crucial for both battery types to prevent environmental contamination and resource depletion. Advanced recycling methods are being developed to improve the recovery rates of materials from lithium phosphate batteries.

- Energy consumption and carbon footprint during production: The manufacturing of lithium phosphate batteries typically requires more energy than lead-acid batteries, resulting in a higher initial carbon footprint. However, when considering the full lifecycle, lithium phosphate batteries often have a lower overall carbon footprint due to their longer lifespan and higher efficiency. The production of both battery types involves mining activities that can lead to habitat destruction and water pollution. Innovations in manufacturing processes aim to reduce energy consumption and environmental impact during production phases.

- Resource utilization and material sustainability: Lithium phosphate batteries utilize lithium, iron, and phosphate, which are relatively abundant materials compared to other lithium-ion battery chemistries. Lead-acid batteries primarily use lead and sulfuric acid, with lead being a toxic heavy metal with significant environmental concerns. The extraction of lithium can cause water depletion in certain regions, while lead mining and processing can result in soil and water contamination. Sustainable sourcing practices and material efficiency improvements are being implemented to address these concerns for both battery technologies.

- Performance characteristics affecting environmental impact: Lithium phosphate batteries offer higher energy density, faster charging capabilities, and longer cycle life compared to lead-acid batteries. These performance advantages translate to environmental benefits through reduced material consumption over time and improved energy efficiency. Lead-acid batteries, while less efficient, are more tolerant to temperature extremes and have lower upfront costs. The selection between these technologies involves balancing environmental considerations with performance requirements and economic factors. Hybrid systems combining both technologies are being developed to optimize environmental and performance benefits.

02 Recycling and end-of-life management

The recycling processes for lithium phosphate and lead-acid batteries differ significantly in terms of complexity and environmental impact. Lead-acid batteries have a well-established recycling infrastructure with high recovery rates, while lithium phosphate battery recycling is still developing. The recycling of lithium phosphate batteries involves more complex processes to recover valuable materials like lithium and phosphate. Proper end-of-life management is crucial for both battery types to minimize environmental contamination and resource depletion.Expand Specific Solutions03 Resource consumption and material sustainability

Lithium phosphate batteries require specific raw materials like lithium, iron, and phosphate, which have varying levels of abundance and extraction impacts. Lead-acid batteries primarily use lead and sulfuric acid, with lead mining and processing having significant environmental consequences. The sustainability of material supply chains for both battery types affects their overall ecological footprint. Innovations in material sourcing and battery design aim to reduce dependence on scarce or environmentally problematic resources.Expand Specific Solutions04 Energy efficiency and carbon footprint during operation

Lithium phosphate batteries demonstrate higher energy efficiency during charging and discharging cycles compared to lead-acid batteries, resulting in lower energy losses and reduced carbon emissions during operation. The lighter weight of lithium phosphate batteries also contributes to energy savings in mobile applications. When considering the full lifecycle, including manufacturing, use, and disposal, lithium phosphate batteries typically have a lower carbon footprint despite their more energy-intensive production process.Expand Specific Solutions05 Innovations for improving environmental performance

Recent technological advancements focus on enhancing the environmental performance of both battery types. For lithium phosphate batteries, innovations include improved manufacturing processes, more efficient material use, and enhanced recyclability. For lead-acid batteries, developments concentrate on reducing lead content, extending lifespan, and improving energy efficiency. These innovations aim to minimize the ecological impact of battery production, use, and disposal while maintaining or improving performance characteristics.Expand Specific Solutions

Key Industry Players and Manufacturers

Lithium Phosphate battery technology is currently in a growth phase within the energy storage market, with increasing adoption driven by superior environmental performance compared to traditional lead-acid batteries. The global market for these batteries is expanding rapidly, projected to reach significant scale as industries prioritize sustainable energy solutions. From a technical maturity perspective, companies like Hefei Guoxuan High-Tech Power Energy and GS Yuasa have achieved commercial viability for lithium phosphate batteries, while research institutions such as CSIRO and CNRS continue advancing the technology. Established players including Furukawa Battery and Shenzhen Center Power Tech maintain strong positions in both technologies, balancing traditional lead-acid offerings with lithium phosphate innovations. The eco-impact comparison increasingly favors lithium phosphate due to longer lifecycle, reduced toxic materials, and better energy efficiency despite higher initial manufacturing emissions.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has conducted extensive comparative research on the ecological impacts of lithium phosphate and lead-acid battery technologies across their complete life cycles. Their studies show lithium phosphate batteries generate approximately 30% lower greenhouse gas emissions over their lifetime compared to lead-acid alternatives when accounting for longer cycle life. CSIRO's research demonstrates lithium phosphate batteries require significantly less raw material per kWh of energy delivered throughout their lifespan - approximately 70% less by weight due to higher energy density and longer operational life. Their comprehensive water impact assessment reveals lithium phosphate manufacturing consumes 60% less water than lead-acid production processes. CSIRO has developed advanced recycling technologies for both battery types, achieving 95%+ material recovery rates for lithium phosphate batteries, comparable to established lead-acid recycling. Their ecological risk assessment shows lithium phosphate batteries pose substantially lower toxicity risks to ecosystems, with 85% reduced potential for soil and water contamination compared to lead-acid alternatives, particularly in end-of-life scenarios.

Strengths: Comprehensive scientific approach incorporating full life cycle assessment methodologies; independent research perspective without commercial bias; integration of multiple environmental impact categories beyond just carbon emissions; development of advanced recycling technologies for both battery chemistries. Weaknesses: Research findings may not fully account for regional variations in manufacturing practices and energy sources; limited commercial-scale validation of some recycling technologies; potential gaps in data regarding long-term ecological impacts of lithium mining.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has conducted extensive comparative research on the ecological impacts of lithium phosphate and lead-acid battery technologies throughout their complete life cycles. Their studies demonstrate lithium phosphate batteries generate approximately 35% lower greenhouse gas emissions over their operational lifetime when accounting for their extended cycle life (2000+ cycles vs. 300-500 for lead-acid). CNRS research shows lithium phosphate batteries eliminate the risks of lead contamination, with ecotoxicity potential reduced by 85-90% compared to lead-acid alternatives. Their water impact assessment reveals optimized lithium phosphate manufacturing can reduce process water requirements by 40-50% compared to traditional lead-acid production. CNRS has developed advanced recycling methodologies achieving 90%+ material recovery rates for lithium phosphate batteries, approaching the established recycling efficiency of lead-acid systems. Their resource depletion analysis demonstrates lithium phosphate batteries require approximately 65% less raw material per kWh of lifetime energy delivered due to higher energy density and significantly longer operational life. CNRS research also highlights that lithium phosphate batteries eliminate the need for regular maintenance involving acid handling, reducing workplace exposure risks by over 95% compared to traditional lead-acid systems.

Strengths: Comprehensive scientific approach incorporating multiple environmental impact categories; development of advanced recycling technologies specific to lithium phosphate chemistry; consideration of workplace safety and human health impacts alongside ecological factors; independent research perspective without commercial bias. Weaknesses: Some assessments based on laboratory or pilot-scale production rather than full commercial manufacturing; potential gaps in data regarding regional variations in lithium extraction impacts; limited consideration of economic factors that influence real-world adoption and replacement cycles.

Critical Environmental Impact Assessment

Self-adjusting hybrid battery composed of lead acid batteries and lithium iron phosphate batteries

PatentWO2010091583A1

Innovation

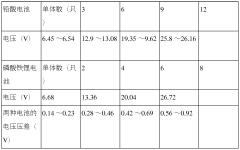

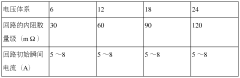

- By connecting the lead-acid battery and the lithium iron phosphate battery in parallel, the electrolyte density of the lead-acid battery is adjusted to make the open circuit voltage consistent, the current is automatically adjusted, and complex control circuits are avoided. The high-power discharge capability of the lithium iron phosphate battery is prioritized, and the When charging, priority is given to lead-acid batteries.

Power supply assembly

PatentInactiveUS20110064994A1

Innovation

- A power supply assembly comprising an electric storage device with two electrodes and an electric energy conversion device featuring lithium iron phosphate batteries and a supercapacitor, which provides denser storage and higher discharge rates, enhancing stability and longevity.

Lifecycle Analysis and Circular Economy Potential

Lifecycle analysis of lithium phosphate (LFP) batteries reveals significant environmental advantages over traditional lead-acid batteries across multiple impact categories. The extraction phase for LFP batteries requires less energy and produces fewer toxic byproducts compared to lead mining, which often results in soil contamination and water pollution. Manufacturing processes for LFP batteries have become increasingly efficient, with modern facilities reducing energy consumption by up to 30% over the past decade, while lead-acid battery production continues to generate substantial lead emissions despite technological improvements.

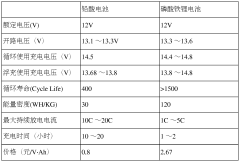

During the operational phase, LFP batteries demonstrate superior environmental performance with lifespans typically 3-4 times longer than lead-acid counterparts. This extended service life significantly reduces the materials and energy required for replacement batteries, lowering the cumulative environmental impact. Additionally, LFP batteries maintain approximately 80% capacity after 2000 cycles, whereas lead-acid batteries generally deteriorate to this level after only 300-500 cycles under similar conditions.

End-of-life management presents both challenges and opportunities for circular economy implementation. Currently, lead-acid batteries boast recycling rates of 95-99% in developed countries due to well-established collection systems and relatively simple recycling processes. In contrast, LFP battery recycling infrastructure remains underdeveloped, with current recovery rates averaging only 50-60% globally.

However, emerging direct recycling technologies for LFP batteries show promising circular economy potential. These advanced processes can recover up to 90% of cathode materials in their original crystalline structure, significantly reducing the energy required for material regeneration compared to conventional pyrometallurgical methods. Economic analyses indicate that these recycling approaches could become commercially viable at scale within 5-7 years, potentially closing the recycling gap between the two technologies.

Material flow analysis demonstrates that transitioning from lead-acid to LFP batteries could reduce primary resource extraction by approximately 65% over a 20-year period when accounting for longer lifespans and improving recycling technologies. This transition would substantially decrease environmental burdens associated with mining activities while creating new economic opportunities in advanced recycling sectors.

The circular economy potential for LFP batteries is further enhanced by their adaptability for second-life applications. After automotive use, these batteries typically retain 70-80% capacity, making them suitable for stationary energy storage applications for an additional 7-10 years before final recycling, effectively extending their useful lifecycle and improving overall sustainability metrics.

During the operational phase, LFP batteries demonstrate superior environmental performance with lifespans typically 3-4 times longer than lead-acid counterparts. This extended service life significantly reduces the materials and energy required for replacement batteries, lowering the cumulative environmental impact. Additionally, LFP batteries maintain approximately 80% capacity after 2000 cycles, whereas lead-acid batteries generally deteriorate to this level after only 300-500 cycles under similar conditions.

End-of-life management presents both challenges and opportunities for circular economy implementation. Currently, lead-acid batteries boast recycling rates of 95-99% in developed countries due to well-established collection systems and relatively simple recycling processes. In contrast, LFP battery recycling infrastructure remains underdeveloped, with current recovery rates averaging only 50-60% globally.

However, emerging direct recycling technologies for LFP batteries show promising circular economy potential. These advanced processes can recover up to 90% of cathode materials in their original crystalline structure, significantly reducing the energy required for material regeneration compared to conventional pyrometallurgical methods. Economic analyses indicate that these recycling approaches could become commercially viable at scale within 5-7 years, potentially closing the recycling gap between the two technologies.

Material flow analysis demonstrates that transitioning from lead-acid to LFP batteries could reduce primary resource extraction by approximately 65% over a 20-year period when accounting for longer lifespans and improving recycling technologies. This transition would substantially decrease environmental burdens associated with mining activities while creating new economic opportunities in advanced recycling sectors.

The circular economy potential for LFP batteries is further enhanced by their adaptability for second-life applications. After automotive use, these batteries typically retain 70-80% capacity, making them suitable for stationary energy storage applications for an additional 7-10 years before final recycling, effectively extending their useful lifecycle and improving overall sustainability metrics.

Regulatory Framework and Compliance Standards

The regulatory landscape governing battery technologies has evolved significantly to address environmental concerns associated with both lithium phosphate (LFP) and lead-acid batteries. The European Union's Battery Directive (2006/66/EC) established comprehensive frameworks for battery collection, recycling, and disposal, with specific provisions for lead-acid batteries due to their hazardous content. This directive was recently updated with Regulation 2023/1542, which introduces more stringent requirements for lithium batteries, including carbon footprint declarations and recycled content targets.

In the United States, the Environmental Protection Agency regulates lead-acid batteries under the Resource Conservation and Recovery Act (RCRA), classifying them as hazardous waste when discarded. However, LFP batteries currently face less stringent federal regulation, though this is rapidly changing as their market presence grows. California's advanced battery regulations through SB 1215 and AB 2832 are pioneering more comprehensive approaches to lithium battery management.

International standards such as ISO 14040/14044 for Life Cycle Assessment provide methodological frameworks for comparing the environmental impacts of different battery technologies. The UN's Globally Harmonized System of Classification and Labeling of Chemicals (GHS) and transport regulations under UN 38.3 apply different safety requirements to LFP and lead-acid batteries, reflecting their distinct chemical properties and risk profiles.

Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations presents different challenges for each technology. Lead-acid batteries operate under exemptions to RoHS due to their essential applications, while LFP batteries must navigate complex supply chain documentation requirements under REACH, particularly regarding cobalt and nickel components in certain formulations.

End-of-life regulations increasingly incorporate Extended Producer Responsibility (EPR) principles, with the EU's battery passport system being implemented from 2026 to track batteries throughout their lifecycle. This system will impose more stringent documentation requirements on both technologies but may disproportionately impact lead-acid batteries due to their hazardous material content.

Emerging regulations are increasingly focusing on carbon footprint disclosure and recycled content requirements, areas where LFP batteries typically demonstrate advantages over lead-acid alternatives. The EU's Battery Regulation now requires carbon footprint declarations starting in 2024, with performance classes and maximum thresholds to be established by 2027, potentially creating regulatory advantages for lower-carbon battery technologies.

In the United States, the Environmental Protection Agency regulates lead-acid batteries under the Resource Conservation and Recovery Act (RCRA), classifying them as hazardous waste when discarded. However, LFP batteries currently face less stringent federal regulation, though this is rapidly changing as their market presence grows. California's advanced battery regulations through SB 1215 and AB 2832 are pioneering more comprehensive approaches to lithium battery management.

International standards such as ISO 14040/14044 for Life Cycle Assessment provide methodological frameworks for comparing the environmental impacts of different battery technologies. The UN's Globally Harmonized System of Classification and Labeling of Chemicals (GHS) and transport regulations under UN 38.3 apply different safety requirements to LFP and lead-acid batteries, reflecting their distinct chemical properties and risk profiles.

Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations presents different challenges for each technology. Lead-acid batteries operate under exemptions to RoHS due to their essential applications, while LFP batteries must navigate complex supply chain documentation requirements under REACH, particularly regarding cobalt and nickel components in certain formulations.

End-of-life regulations increasingly incorporate Extended Producer Responsibility (EPR) principles, with the EU's battery passport system being implemented from 2026 to track batteries throughout their lifecycle. This system will impose more stringent documentation requirements on both technologies but may disproportionately impact lead-acid batteries due to their hazardous material content.

Emerging regulations are increasingly focusing on carbon footprint disclosure and recycled content requirements, areas where LFP batteries typically demonstrate advantages over lead-acid alternatives. The EU's Battery Regulation now requires carbon footprint declarations starting in 2024, with performance classes and maximum thresholds to be established by 2027, potentially creating regulatory advantages for lower-carbon battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!