Benchmarking Lithium Phosphate Safety in Batteries: Tests & Metrics

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Battery Safety Background and Objectives

Lithium phosphate batteries, particularly lithium iron phosphate (LiFePO4 or LFP) technology, have emerged as a significant advancement in energy storage systems over the past two decades. The evolution of this technology can be traced back to the early 1990s when researchers first identified the potential of phosphate-based cathode materials for lithium-ion batteries. Since then, continuous improvements in manufacturing processes, material science, and cell design have propelled LFP batteries to become a prominent solution in various applications.

The technological trajectory of lithium phosphate batteries has been characterized by steady enhancements in energy density, cycle life, and thermal stability. Unlike their lithium cobalt oxide counterparts, LFP batteries have gained recognition primarily for their inherent safety characteristics, which stem from the strong phosphate bonds in their cathode structure. This chemical stability has positioned them as a preferred choice for applications where safety is paramount.

Current market trends indicate a resurgence of interest in LFP technology, particularly in electric vehicles, stationary energy storage, and industrial applications. This renewed focus is largely driven by the increasing emphasis on battery safety standards and regulations worldwide, as well as concerns about the supply chain security and ethical sourcing of cobalt and nickel used in alternative lithium-ion chemistries.

The primary objective of benchmarking lithium phosphate battery safety is to establish standardized testing protocols and performance metrics that accurately reflect real-world safety risks and failure modes. These benchmarks must address thermal runaway resistance, structural integrity during mechanical abuse, electrical safety during overcharge and short-circuit conditions, and long-term stability under various environmental stressors.

Additionally, this technical exploration aims to identify key performance indicators that can serve as reliable predictors of battery safety across different applications and use cases. By developing comprehensive testing methodologies, we seek to enable meaningful comparisons between different lithium phosphate battery formulations and manufacturing techniques.

The ultimate goal is to provide industry stakeholders with robust data-driven frameworks for evaluating and improving battery safety, thereby accelerating the adoption of lithium phosphate technology in critical applications. This includes establishing correlations between laboratory test results and field performance, identifying early warning indicators of potential safety issues, and developing accelerated testing protocols that can reliably predict long-term safety performance.

Furthermore, this benchmarking initiative seeks to address the evolving regulatory landscape surrounding battery safety, providing manufacturers and integrators with clear guidelines for compliance and certification across global markets.

The technological trajectory of lithium phosphate batteries has been characterized by steady enhancements in energy density, cycle life, and thermal stability. Unlike their lithium cobalt oxide counterparts, LFP batteries have gained recognition primarily for their inherent safety characteristics, which stem from the strong phosphate bonds in their cathode structure. This chemical stability has positioned them as a preferred choice for applications where safety is paramount.

Current market trends indicate a resurgence of interest in LFP technology, particularly in electric vehicles, stationary energy storage, and industrial applications. This renewed focus is largely driven by the increasing emphasis on battery safety standards and regulations worldwide, as well as concerns about the supply chain security and ethical sourcing of cobalt and nickel used in alternative lithium-ion chemistries.

The primary objective of benchmarking lithium phosphate battery safety is to establish standardized testing protocols and performance metrics that accurately reflect real-world safety risks and failure modes. These benchmarks must address thermal runaway resistance, structural integrity during mechanical abuse, electrical safety during overcharge and short-circuit conditions, and long-term stability under various environmental stressors.

Additionally, this technical exploration aims to identify key performance indicators that can serve as reliable predictors of battery safety across different applications and use cases. By developing comprehensive testing methodologies, we seek to enable meaningful comparisons between different lithium phosphate battery formulations and manufacturing techniques.

The ultimate goal is to provide industry stakeholders with robust data-driven frameworks for evaluating and improving battery safety, thereby accelerating the adoption of lithium phosphate technology in critical applications. This includes establishing correlations between laboratory test results and field performance, identifying early warning indicators of potential safety issues, and developing accelerated testing protocols that can reliably predict long-term safety performance.

Furthermore, this benchmarking initiative seeks to address the evolving regulatory landscape surrounding battery safety, providing manufacturers and integrators with clear guidelines for compliance and certification across global markets.

Market Demand Analysis for Safe Battery Technologies

The global market for safe battery technologies has experienced unprecedented growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. The compound annual growth rate (CAGR) for lithium phosphate (LFP) batteries specifically has exceeded 20% since 2019, with projections indicating continued strong growth through 2030.

Safety concerns have emerged as the primary market driver, particularly following high-profile thermal runaway incidents in consumer electronics and EVs. These incidents have heightened regulatory scrutiny and consumer awareness, creating substantial market demand for batteries with enhanced safety profiles. Lithium phosphate chemistry, with its superior thermal stability compared to nickel-manganese-cobalt (NMC) alternatives, has consequently gained significant market traction.

The automotive sector represents the largest market segment for safe battery technologies, accounting for approximately 60% of total demand. Major automakers including Tesla, BYD, and Volkswagen have increased their adoption of LFP batteries for entry and mid-range EV models, citing safety advantages and cost efficiency. This trend is particularly pronounced in China, where government policies actively promote LFP technology.

Energy storage systems (ESS) constitute the fastest-growing application segment, with demand increasing as utilities and commercial entities deploy large-scale battery installations. Safety considerations are paramount in these applications due to the scale of deployment and proximity to infrastructure and populations. The ESS market has shown particular sensitivity to safety benchmarking metrics, with procurement decisions increasingly influenced by standardized safety performance data.

Consumer demand patterns reveal a growing willingness to prioritize safety over energy density, particularly in applications where the volumetric and gravimetric penalties of LFP chemistry are acceptable trade-offs. Market research indicates that 73% of EV consumers rank safety features among their top three purchase considerations, above range in many market segments.

Geographically, Asia-Pacific dominates the market for safe battery technologies, with China leading in both production capacity and consumption. North America and Europe follow, with both regions showing accelerated growth rates as domestic battery manufacturing expands to meet regulatory requirements and reduce supply chain vulnerabilities.

The market landscape is further shaped by evolving regulatory frameworks, with the UN Transportation Testing requirements, IEC standards, and UL safety certifications creating baseline expectations for battery safety. These standards are increasingly incorporating specific benchmarking protocols for thermal runaway resistance, propagation prevention, and gas emission characteristics—metrics where lithium phosphate chemistry demonstrates competitive advantages.

Safety concerns have emerged as the primary market driver, particularly following high-profile thermal runaway incidents in consumer electronics and EVs. These incidents have heightened regulatory scrutiny and consumer awareness, creating substantial market demand for batteries with enhanced safety profiles. Lithium phosphate chemistry, with its superior thermal stability compared to nickel-manganese-cobalt (NMC) alternatives, has consequently gained significant market traction.

The automotive sector represents the largest market segment for safe battery technologies, accounting for approximately 60% of total demand. Major automakers including Tesla, BYD, and Volkswagen have increased their adoption of LFP batteries for entry and mid-range EV models, citing safety advantages and cost efficiency. This trend is particularly pronounced in China, where government policies actively promote LFP technology.

Energy storage systems (ESS) constitute the fastest-growing application segment, with demand increasing as utilities and commercial entities deploy large-scale battery installations. Safety considerations are paramount in these applications due to the scale of deployment and proximity to infrastructure and populations. The ESS market has shown particular sensitivity to safety benchmarking metrics, with procurement decisions increasingly influenced by standardized safety performance data.

Consumer demand patterns reveal a growing willingness to prioritize safety over energy density, particularly in applications where the volumetric and gravimetric penalties of LFP chemistry are acceptable trade-offs. Market research indicates that 73% of EV consumers rank safety features among their top three purchase considerations, above range in many market segments.

Geographically, Asia-Pacific dominates the market for safe battery technologies, with China leading in both production capacity and consumption. North America and Europe follow, with both regions showing accelerated growth rates as domestic battery manufacturing expands to meet regulatory requirements and reduce supply chain vulnerabilities.

The market landscape is further shaped by evolving regulatory frameworks, with the UN Transportation Testing requirements, IEC standards, and UL safety certifications creating baseline expectations for battery safety. These standards are increasingly incorporating specific benchmarking protocols for thermal runaway resistance, propagation prevention, and gas emission characteristics—metrics where lithium phosphate chemistry demonstrates competitive advantages.

Current Safety Challenges in Lithium Phosphate Batteries

Despite the inherent safety advantages of lithium iron phosphate (LFP) batteries compared to other lithium-ion chemistries, several significant safety challenges persist that require comprehensive benchmarking and evaluation. Thermal runaway, though less severe than in nickel-based cathodes, remains a critical concern in LFP batteries, particularly when subjected to extreme conditions such as physical damage, manufacturing defects, or electrical abuse.

One major challenge is the variability in safety performance across different manufacturers and production batches. The lack of standardized testing protocols specifically optimized for LFP chemistry makes consistent safety evaluation difficult, as many current standards were developed primarily for other lithium-ion variants. This inconsistency creates obstacles for accurate risk assessment and comparative analysis between different LFP battery products.

Electrolyte decomposition presents another significant safety issue. While the phosphate cathode itself is stable, the interaction between electrolytes and the anode during abnormal operating conditions can still generate flammable gases. Current safety metrics often fail to adequately characterize this risk factor specific to LFP systems, focusing instead on catastrophic failure modes more common in other chemistries.

The aging effects on safety parameters represent a particularly challenging area for benchmarking. LFP batteries may exhibit different safety profiles as they age, with potential degradation mechanisms that affect thermal stability and abuse tolerance. Existing accelerated aging protocols may not accurately reflect real-world safety evolution in LFP systems, creating a disconnect between laboratory testing and actual field performance.

Low-temperature operation introduces additional safety concerns that current metrics struggle to quantify effectively. At temperatures below freezing, lithium plating can occur during charging, creating potential internal short circuits. The relationship between low-temperature operation and long-term safety degradation remains inadequately characterized by existing benchmarking approaches.

Cell-to-module-to-pack scaling effects present complex safety challenges. Safety behaviors observed at the cell level may not linearly translate to module or pack level, where thermal management systems, electrical connections, and mechanical constraints introduce new variables. Current benchmarking methodologies often fail to capture these system-level interactions that are critical for real-world safety assessment.

Finally, the industry faces challenges in developing predictive safety models specific to LFP chemistry. While significant data exists on catastrophic failures, less attention has been paid to early warning indicators and precursors to safety incidents in LFP systems. This gap hampers the development of proactive safety management strategies and more sophisticated benchmarking metrics that could better characterize the unique safety profile of lithium phosphate batteries.

One major challenge is the variability in safety performance across different manufacturers and production batches. The lack of standardized testing protocols specifically optimized for LFP chemistry makes consistent safety evaluation difficult, as many current standards were developed primarily for other lithium-ion variants. This inconsistency creates obstacles for accurate risk assessment and comparative analysis between different LFP battery products.

Electrolyte decomposition presents another significant safety issue. While the phosphate cathode itself is stable, the interaction between electrolytes and the anode during abnormal operating conditions can still generate flammable gases. Current safety metrics often fail to adequately characterize this risk factor specific to LFP systems, focusing instead on catastrophic failure modes more common in other chemistries.

The aging effects on safety parameters represent a particularly challenging area for benchmarking. LFP batteries may exhibit different safety profiles as they age, with potential degradation mechanisms that affect thermal stability and abuse tolerance. Existing accelerated aging protocols may not accurately reflect real-world safety evolution in LFP systems, creating a disconnect between laboratory testing and actual field performance.

Low-temperature operation introduces additional safety concerns that current metrics struggle to quantify effectively. At temperatures below freezing, lithium plating can occur during charging, creating potential internal short circuits. The relationship between low-temperature operation and long-term safety degradation remains inadequately characterized by existing benchmarking approaches.

Cell-to-module-to-pack scaling effects present complex safety challenges. Safety behaviors observed at the cell level may not linearly translate to module or pack level, where thermal management systems, electrical connections, and mechanical constraints introduce new variables. Current benchmarking methodologies often fail to capture these system-level interactions that are critical for real-world safety assessment.

Finally, the industry faces challenges in developing predictive safety models specific to LFP chemistry. While significant data exists on catastrophic failures, less attention has been paid to early warning indicators and precursors to safety incidents in LFP systems. This gap hampers the development of proactive safety management strategies and more sophisticated benchmarking metrics that could better characterize the unique safety profile of lithium phosphate batteries.

Established Safety Test Protocols and Metrics

01 Thermal management systems for lithium phosphate batteries

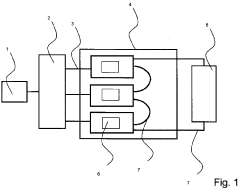

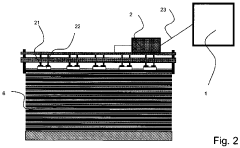

Effective thermal management systems are crucial for lithium phosphate battery safety. These systems monitor and control battery temperature to prevent overheating and thermal runaway. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation materials, help maintain optimal operating temperatures. Some designs incorporate phase change materials that absorb excess heat during high-load operations. These thermal management solutions significantly reduce fire risks and extend battery lifespan.- Thermal management systems for lithium phosphate batteries: Effective thermal management systems are crucial for lithium phosphate battery safety. These systems monitor and control battery temperature to prevent thermal runaway and ensure safe operation. Advanced cooling mechanisms, including liquid cooling circuits and heat dissipation structures, help maintain optimal operating temperatures. Temperature sensors and thermal management controllers provide real-time monitoring and automated response to temperature fluctuations, significantly reducing fire and explosion risks.

- Battery management systems (BMS) for safety monitoring: Battery management systems play a vital role in lithium phosphate battery safety by continuously monitoring critical parameters such as voltage, current, and temperature. These systems implement protective measures including overcharge protection, over-discharge prevention, and short-circuit detection. Advanced BMS designs incorporate fault diagnosis algorithms and early warning systems that can predict potential failures before they occur, allowing for preventive actions to maintain safe operation conditions.

- Structural safety enhancements for battery cells and packs: Structural safety features in lithium phosphate batteries include reinforced cell casings, impact-resistant materials, and specialized battery pack designs that prevent physical damage. Safety vents and pressure relief mechanisms are incorporated to release excess pressure during abnormal conditions. Isolation systems between cells prevent cascading failures, while flame-retardant separators and enhanced electrode designs improve intrinsic safety. These structural improvements significantly reduce the risk of mechanical damage leading to thermal events.

- Electrolyte and separator safety innovations: Safety innovations in electrolytes and separators for lithium phosphate batteries include flame-retardant additives that suppress combustion and non-flammable electrolyte formulations. Advanced ceramic-coated separators provide enhanced thermal stability and prevent internal short circuits. Solid-state and gel electrolytes offer improved safety profiles by eliminating or reducing flammable components. These innovations address one of the primary safety concerns in lithium batteries by minimizing the risk of electrolyte-fueled fires.

- Safety certification standards and testing protocols: Comprehensive safety certification standards and testing protocols have been developed specifically for lithium phosphate batteries. These include abuse testing such as nail penetration, crush tests, and thermal shock to verify battery resilience under extreme conditions. Standardized safety evaluation methods assess performance during overcharge, short circuit, and thermal runaway scenarios. Compliance with international safety standards ensures consistent safety performance across different applications and operating environments.

02 Battery management systems (BMS) for safety monitoring

Battery management systems provide comprehensive monitoring and protection for lithium phosphate batteries. These systems continuously track critical parameters such as voltage, current, temperature, and state of charge across individual cells and the entire battery pack. Advanced BMS implementations include early warning mechanisms that detect abnormal conditions before they become hazardous. They can automatically disconnect batteries when unsafe conditions are detected and balance cell charges to prevent overcharging or deep discharging, significantly enhancing overall battery safety.Expand Specific Solutions03 Structural safety enhancements for battery packs

Structural design improvements play a vital role in lithium phosphate battery safety. Reinforced battery casings and impact-resistant materials protect cells from physical damage during accidents or extreme conditions. Some designs incorporate internal barriers between cells to prevent thermal propagation if one cell fails. Specialized venting mechanisms safely release pressure during abnormal conditions, while flame-retardant materials in battery construction reduce fire spread risk. These structural enhancements significantly improve battery resilience against mechanical stress and thermal events.Expand Specific Solutions04 Electrolyte and separator safety innovations

Advanced electrolyte formulations and separator designs enhance lithium phosphate battery safety. Non-flammable or flame-retardant electrolytes reduce fire risks, while additives improve thermal stability and prevent dendrite formation. Specialized ceramic-coated separators maintain integrity at high temperatures, preventing short circuits. Some designs incorporate shutdown separators that close their pores when overheated, stopping ion flow and preventing thermal runaway. These material innovations address fundamental safety challenges in lithium phosphate batteries without compromising performance.Expand Specific Solutions05 Safety testing and certification protocols

Comprehensive testing and certification protocols ensure lithium phosphate battery safety across various conditions. These include abuse testing (crush, puncture, overcharge, short circuit) to verify battery response to extreme situations. Thermal stability tests evaluate performance under temperature fluctuations, while cycle life testing confirms long-term safety. Advanced diagnostic techniques identify potential failure modes before deployment. Standardized certification processes verify compliance with international safety standards, providing confidence in battery safety performance across diverse applications and operating environments.Expand Specific Solutions

Key Industry Players in Battery Safety Benchmarking

The lithium phosphate battery safety benchmarking landscape is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for safer energy storage solutions. Major players like CATL, Samsung SDI, LG Energy Solution, and Panasonic are leading technological advancements in safety testing methodologies. Chinese companies including EVE Energy and Ningde Amperex Technology have made substantial progress in developing standardized safety metrics, while automotive manufacturers such as Mercedes-Benz and Volvo are driving requirements for enhanced safety protocols. Research institutions like Harbin University of Science & Technology and Sichuan University contribute valuable academic insights, creating a competitive environment where safety performance increasingly differentiates market leaders from followers in both consumer electronics and electric vehicle applications.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed comprehensive benchmarking protocols for lithium phosphate (LFP) battery safety testing. Their approach includes multi-level testing from cell to pack level with standardized metrics for thermal runaway propagation. The company employs nail penetration tests with high-speed thermal imaging to measure heat generation rates and propagation speeds[1]. Their advanced calorimetry methods measure heat release during thermal events with precision of ±0.05°C. Samsung's benchmarking includes comparative analysis between LFP and other chemistries (NMC, NCA) under identical test conditions, demonstrating LFP's superior thermal stability with onset temperatures approximately 30°C higher than NMC cells[2]. They've established quantifiable safety metrics including Time to Thermal Runaway (TTR), Peak Temperature Rate (PTR), and Total Heat Released (THR) as standardized benchmarks for industry comparison.

Strengths: Industry-leading thermal imaging technology provides exceptional detail in failure mode analysis. Their comparative testing methodology allows direct safety comparison across multiple chemistries. Weaknesses: Testing protocols may be optimized for their specific cell designs rather than representing universal standards. Their benchmarking may underrepresent real-world abuse conditions that combine multiple failure modes simultaneously.

Panasonic Holdings Corp.

Technical Solution: Panasonic has established a sophisticated benchmarking system for lithium phosphate battery safety focused on accelerated life testing and extreme condition simulation. Their methodology includes proprietary crush tests that simulate progressive deformation while monitoring voltage, temperature, and gas evolution in real-time[3]. Panasonic's thermal stability tests employ differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) to precisely measure exothermic reactions with temperature resolution of 0.1°C. Their benchmarking includes unique "thermal index" metrics that combine multiple safety parameters into single comparative values. For LFP specifically, they've developed specialized overcharge tolerance tests showing LFP cells can withstand up to 200% state-of-charge without thermal runaway compared to 130-150% for conventional lithium-ion chemistries[4]. Panasonic's safety metrics include quantifiable measurements of gas composition analysis during failure events, correlating specific gas ratios to failure severity and propagation risk.

Strengths: Exceptional precision in thermal measurement systems allows detection of subtle safety differences between cell designs. Their gas analysis capabilities provide early warning indicators before catastrophic failure. Weaknesses: Testing focuses heavily on cell-level performance rather than system-level safety considerations. Their proprietary metrics make direct comparison with other manufacturers' data challenging.

Critical Safety Technologies and Patents Review

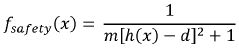

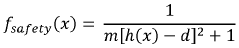

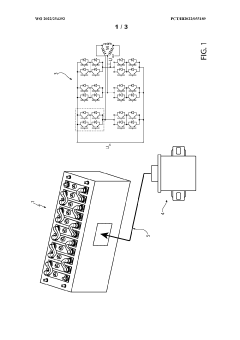

Method of determining the state of safety (SOS) of a rechargeable battery

PatentWO2022254392A1

Innovation

- A method that measures various battery variables like direct current internal resistance, temperature, open-circuit voltage, state of health, state of charge, and insulation resistance, calculates their variations, and uses a safety function to provide a numerical State of Safety (SOS) value, allowing for continuous monitoring and automatic notifications of safe, warning, or unsafe states.

Method for testing battery, such as lithium-ion batteries for electronic devices, such as mobile phones or laptops, and in automotive sector, involves measuring parameter of battery at time period and heating of battery

PatentInactiveDE102011109160A1

Innovation

- A method involving measuring a parameter at two different times, heating the battery in between, and comparing the parameter differences with a predefined limit value to detect defects, using a sensor and a climatic chamber to simulate temperature conditions that enhance self-discharge.

Regulatory Compliance and Safety Standards

The regulatory landscape for lithium phosphate batteries is governed by a complex framework of international, regional, and national standards that manufacturers must navigate to ensure market access. Key international standards include IEC 62133 for secondary cells and batteries containing alkaline or other non-acid electrolytes, and UN 38.3 for transportation safety testing. These standards establish baseline requirements for safety performance, testing methodologies, and certification processes.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries, while the Consumer Product Safety Commission (CPSC) enforces additional regulations. The European Union implements the Battery Directive (2006/66/EC) and subsequent amendments, which address environmental concerns alongside safety requirements. Additionally, the EU's REACH and RoHS directives impose restrictions on hazardous substances in battery manufacturing.

Asian markets, particularly China, Japan, and South Korea, have established their own certification systems. China's GB standards (GB/T 18287-2013) specifically address lithium phosphate battery safety, while Japan's JIS C8714 provides detailed testing protocols. These regional variations necessitate tailored compliance strategies for global market access.

Safety certification processes typically involve third-party testing by accredited laboratories, documentation of test results, and ongoing compliance monitoring. For lithium phosphate batteries, specific safety tests include thermal stability assessments, overcharge protection verification, short circuit response evaluation, and mechanical integrity testing under various environmental conditions.

Recent regulatory trends indicate a move toward harmonization of standards, with increasing emphasis on lifecycle safety management rather than just point-of-manufacture certification. The International Electrotechnical Commission (IEC) has been working to develop unified testing protocols that address emerging concerns about battery safety in various applications, from consumer electronics to electric vehicles and grid storage systems.

Compliance costs represent a significant consideration for manufacturers, with testing and certification expenses varying by market and application. However, these investments typically yield returns through reduced liability exposure, enhanced market access, and improved consumer confidence. Forward-looking manufacturers are increasingly adopting compliance strategies that anticipate regulatory evolution rather than merely meeting current requirements.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries, while the Consumer Product Safety Commission (CPSC) enforces additional regulations. The European Union implements the Battery Directive (2006/66/EC) and subsequent amendments, which address environmental concerns alongside safety requirements. Additionally, the EU's REACH and RoHS directives impose restrictions on hazardous substances in battery manufacturing.

Asian markets, particularly China, Japan, and South Korea, have established their own certification systems. China's GB standards (GB/T 18287-2013) specifically address lithium phosphate battery safety, while Japan's JIS C8714 provides detailed testing protocols. These regional variations necessitate tailored compliance strategies for global market access.

Safety certification processes typically involve third-party testing by accredited laboratories, documentation of test results, and ongoing compliance monitoring. For lithium phosphate batteries, specific safety tests include thermal stability assessments, overcharge protection verification, short circuit response evaluation, and mechanical integrity testing under various environmental conditions.

Recent regulatory trends indicate a move toward harmonization of standards, with increasing emphasis on lifecycle safety management rather than just point-of-manufacture certification. The International Electrotechnical Commission (IEC) has been working to develop unified testing protocols that address emerging concerns about battery safety in various applications, from consumer electronics to electric vehicles and grid storage systems.

Compliance costs represent a significant consideration for manufacturers, with testing and certification expenses varying by market and application. However, these investments typically yield returns through reduced liability exposure, enhanced market access, and improved consumer confidence. Forward-looking manufacturers are increasingly adopting compliance strategies that anticipate regulatory evolution rather than merely meeting current requirements.

Environmental Impact of Battery Safety Testing

Battery safety testing, while crucial for ensuring consumer safety and product reliability, carries significant environmental implications that warrant careful consideration. The testing processes for lithium phosphate batteries involve various destructive and non-destructive methods that generate waste materials, consume energy, and potentially release harmful substances into the environment.

The primary environmental concern stems from the disposal of tested batteries, particularly those subjected to destructive testing protocols. These batteries often contain electrolytes, heavy metals, and other potentially hazardous materials that require specialized handling and disposal procedures. When improperly managed, these components can leach into soil and water systems, causing long-term environmental contamination.

Energy consumption represents another substantial environmental impact factor in battery safety testing. Thermal runaway tests, cycling tests, and other performance evaluations require significant energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. A single comprehensive battery testing program can consume thousands of kilowatt-hours of electricity, equivalent to the monthly consumption of multiple households.

Chemical emissions during testing procedures pose additional environmental risks. Abuse tests that intentionally induce thermal events or venting can release toxic gases including hydrogen fluoride, carbon monoxide, and volatile organic compounds. These emissions require sophisticated containment and filtration systems to prevent atmospheric pollution and protect testing personnel.

Water usage in battery testing facilities, particularly for cooling systems and fire suppression equipment, represents another environmental consideration. Large-scale testing operations may consume substantial water resources, potentially competing with other community needs in water-stressed regions.

Recent industry initiatives have begun addressing these environmental concerns through the development of more sustainable testing protocols. These include simulation-based preliminary testing to reduce physical test requirements, regenerative load banks that capture and reuse energy during discharge tests, and closed-loop testing systems that minimize waste generation and emissions.

Regulatory frameworks are evolving to incorporate environmental impact assessments into battery testing requirements. The European Union's Battery Directive and similar regulations worldwide increasingly mandate life-cycle assessments that include the environmental footprint of testing procedures alongside manufacturing and disposal considerations.

The battery industry faces the challenge of balancing rigorous safety testing with environmental responsibility. This balance requires innovative approaches to test design, material recovery, and the development of standardized protocols that minimize environmental impact while maintaining the integrity of safety evaluations.

The primary environmental concern stems from the disposal of tested batteries, particularly those subjected to destructive testing protocols. These batteries often contain electrolytes, heavy metals, and other potentially hazardous materials that require specialized handling and disposal procedures. When improperly managed, these components can leach into soil and water systems, causing long-term environmental contamination.

Energy consumption represents another substantial environmental impact factor in battery safety testing. Thermal runaway tests, cycling tests, and other performance evaluations require significant energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. A single comprehensive battery testing program can consume thousands of kilowatt-hours of electricity, equivalent to the monthly consumption of multiple households.

Chemical emissions during testing procedures pose additional environmental risks. Abuse tests that intentionally induce thermal events or venting can release toxic gases including hydrogen fluoride, carbon monoxide, and volatile organic compounds. These emissions require sophisticated containment and filtration systems to prevent atmospheric pollution and protect testing personnel.

Water usage in battery testing facilities, particularly for cooling systems and fire suppression equipment, represents another environmental consideration. Large-scale testing operations may consume substantial water resources, potentially competing with other community needs in water-stressed regions.

Recent industry initiatives have begun addressing these environmental concerns through the development of more sustainable testing protocols. These include simulation-based preliminary testing to reduce physical test requirements, regenerative load banks that capture and reuse energy during discharge tests, and closed-loop testing systems that minimize waste generation and emissions.

Regulatory frameworks are evolving to incorporate environmental impact assessments into battery testing requirements. The European Union's Battery Directive and similar regulations worldwide increasingly mandate life-cycle assessments that include the environmental footprint of testing procedures alongside manufacturing and disposal considerations.

The battery industry faces the challenge of balancing rigorous safety testing with environmental responsibility. This balance requires innovative approaches to test design, material recovery, and the development of standardized protocols that minimize environmental impact while maintaining the integrity of safety evaluations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!