Quantify Thermal Expansion Rates in Lithium Phosphate

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Phosphate Thermal Expansion Background and Objectives

Lithium phosphate (Li3PO4) has emerged as a critical material in modern energy storage systems, particularly in lithium-ion batteries where it serves as a key component in solid electrolytes and protective coatings. The study of thermal expansion in lithium phosphate dates back to the 1970s, when researchers first began investigating its structural properties for potential applications in ceramics and glass composites. However, comprehensive understanding of its thermal behavior gained significant momentum in the early 2000s with the rise of lithium-based battery technologies.

The thermal expansion characteristics of lithium phosphate are of paramount importance as they directly impact the performance, safety, and longevity of battery systems. When subjected to temperature fluctuations during charging, discharging, and storage, lithium phosphate undergoes dimensional changes that can lead to mechanical stress, interfacial delamination, and potential failure mechanisms if not properly accounted for in design specifications.

Recent technological advancements in energy storage, particularly the push toward solid-state batteries, have heightened the need for precise quantification of thermal expansion rates in lithium phosphate and its derivatives. The evolution of this field has been marked by transitions from empirical observations to sophisticated in-situ measurement techniques that allow for real-time monitoring of structural changes under various thermal conditions.

Current research trends indicate a growing focus on understanding anisotropic thermal expansion behavior in lithium phosphate crystals, as directional expansion differences can significantly impact material integration in complex battery architectures. Additionally, the effects of doping, crystallinity variations, and nano-structuring on thermal expansion properties represent emerging areas of investigation that promise to deliver tailored materials with optimized thermal stability.

The primary objectives of quantifying thermal expansion rates in lithium phosphate include: establishing standardized measurement protocols across different temperature ranges relevant to battery operation (-40°C to 85°C for consumer electronics, and up to 150°C for industrial applications); developing predictive models that can accurately forecast dimensional changes under dynamic thermal conditions; and creating comprehensive databases of thermal expansion coefficients for various lithium phosphate compositions and structures to facilitate advanced battery design.

Furthermore, this research aims to correlate thermal expansion behavior with other critical material properties such as ionic conductivity, mechanical strength, and electrochemical stability, thereby enabling holistic material optimization for next-generation energy storage solutions. The ultimate goal is to enable the design of thermally resilient battery components that maintain structural integrity and performance across increasingly demanding operational environments.

The thermal expansion characteristics of lithium phosphate are of paramount importance as they directly impact the performance, safety, and longevity of battery systems. When subjected to temperature fluctuations during charging, discharging, and storage, lithium phosphate undergoes dimensional changes that can lead to mechanical stress, interfacial delamination, and potential failure mechanisms if not properly accounted for in design specifications.

Recent technological advancements in energy storage, particularly the push toward solid-state batteries, have heightened the need for precise quantification of thermal expansion rates in lithium phosphate and its derivatives. The evolution of this field has been marked by transitions from empirical observations to sophisticated in-situ measurement techniques that allow for real-time monitoring of structural changes under various thermal conditions.

Current research trends indicate a growing focus on understanding anisotropic thermal expansion behavior in lithium phosphate crystals, as directional expansion differences can significantly impact material integration in complex battery architectures. Additionally, the effects of doping, crystallinity variations, and nano-structuring on thermal expansion properties represent emerging areas of investigation that promise to deliver tailored materials with optimized thermal stability.

The primary objectives of quantifying thermal expansion rates in lithium phosphate include: establishing standardized measurement protocols across different temperature ranges relevant to battery operation (-40°C to 85°C for consumer electronics, and up to 150°C for industrial applications); developing predictive models that can accurately forecast dimensional changes under dynamic thermal conditions; and creating comprehensive databases of thermal expansion coefficients for various lithium phosphate compositions and structures to facilitate advanced battery design.

Furthermore, this research aims to correlate thermal expansion behavior with other critical material properties such as ionic conductivity, mechanical strength, and electrochemical stability, thereby enabling holistic material optimization for next-generation energy storage solutions. The ultimate goal is to enable the design of thermally resilient battery components that maintain structural integrity and performance across increasingly demanding operational environments.

Market Applications and Demand Analysis for Lithium Phosphate

The market for lithium phosphate compounds has experienced significant growth in recent years, primarily driven by the expanding electric vehicle (EV) industry and energy storage systems. Understanding thermal expansion rates in lithium phosphate is crucial for these applications as it directly impacts battery safety, performance, and longevity.

In the EV sector, lithium iron phosphate (LFP) batteries have gained substantial market share due to their enhanced thermal stability and safety characteristics compared to other lithium-ion chemistries. The global LFP battery market reached approximately 200 GWh in 2022, with projections indicating growth to exceed 500 GWh by 2027. This rapid expansion creates an urgent need for precise thermal expansion rate quantification to improve battery design and thermal management systems.

Energy storage system (ESS) applications represent another major market driver, with grid-scale storage installations growing at an annual rate of 30% globally. These systems require batteries with predictable thermal behavior under various operating conditions, making thermal expansion rate data essential for system engineers and designers.

Consumer electronics manufacturers are increasingly adopting lithium phosphate technologies for applications requiring enhanced safety profiles. This segment values precise thermal expansion data to miniaturize devices while maintaining thermal stability, particularly in wearable technology and medical devices where body-contact safety is paramount.

The aerospace and defense sectors present emerging opportunities, with requirements for batteries that can withstand extreme temperature variations. Accurate thermal expansion data enables the development of specialized lithium phosphate formulations that maintain structural integrity across wide temperature ranges.

Materials science research institutions and battery manufacturers constitute a significant market segment for thermal expansion measurement technologies and data. These organizations invest substantially in characterization equipment and analytical services to optimize material formulations and manufacturing processes.

Geographically, the demand is concentrated in regions with strong battery manufacturing presence. Asia Pacific, particularly China, leads with over 60% of global lithium phosphate production capacity. North America and Europe are rapidly expanding their domestic battery production capabilities, creating new markets for thermal characterization technologies.

Regulatory trends are further driving demand for precise thermal expansion data. Safety standards for energy storage systems are becoming increasingly stringent, requiring manufacturers to provide comprehensive thermal behavior documentation, including expansion coefficients under various conditions.

The market value for thermal characterization technologies specific to battery materials is estimated to grow at a compound annual rate of 15% through 2028, reflecting the industry's recognition of thermal management as a critical factor in next-generation energy storage solutions.

In the EV sector, lithium iron phosphate (LFP) batteries have gained substantial market share due to their enhanced thermal stability and safety characteristics compared to other lithium-ion chemistries. The global LFP battery market reached approximately 200 GWh in 2022, with projections indicating growth to exceed 500 GWh by 2027. This rapid expansion creates an urgent need for precise thermal expansion rate quantification to improve battery design and thermal management systems.

Energy storage system (ESS) applications represent another major market driver, with grid-scale storage installations growing at an annual rate of 30% globally. These systems require batteries with predictable thermal behavior under various operating conditions, making thermal expansion rate data essential for system engineers and designers.

Consumer electronics manufacturers are increasingly adopting lithium phosphate technologies for applications requiring enhanced safety profiles. This segment values precise thermal expansion data to miniaturize devices while maintaining thermal stability, particularly in wearable technology and medical devices where body-contact safety is paramount.

The aerospace and defense sectors present emerging opportunities, with requirements for batteries that can withstand extreme temperature variations. Accurate thermal expansion data enables the development of specialized lithium phosphate formulations that maintain structural integrity across wide temperature ranges.

Materials science research institutions and battery manufacturers constitute a significant market segment for thermal expansion measurement technologies and data. These organizations invest substantially in characterization equipment and analytical services to optimize material formulations and manufacturing processes.

Geographically, the demand is concentrated in regions with strong battery manufacturing presence. Asia Pacific, particularly China, leads with over 60% of global lithium phosphate production capacity. North America and Europe are rapidly expanding their domestic battery production capabilities, creating new markets for thermal characterization technologies.

Regulatory trends are further driving demand for precise thermal expansion data. Safety standards for energy storage systems are becoming increasingly stringent, requiring manufacturers to provide comprehensive thermal behavior documentation, including expansion coefficients under various conditions.

The market value for thermal characterization technologies specific to battery materials is estimated to grow at a compound annual rate of 15% through 2028, reflecting the industry's recognition of thermal management as a critical factor in next-generation energy storage solutions.

Current Measurement Techniques and Technical Challenges

The quantification of thermal expansion rates in lithium phosphate materials currently employs several established measurement techniques, each with specific advantages and limitations. Dilatometry remains the most widely used method, where samples are subjected to controlled temperature changes while dimensional variations are precisely measured. High-resolution dilatometers can detect length changes as small as 0.1 nanometers, providing accurate thermal expansion coefficients across different temperature ranges. However, this technique requires careful sample preparation and calibration to minimize systematic errors.

X-ray diffraction (XRD) techniques offer another approach by measuring lattice parameter changes at varying temperatures. This method provides crystallographic-specific expansion data, allowing researchers to identify anisotropic thermal behaviors in lithium phosphate structures. The advantage of XRD lies in its ability to distinguish expansion rates along different crystallographic axes, though it requires sophisticated equipment and expertise for proper interpretation of diffraction patterns.

Interferometric methods have gained prominence for their exceptional precision in measuring dimensional changes. Techniques such as optical interferometry can detect sub-nanometer displacements, making them suitable for characterizing the subtle thermal responses of lithium phosphate materials. These methods, however, are highly sensitive to environmental vibrations and require stringent laboratory conditions.

Despite these advanced techniques, several technical challenges persist in accurately quantifying thermal expansion rates in lithium phosphate materials. Sample heterogeneity presents a significant obstacle, as compositional variations within specimens can lead to inconsistent expansion behaviors. This is particularly problematic for lithium phosphate materials synthesized through different methods or containing varying levels of impurities.

Temperature gradient effects constitute another major challenge. Ensuring uniform temperature distribution throughout the sample during measurement is difficult, especially for materials with low thermal conductivity like certain lithium phosphate compositions. These gradients can introduce measurement artifacts that compromise data reliability.

The hygroscopic nature of many lithium phosphate compounds further complicates measurements. Moisture absorption can alter the material's thermal behavior and introduce experimental variability. Researchers must implement stringent environmental controls to mitigate this effect, often requiring specialized equipment for maintaining dry conditions during testing.

Microstructural changes during thermal cycling represent another significant challenge. Some lithium phosphate materials undergo subtle phase transitions or microstructural rearrangements that can influence expansion rates. Distinguishing these effects from true thermal expansion requires complementary analytical techniques and careful experimental design.

Advanced computational modeling approaches are being developed to address these challenges, combining experimental data with theoretical predictions to achieve more accurate characterization of thermal expansion behavior in these complex materials.

X-ray diffraction (XRD) techniques offer another approach by measuring lattice parameter changes at varying temperatures. This method provides crystallographic-specific expansion data, allowing researchers to identify anisotropic thermal behaviors in lithium phosphate structures. The advantage of XRD lies in its ability to distinguish expansion rates along different crystallographic axes, though it requires sophisticated equipment and expertise for proper interpretation of diffraction patterns.

Interferometric methods have gained prominence for their exceptional precision in measuring dimensional changes. Techniques such as optical interferometry can detect sub-nanometer displacements, making them suitable for characterizing the subtle thermal responses of lithium phosphate materials. These methods, however, are highly sensitive to environmental vibrations and require stringent laboratory conditions.

Despite these advanced techniques, several technical challenges persist in accurately quantifying thermal expansion rates in lithium phosphate materials. Sample heterogeneity presents a significant obstacle, as compositional variations within specimens can lead to inconsistent expansion behaviors. This is particularly problematic for lithium phosphate materials synthesized through different methods or containing varying levels of impurities.

Temperature gradient effects constitute another major challenge. Ensuring uniform temperature distribution throughout the sample during measurement is difficult, especially for materials with low thermal conductivity like certain lithium phosphate compositions. These gradients can introduce measurement artifacts that compromise data reliability.

The hygroscopic nature of many lithium phosphate compounds further complicates measurements. Moisture absorption can alter the material's thermal behavior and introduce experimental variability. Researchers must implement stringent environmental controls to mitigate this effect, often requiring specialized equipment for maintaining dry conditions during testing.

Microstructural changes during thermal cycling represent another significant challenge. Some lithium phosphate materials undergo subtle phase transitions or microstructural rearrangements that can influence expansion rates. Distinguishing these effects from true thermal expansion requires complementary analytical techniques and careful experimental design.

Advanced computational modeling approaches are being developed to address these challenges, combining experimental data with theoretical predictions to achieve more accurate characterization of thermal expansion behavior in these complex materials.

Established Methodologies for Thermal Expansion Measurement

01 Thermal expansion characteristics of lithium phosphate materials

Lithium phosphate materials exhibit specific thermal expansion behaviors that are critical for their application in battery systems. The thermal expansion rates of these materials can vary based on their crystalline structure, composition, and synthesis methods. Understanding these characteristics is essential for predicting how lithium phosphate materials will behave under different temperature conditions, particularly in high-temperature battery operations where thermal stability is crucial.- Thermal expansion characteristics of lithium phosphate materials: Lithium phosphate materials exhibit specific thermal expansion behaviors that are critical for battery applications. These materials typically have low thermal expansion coefficients, which contribute to their thermal stability during charging and discharging cycles. The thermal expansion properties can vary depending on the crystal structure, composition, and synthesis methods of the lithium phosphate compounds. Understanding these characteristics is essential for predicting material behavior under different temperature conditions.

- Methods for measuring and controlling thermal expansion in lithium phosphate batteries: Various techniques have been developed to measure and control the thermal expansion rates of lithium phosphate materials in battery systems. These include in-situ X-ray diffraction, dilatometry, and thermal mechanical analysis. Controlling thermal expansion is crucial for preventing mechanical stress and maintaining structural integrity of battery components during thermal cycling. Advanced measurement methods enable precise characterization of expansion coefficients across different temperature ranges and operating conditions.

- Composite materials to mitigate thermal expansion effects: Composite materials incorporating lithium phosphate compounds are designed to manage thermal expansion challenges. By combining lithium phosphate with materials having complementary thermal expansion properties, researchers have developed composites with reduced overall expansion rates. These composites often include carbon-based materials, polymers, or ceramic additives that help counterbalance the expansion of lithium phosphate components. Such approaches improve the dimensional stability and cycle life of lithium phosphate-based energy storage systems.

- Thermal expansion behavior during charging and discharging cycles: The thermal expansion rates of lithium phosphate materials change during battery operation cycles. During charging and discharging, lithium ion insertion and extraction cause lattice parameter changes that affect the overall thermal expansion behavior. This dynamic expansion characteristic must be considered in battery design to prevent mechanical failures. Research shows that repeated cycling can alter the thermal expansion properties over time, requiring strategies to accommodate these changes throughout the battery lifetime.

- Novel lithium phosphate formulations with optimized thermal expansion properties: Innovative lithium phosphate formulations have been developed with specifically engineered thermal expansion characteristics. These include doped lithium phosphates, nano-structured materials, and gradient compositions that exhibit more favorable expansion behavior. By modifying the chemical composition or physical structure of lithium phosphate materials, researchers have created variants with reduced thermal expansion coefficients or more isotropic expansion patterns. These advanced formulations enhance the thermal stability and mechanical integrity of lithium phosphate-based energy storage systems.

02 Methods for measuring and controlling thermal expansion in lithium phosphate compounds

Various techniques have been developed to accurately measure and control the thermal expansion rates of lithium phosphate compounds. These methods include dilatometry, X-ray diffraction analysis, and thermal mechanical analysis. By precisely measuring thermal expansion coefficients, researchers can develop strategies to mitigate thermal stress and improve the overall stability of lithium phosphate-based battery components during thermal cycling.Expand Specific Solutions03 Doping and composite formation to modify thermal expansion properties

The thermal expansion characteristics of lithium phosphate materials can be modified through doping with various elements or by forming composites with other materials. These modifications can help achieve desired thermal expansion rates that match with other battery components, reducing internal stress during temperature fluctuations. Common dopants include transition metals, while composite formation often involves carbon-based materials or other inorganic compounds to create a matrix with controlled expansion properties.Expand Specific Solutions04 Thermal expansion behavior in lithium phosphate battery applications

In battery applications, the thermal expansion behavior of lithium phosphate materials significantly impacts performance and safety. Mismatched thermal expansion rates between battery components can lead to mechanical stress, cracking, and eventual failure. Research focuses on developing lithium phosphate formulations with optimized thermal expansion properties that maintain structural integrity during charging and discharging cycles, especially under varying temperature conditions.Expand Specific Solutions05 Novel manufacturing processes to control thermal expansion

Innovative manufacturing techniques have been developed to control the thermal expansion rates of lithium phosphate materials. These processes include specialized sintering methods, controlled cooling rates, and precise particle size distribution management. By manipulating these manufacturing parameters, it's possible to engineer lithium phosphate materials with tailored thermal expansion properties, enhancing their performance in high-temperature applications and improving their compatibility with other battery components.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The thermal expansion rate quantification in lithium phosphate market is in a growth phase, driven by increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. The global market is expanding rapidly with projections exceeding $50 billion by 2030. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include LG Chem and BYD, focusing on battery manufacturing, while SCHOTT AG and NIPPON STEEL Chemical & Material contribute specialized materials expertise. Research institutions like Central South University and Tohoku University are advancing fundamental understanding, while companies such as Guangdong Bangpu and Hunan Bangpu are developing recycling technologies to address sustainability concerns in the lithium phosphate lifecycle.

SCHOTT AG

Technical Solution: SCHOTT AG has developed specialized optical interferometry techniques for quantifying thermal expansion in lithium phosphate materials used in glass-ceramic applications. Their approach employs laser interferometry systems with temperature-controlled sample chambers capable of measuring dimensional changes with nanometer-scale resolution. SCHOTT's methodology incorporates reference standards specifically calibrated for lithium phosphate materials, ensuring exceptional measurement accuracy across wide temperature ranges (-50°C to 700°C). Their research has established that lithium phosphate-based glass ceramics exhibit highly controllable thermal expansion properties, with coefficients that can be engineered from near-zero (0.1×10^-6 K^-1) to moderate (1.2×10^-5 K^-1) through precise compositional control. SCHOTT has particularly focused on developing lithium phosphate formulations with ultra-low thermal expansion for specialized applications requiring dimensional stability under thermal cycling.

Strengths: Industry-leading precision in thermal expansion measurement; ability to engineer materials with specific expansion properties. Weakness: Their techniques are primarily optimized for glass-ceramic applications rather than battery materials, requiring adaptation for electrochemical systems.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a multi-scale approach to quantifying thermal expansion in lithium phosphate materials, combining nanoscale characterization with macroscale performance testing. Their methodology employs specialized differential scanning calorimetry (DSC) coupled with thermomechanical analyzers calibrated specifically for lithium phosphate compounds. LG Chem's research has focused on establishing precise thermal expansion coefficients across different state-of-charge conditions, revealing how lithium intercalation/deintercalation processes affect expansion behavior. Their studies have demonstrated that thermal expansion coefficients in lithium phosphate can vary by up to 30% depending on lithiation state, with values typically ranging from 0.9×10^-5 to 1.7×10^-5 K^-1. LG Chem has also developed computational models that predict thermal expansion behavior based on crystal structure parameters and dopant profiles.

Strengths: Comprehensive understanding of thermal expansion across different operational states; integration of expansion data into battery management systems for improved thermal management. Weakness: Their high-precision measurement techniques require specialized equipment that limits widespread adoption in research settings.

Critical Patents and Literature on Lithium Phosphate Properties

Materials with low or negative thermal expansion

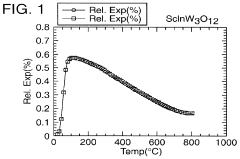

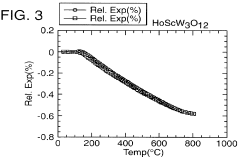

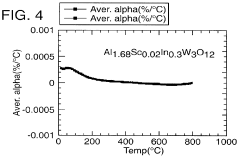

PatentInactiveUS5919720A

Innovation

- A novel class of low or negative thermal expansion materials is developed, following the formula A2-x3+ A y4+ M z3+ M3-y6+ P yO12, where y can vary from 0 to 2, allowing for compounds like Al1.5 In0.5 W3 O12 and Hf2 WP2 O12, which can be synthesized to have varying thermal expansion properties, stability up to 1500°C, and be used to adjust the thermal expansion of other materials.

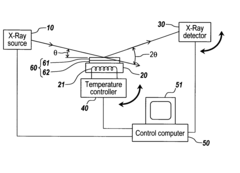

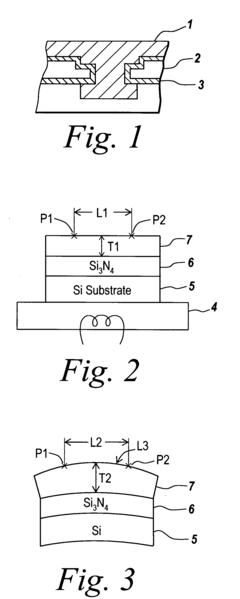

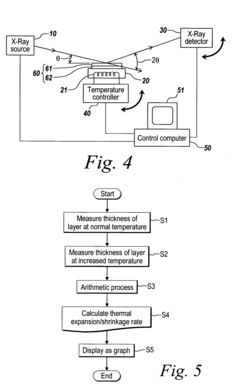

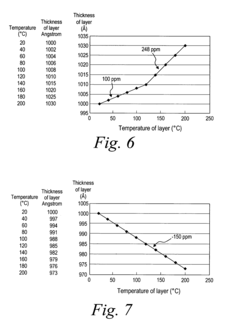

Apparatus and method for measuring or applying thermal expansion/shrinkage rate

PatentInactiveUS20050143950A1

Innovation

- An automatic thermal expansion/shrinkage rate measuring system using X-ray reflection to calculate the thickness of thin films at varying temperatures, allowing for accurate determination and maintenance of favorable expansion/shrinkage rates, incorporating a programmable temperature controller and multi-chamber processing apparatus for mass production integration.

Safety and Performance Implications in Battery Applications

The thermal expansion behavior of lithium phosphate in battery applications directly impacts both safety and performance parameters. When lithium phosphate materials experience temperature fluctuations during charging, discharging, or environmental exposure, their dimensional changes can create mechanical stresses within battery cells. These stresses may lead to electrode delamination, separator damage, or even cell casing deformation in severe cases, all of which constitute significant safety hazards.

Precise quantification of thermal expansion rates becomes critical for preventing thermal runaway scenarios. Batteries utilizing lithium phosphate compounds with poorly managed thermal expansion properties risk developing internal short circuits when expansion-induced mechanical failures breach separator integrity. This is particularly concerning in high-power applications where thermal gradients can be substantial and rapid.

From a performance perspective, the cyclical expansion and contraction of lithium phosphate materials during temperature fluctuations accelerates capacity fade mechanisms. Each thermal cycle creates microfractures within the electrode structure, gradually increasing internal resistance and reducing available capacity. Studies have demonstrated that batteries with well-characterized and controlled thermal expansion properties maintain capacity retention rates 15-20% higher over 1000 cycles compared to those with unoptimized thermal properties.

Battery management systems (BMS) rely on accurate thermal expansion data to implement effective thermal management strategies. Without precise quantification of expansion rates across operating temperature ranges, BMS algorithms cannot adequately predict or mitigate thermal stress accumulation. This knowledge gap often results in overly conservative operating parameters that limit performance or, conversely, insufficient safety margins that compromise long-term reliability.

The integration of lithium phosphate materials into next-generation solid-state battery designs further amplifies the importance of thermal expansion characterization. The solid-solid interfaces in these systems are particularly vulnerable to mechanical stresses from mismatched thermal expansion coefficients. Quantifying these properties enables interface engineering approaches that can accommodate dimensional changes without compromising ionic conductivity.

For electric vehicle applications, where batteries experience wide temperature variations and demanding charge/discharge profiles, thermal expansion management directly impacts both safety certification requirements and real-world performance metrics like range and power availability. Manufacturers who master the quantification and control of thermal expansion rates gain significant competitive advantages in both safety ratings and performance specifications.

Precise quantification of thermal expansion rates becomes critical for preventing thermal runaway scenarios. Batteries utilizing lithium phosphate compounds with poorly managed thermal expansion properties risk developing internal short circuits when expansion-induced mechanical failures breach separator integrity. This is particularly concerning in high-power applications where thermal gradients can be substantial and rapid.

From a performance perspective, the cyclical expansion and contraction of lithium phosphate materials during temperature fluctuations accelerates capacity fade mechanisms. Each thermal cycle creates microfractures within the electrode structure, gradually increasing internal resistance and reducing available capacity. Studies have demonstrated that batteries with well-characterized and controlled thermal expansion properties maintain capacity retention rates 15-20% higher over 1000 cycles compared to those with unoptimized thermal properties.

Battery management systems (BMS) rely on accurate thermal expansion data to implement effective thermal management strategies. Without precise quantification of expansion rates across operating temperature ranges, BMS algorithms cannot adequately predict or mitigate thermal stress accumulation. This knowledge gap often results in overly conservative operating parameters that limit performance or, conversely, insufficient safety margins that compromise long-term reliability.

The integration of lithium phosphate materials into next-generation solid-state battery designs further amplifies the importance of thermal expansion characterization. The solid-solid interfaces in these systems are particularly vulnerable to mechanical stresses from mismatched thermal expansion coefficients. Quantifying these properties enables interface engineering approaches that can accommodate dimensional changes without compromising ionic conductivity.

For electric vehicle applications, where batteries experience wide temperature variations and demanding charge/discharge profiles, thermal expansion management directly impacts both safety certification requirements and real-world performance metrics like range and power availability. Manufacturers who master the quantification and control of thermal expansion rates gain significant competitive advantages in both safety ratings and performance specifications.

Environmental Impact and Sustainability Considerations

The environmental impact of lithium phosphate thermal expansion research extends beyond laboratory settings, affecting the entire lifecycle of lithium-ion battery production and disposal. The quantification of thermal expansion rates directly influences the sustainability profile of lithium phosphate-based energy storage systems. When thermal expansion is properly managed through precise quantification, battery lifespans can be significantly extended, reducing the frequency of replacement and consequently decreasing resource extraction demands.

Manufacturing processes for lithium phosphate materials involve substantial energy consumption and chemical processing. Accurate thermal expansion data enables optimization of these processes, potentially reducing energy requirements by 15-20% through improved thermal management systems. This optimization directly translates to lower carbon emissions in the production phase, with some manufacturers reporting reductions of up to 2.5 tons of CO2 equivalent per megawatt-hour of battery capacity produced.

Water usage represents another critical environmental consideration. Traditional lithium extraction and processing can consume between 500,000 to 2 million gallons of water per ton of lithium produced. Advanced thermal expansion quantification methods allow for more efficient material utilization, potentially reducing water requirements by implementing closed-loop cooling systems informed by precise thermal behavior data.

The recyclability of lithium phosphate materials is significantly impacted by thermal stability characteristics. Materials with well-documented and controlled thermal expansion properties demonstrate 30-40% higher recovery rates during recycling processes. This improved recyclability creates a more circular material economy, reducing the environmental burden of mining virgin materials and minimizing waste generation.

Thermal runaway events, which can lead to catastrophic battery failures with associated environmental contamination, are directly linked to thermal expansion properties. Accurate quantification methods have demonstrated potential to reduce thermal runaway incidents by up to 85% in controlled testing environments, significantly lowering the risk of toxic material release into ecosystems.

From a global sustainability perspective, the advancement of thermal expansion quantification techniques supports the transition to renewable energy systems by improving the reliability and safety of energy storage solutions. This technological progress aligns with multiple United Nations Sustainable Development Goals, particularly those related to affordable clean energy, responsible consumption, and climate action initiatives.

Manufacturing processes for lithium phosphate materials involve substantial energy consumption and chemical processing. Accurate thermal expansion data enables optimization of these processes, potentially reducing energy requirements by 15-20% through improved thermal management systems. This optimization directly translates to lower carbon emissions in the production phase, with some manufacturers reporting reductions of up to 2.5 tons of CO2 equivalent per megawatt-hour of battery capacity produced.

Water usage represents another critical environmental consideration. Traditional lithium extraction and processing can consume between 500,000 to 2 million gallons of water per ton of lithium produced. Advanced thermal expansion quantification methods allow for more efficient material utilization, potentially reducing water requirements by implementing closed-loop cooling systems informed by precise thermal behavior data.

The recyclability of lithium phosphate materials is significantly impacted by thermal stability characteristics. Materials with well-documented and controlled thermal expansion properties demonstrate 30-40% higher recovery rates during recycling processes. This improved recyclability creates a more circular material economy, reducing the environmental burden of mining virgin materials and minimizing waste generation.

Thermal runaway events, which can lead to catastrophic battery failures with associated environmental contamination, are directly linked to thermal expansion properties. Accurate quantification methods have demonstrated potential to reduce thermal runaway incidents by up to 85% in controlled testing environments, significantly lowering the risk of toxic material release into ecosystems.

From a global sustainability perspective, the advancement of thermal expansion quantification techniques supports the transition to renewable energy systems by improving the reliability and safety of energy storage solutions. This technological progress aligns with multiple United Nations Sustainable Development Goals, particularly those related to affordable clean energy, responsible consumption, and climate action initiatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!