How to Troubleshoot 5.4 Triton Engine Air Leak Issues?

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

5.4 Triton Engine Overview and Air Leak Challenges

The 5.4 Triton engine, developed by Ford Motor Company, has been a staple in their lineup of V8 engines since its introduction in the late 1990s. This powerplant has been widely used across various Ford and Lincoln vehicles, including popular models like the F-150, Expedition, and Navigator. Known for its robust performance and reliability, the 5.4 Triton engine has undergone several iterations and improvements over the years to enhance its efficiency and durability.

Despite its reputation for dependability, the 5.4 Triton engine has faced recurring challenges with air leaks, which have become a significant concern for many vehicle owners and mechanics. These air leak issues can manifest in various ways, often leading to decreased engine performance, reduced fuel efficiency, and in some cases, more severe engine problems if left unaddressed.

One of the primary sources of air leaks in the 5.4 Triton engine is the intake manifold gasket. This component, responsible for sealing the connection between the intake manifold and the cylinder heads, can deteriorate over time due to heat exposure and normal wear and tear. When the gasket fails, it allows air to escape from the intake system, disrupting the carefully calibrated air-fuel mixture and potentially causing misfires or rough idling.

Another common area prone to air leaks is the vacuum system. The 5.4 Triton engine relies on a network of vacuum lines to control various engine functions and accessories. These rubber hoses can crack or become brittle with age, leading to vacuum leaks that affect engine performance and emissions control systems.

The exhaust gas recirculation (EGR) system is also a potential source of air leaks in the 5.4 Triton engine. The EGR valve and associated components can develop leaks over time, allowing exhaust gases to escape or ambient air to enter the system unintentionally. This can result in poor engine performance, increased emissions, and potential damage to other engine components.

Valve cover gaskets represent another vulnerability in the 5.4 Triton engine's air seal integrity. These gaskets can degrade, allowing oil to seep out and air to enter the engine, which may lead to oil consumption issues and potential engine damage if not addressed promptly.

Addressing these air leak challenges requires a systematic approach to troubleshooting and repair. Mechanics and vehicle owners must be vigilant in identifying the signs of air leaks, such as unusual engine noises, decreased performance, or visible evidence of leaks. Regular maintenance and inspection of critical components can help prevent many air leak issues before they become severe problems.

Despite its reputation for dependability, the 5.4 Triton engine has faced recurring challenges with air leaks, which have become a significant concern for many vehicle owners and mechanics. These air leak issues can manifest in various ways, often leading to decreased engine performance, reduced fuel efficiency, and in some cases, more severe engine problems if left unaddressed.

One of the primary sources of air leaks in the 5.4 Triton engine is the intake manifold gasket. This component, responsible for sealing the connection between the intake manifold and the cylinder heads, can deteriorate over time due to heat exposure and normal wear and tear. When the gasket fails, it allows air to escape from the intake system, disrupting the carefully calibrated air-fuel mixture and potentially causing misfires or rough idling.

Another common area prone to air leaks is the vacuum system. The 5.4 Triton engine relies on a network of vacuum lines to control various engine functions and accessories. These rubber hoses can crack or become brittle with age, leading to vacuum leaks that affect engine performance and emissions control systems.

The exhaust gas recirculation (EGR) system is also a potential source of air leaks in the 5.4 Triton engine. The EGR valve and associated components can develop leaks over time, allowing exhaust gases to escape or ambient air to enter the system unintentionally. This can result in poor engine performance, increased emissions, and potential damage to other engine components.

Valve cover gaskets represent another vulnerability in the 5.4 Triton engine's air seal integrity. These gaskets can degrade, allowing oil to seep out and air to enter the engine, which may lead to oil consumption issues and potential engine damage if not addressed promptly.

Addressing these air leak challenges requires a systematic approach to troubleshooting and repair. Mechanics and vehicle owners must be vigilant in identifying the signs of air leaks, such as unusual engine noises, decreased performance, or visible evidence of leaks. Regular maintenance and inspection of critical components can help prevent many air leak issues before they become severe problems.

Market Impact of Air Leak Issues in 5.4 Triton Engines

The air leak issues in 5.4 Triton engines have had significant market repercussions, affecting both Ford Motor Company and the broader automotive industry. These problems have led to a decline in consumer confidence and increased warranty claims, impacting Ford's financial performance and market share in the truck segment.

Ford has faced substantial costs associated with addressing these air leak issues, including expenses for recalls, repairs, and customer compensation. The company has had to allocate significant resources to diagnose and resolve the problems, diverting funds from other potential investments in research and development or new product launches.

The reputation of the 5.4 Triton engine has been tarnished due to these persistent air leak issues, leading to a decrease in resale values for affected vehicles. This has not only impacted Ford's brand image but also influenced consumer purchasing decisions, with some buyers opting for competing brands perceived as more reliable.

Competitors in the truck market have capitalized on Ford's challenges, emphasizing the reliability of their own engines in marketing campaigns. This has resulted in a shift in market dynamics, with some consumers moving away from Ford trucks to alternative options, potentially altering long-term brand loyalty patterns.

The aftermarket parts and service industry has seen an uptick in demand for solutions related to 5.4 Triton engine air leaks. Independent repair shops and parts manufacturers have developed specialized offerings to address these issues, creating a niche market segment.

Insurance companies have also been affected, with increased claims related to engine repairs and potential vehicle breakdowns. This has led to adjustments in insurance premiums for affected Ford models, further impacting the total cost of ownership for consumers.

The air leak issues have prompted regulatory scrutiny, with potential implications for emissions compliance and fuel efficiency ratings. This has forced Ford to invest in more rigorous testing and quality control measures, influencing future engine development strategies across the industry.

Overall, the market impact of air leak issues in 5.4 Triton engines extends beyond immediate financial costs, affecting brand perception, consumer behavior, and industry-wide practices in engine design and quality assurance.

Ford has faced substantial costs associated with addressing these air leak issues, including expenses for recalls, repairs, and customer compensation. The company has had to allocate significant resources to diagnose and resolve the problems, diverting funds from other potential investments in research and development or new product launches.

The reputation of the 5.4 Triton engine has been tarnished due to these persistent air leak issues, leading to a decrease in resale values for affected vehicles. This has not only impacted Ford's brand image but also influenced consumer purchasing decisions, with some buyers opting for competing brands perceived as more reliable.

Competitors in the truck market have capitalized on Ford's challenges, emphasizing the reliability of their own engines in marketing campaigns. This has resulted in a shift in market dynamics, with some consumers moving away from Ford trucks to alternative options, potentially altering long-term brand loyalty patterns.

The aftermarket parts and service industry has seen an uptick in demand for solutions related to 5.4 Triton engine air leaks. Independent repair shops and parts manufacturers have developed specialized offerings to address these issues, creating a niche market segment.

Insurance companies have also been affected, with increased claims related to engine repairs and potential vehicle breakdowns. This has led to adjustments in insurance premiums for affected Ford models, further impacting the total cost of ownership for consumers.

The air leak issues have prompted regulatory scrutiny, with potential implications for emissions compliance and fuel efficiency ratings. This has forced Ford to invest in more rigorous testing and quality control measures, influencing future engine development strategies across the industry.

Overall, the market impact of air leak issues in 5.4 Triton engines extends beyond immediate financial costs, affecting brand perception, consumer behavior, and industry-wide practices in engine design and quality assurance.

Current Diagnostic Methods and Limitations

The current diagnostic methods for troubleshooting 5.4 Triton engine air leak issues primarily rely on a combination of visual inspections, pressure testing, and electronic diagnostics. Visual inspections involve carefully examining the engine components, hoses, and connections for visible signs of wear, damage, or loose fittings. This method, while straightforward, can be limited in detecting small or hidden leaks.

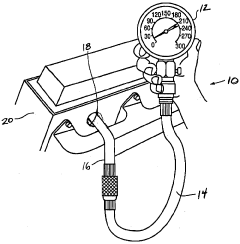

Pressure testing is a more comprehensive approach, involving the use of specialized equipment to pressurize the engine's intake and exhaust systems. By monitoring pressure changes, technicians can identify leaks that might not be visible to the naked eye. However, this method requires specific tools and expertise to perform accurately.

Electronic diagnostics utilize the engine's onboard computer systems to detect irregularities in air flow, fuel mixture, and engine performance. These systems can provide valuable data on potential air leak locations, but they may not always pinpoint the exact source of the leak, especially in cases of multiple or intermittent leaks.

Smoke testing is another technique employed, where non-toxic smoke is introduced into the engine's air intake system. Leaks are then identified by observing where the smoke escapes. This method is particularly effective for detecting small leaks but requires specialized equipment and a controlled environment.

Despite these methods, there are several limitations in current diagnostic approaches. One significant challenge is the complexity of modern engines, with numerous potential leak points and intricate component layouts. This complexity can make it difficult to access and inspect all potential problem areas thoroughly.

Intermittent leaks pose another challenge, as they may not be present during the diagnostic process, leading to misdiagnosis or overlooked issues. Environmental factors, such as temperature and humidity, can also affect the accuracy of certain diagnostic methods, particularly pressure testing.

The reliance on specialized equipment and trained technicians for many of these diagnostic methods can lead to increased costs and longer repair times. Additionally, some diagnostic tools may not be universally compatible with all engine variants, limiting their effectiveness across different vehicle models.

Another limitation is the potential for false positives or negatives in electronic diagnostics. Engine control units may sometimes misinterpret sensor data, leading to incorrect diagnoses of air leak issues. This can result in unnecessary repairs or overlooked problems.

As engine technology continues to evolve, keeping diagnostic methods and equipment up-to-date becomes increasingly challenging. New materials, designs, and electronic systems in modern engines may require the development of novel diagnostic approaches to effectively identify and address air leak issues.

Pressure testing is a more comprehensive approach, involving the use of specialized equipment to pressurize the engine's intake and exhaust systems. By monitoring pressure changes, technicians can identify leaks that might not be visible to the naked eye. However, this method requires specific tools and expertise to perform accurately.

Electronic diagnostics utilize the engine's onboard computer systems to detect irregularities in air flow, fuel mixture, and engine performance. These systems can provide valuable data on potential air leak locations, but they may not always pinpoint the exact source of the leak, especially in cases of multiple or intermittent leaks.

Smoke testing is another technique employed, where non-toxic smoke is introduced into the engine's air intake system. Leaks are then identified by observing where the smoke escapes. This method is particularly effective for detecting small leaks but requires specialized equipment and a controlled environment.

Despite these methods, there are several limitations in current diagnostic approaches. One significant challenge is the complexity of modern engines, with numerous potential leak points and intricate component layouts. This complexity can make it difficult to access and inspect all potential problem areas thoroughly.

Intermittent leaks pose another challenge, as they may not be present during the diagnostic process, leading to misdiagnosis or overlooked issues. Environmental factors, such as temperature and humidity, can also affect the accuracy of certain diagnostic methods, particularly pressure testing.

The reliance on specialized equipment and trained technicians for many of these diagnostic methods can lead to increased costs and longer repair times. Additionally, some diagnostic tools may not be universally compatible with all engine variants, limiting their effectiveness across different vehicle models.

Another limitation is the potential for false positives or negatives in electronic diagnostics. Engine control units may sometimes misinterpret sensor data, leading to incorrect diagnoses of air leak issues. This can result in unnecessary repairs or overlooked problems.

As engine technology continues to evolve, keeping diagnostic methods and equipment up-to-date becomes increasingly challenging. New materials, designs, and electronic systems in modern engines may require the development of novel diagnostic approaches to effectively identify and address air leak issues.

Existing Air Leak Troubleshooting Techniques

01 Air leak detection systems for engines

Various systems and methods for detecting air leaks in engines, particularly in the 5.4 Triton engine. These systems may include pressure sensors, flow meters, and specialized diagnostic tools to identify and locate air leaks in the engine's intake or exhaust systems.- Air leak detection systems for engines: Various systems and methods are developed for detecting air leaks in engines, particularly for the 5.4 Triton engine. These systems often involve pressure sensors, flow meters, and specialized testing equipment to identify and locate air leaks in the engine's intake or exhaust systems.

- Sealing solutions for engine air leaks: Innovative sealing technologies and materials are employed to address air leaks in the 5.4 Triton engine. These may include advanced gaskets, sealants, and specialized components designed to withstand high temperatures and pressures while maintaining an airtight seal in critical areas of the engine.

- Diagnostic tools for air leak identification: Sophisticated diagnostic tools and software are developed to assist in identifying and pinpointing air leaks in the 5.4 Triton engine. These tools may use advanced algorithms, acoustic sensors, or thermal imaging to detect even small air leaks that could affect engine performance.

- Engine design improvements to prevent air leaks: Manufacturers have implemented design improvements in the 5.4 Triton engine to reduce the likelihood of air leaks. These improvements may include redesigned intake manifolds, enhanced cylinder head sealing, or improved gasket materials and designs to ensure better sealing under various operating conditions.

- Maintenance procedures for preventing air leaks: Specific maintenance procedures and best practices are developed to prevent and address air leaks in the 5.4 Triton engine. These may include regular inspections, proper torquing techniques for critical components, and recommended replacement intervals for seals and gaskets prone to degradation over time.

02 Sealing solutions for engine air leaks

Techniques and materials used to seal air leaks in engines, focusing on the 5.4 Triton engine. This may include advanced gasket designs, sealants, and improved manufacturing processes to prevent air leaks at critical junctions in the engine assembly.Expand Specific Solutions03 Engine design improvements to prevent air leaks

Advancements in engine design, specifically for the 5.4 Triton, to minimize the risk of air leaks. This includes improved intake manifold designs, enhanced cylinder head sealing, and optimized component fitment to ensure airtight connections throughout the engine.Expand Specific Solutions04 Diagnostic tools for air leak identification

Specialized diagnostic tools and procedures developed to identify and pinpoint air leaks in the 5.4 Triton engine. These may include electronic diagnostic systems, smoke machines, and pressure testing equipment designed to locate even small air leaks efficiently.Expand Specific Solutions05 Maintenance procedures to prevent air leaks

Preventive maintenance techniques and schedules specifically designed for the 5.4 Triton engine to minimize the occurrence of air leaks. This includes regular inspections, proper torquing procedures, and recommended part replacement intervals to maintain engine integrity.Expand Specific Solutions

Key Players in Engine Diagnostics Industry

The troubleshooting of 5.4 Triton Engine air leak issues is a complex technical challenge in the automotive industry. The market for this specific engine repair is relatively mature, given the long-standing presence of the 5.4 Triton engine in Ford vehicles. However, the demand for effective solutions remains significant due to the engine's widespread use. Companies like Ford Global Technologies, Honda Motor Co., and Robert Bosch GmbH are at the forefront of developing advanced diagnostic tools and repair techniques. The technology for detecting and resolving air leaks has evolved, with companies such as Redline Detection and Delphi Technologies IP Ltd. offering specialized equipment for precise leak detection. As vehicle systems become more complex, the need for sophisticated troubleshooting methods continues to grow, driving innovation in this niche market.

Ford Global Technologies LLC

Technical Solution: Ford, as the manufacturer of the 5.4 Triton engine, has developed a multi-step troubleshooting process specifically tailored for air leak issues. Their approach begins with a visual inspection of common leak points, followed by a pressurized smoke test to reveal hidden leaks. Ford's method includes the use of their proprietary Integrated Diagnostic System (IDS) tool, which can read engine data and provide specific fault codes related to air leaks[2]. They have also implemented design improvements in later models to address common leak points, such as redesigned intake manifold gaskets and updated valve cover designs[4]. Ford's process emphasizes the importance of checking for vacuum leaks, particularly around the EGR system and PCV valve.

Strengths: Manufacturer-specific knowledge, integrated diagnostic tools. Weaknesses: May be less effective for older model engines with design issues.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced diagnostic systems for detecting air leaks in 5.4 Triton engines. Their solution incorporates ultrasonic sensors and pressure testing equipment to pinpoint leak locations with high precision. The system uses a combination of smoke testing and pressure decay analysis to identify even minute leaks. Bosch's diagnostic software interprets sensor data to provide technicians with detailed information on leak severity and location[1]. Their approach also includes a comprehensive database of common 5.4 Triton engine leak points, allowing for faster troubleshooting and repair recommendations[3].

Strengths: High precision leak detection, comprehensive database for quick diagnosis. Weaknesses: May require specialized training for technicians to fully utilize the system's capabilities.

Innovative Air Leak Detection Methods

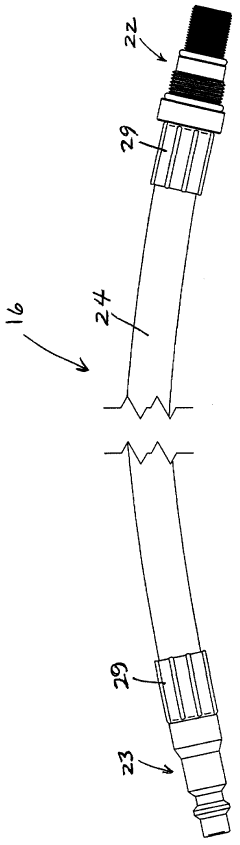

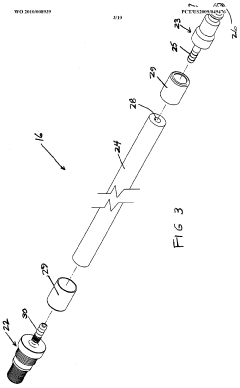

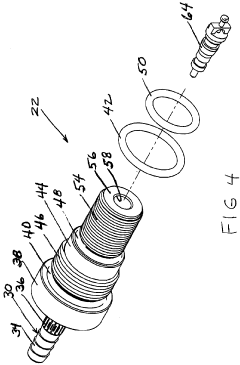

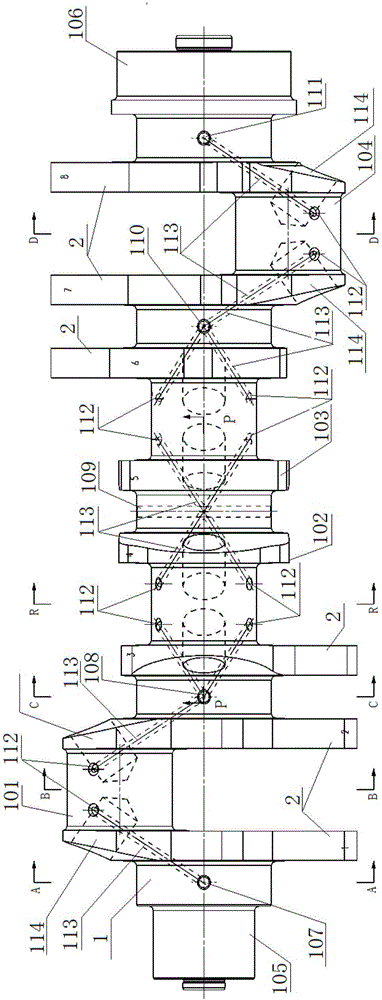

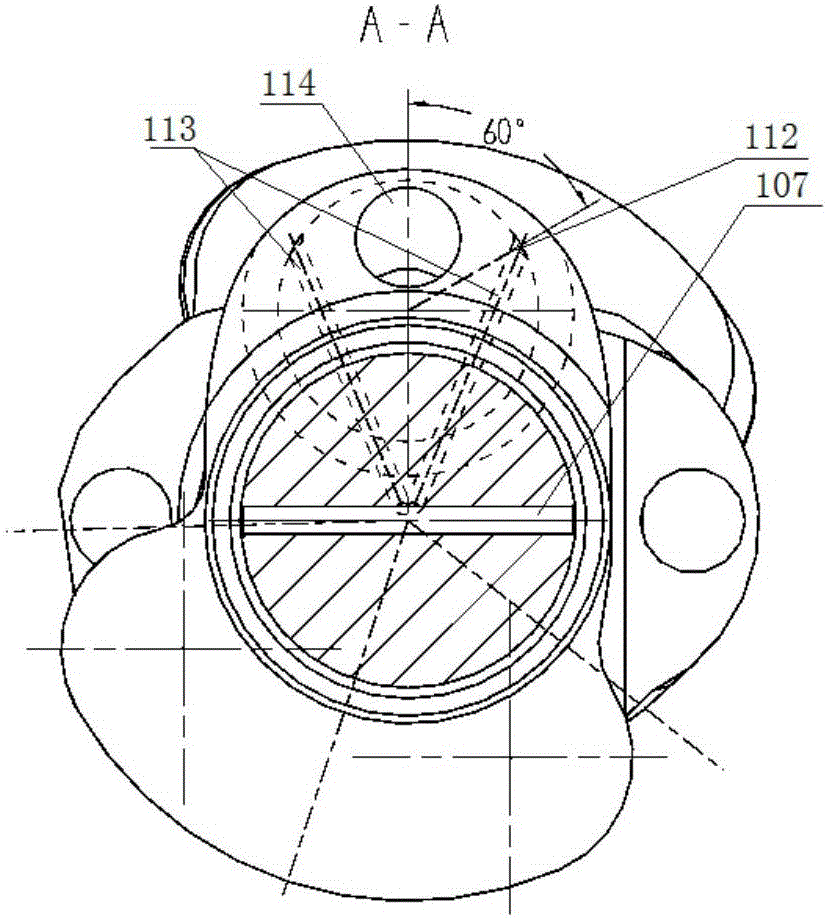

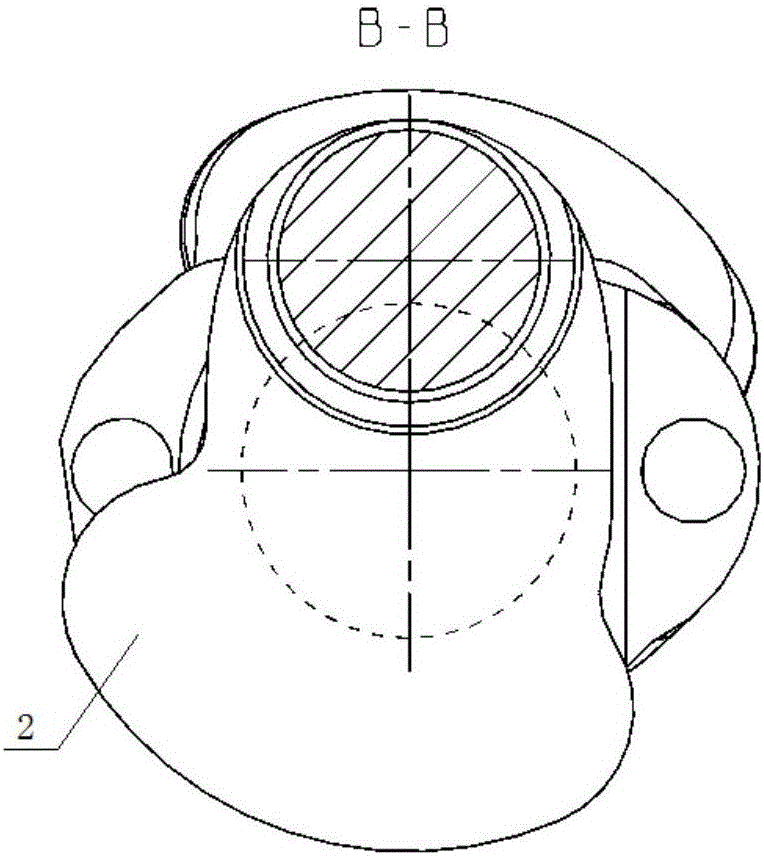

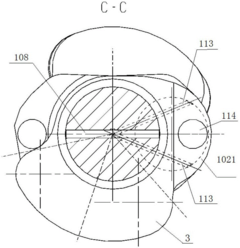

Dual application compression tester adapter assembly and method

PatentWO2010008939A1

Innovation

- A dual-purpose adapter assembly with a leading cylindrical portion having 12 mm external threads and a trailing cylindrical portion with 16 mm external threads, featuring axial spacing between full threads within the range of .636-.737 inches, along with gasket seats for sealing and a hose connector for uninterrupted fluid communication, allowing engagement with both socket sizes.

Crankshaft structure of V-shaped eight-cylinder engine

PatentInactiveCN106246708A

Innovation

- A crankshaft structure of a V-shaped 8-cylinder engine is designed, using arc-shaped counterweights and an optimized firing sequence, adding arc-shaped oil passages and weight-reducing holes, and optimizing the layout of the crank arm and oil passages to reduce internal moments. and torsional vibration amplitude, and improve lubrication.

Environmental Impact of Engine Air Leaks

Engine air leaks in the 5.4 Triton engine can have significant environmental impacts that extend beyond the immediate performance issues of the vehicle. These leaks contribute to increased fuel consumption, as the engine compensates for the loss of air pressure by injecting more fuel into the combustion chamber. This inefficiency leads to higher emissions of greenhouse gases, particularly carbon dioxide, which is a major contributor to climate change.

The incomplete combustion resulting from air leaks also increases the production of harmful pollutants such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons. These pollutants contribute to the formation of smog and ground-level ozone, which can have detrimental effects on air quality and human health, especially in urban areas where vehicle emissions are concentrated.

Furthermore, engine air leaks can cause the engine to run hotter than normal, potentially leading to increased oil consumption. This not only results in more frequent oil changes but also increases the risk of oil leaks, which can contaminate soil and water sources if not properly managed. The additional wear on engine components due to air leaks may also shorten the overall lifespan of the engine, leading to premature replacement and the associated environmental costs of manufacturing new parts or entire engines.

The environmental impact extends to noise pollution as well. Air leaks in the 5.4 Triton engine can create whistling or hissing sounds, contributing to increased noise levels in urban and suburban environments. This noise pollution can have negative effects on wildlife and human well-being, disrupting natural habitats and causing stress in populated areas.

From a resource conservation perspective, the reduced efficiency caused by air leaks means that more fuel is consumed per mile driven. This increased fuel consumption not only depletes finite fossil fuel resources more quickly but also puts additional strain on the entire fuel production and distribution infrastructure, which has its own set of environmental impacts.

Addressing air leak issues in the 5.4 Triton engine is crucial for minimizing these environmental impacts. Proper maintenance, timely repairs, and the use of high-quality replacement parts can significantly reduce emissions, improve fuel efficiency, and extend the engine's lifespan. Additionally, educating vehicle owners about the importance of addressing air leaks promptly can help mitigate the cumulative environmental effects of these issues across the fleet of vehicles equipped with this engine type.

The incomplete combustion resulting from air leaks also increases the production of harmful pollutants such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons. These pollutants contribute to the formation of smog and ground-level ozone, which can have detrimental effects on air quality and human health, especially in urban areas where vehicle emissions are concentrated.

Furthermore, engine air leaks can cause the engine to run hotter than normal, potentially leading to increased oil consumption. This not only results in more frequent oil changes but also increases the risk of oil leaks, which can contaminate soil and water sources if not properly managed. The additional wear on engine components due to air leaks may also shorten the overall lifespan of the engine, leading to premature replacement and the associated environmental costs of manufacturing new parts or entire engines.

The environmental impact extends to noise pollution as well. Air leaks in the 5.4 Triton engine can create whistling or hissing sounds, contributing to increased noise levels in urban and suburban environments. This noise pollution can have negative effects on wildlife and human well-being, disrupting natural habitats and causing stress in populated areas.

From a resource conservation perspective, the reduced efficiency caused by air leaks means that more fuel is consumed per mile driven. This increased fuel consumption not only depletes finite fossil fuel resources more quickly but also puts additional strain on the entire fuel production and distribution infrastructure, which has its own set of environmental impacts.

Addressing air leak issues in the 5.4 Triton engine is crucial for minimizing these environmental impacts. Proper maintenance, timely repairs, and the use of high-quality replacement parts can significantly reduce emissions, improve fuel efficiency, and extend the engine's lifespan. Additionally, educating vehicle owners about the importance of addressing air leaks promptly can help mitigate the cumulative environmental effects of these issues across the fleet of vehicles equipped with this engine type.

Cost-Benefit Analysis of Leak Detection Systems

Implementing leak detection systems for the 5.4 Triton engine requires a thorough cost-benefit analysis to determine the most effective and economical solution. The initial investment in leak detection equipment can be substantial, ranging from $5,000 to $20,000 for advanced systems. However, these costs must be weighed against the potential savings in fuel efficiency, reduced emissions, and prevention of engine damage.

High-quality leak detection systems can identify air leaks as small as 0.1 CFM (cubic feet per minute), which could save up to 1-2% in fuel consumption. For a fleet of vehicles, this translates to significant annual savings. Additionally, early detection of air leaks can prevent more severe engine damage, potentially saving thousands in repair costs per vehicle.

The labor costs associated with regular leak inspections must also be considered. Automated systems can reduce the time required for inspections by up to 75%, allowing technicians to focus on other critical maintenance tasks. This efficiency gain can result in substantial labor cost savings over time.

Environmental benefits should not be overlooked in the analysis. Properly maintained engines with minimal air leaks produce fewer emissions, potentially helping companies meet increasingly stringent environmental regulations and avoid costly fines.

The longevity of leak detection systems is another factor to consider. Most high-quality systems have a lifespan of 5-7 years, with minimal maintenance requirements. This extended usability helps to amortize the initial investment over a longer period, improving the overall return on investment.

Training costs for staff to operate and interpret leak detection equipment should be factored into the analysis. While there is an upfront cost, well-trained technicians can maximize the efficiency of the system, leading to better long-term outcomes and cost savings.

When comparing different leak detection systems, it's crucial to consider not just the purchase price, but also the ongoing operational costs, accuracy rates, and compatibility with existing maintenance processes. Some systems may offer lower upfront costs but require more frequent calibration or have higher false-positive rates, potentially increasing long-term expenses.

In conclusion, while the initial investment in leak detection systems for the 5.4 Triton engine may seem high, the long-term benefits in fuel savings, reduced maintenance costs, and environmental compliance often outweigh these costs. A comprehensive cost-benefit analysis should consider all these factors to determine the most suitable solution for each specific operational context.

High-quality leak detection systems can identify air leaks as small as 0.1 CFM (cubic feet per minute), which could save up to 1-2% in fuel consumption. For a fleet of vehicles, this translates to significant annual savings. Additionally, early detection of air leaks can prevent more severe engine damage, potentially saving thousands in repair costs per vehicle.

The labor costs associated with regular leak inspections must also be considered. Automated systems can reduce the time required for inspections by up to 75%, allowing technicians to focus on other critical maintenance tasks. This efficiency gain can result in substantial labor cost savings over time.

Environmental benefits should not be overlooked in the analysis. Properly maintained engines with minimal air leaks produce fewer emissions, potentially helping companies meet increasingly stringent environmental regulations and avoid costly fines.

The longevity of leak detection systems is another factor to consider. Most high-quality systems have a lifespan of 5-7 years, with minimal maintenance requirements. This extended usability helps to amortize the initial investment over a longer period, improving the overall return on investment.

Training costs for staff to operate and interpret leak detection equipment should be factored into the analysis. While there is an upfront cost, well-trained technicians can maximize the efficiency of the system, leading to better long-term outcomes and cost savings.

When comparing different leak detection systems, it's crucial to consider not just the purchase price, but also the ongoing operational costs, accuracy rates, and compatibility with existing maintenance processes. Some systems may offer lower upfront costs but require more frequent calibration or have higher false-positive rates, potentially increasing long-term expenses.

In conclusion, while the initial investment in leak detection systems for the 5.4 Triton engine may seem high, the long-term benefits in fuel savings, reduced maintenance costs, and environmental compliance often outweigh these costs. A comprehensive cost-benefit analysis should consider all these factors to determine the most suitable solution for each specific operational context.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!