How to Utilize Switch Mode Power Supply Designs to Reduce Coil Whine?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SMPS Coil Whine Background and Objectives

Switch Mode Power Supply (SMPS) designs have become ubiquitous in modern electronics due to their high efficiency and compact size. However, a persistent challenge in SMPS implementation is the phenomenon known as coil whine. This audible noise, typically ranging from 20 Hz to 20 kHz, is produced by electromagnetic forces causing vibrations in the inductor or transformer cores of the power supply.

The origins of coil whine can be traced back to the early days of switched-mode power conversion. As electronic devices became more compact and power-efficient, the need for smaller, more efficient power supplies grew. This led to the widespread adoption of SMPS technology, which, while solving many problems, introduced new challenges such as electromagnetic interference (EMI) and acoustic noise.

Over the years, coil whine has evolved from a minor annoyance to a significant concern for manufacturers and consumers alike. In high-performance computing, gaming systems, and audio equipment, where silence is often valued, coil whine can be particularly problematic. The issue has gained prominence with the increasing power demands of modern GPUs and CPUs, which require more sophisticated power delivery systems.

The primary objective in addressing coil whine is to minimize or eliminate the audible noise without compromising the efficiency and performance of the SMPS. This goal encompasses several key areas of focus:

1. Understanding the root causes of coil whine in different SMPS topologies and operating conditions.

2. Developing innovative circuit designs and control strategies to mitigate the mechanical vibrations that lead to coil whine.

3. Exploring advanced materials and construction techniques for inductors and transformers that are less susceptible to vibration.

4. Implementing effective shielding and damping solutions to contain and absorb the acoustic energy generated by coil whine.

Additionally, there is a growing emphasis on creating standardized testing and measurement protocols for coil whine. This standardization aims to provide consistent benchmarks for manufacturers and allow for more accurate comparisons between different SMPS designs.

As we look to the future, the reduction of coil whine is not just about improving user experience; it's also closely tied to the broader goals of energy efficiency and electronic miniaturization. By addressing this issue, we can pave the way for even more compact and quiet electronic devices, from smartphones to electric vehicles.

The origins of coil whine can be traced back to the early days of switched-mode power conversion. As electronic devices became more compact and power-efficient, the need for smaller, more efficient power supplies grew. This led to the widespread adoption of SMPS technology, which, while solving many problems, introduced new challenges such as electromagnetic interference (EMI) and acoustic noise.

Over the years, coil whine has evolved from a minor annoyance to a significant concern for manufacturers and consumers alike. In high-performance computing, gaming systems, and audio equipment, where silence is often valued, coil whine can be particularly problematic. The issue has gained prominence with the increasing power demands of modern GPUs and CPUs, which require more sophisticated power delivery systems.

The primary objective in addressing coil whine is to minimize or eliminate the audible noise without compromising the efficiency and performance of the SMPS. This goal encompasses several key areas of focus:

1. Understanding the root causes of coil whine in different SMPS topologies and operating conditions.

2. Developing innovative circuit designs and control strategies to mitigate the mechanical vibrations that lead to coil whine.

3. Exploring advanced materials and construction techniques for inductors and transformers that are less susceptible to vibration.

4. Implementing effective shielding and damping solutions to contain and absorb the acoustic energy generated by coil whine.

Additionally, there is a growing emphasis on creating standardized testing and measurement protocols for coil whine. This standardization aims to provide consistent benchmarks for manufacturers and allow for more accurate comparisons between different SMPS designs.

As we look to the future, the reduction of coil whine is not just about improving user experience; it's also closely tied to the broader goals of energy efficiency and electronic miniaturization. By addressing this issue, we can pave the way for even more compact and quiet electronic devices, from smartphones to electric vehicles.

Market Demand for Quiet Power Supplies

The market demand for quiet power supplies has been steadily increasing across various industries, driven by the growing awareness of noise pollution and its impact on user experience. In consumer electronics, particularly in personal computers, gaming consoles, and high-end audio equipment, there is a significant push for silent operation. Users are becoming more discerning, demanding devices that not only perform well but also operate quietly, enhancing their overall experience.

In the professional sector, quiet power supplies are crucial for environments such as recording studios, healthcare facilities, and office spaces. The need for noise reduction in these settings is paramount to maintain concentration, ensure clear audio recordings, and provide a comfortable working atmosphere. This demand extends to industrial applications, where reducing noise levels can contribute to improved workplace safety and compliance with occupational health regulations.

The automotive industry is another key driver of the quiet power supply market. As electric and hybrid vehicles gain popularity, the need for silent power conversion systems becomes more pronounced. Consumers expect a quiet ride, and manufacturers are investing heavily in technologies that minimize noise from power electronics.

Data centers and server farms represent a significant market segment for quiet power supplies. With the exponential growth of cloud computing and big data, these facilities are under pressure to reduce their noise footprint, especially when located near residential areas. This has led to increased demand for power supplies that can handle high loads while maintaining low noise levels.

The telecommunications sector also contributes to the market demand for quiet power supplies. As 5G networks expand, the need for silent operation in base stations and network equipment becomes critical, particularly in urban environments where noise regulations are stringent.

Furthermore, the global trend towards energy efficiency and sustainability indirectly boosts the demand for quiet power supplies. Many energy-efficient designs inherently produce less noise, aligning with both environmental goals and noise reduction objectives.

Market research indicates that the quiet power supply segment is expected to grow significantly in the coming years. This growth is fueled by technological advancements in power electronics, materials science, and acoustic engineering, which enable manufacturers to develop increasingly silent and efficient power supply solutions.

In the professional sector, quiet power supplies are crucial for environments such as recording studios, healthcare facilities, and office spaces. The need for noise reduction in these settings is paramount to maintain concentration, ensure clear audio recordings, and provide a comfortable working atmosphere. This demand extends to industrial applications, where reducing noise levels can contribute to improved workplace safety and compliance with occupational health regulations.

The automotive industry is another key driver of the quiet power supply market. As electric and hybrid vehicles gain popularity, the need for silent power conversion systems becomes more pronounced. Consumers expect a quiet ride, and manufacturers are investing heavily in technologies that minimize noise from power electronics.

Data centers and server farms represent a significant market segment for quiet power supplies. With the exponential growth of cloud computing and big data, these facilities are under pressure to reduce their noise footprint, especially when located near residential areas. This has led to increased demand for power supplies that can handle high loads while maintaining low noise levels.

The telecommunications sector also contributes to the market demand for quiet power supplies. As 5G networks expand, the need for silent operation in base stations and network equipment becomes critical, particularly in urban environments where noise regulations are stringent.

Furthermore, the global trend towards energy efficiency and sustainability indirectly boosts the demand for quiet power supplies. Many energy-efficient designs inherently produce less noise, aligning with both environmental goals and noise reduction objectives.

Market research indicates that the quiet power supply segment is expected to grow significantly in the coming years. This growth is fueled by technological advancements in power electronics, materials science, and acoustic engineering, which enable manufacturers to develop increasingly silent and efficient power supply solutions.

Current Challenges in SMPS Noise Reduction

Switch Mode Power Supply (SMPS) designs have revolutionized power conversion efficiency, but they face a persistent challenge in the form of coil whine. This audible noise, emanating from the magnetic components, particularly inductors and transformers, poses significant issues for both manufacturers and end-users.

The primary source of coil whine in SMPS is the magnetostriction effect, where magnetic materials change shape under varying magnetic fields. As the SMPS rapidly switches currents, it creates fluctuating magnetic fields that cause physical vibrations in the coil windings and core materials. These vibrations, often occurring at frequencies within the human audible range, result in the characteristic high-pitched noise known as coil whine.

Another contributing factor to SMPS noise is the switching frequency itself. While higher switching frequencies can improve efficiency and reduce component size, they can also lead to increased electromagnetic interference (EMI) and potentially more audible noise if not properly managed. The challenge lies in finding the optimal balance between switching frequency, efficiency, and noise reduction.

The physical construction of SMPS components also plays a crucial role in noise generation. Loose windings, improperly secured cores, and suboptimal PCB layouts can exacerbate coil whine. Engineers face the challenge of designing robust mechanical structures that minimize vibrations while maintaining thermal performance and cost-effectiveness.

Temperature variations present another hurdle in SMPS noise reduction. As components heat up during operation, their physical properties change, potentially altering their acoustic characteristics. Designing for consistent noise performance across a wide temperature range adds complexity to the engineering process.

Moreover, the miniaturization trend in electronics poses additional challenges. As SMPS designs become more compact, the proximity of components can lead to increased electromagnetic coupling and potentially more noise. Engineers must navigate the trade-offs between size, performance, and acoustic properties.

The regulatory landscape further complicates SMPS noise reduction efforts. Stringent EMI standards require careful design considerations, often leading to compromises that can impact audible noise performance. Balancing regulatory compliance with noise reduction goals remains an ongoing challenge for SMPS designers.

Lastly, the diverse application environments of SMPS present unique noise reduction challenges. A design that performs quietly in one setting may produce noticeable coil whine in another due to differences in ambient noise levels, mounting configurations, or load conditions. Creating versatile SMPS designs that maintain low noise characteristics across various applications and operating conditions continues to be a significant engineering challenge.

The primary source of coil whine in SMPS is the magnetostriction effect, where magnetic materials change shape under varying magnetic fields. As the SMPS rapidly switches currents, it creates fluctuating magnetic fields that cause physical vibrations in the coil windings and core materials. These vibrations, often occurring at frequencies within the human audible range, result in the characteristic high-pitched noise known as coil whine.

Another contributing factor to SMPS noise is the switching frequency itself. While higher switching frequencies can improve efficiency and reduce component size, they can also lead to increased electromagnetic interference (EMI) and potentially more audible noise if not properly managed. The challenge lies in finding the optimal balance between switching frequency, efficiency, and noise reduction.

The physical construction of SMPS components also plays a crucial role in noise generation. Loose windings, improperly secured cores, and suboptimal PCB layouts can exacerbate coil whine. Engineers face the challenge of designing robust mechanical structures that minimize vibrations while maintaining thermal performance and cost-effectiveness.

Temperature variations present another hurdle in SMPS noise reduction. As components heat up during operation, their physical properties change, potentially altering their acoustic characteristics. Designing for consistent noise performance across a wide temperature range adds complexity to the engineering process.

Moreover, the miniaturization trend in electronics poses additional challenges. As SMPS designs become more compact, the proximity of components can lead to increased electromagnetic coupling and potentially more noise. Engineers must navigate the trade-offs between size, performance, and acoustic properties.

The regulatory landscape further complicates SMPS noise reduction efforts. Stringent EMI standards require careful design considerations, often leading to compromises that can impact audible noise performance. Balancing regulatory compliance with noise reduction goals remains an ongoing challenge for SMPS designers.

Lastly, the diverse application environments of SMPS present unique noise reduction challenges. A design that performs quietly in one setting may produce noticeable coil whine in another due to differences in ambient noise levels, mounting configurations, or load conditions. Creating versatile SMPS designs that maintain low noise characteristics across various applications and operating conditions continues to be a significant engineering challenge.

Existing Solutions for Coil Whine Mitigation

01 Noise reduction techniques in switch mode power supplies

Various methods are employed to reduce coil whine in switch mode power supplies. These include optimizing the switching frequency, using advanced control algorithms, implementing spread spectrum techniques, and improving the physical design of the transformer and inductor components. These approaches aim to minimize electromagnetic interference and acoustic noise generated by the power supply.- Noise reduction techniques in switch mode power supplies: Various methods are employed to reduce coil whine in switch mode power supplies. These include optimizing the switching frequency, using spread spectrum techniques, implementing soft-switching topologies, and improving the overall design of the power supply to minimize electromagnetic interference and acoustic noise.

- Magnetic component design for reduced audible noise: Careful design of magnetic components, such as transformers and inductors, can significantly reduce coil whine. This involves selecting appropriate core materials, optimizing winding techniques, and using specialized construction methods to minimize mechanical vibrations that contribute to audible noise.

- Active noise cancellation in power supplies: Active noise cancellation techniques can be implemented in switch mode power supplies to counteract coil whine. This involves sensing the noise produced by the power supply and generating an out-of-phase signal to cancel it out, resulting in reduced audible noise.

- Resonant and quasi-resonant power supply topologies: Resonant and quasi-resonant power supply topologies can help reduce coil whine by smoothing out the switching waveforms and reducing the stress on components. These topologies often operate at higher frequencies, which can move the audible noise outside the human hearing range.

- Thermal management and mechanical damping: Proper thermal management and mechanical damping techniques can help reduce coil whine in switch mode power supplies. This includes using appropriate heat sinking, potting compounds, and vibration-absorbing materials to minimize mechanical resonances and thermal-induced noise.

02 Magnetic core material selection and design

The choice of magnetic core materials and their design play a crucial role in reducing coil whine. Using high-quality ferrite cores, implementing gapped core designs, and optimizing the core geometry can help minimize magnetostriction effects and reduce acoustic noise emissions from the power supply components.Expand Specific Solutions03 Active noise cancellation in power supplies

Active noise cancellation techniques are implemented to counteract coil whine in switch mode power supplies. These methods involve generating anti-phase signals to cancel out the acoustic noise produced by the power supply components, resulting in reduced audible noise and improved overall performance.Expand Specific Solutions04 Thermal management and mechanical damping

Effective thermal management and mechanical damping techniques are employed to minimize coil whine. This includes using thermal compounds, implementing proper heat dissipation methods, and incorporating vibration-absorbing materials to reduce mechanical resonance and acoustic noise transmission from the power supply components.Expand Specific Solutions05 Advanced control and modulation schemes

Sophisticated control and modulation schemes are developed to address coil whine issues in switch mode power supplies. These include implementing variable switching frequencies, pulse-width modulation techniques, and adaptive control algorithms to optimize power conversion efficiency while minimizing acoustic noise generation.Expand Specific Solutions

Key Players in SMPS Industry

The market for switch mode power supply designs to reduce coil whine is in a mature stage, with a significant global market size driven by increasing demand for energy-efficient power solutions across various industries. The technology has reached a high level of maturity, with established players like Murata Manufacturing, ON Semiconductor, and Renesas Electronics leading the field. These companies, along with others such as Power Integrations and NXP Semiconductors, are continuously innovating to improve efficiency and reduce electromagnetic interference. The competitive landscape is characterized by a mix of large multinational corporations and specialized power supply manufacturers, all striving to develop more advanced solutions for noise reduction in switch mode power supplies.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed innovative approaches to reduce coil whine in switch mode power supplies, leveraging their expertise in passive components and power modules. Their MYMGK series of DC-DC converters incorporates advanced EMI suppression techniques, including the use of low-ESR capacitors and optimized PCB layouts to minimize high-frequency noise[8]. Murata has also focused on improving the mechanical design of their power inductors, such as the DFEH series, which features a closed magnetic core structure that helps contain electromagnetic fields and reduce acoustic noise[9]. Furthermore, their power supply modules often integrate spread spectrum frequency modulation to distribute switching noise over a wider frequency range, effectively reducing audible coil whine[10].

Strengths: Extensive experience in passive components and EMI suppression, vertically integrated manufacturing capabilities. Weaknesses: Primary focus on component-level solutions may require additional integration effort for system-level implementations.

Renesas Electronics Corp.

Technical Solution: Renesas Electronics has developed advanced techniques for reducing coil whine in switch mode power supplies, focusing on both hardware and software solutions. Their RAA2230XX series of digital multiphase controllers incorporates proprietary Acoustic Noise Reduction (ANR) technology, which uses a combination of frequency dithering and phase-shedding techniques to minimize audible noise[6]. The company's R-Car power management ICs for automotive applications feature spread-spectrum clock generation to reduce EMI and associated acoustic noise. Additionally, Renesas has implemented adaptive voltage positioning (AVP) in their power management solutions, which helps reduce voltage stress on capacitors, potentially decreasing their contribution to coil whine[7].

Strengths: Strong presence in automotive and industrial markets, integrated solutions combining power management and microcontrollers. Weaknesses: Some solutions may be optimized for specific markets, potentially limiting cross-industry applicability.

Core Innovations in SMPS Noise Reduction

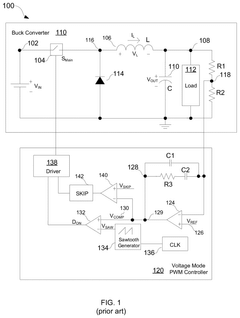

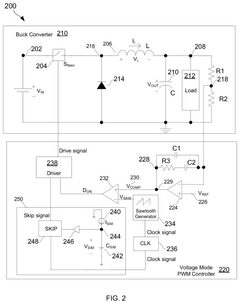

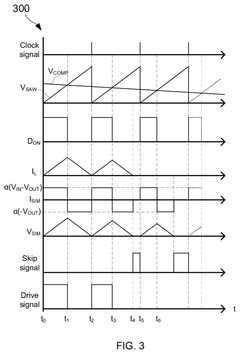

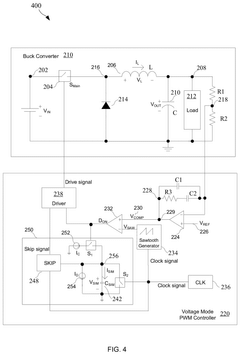

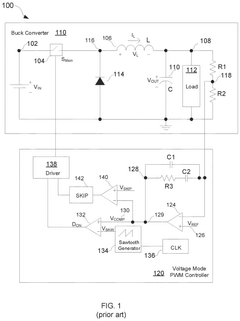

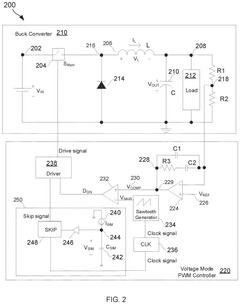

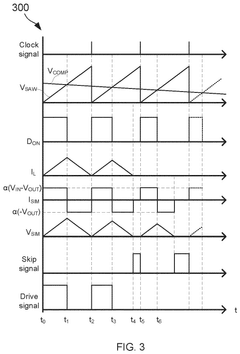

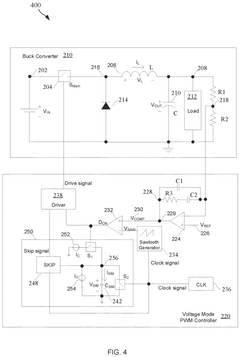

Switching Mode Power Converter with Pulse Skipping and Control Method Thereof

PatentPendingUS20250192666A1

Innovation

- A switching mode power converter with pulse skipping and a control method that includes a control circuit with a current source and a capacitor, which charges and discharges based on the PWM signal, triggering pulse skipping when the capacitor voltage drops below a skip threshold.

Switching mode power converter with pulse skipping and control method thereof

PatentPendingEP4568092A1

Innovation

- A circuit and method that include a control circuit with a current source and capacitor to charge and discharge based on PWM signals, triggering the PWM controller to skip pulses when the capacitor voltage drops below a skip threshold before the end of a switching cycle.

EMC Regulations for Power Supplies

Electromagnetic Compatibility (EMC) regulations for power supplies are critical in ensuring that electronic devices operate without causing or experiencing electromagnetic interference. These regulations are established by various international and regional bodies to maintain the integrity of electrical systems and prevent potential hazards. The International Electrotechnical Commission (IEC) sets global standards, while regional entities like the Federal Communications Commission (FCC) in the United States and the European Union's CE marking system enforce specific requirements.

Power supplies, particularly Switch Mode Power Supplies (SMPS), must comply with EMC standards to minimize electromagnetic emissions and ensure immunity to external electromagnetic disturbances. These regulations typically cover two main aspects: emissions and susceptibility. Emissions standards limit the amount of electromagnetic energy a device can radiate or conduct into its environment, while susceptibility standards ensure that the device can operate correctly in the presence of electromagnetic disturbances.

Key EMC regulations for power supplies include IEC 61000-3-2 for harmonic current emissions, IEC 61000-3-3 for voltage fluctuations and flicker, and IEC 61000-4 series for various immunity tests. In the context of coil whine reduction in SMPS designs, EMC regulations play a crucial role. Coil whine, often caused by electromagnetic forces in inductors or transformers, can contribute to both audible noise and electromagnetic emissions.

To address coil whine while maintaining EMC compliance, SMPS designers must consider several strategies. These may include optimizing switching frequencies to move potential noise outside the audible range, implementing spread spectrum techniques to distribute emissions across a wider frequency band, and using advanced shielding and filtering methods. Additionally, careful component selection and layout design are essential to minimize parasitic effects that can exacerbate EMC issues.

Compliance with EMC regulations often requires extensive testing and validation processes. Power supplies must undergo various tests, including radiated and conducted emissions measurements, electrostatic discharge (ESD) immunity, and surge immunity tests. These tests ensure that the power supply not only performs its primary function but also coexists harmoniously with other electronic devices in its intended environment.

As technology advances and electronic devices become more prevalent and complex, EMC regulations continue to evolve. Designers must stay informed about the latest standards and testing methodologies to ensure their power supply designs remain compliant. This ongoing process of adaptation and improvement is crucial in addressing challenges like coil whine reduction while maintaining the overall electromagnetic compatibility of the system.

Power supplies, particularly Switch Mode Power Supplies (SMPS), must comply with EMC standards to minimize electromagnetic emissions and ensure immunity to external electromagnetic disturbances. These regulations typically cover two main aspects: emissions and susceptibility. Emissions standards limit the amount of electromagnetic energy a device can radiate or conduct into its environment, while susceptibility standards ensure that the device can operate correctly in the presence of electromagnetic disturbances.

Key EMC regulations for power supplies include IEC 61000-3-2 for harmonic current emissions, IEC 61000-3-3 for voltage fluctuations and flicker, and IEC 61000-4 series for various immunity tests. In the context of coil whine reduction in SMPS designs, EMC regulations play a crucial role. Coil whine, often caused by electromagnetic forces in inductors or transformers, can contribute to both audible noise and electromagnetic emissions.

To address coil whine while maintaining EMC compliance, SMPS designers must consider several strategies. These may include optimizing switching frequencies to move potential noise outside the audible range, implementing spread spectrum techniques to distribute emissions across a wider frequency band, and using advanced shielding and filtering methods. Additionally, careful component selection and layout design are essential to minimize parasitic effects that can exacerbate EMC issues.

Compliance with EMC regulations often requires extensive testing and validation processes. Power supplies must undergo various tests, including radiated and conducted emissions measurements, electrostatic discharge (ESD) immunity, and surge immunity tests. These tests ensure that the power supply not only performs its primary function but also coexists harmoniously with other electronic devices in its intended environment.

As technology advances and electronic devices become more prevalent and complex, EMC regulations continue to evolve. Designers must stay informed about the latest standards and testing methodologies to ensure their power supply designs remain compliant. This ongoing process of adaptation and improvement is crucial in addressing challenges like coil whine reduction while maintaining the overall electromagnetic compatibility of the system.

Thermal Management in Low-Noise SMPS

Thermal management plays a crucial role in the design of low-noise Switch Mode Power Supplies (SMPS). Effective thermal management not only ensures the longevity and reliability of the power supply but also contributes significantly to reducing coil whine. The primary sources of heat in SMPS are switching components, such as MOSFETs and diodes, as well as magnetic components like transformers and inductors.

To address thermal issues in low-noise SMPS designs, engineers employ various strategies. One common approach is the use of heat sinks and thermal pads to dissipate heat from critical components. These passive cooling solutions help maintain optimal operating temperatures, reducing the likelihood of thermal-induced coil whine. Additionally, careful component selection, such as choosing low-ESR capacitors and high-efficiency magnetic cores, can minimize heat generation at the source.

Active cooling methods, including forced-air cooling with fans or liquid cooling systems, may be implemented in high-power applications where passive cooling is insufficient. However, these solutions must be carefully designed to avoid introducing additional noise into the system. Low-noise fans and vibration-dampening mounts are often utilized to mitigate potential acoustic issues.

Thermal simulation and analysis tools play a vital role in optimizing SMPS designs for low noise and efficient heat dissipation. These tools allow engineers to identify hotspots and optimize component placement and PCB layout for improved thermal performance. Advanced techniques such as thermal vias and copper pour areas on PCBs can enhance heat distribution and dissipation.

Another critical aspect of thermal management in low-noise SMPS is the selection of appropriate enclosure materials and designs. Enclosures with good thermal conductivity and strategically placed vents can facilitate natural convection cooling without compromising electromagnetic interference (EMI) shielding. Some designs incorporate thermally conductive materials or heat-spreading technologies within the enclosure to enhance overall thermal performance.

Implementing temperature monitoring and thermal protection circuits is essential for maintaining safe operating conditions and preventing thermal runaway. These circuits can adjust the SMPS operation or initiate a controlled shutdown if temperature thresholds are exceeded, ensuring long-term reliability and minimizing the risk of thermal-induced noise issues.

By addressing thermal management comprehensively in low-noise SMPS designs, engineers can significantly reduce the occurrence of coil whine and other noise-related problems, while also improving overall system efficiency and reliability.

To address thermal issues in low-noise SMPS designs, engineers employ various strategies. One common approach is the use of heat sinks and thermal pads to dissipate heat from critical components. These passive cooling solutions help maintain optimal operating temperatures, reducing the likelihood of thermal-induced coil whine. Additionally, careful component selection, such as choosing low-ESR capacitors and high-efficiency magnetic cores, can minimize heat generation at the source.

Active cooling methods, including forced-air cooling with fans or liquid cooling systems, may be implemented in high-power applications where passive cooling is insufficient. However, these solutions must be carefully designed to avoid introducing additional noise into the system. Low-noise fans and vibration-dampening mounts are often utilized to mitigate potential acoustic issues.

Thermal simulation and analysis tools play a vital role in optimizing SMPS designs for low noise and efficient heat dissipation. These tools allow engineers to identify hotspots and optimize component placement and PCB layout for improved thermal performance. Advanced techniques such as thermal vias and copper pour areas on PCBs can enhance heat distribution and dissipation.

Another critical aspect of thermal management in low-noise SMPS is the selection of appropriate enclosure materials and designs. Enclosures with good thermal conductivity and strategically placed vents can facilitate natural convection cooling without compromising electromagnetic interference (EMI) shielding. Some designs incorporate thermally conductive materials or heat-spreading technologies within the enclosure to enhance overall thermal performance.

Implementing temperature monitoring and thermal protection circuits is essential for maintaining safe operating conditions and preventing thermal runaway. These circuits can adjust the SMPS operation or initiate a controlled shutdown if temperature thresholds are exceeded, ensuring long-term reliability and minimizing the risk of thermal-induced noise issues.

By addressing thermal management comprehensively in low-noise SMPS designs, engineers can significantly reduce the occurrence of coil whine and other noise-related problems, while also improving overall system efficiency and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!