Innovations in LS Engine Balance Shaft Designs

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Balance Evolution

The evolution of LS engine balance shaft designs represents a significant journey in automotive engineering, marked by continuous innovation and refinement. Initially, LS engines, known for their compact and lightweight design, faced challenges in maintaining smooth operation, particularly at higher RPMs. The early iterations of these engines relied primarily on inherent design characteristics and counterweights to mitigate vibrations.

As automotive technology progressed, engineers recognized the need for more sophisticated balance solutions to meet increasing demands for engine refinement and efficiency. This led to the introduction of balance shafts in LS engines, a pivotal moment in their evolution. These balance shafts, typically rotating at twice the engine speed, were designed to counteract the second-order vibrations inherent in inline and V-configuration engines.

The first generation of balance shafts in LS engines were relatively simple, focusing on basic vibration reduction. However, as performance expectations grew, so did the complexity of these systems. Engineers began experimenting with various materials, such as lightweight alloys, to reduce the overall mass of the balance shafts while maintaining their effectiveness. This period also saw the development of more precise manufacturing techniques, allowing for tighter tolerances and better balancing.

A significant leap forward came with the integration of computer-aided design and simulation tools. These technologies enabled engineers to model and predict engine vibrations with unprecedented accuracy, leading to more effective balance shaft designs. This era saw the emergence of asymmetrical balance shaft configurations, tailored to address specific vibration patterns unique to different LS engine variants.

The pursuit of fuel efficiency and emissions reduction also played a crucial role in balance shaft evolution. Engineers began focusing on reducing the parasitic losses associated with balance shafts, leading to innovations in bearing technology and lubrication systems. Some designs incorporated variable activation mechanisms, allowing the balance shafts to disengage under certain operating conditions, further improving efficiency.

Recent advancements have seen the integration of balance shafts with other engine systems. For instance, some designs now incorporate oil pumps or other auxiliary components directly into the balance shaft assembly, maximizing space utilization and reducing overall engine complexity. Additionally, the use of advanced materials like carbon fiber composites in balance shaft construction is being explored, promising further weight reduction and improved performance.

The latest frontier in LS engine balance shaft design involves the use of active vibration control systems. These cutting-edge solutions utilize sensors and actuators to dynamically counteract engine vibrations in real-time, offering unprecedented levels of refinement across a wide range of operating conditions. This technology represents a paradigm shift from purely mechanical solutions to intelligent, adaptive systems that can respond to changing engine dynamics instantaneously.

As automotive technology progressed, engineers recognized the need for more sophisticated balance solutions to meet increasing demands for engine refinement and efficiency. This led to the introduction of balance shafts in LS engines, a pivotal moment in their evolution. These balance shafts, typically rotating at twice the engine speed, were designed to counteract the second-order vibrations inherent in inline and V-configuration engines.

The first generation of balance shafts in LS engines were relatively simple, focusing on basic vibration reduction. However, as performance expectations grew, so did the complexity of these systems. Engineers began experimenting with various materials, such as lightweight alloys, to reduce the overall mass of the balance shafts while maintaining their effectiveness. This period also saw the development of more precise manufacturing techniques, allowing for tighter tolerances and better balancing.

A significant leap forward came with the integration of computer-aided design and simulation tools. These technologies enabled engineers to model and predict engine vibrations with unprecedented accuracy, leading to more effective balance shaft designs. This era saw the emergence of asymmetrical balance shaft configurations, tailored to address specific vibration patterns unique to different LS engine variants.

The pursuit of fuel efficiency and emissions reduction also played a crucial role in balance shaft evolution. Engineers began focusing on reducing the parasitic losses associated with balance shafts, leading to innovations in bearing technology and lubrication systems. Some designs incorporated variable activation mechanisms, allowing the balance shafts to disengage under certain operating conditions, further improving efficiency.

Recent advancements have seen the integration of balance shafts with other engine systems. For instance, some designs now incorporate oil pumps or other auxiliary components directly into the balance shaft assembly, maximizing space utilization and reducing overall engine complexity. Additionally, the use of advanced materials like carbon fiber composites in balance shaft construction is being explored, promising further weight reduction and improved performance.

The latest frontier in LS engine balance shaft design involves the use of active vibration control systems. These cutting-edge solutions utilize sensors and actuators to dynamically counteract engine vibrations in real-time, offering unprecedented levels of refinement across a wide range of operating conditions. This technology represents a paradigm shift from purely mechanical solutions to intelligent, adaptive systems that can respond to changing engine dynamics instantaneously.

Market Demand Analysis

The market demand for innovations in LS engine balance shaft designs has been steadily increasing in recent years, driven by several key factors. Automotive manufacturers are facing stricter emissions regulations and fuel efficiency standards globally, pushing them to develop more refined and efficient engines. This has led to a growing interest in balance shaft technologies that can reduce engine vibrations and improve overall performance.

The passenger vehicle segment, particularly in the mid-range and luxury markets, has shown significant demand for smoother-running engines. Consumers are increasingly prioritizing comfort and refinement in their vehicles, making balance shaft innovations a crucial selling point. This trend is especially pronounced in regions with mature automotive markets, such as North America, Europe, and parts of Asia.

In the commercial vehicle sector, there is a rising demand for balance shaft technologies that can enhance engine durability and reduce maintenance costs. Fleet operators are seeking ways to improve fuel efficiency and extend engine life, making advanced balance shaft designs an attractive option. This demand is particularly strong in the long-haul trucking industry, where engine reliability and efficiency directly impact operational costs.

The aftermarket segment also presents a growing opportunity for balance shaft innovations. As vehicle owners become more aware of the benefits of reduced engine vibrations, there is an increasing willingness to invest in aftermarket balance shaft upgrades. This trend is especially notable among enthusiasts and owners of older vehicles looking to improve their driving experience.

Emerging markets, particularly in Asia and South America, are showing rapid growth in demand for vehicles with more refined engines. As disposable incomes rise in these regions, consumers are gravitating towards vehicles with higher levels of comfort and performance, creating new opportunities for balance shaft technologies.

The electric vehicle (EV) market, while primarily focused on battery-electric powertrains, is also driving demand for balance shaft innovations in range extender engines and hybrid powertrains. As automakers develop more sophisticated hybrid systems, there is a need for compact, efficient, and smooth-running internal combustion engines to complement electric motors.

Industry analysts project that the global market for engine balance shaft systems will continue to grow at a compound annual growth rate (CAGR) of around 4-5% over the next five years. This growth is expected to be driven by the increasing adoption of four-cylinder engines in place of larger V6 and V8 engines, as well as the ongoing push for improved NVH (Noise, Vibration, and Harshness) characteristics across all vehicle segments.

The passenger vehicle segment, particularly in the mid-range and luxury markets, has shown significant demand for smoother-running engines. Consumers are increasingly prioritizing comfort and refinement in their vehicles, making balance shaft innovations a crucial selling point. This trend is especially pronounced in regions with mature automotive markets, such as North America, Europe, and parts of Asia.

In the commercial vehicle sector, there is a rising demand for balance shaft technologies that can enhance engine durability and reduce maintenance costs. Fleet operators are seeking ways to improve fuel efficiency and extend engine life, making advanced balance shaft designs an attractive option. This demand is particularly strong in the long-haul trucking industry, where engine reliability and efficiency directly impact operational costs.

The aftermarket segment also presents a growing opportunity for balance shaft innovations. As vehicle owners become more aware of the benefits of reduced engine vibrations, there is an increasing willingness to invest in aftermarket balance shaft upgrades. This trend is especially notable among enthusiasts and owners of older vehicles looking to improve their driving experience.

Emerging markets, particularly in Asia and South America, are showing rapid growth in demand for vehicles with more refined engines. As disposable incomes rise in these regions, consumers are gravitating towards vehicles with higher levels of comfort and performance, creating new opportunities for balance shaft technologies.

The electric vehicle (EV) market, while primarily focused on battery-electric powertrains, is also driving demand for balance shaft innovations in range extender engines and hybrid powertrains. As automakers develop more sophisticated hybrid systems, there is a need for compact, efficient, and smooth-running internal combustion engines to complement electric motors.

Industry analysts project that the global market for engine balance shaft systems will continue to grow at a compound annual growth rate (CAGR) of around 4-5% over the next five years. This growth is expected to be driven by the increasing adoption of four-cylinder engines in place of larger V6 and V8 engines, as well as the ongoing push for improved NVH (Noise, Vibration, and Harshness) characteristics across all vehicle segments.

Technical Challenges

The development of LS engine balance shaft designs faces several significant technical challenges that require innovative solutions. One of the primary obstacles is achieving optimal balance and vibration reduction without substantially increasing engine weight or complexity. Engineers must carefully consider the trade-offs between performance improvements and the added mass of balance shafts.

Another critical challenge lies in the integration of balance shafts into existing engine architectures. Retrofitting balance shafts into established LS engine designs often requires extensive modifications to the engine block, oil system, and surrounding components. This integration process can be particularly complex when dealing with limited space within the engine bay.

The durability and longevity of balance shaft systems present additional hurdles. These components operate at high speeds and are subjected to significant forces, necessitating robust materials and precise manufacturing techniques. Ensuring long-term reliability while maintaining cost-effectiveness remains a persistent challenge for engineers.

Noise, vibration, and harshness (NVH) reduction is a key focus area in balance shaft design. While the primary goal is to counteract engine vibrations, poorly designed or implemented balance shafts can introduce new sources of noise or vibration. Achieving a harmonious balance between vibration reduction and overall NVH performance requires sophisticated modeling and testing.

Power loss is another concern in balance shaft implementation. The rotating mass of balance shafts inevitably consumes some engine power, which can impact overall efficiency. Minimizing this power loss while maintaining effective vibration cancellation is a delicate balancing act that engineers must navigate.

The complexity of control systems for balance shafts adds another layer of technical difficulty. Precise timing and speed control are crucial for optimal performance, especially in engines with variable displacement or cylinder deactivation technologies. Developing robust control algorithms and integrating them seamlessly with existing engine management systems pose significant challenges.

Lastly, cost considerations play a crucial role in balance shaft innovations. While performance improvements are desirable, they must be achieved within reasonable cost parameters to ensure commercial viability. This necessitates creative engineering solutions and careful material selection to optimize the cost-benefit ratio of balance shaft implementations in LS engines.

Another critical challenge lies in the integration of balance shafts into existing engine architectures. Retrofitting balance shafts into established LS engine designs often requires extensive modifications to the engine block, oil system, and surrounding components. This integration process can be particularly complex when dealing with limited space within the engine bay.

The durability and longevity of balance shaft systems present additional hurdles. These components operate at high speeds and are subjected to significant forces, necessitating robust materials and precise manufacturing techniques. Ensuring long-term reliability while maintaining cost-effectiveness remains a persistent challenge for engineers.

Noise, vibration, and harshness (NVH) reduction is a key focus area in balance shaft design. While the primary goal is to counteract engine vibrations, poorly designed or implemented balance shafts can introduce new sources of noise or vibration. Achieving a harmonious balance between vibration reduction and overall NVH performance requires sophisticated modeling and testing.

Power loss is another concern in balance shaft implementation. The rotating mass of balance shafts inevitably consumes some engine power, which can impact overall efficiency. Minimizing this power loss while maintaining effective vibration cancellation is a delicate balancing act that engineers must navigate.

The complexity of control systems for balance shafts adds another layer of technical difficulty. Precise timing and speed control are crucial for optimal performance, especially in engines with variable displacement or cylinder deactivation technologies. Developing robust control algorithms and integrating them seamlessly with existing engine management systems pose significant challenges.

Lastly, cost considerations play a crucial role in balance shaft innovations. While performance improvements are desirable, they must be achieved within reasonable cost parameters to ensure commercial viability. This necessitates creative engineering solutions and careful material selection to optimize the cost-benefit ratio of balance shaft implementations in LS engines.

Current Design Solutions

01 Balance shaft design for LS engines

Balance shafts are used in LS engines to reduce vibration and improve overall engine smoothness. These shafts are designed to counteract the inherent imbalances in the engine's rotating assembly. The design of these balance shafts is crucial for optimal engine performance and longevity.- Balance shaft design for LS engines: Balance shafts are used in LS engines to reduce vibration and improve overall engine smoothness. These shafts are designed to counteract the inherent imbalances in the engine's rotating assembly. The design typically includes counterweights and precise positioning to effectively cancel out unwanted vibrations.

- Integration of balance shafts with engine components: Balance shafts in LS engines are often integrated with other engine components to optimize space and efficiency. This integration may involve incorporating the balance shafts into the oil pump drive system or positioning them within the engine block. Such designs help to reduce overall engine size and weight while maintaining effective vibration control.

- Material selection for balance shafts: The choice of materials for balance shafts in LS engines is crucial for their performance and durability. Materials are selected based on their strength, weight, and ability to withstand high rotational speeds. Advanced alloys or composite materials may be used to achieve the desired balance between weight reduction and structural integrity.

- Balance shaft drive mechanisms: Various drive mechanisms are employed to power the balance shafts in LS engines. These may include gear-driven systems, chain drives, or belt-driven arrangements. The choice of drive mechanism affects the overall efficiency, noise levels, and maintenance requirements of the balance shaft system.

- Electronic control and monitoring of balance shafts: Advanced LS engine designs may incorporate electronic control and monitoring systems for balance shafts. These systems can adjust the operation of balance shafts based on engine speed and load conditions, optimizing their effectiveness across different operating ranges. Sensors and control units may be used to ensure proper functioning and detect any issues with the balance shaft system.

02 Balance shaft positioning and mounting

The positioning and mounting of balance shafts in LS engines are critical for their effectiveness. Proper placement ensures that the counterbalancing forces are applied correctly to minimize vibrations. Various mounting techniques and locations within the engine block are employed to achieve optimal balance.Expand Specific Solutions03 Balance shaft drive mechanisms

Different drive mechanisms are used to rotate the balance shafts in LS engines. These can include gear-driven systems, chain drives, or belt-driven setups. The choice of drive mechanism affects the overall efficiency and reliability of the balance shaft system.Expand Specific Solutions04 Material selection for balance shafts

The materials used in manufacturing balance shafts for LS engines play a crucial role in their performance and durability. Lightweight yet strong materials are preferred to minimize the additional mass while maintaining structural integrity. Various alloys and composites are explored to achieve the optimal balance between weight and strength.Expand Specific Solutions05 Balance shaft lubrication systems

Proper lubrication is essential for the smooth operation and longevity of balance shafts in LS engines. Specialized lubrication systems are designed to ensure adequate oil flow to the balance shaft bearings and other critical components. These systems may include dedicated oil passages, spray nozzles, or integrated lubrication channels within the engine block.Expand Specific Solutions

Key Industry Players

The competitive landscape for innovations in LS Engine Balance Shaft Designs is characterized by a mature market with established players and ongoing technological advancements. Major automotive manufacturers like Honda, BMW, and Hyundai are actively involved in refining balance shaft designs to improve engine performance and efficiency. The market size is substantial, given the widespread use of LS engines in various vehicle types. Companies such as Magna Powertrain and Schaeffler Technologies are at the forefront of developing advanced balance shaft solutions, leveraging their expertise in drivetrain components. The technology's maturity is evident, with continuous incremental improvements rather than disruptive innovations, as manufacturers focus on optimizing existing designs for better fuel economy and reduced vibrations.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed innovative LS engine balance shaft designs to improve engine smoothness and reduce vibration. Their approach involves using counter-rotating balance shafts with optimized weight distribution to cancel out second-order vibrations inherent in inline-four engines[1]. Honda's design incorporates lightweight materials and precision manufacturing techniques to minimize parasitic losses. The company has also implemented a modular balance shaft system that can be easily adapted to different engine sizes and configurations, allowing for greater flexibility in engine design and production[3]. Additionally, Honda has integrated advanced bearing technologies to reduce friction and improve durability of the balance shaft system[5].

Strengths: Improved engine smoothness, reduced vibration, adaptable to various engine sizes. Weaknesses: Increased complexity and cost, potential for additional maintenance requirements.

Bayerische Motoren Werke AG

Technical Solution: BMW has made significant advancements in LS engine balance shaft designs, focusing on enhancing performance and efficiency. Their innovative approach includes the use of hollow balance shafts to reduce rotating mass while maintaining structural integrity[2]. BMW has also implemented a variable balance shaft system that can adjust its counterbalancing effect based on engine speed and load, optimizing performance across different operating conditions[4]. The company has integrated advanced materials such as carbon fiber reinforced polymers in balance shaft components to further reduce weight and improve responsiveness[6]. BMW's balance shaft designs also incorporate sophisticated oil management systems to ensure proper lubrication and heat dissipation, contributing to increased longevity and reliability of the engine[8].

Strengths: Reduced rotating mass, adaptive performance, improved efficiency. Weaknesses: Higher production costs, increased system complexity.

Innovative Shaft Patents

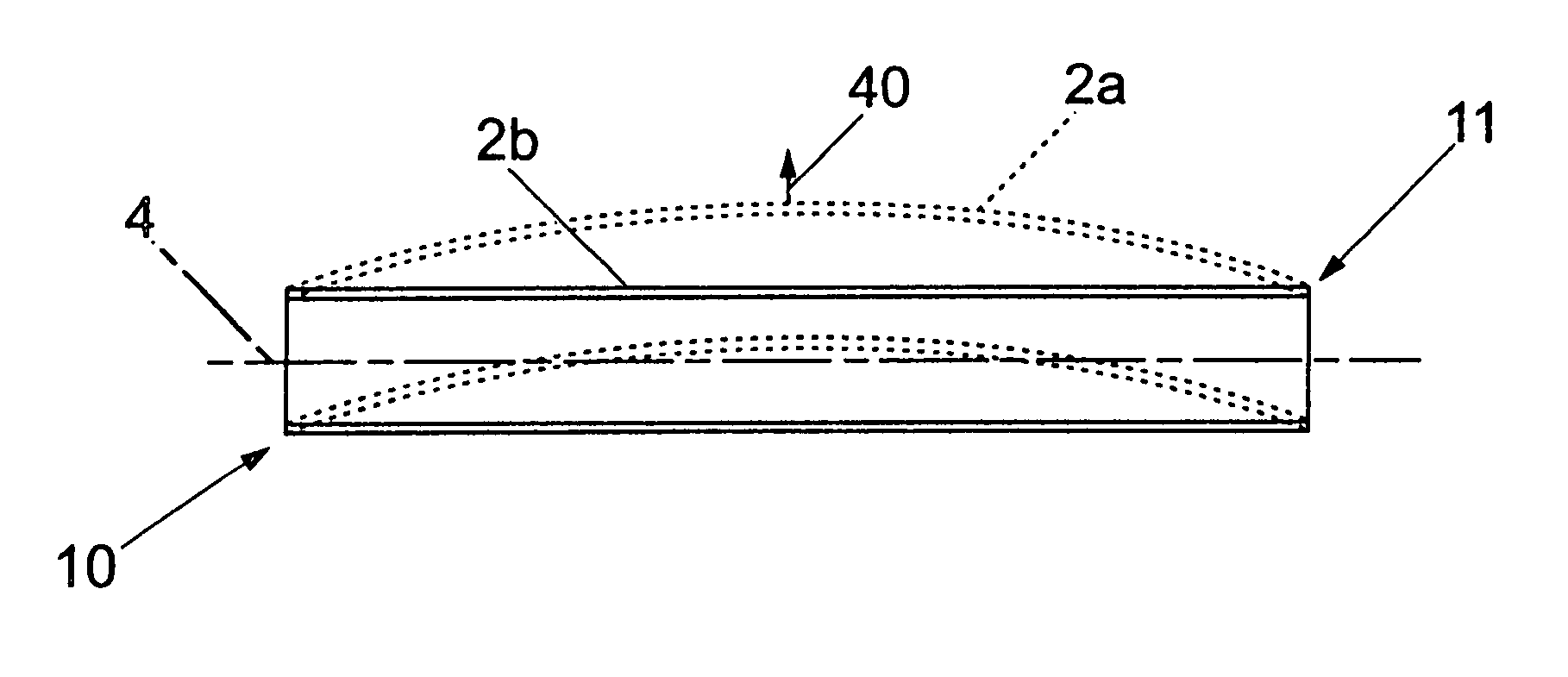

Balance shaft

PatentWO2020043241A1

Innovation

- A balancing shaft design where the clamping element is axially connected to both the unbalanced shaft and the bearing ring, indirectly securing the bearing ring against axial displacement, with a groove in the bearing pin and snap hooks or projections for additional stability, allowing the bearing ring to radially spring back and enhance the ratio of shaft unbalance to mass for a lightweight construction.

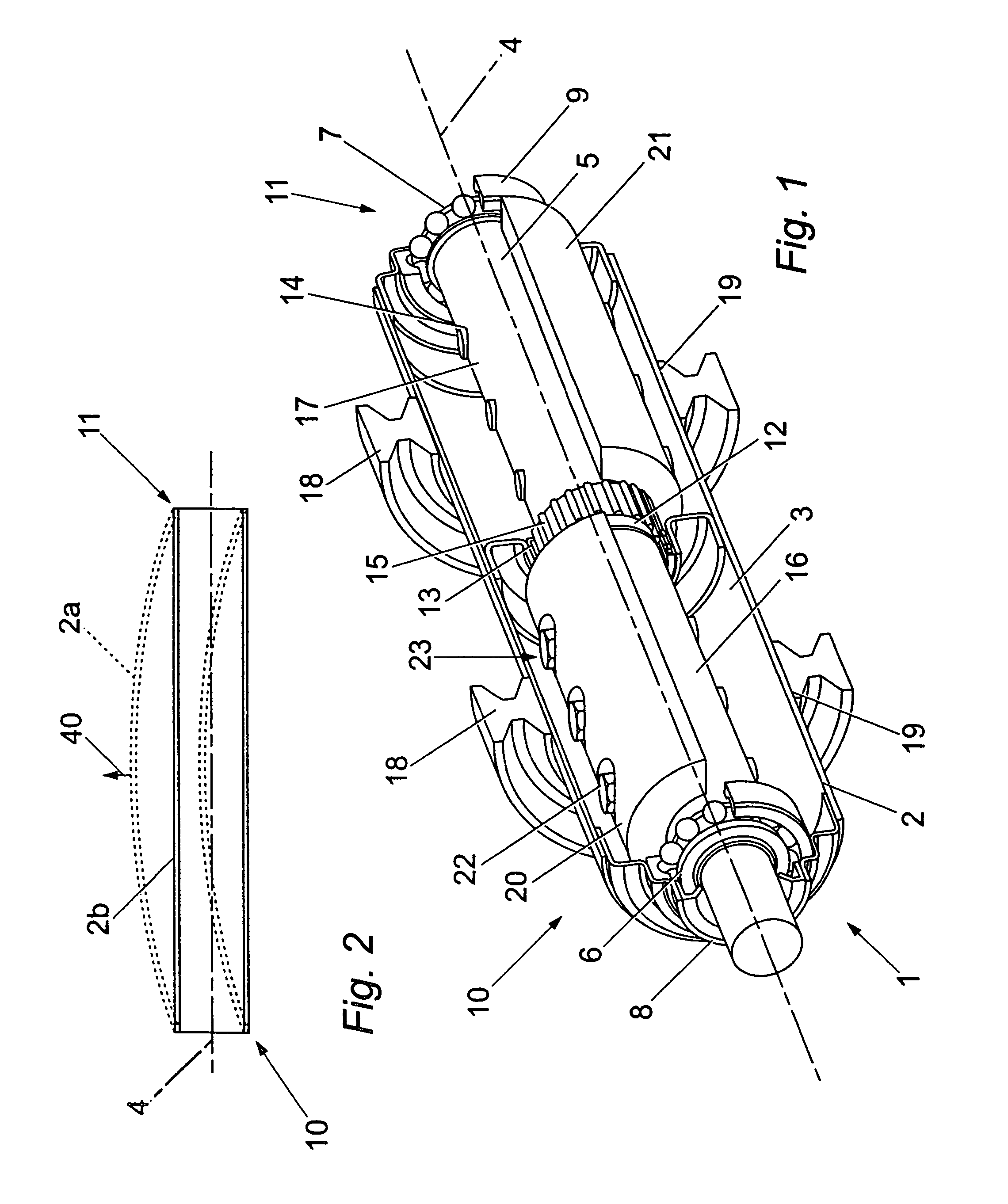

Balance shaft assembly

PatentInactiveUS6971361B2

Innovation

- A flexible tubular housing with front, rear, and intermediate bearings supports a balance shaft, allowing for greater transverse bending stiffness and accommodating misalignment, enabling longer balance shafts and a self-contained lubrication system, reducing the need for precise alignment and machining.

NVH Performance Metrics

NVH (Noise, Vibration, and Harshness) performance metrics are crucial indicators for evaluating the effectiveness of balance shaft designs in LS engines. These metrics provide quantitative measures of the engine's smoothness, quietness, and overall refinement, which are essential for customer satisfaction and brand perception.

One key NVH metric is vibration amplitude, typically measured in millimeters per second (mm/s) or inches per second (in/s). Lower vibration amplitudes indicate better balance and reduced engine shake. For LS engines with innovative balance shaft designs, vibration amplitudes are often targeted to be below 0.5 mm/s across the engine's operating range.

Noise levels, measured in decibels (dB), are another critical NVH metric. Advanced balance shaft designs aim to reduce engine noise, particularly in the frequency range of 20-200 Hz, where human hearing is most sensitive. A well-designed balance shaft system can achieve noise reductions of up to 3-5 dB compared to conventional designs.

Frequency analysis is an essential tool for assessing NVH performance. Fast Fourier Transform (FFT) analysis helps identify specific frequencies at which vibrations or noise peaks occur. Innovative balance shaft designs strive to minimize peaks at engine firing frequencies and their harmonics.

Torsional vibration is another important metric, measured in degrees of crankshaft rotation. Effective balance shaft designs can reduce torsional vibration by up to 30% compared to engines without balance shafts, improving driveline smoothness and component longevity.

Subjective evaluations also play a role in NVH performance assessment. Metrics such as the Articulation Index (AI) or Speech Interference Level (SIL) quantify the impact of engine noise on in-cabin communication. Higher AI values and lower SIL values indicate better NVH performance.

Engine mount transmissibility is a critical metric for assessing how effectively vibrations are isolated from the vehicle structure. Innovative balance shaft designs aim to reduce transmissibility by 20-30% across a wide frequency range, particularly at idle and low engine speeds.

Acceleration measurements at various points on the engine and vehicle body provide valuable NVH data. Root Mean Square (RMS) acceleration values, typically measured in m/s², offer a comprehensive view of overall vibration levels. Advanced balance shaft designs target RMS acceleration reductions of 15-25% compared to baseline engines.

By focusing on these NVH performance metrics, engineers can quantitatively assess the effectiveness of new balance shaft designs in LS engines. This data-driven approach enables continuous improvement and optimization of engine refinement, ultimately leading to enhanced customer satisfaction and competitive advantage in the marketplace.

One key NVH metric is vibration amplitude, typically measured in millimeters per second (mm/s) or inches per second (in/s). Lower vibration amplitudes indicate better balance and reduced engine shake. For LS engines with innovative balance shaft designs, vibration amplitudes are often targeted to be below 0.5 mm/s across the engine's operating range.

Noise levels, measured in decibels (dB), are another critical NVH metric. Advanced balance shaft designs aim to reduce engine noise, particularly in the frequency range of 20-200 Hz, where human hearing is most sensitive. A well-designed balance shaft system can achieve noise reductions of up to 3-5 dB compared to conventional designs.

Frequency analysis is an essential tool for assessing NVH performance. Fast Fourier Transform (FFT) analysis helps identify specific frequencies at which vibrations or noise peaks occur. Innovative balance shaft designs strive to minimize peaks at engine firing frequencies and their harmonics.

Torsional vibration is another important metric, measured in degrees of crankshaft rotation. Effective balance shaft designs can reduce torsional vibration by up to 30% compared to engines without balance shafts, improving driveline smoothness and component longevity.

Subjective evaluations also play a role in NVH performance assessment. Metrics such as the Articulation Index (AI) or Speech Interference Level (SIL) quantify the impact of engine noise on in-cabin communication. Higher AI values and lower SIL values indicate better NVH performance.

Engine mount transmissibility is a critical metric for assessing how effectively vibrations are isolated from the vehicle structure. Innovative balance shaft designs aim to reduce transmissibility by 20-30% across a wide frequency range, particularly at idle and low engine speeds.

Acceleration measurements at various points on the engine and vehicle body provide valuable NVH data. Root Mean Square (RMS) acceleration values, typically measured in m/s², offer a comprehensive view of overall vibration levels. Advanced balance shaft designs target RMS acceleration reductions of 15-25% compared to baseline engines.

By focusing on these NVH performance metrics, engineers can quantitatively assess the effectiveness of new balance shaft designs in LS engines. This data-driven approach enables continuous improvement and optimization of engine refinement, ultimately leading to enhanced customer satisfaction and competitive advantage in the marketplace.

Manufacturing Processes

The manufacturing processes for LS engine balance shaft designs have evolved significantly to meet the demands of modern automotive production. Precision machining techniques are crucial in producing balance shafts that effectively reduce engine vibrations. Computer Numerical Control (CNC) machining is widely employed to achieve the tight tolerances required for these components. This process allows for consistent and accurate production of complex shaft geometries, including precisely positioned counterweights.

Forging is another key manufacturing method used in balance shaft production. This process involves shaping metal through compressive forces, resulting in a stronger and more durable component compared to traditional casting methods. Hot forging is particularly beneficial for balance shafts, as it allows for the creation of near-net-shape parts with improved grain structure and mechanical properties.

Heat treatment processes play a vital role in enhancing the performance and longevity of balance shafts. Techniques such as induction hardening are employed to increase the surface hardness of specific areas on the shaft, particularly the bearing surfaces. This localized hardening improves wear resistance without compromising the overall ductility of the component.

Surface finishing techniques are essential in achieving the required smoothness and dimensional accuracy of balance shafts. Grinding and polishing operations are commonly used to refine the shaft's surface, ensuring proper fitment and reducing friction in operation. Advanced coating technologies, such as Diamond-Like Carbon (DLC) coatings, are sometimes applied to further reduce friction and improve wear resistance.

In recent years, additive manufacturing techniques have begun to make inroads into balance shaft production. While not yet widely adopted for high-volume production, 3D printing technologies offer the potential for rapid prototyping and the creation of complex, lightweight designs that would be challenging to produce using traditional methods.

Quality control measures are integral to the manufacturing process. Coordinate Measuring Machines (CMMs) are used to verify dimensional accuracy, while non-destructive testing methods such as ultrasonic inspection ensure the structural integrity of the balance shafts. These rigorous quality checks are essential in maintaining the high standards required for automotive components.

As automotive manufacturers continue to push for lighter, more efficient engines, the manufacturing processes for balance shafts are likely to see further innovations. The integration of advanced materials, such as high-strength alloys or even composite materials, may necessitate the development of new manufacturing techniques tailored to these materials' unique properties.

Forging is another key manufacturing method used in balance shaft production. This process involves shaping metal through compressive forces, resulting in a stronger and more durable component compared to traditional casting methods. Hot forging is particularly beneficial for balance shafts, as it allows for the creation of near-net-shape parts with improved grain structure and mechanical properties.

Heat treatment processes play a vital role in enhancing the performance and longevity of balance shafts. Techniques such as induction hardening are employed to increase the surface hardness of specific areas on the shaft, particularly the bearing surfaces. This localized hardening improves wear resistance without compromising the overall ductility of the component.

Surface finishing techniques are essential in achieving the required smoothness and dimensional accuracy of balance shafts. Grinding and polishing operations are commonly used to refine the shaft's surface, ensuring proper fitment and reducing friction in operation. Advanced coating technologies, such as Diamond-Like Carbon (DLC) coatings, are sometimes applied to further reduce friction and improve wear resistance.

In recent years, additive manufacturing techniques have begun to make inroads into balance shaft production. While not yet widely adopted for high-volume production, 3D printing technologies offer the potential for rapid prototyping and the creation of complex, lightweight designs that would be challenging to produce using traditional methods.

Quality control measures are integral to the manufacturing process. Coordinate Measuring Machines (CMMs) are used to verify dimensional accuracy, while non-destructive testing methods such as ultrasonic inspection ensure the structural integrity of the balance shafts. These rigorous quality checks are essential in maintaining the high standards required for automotive components.

As automotive manufacturers continue to push for lighter, more efficient engines, the manufacturing processes for balance shafts are likely to see further innovations. The integration of advanced materials, such as high-strength alloys or even composite materials, may necessitate the development of new manufacturing techniques tailored to these materials' unique properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!