Integration of LS Engines in Maritime Applications

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Maritime Integration Background

The integration of LS (Luxury Sport) engines in maritime applications represents a significant technological shift in the marine industry. This trend has emerged from the automotive sector, where LS engines have gained popularity due to their robust performance, reliability, and adaptability. The maritime industry's interest in these engines stems from the need for more efficient, powerful, and compact propulsion systems for various watercraft.

LS engines, originally designed for high-performance vehicles, have undergone substantial modifications to suit marine environments. These adaptations address the unique challenges posed by saltwater exposure, constant operation, and varying load conditions encountered in maritime settings. The evolution of LS engines for marine use has been driven by the demand for increased fuel efficiency, reduced emissions, and improved power-to-weight ratios in boats and ships.

The development of marine-specific LS engines has been marked by several key milestones. Initially, these engines were primarily used in smaller recreational vessels. However, as the technology matured, their application expanded to larger craft, including commercial boats and even some smaller ships. This expansion has been facilitated by advancements in engine management systems, corrosion-resistant materials, and cooling technologies tailored for marine use.

One of the primary goals in integrating LS engines into maritime applications is to enhance vessel performance while meeting increasingly stringent environmental regulations. This objective aligns with the global push towards more sustainable maritime operations, as LS engines offer the potential for reduced fuel consumption and lower emissions compared to traditional marine engines.

The integration process has also spurred innovation in related systems, such as marine-grade exhaust systems, specialized cooling circuits, and advanced electronic control units. These developments have not only improved the performance of LS engines in marine environments but have also contributed to the overall advancement of marine propulsion technology.

As the maritime industry continues to evolve, the integration of LS engines represents a convergence of automotive and marine technologies. This cross-pollination of ideas and engineering solutions has opened new avenues for research and development in marine propulsion. It has also challenged traditional notions of marine engine design, encouraging a more holistic approach to vessel power systems that considers factors such as fuel efficiency, environmental impact, and operational flexibility.

LS engines, originally designed for high-performance vehicles, have undergone substantial modifications to suit marine environments. These adaptations address the unique challenges posed by saltwater exposure, constant operation, and varying load conditions encountered in maritime settings. The evolution of LS engines for marine use has been driven by the demand for increased fuel efficiency, reduced emissions, and improved power-to-weight ratios in boats and ships.

The development of marine-specific LS engines has been marked by several key milestones. Initially, these engines were primarily used in smaller recreational vessels. However, as the technology matured, their application expanded to larger craft, including commercial boats and even some smaller ships. This expansion has been facilitated by advancements in engine management systems, corrosion-resistant materials, and cooling technologies tailored for marine use.

One of the primary goals in integrating LS engines into maritime applications is to enhance vessel performance while meeting increasingly stringent environmental regulations. This objective aligns with the global push towards more sustainable maritime operations, as LS engines offer the potential for reduced fuel consumption and lower emissions compared to traditional marine engines.

The integration process has also spurred innovation in related systems, such as marine-grade exhaust systems, specialized cooling circuits, and advanced electronic control units. These developments have not only improved the performance of LS engines in marine environments but have also contributed to the overall advancement of marine propulsion technology.

As the maritime industry continues to evolve, the integration of LS engines represents a convergence of automotive and marine technologies. This cross-pollination of ideas and engineering solutions has opened new avenues for research and development in marine propulsion. It has also challenged traditional notions of marine engine design, encouraging a more holistic approach to vessel power systems that considers factors such as fuel efficiency, environmental impact, and operational flexibility.

Marine Market Demand Analysis

The maritime industry has been experiencing a growing demand for more efficient and environmentally friendly propulsion systems, creating a significant market opportunity for the integration of LS (Lightweight and Sustainable) engines in marine applications. This demand is driven by several factors, including stricter environmental regulations, rising fuel costs, and the need for improved vessel performance.

The global marine engine market is projected to expand substantially in the coming years, with a particular focus on sustainable solutions. LS engines, known for their reduced weight and improved fuel efficiency, are well-positioned to capture a significant share of this growing market. The demand for these engines is particularly strong in commercial shipping, passenger vessels, and offshore support vessels.

Environmental regulations, such as the International Maritime Organization's (IMO) sulfur cap and greenhouse gas emission reduction targets, are key drivers for the adoption of LS engines. Ship owners and operators are increasingly seeking propulsion systems that can meet these stringent requirements while maintaining operational efficiency. LS engines, with their advanced combustion technologies and compatibility with alternative fuels, offer a viable solution to address these regulatory challenges.

The cruise and ferry sectors represent another substantial market for LS engine integration. As these industries recover from the impact of the global pandemic, there is a renewed focus on sustainability and passenger comfort. LS engines, with their reduced noise and vibration characteristics, align well with the demands of these sectors.

In the offshore support vessel market, the push for more efficient operations and reduced environmental impact is creating opportunities for LS engine integration. These vessels often operate in environmentally sensitive areas, making the adoption of cleaner propulsion systems a priority for operators.

The fishing industry, while traditionally conservative in adopting new technologies, is showing increasing interest in LS engines. The potential for fuel savings and reduced emissions is particularly attractive in this sector, where operating costs significantly impact profitability.

Geographically, the demand for LS engines in maritime applications varies. Developed markets such as Europe and North America are leading the adoption, driven by stricter regulations and a greater emphasis on sustainability. However, emerging markets in Asia and South America are also showing growing interest, particularly as they modernize their fleets and seek to compete in the global maritime industry.

The market demand for LS engines in maritime applications is further bolstered by the increasing focus on total cost of ownership. While the initial investment in LS engines may be higher, the long-term benefits in terms of fuel efficiency, maintenance costs, and compliance with future regulations make them an attractive option for many vessel operators.

The global marine engine market is projected to expand substantially in the coming years, with a particular focus on sustainable solutions. LS engines, known for their reduced weight and improved fuel efficiency, are well-positioned to capture a significant share of this growing market. The demand for these engines is particularly strong in commercial shipping, passenger vessels, and offshore support vessels.

Environmental regulations, such as the International Maritime Organization's (IMO) sulfur cap and greenhouse gas emission reduction targets, are key drivers for the adoption of LS engines. Ship owners and operators are increasingly seeking propulsion systems that can meet these stringent requirements while maintaining operational efficiency. LS engines, with their advanced combustion technologies and compatibility with alternative fuels, offer a viable solution to address these regulatory challenges.

The cruise and ferry sectors represent another substantial market for LS engine integration. As these industries recover from the impact of the global pandemic, there is a renewed focus on sustainability and passenger comfort. LS engines, with their reduced noise and vibration characteristics, align well with the demands of these sectors.

In the offshore support vessel market, the push for more efficient operations and reduced environmental impact is creating opportunities for LS engine integration. These vessels often operate in environmentally sensitive areas, making the adoption of cleaner propulsion systems a priority for operators.

The fishing industry, while traditionally conservative in adopting new technologies, is showing increasing interest in LS engines. The potential for fuel savings and reduced emissions is particularly attractive in this sector, where operating costs significantly impact profitability.

Geographically, the demand for LS engines in maritime applications varies. Developed markets such as Europe and North America are leading the adoption, driven by stricter regulations and a greater emphasis on sustainability. However, emerging markets in Asia and South America are also showing growing interest, particularly as they modernize their fleets and seek to compete in the global maritime industry.

The market demand for LS engines in maritime applications is further bolstered by the increasing focus on total cost of ownership. While the initial investment in LS engines may be higher, the long-term benefits in terms of fuel efficiency, maintenance costs, and compliance with future regulations make them an attractive option for many vessel operators.

Current Challenges in Maritime LS Engine Adoption

The integration of LS (Luxury Sport) engines in maritime applications faces several significant challenges that hinder widespread adoption. One of the primary obstacles is the adaptation of these engines to the harsh marine environment. Unlike their automotive counterparts, marine engines must withstand constant exposure to saltwater, high humidity, and corrosive elements. This necessitates extensive modifications to the engine's materials, coatings, and sealing systems to ensure longevity and reliability in maritime conditions.

Another major challenge lies in the power delivery and cooling systems. LS engines, originally designed for land-based vehicles, require substantial re-engineering to meet the specific power demands of marine vessels. The continuous high-load operation typical in maritime applications puts increased stress on engine components, necessitating robust cooling solutions. Developing efficient heat exchangers and closed-loop cooling systems that can effectively manage engine temperatures in a marine environment presents a significant technical hurdle.

Fuel efficiency and emissions regulations pose additional challenges. While LS engines are known for their performance, adapting them to meet stringent maritime emissions standards requires considerable effort. The implementation of advanced fuel injection systems, exhaust after-treatment technologies, and engine management systems tailored for marine use is essential to comply with international maritime regulations such as IMO Tier III.

The integration of LS engines with marine propulsion systems presents another set of challenges. Adapting these engines to work efficiently with various types of marine transmissions, propeller systems, and vessel control interfaces requires extensive development and testing. Ensuring seamless integration with existing maritime technologies and control systems is crucial for operational efficiency and safety.

Weight and space constraints in marine vessels further complicate the adoption of LS engines. Naval architects and marine engineers must balance the power-to-weight ratio advantages of LS engines against the need for compact engine room designs. This often necessitates creative solutions in engine mounting, accessory placement, and overall layout to optimize space utilization without compromising performance or maintenance accessibility.

Lastly, the maritime industry's conservative nature and reliance on proven technologies create resistance to adopting new engine types. Overcoming this inertia requires demonstrating the long-term reliability, cost-effectiveness, and performance benefits of LS engines in maritime applications. Extensive sea trials, durability testing, and real-world performance data are necessary to build confidence among shipbuilders and operators in the viability of LS engines for marine use.

Another major challenge lies in the power delivery and cooling systems. LS engines, originally designed for land-based vehicles, require substantial re-engineering to meet the specific power demands of marine vessels. The continuous high-load operation typical in maritime applications puts increased stress on engine components, necessitating robust cooling solutions. Developing efficient heat exchangers and closed-loop cooling systems that can effectively manage engine temperatures in a marine environment presents a significant technical hurdle.

Fuel efficiency and emissions regulations pose additional challenges. While LS engines are known for their performance, adapting them to meet stringent maritime emissions standards requires considerable effort. The implementation of advanced fuel injection systems, exhaust after-treatment technologies, and engine management systems tailored for marine use is essential to comply with international maritime regulations such as IMO Tier III.

The integration of LS engines with marine propulsion systems presents another set of challenges. Adapting these engines to work efficiently with various types of marine transmissions, propeller systems, and vessel control interfaces requires extensive development and testing. Ensuring seamless integration with existing maritime technologies and control systems is crucial for operational efficiency and safety.

Weight and space constraints in marine vessels further complicate the adoption of LS engines. Naval architects and marine engineers must balance the power-to-weight ratio advantages of LS engines against the need for compact engine room designs. This often necessitates creative solutions in engine mounting, accessory placement, and overall layout to optimize space utilization without compromising performance or maintenance accessibility.

Lastly, the maritime industry's conservative nature and reliance on proven technologies create resistance to adopting new engine types. Overcoming this inertia requires demonstrating the long-term reliability, cost-effectiveness, and performance benefits of LS engines in maritime applications. Extensive sea trials, durability testing, and real-world performance data are necessary to build confidence among shipbuilders and operators in the viability of LS engines for marine use.

Existing LS Engine Maritime Solutions

01 Engine design and performance improvements

LS engines have undergone various design improvements to enhance performance, efficiency, and reliability. These modifications include advancements in cylinder head design, combustion chamber optimization, and valve train enhancements. Such improvements contribute to increased power output, better fuel economy, and reduced emissions.- LS engine design and improvements: LS engines are a series of small-block V8 automotive engines developed by General Motors. Various improvements and design modifications have been made to enhance performance, efficiency, and reliability. These include advancements in cylinder head design, intake manifold optimization, and combustion chamber improvements.

- Fuel injection systems for LS engines: Advanced fuel injection systems have been developed for LS engines to improve fuel efficiency and power output. These systems include direct injection technology, variable fuel pressure systems, and electronically controlled injectors that optimize fuel delivery based on engine load and operating conditions.

- LS engine control systems and electronics: Modern LS engines incorporate sophisticated control systems and electronics to manage various engine functions. These include engine control units (ECUs) with advanced algorithms, variable valve timing systems, and integrated sensors for real-time monitoring and adjustment of engine parameters.

- LS engine cooling and lubrication systems: Innovative cooling and lubrication systems have been developed for LS engines to improve thermal management and reduce friction. These include advanced coolant flow designs, oil cooling systems, and high-efficiency oil pumps to ensure optimal engine performance and longevity.

- LS engine performance modifications: Various aftermarket modifications and performance enhancements are available for LS engines. These include high-flow intake and exhaust systems, forced induction options such as superchargers and turbochargers, and camshaft upgrades to increase power output and overall engine performance.

02 Fuel injection and management systems

Advanced fuel injection and management systems have been developed for LS engines to optimize fuel delivery and combustion. These systems incorporate sophisticated electronic controls, high-pressure fuel pumps, and precision injectors to improve engine performance, responsiveness, and fuel efficiency across various operating conditions.Expand Specific Solutions03 Cooling and thermal management

Innovative cooling and thermal management solutions have been implemented in LS engines to maintain optimal operating temperatures and enhance overall efficiency. These include improved coolant flow designs, advanced thermostat systems, and integrated oil coolers to ensure consistent performance and longevity of engine components.Expand Specific Solutions04 Aftermarket modifications and performance upgrades

A wide range of aftermarket modifications and performance upgrades are available for LS engines, allowing enthusiasts to customize and enhance their vehicles. These upgrades may include high-flow intake systems, performance camshafts, forged internals, and forced induction systems such as superchargers or turbochargers to significantly increase power output.Expand Specific Solutions05 Integration with hybrid and electric powertrains

Recent developments have focused on integrating LS engines with hybrid and electric powertrains to meet evolving emissions standards and improve overall vehicle efficiency. These hybrid systems combine the power and reliability of LS engines with electric motors and advanced energy storage technologies to provide enhanced performance and reduced fuel consumption.Expand Specific Solutions

Key Players in Marine LS Engine Market

The integration of LS Engines in maritime applications is in a developing stage, with the market showing significant growth potential. The technology's maturity varies across different players, with established companies like Wärtsilä Finland Oy and Mitsubishi Shipbuilding Co., Ltd. leading in innovation. Chinese institutions such as Dalian Maritime University and Harbin Engineering University are contributing to research and development. The competitive landscape includes both traditional maritime powerhouses and emerging players, reflecting a blend of established expertise and new technological approaches. As environmental regulations tighten, the market for efficient and cleaner marine propulsion systems is expected to expand, driving further advancements in LS Engine integration for maritime use.

Wärtsilä Finland Oy

Technical Solution: Wärtsilä has developed advanced LS (Low-Speed) engine solutions specifically for maritime applications. Their latest LS engines incorporate dual-fuel technology, allowing vessels to run on both traditional marine fuels and liquefied natural gas (LNG). This flexibility enhances fuel efficiency and reduces emissions. Wärtsilä's LS engines feature advanced electronic control systems that optimize combustion processes, resulting in improved performance and reduced fuel consumption. The company has also integrated waste heat recovery systems into their LS engine designs, further improving overall energy efficiency[1][3].

Strengths: Dual-fuel capability, advanced electronic control, and integrated waste heat recovery systems. Weaknesses: Higher initial cost compared to traditional engines, and potential complexity in maintenance due to advanced systems.

CSSC Marine Power Co., Ltd.

Technical Solution: CSSC Marine Power has developed a range of LS engines tailored for maritime applications, focusing on large container ships and bulk carriers. Their engines incorporate advanced fuel injection systems and turbocharging technologies to enhance combustion efficiency. CSSC has also implemented a modular design approach, allowing for easier maintenance and upgrades. The company's LS engines feature an intelligent monitoring system that provides real-time performance data and predictive maintenance alerts, improving overall reliability and reducing downtime[2][4].

Strengths: Modular design for easy maintenance, intelligent monitoring system, and focus on large vessel applications. Weaknesses: Limited experience compared to some Western competitors, and potential challenges in global service network coverage.

Core Innovations in Marine LS Technology

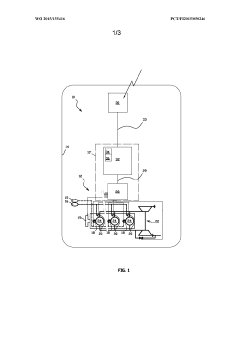

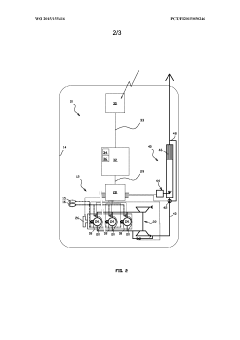

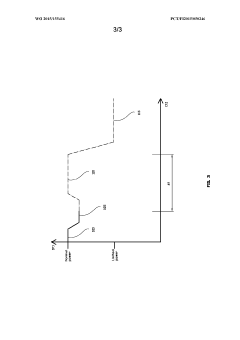

Method of operating a power system in a marine vessel and a supervising arrangement for a power system in a marine vessel

PatentWO2015155416A1

Innovation

- A method and arrangement that utilize a restriction information map to determine operational restrictions based on the vessel's location, allowing for intensified supervision and data logging to ensure compliance with emission regulations, with the option to temporarily lift restrictions in emergency situations.

Method of operating a power system in a marine vessel and a supervising arrangement for a power system in a marine vessel

PatentWO2015155416A1

Innovation

- A method and arrangement that utilize a restriction information map to determine operational restrictions based on the vessel's location, allowing for intensified supervision and data logging to ensure compliance with emission regulations, with the option to temporarily lift restrictions in emergency situations.

Environmental Regulations Impact

The integration of LS engines in maritime applications is significantly influenced by environmental regulations, which have become increasingly stringent in recent years. These regulations aim to reduce the environmental impact of maritime activities, particularly in terms of emissions and pollution. The International Maritime Organization (IMO) has implemented several measures to address these concerns, including the MARPOL Convention and its annexes.

One of the most impactful regulations is the IMO 2020 rule, which mandates a global sulfur cap of 0.5% for marine fuels. This regulation has forced ship operators to either switch to low-sulfur fuels or install exhaust gas cleaning systems (scrubbers). The integration of LS engines must take these requirements into account, as they directly affect the engine's design and performance characteristics.

Nitrogen oxide (NOx) emissions are another area of focus for environmental regulations. The IMO Tier III standards, applicable in designated Emission Control Areas (ECAs), require substantial reductions in NOx emissions compared to previous standards. This has led to the development of advanced emission control technologies, such as Selective Catalytic Reduction (SCR) systems, which must be considered when integrating LS engines into maritime applications.

Carbon dioxide (CO2) emissions are also under scrutiny, with the IMO adopting measures to reduce greenhouse gas emissions from international shipping. The Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) are two key initiatives aimed at improving the energy efficiency of vessels. These regulations impact the design and operation of LS engines, requiring manufacturers to focus on fuel efficiency and alternative fuel compatibility.

The increasing focus on environmental sustainability has led to the exploration of alternative fuels in maritime applications. Liquefied Natural Gas (LNG), biofuels, and hydrogen are being considered as potential replacements for traditional marine fuels. The integration of LS engines must account for the possibility of using these alternative fuels, which may require modifications to engine design and fuel delivery systems.

Ballast water management regulations, while not directly related to engine emissions, also impact the overall environmental performance of vessels. The Ballast Water Management Convention requires ships to manage their ballast water to prevent the spread of invasive aquatic species. This regulation indirectly affects engine integration by influencing the overall design and power requirements of vessels.

As environmental regulations continue to evolve, the integration of LS engines in maritime applications must remain adaptable. Future regulations may focus on particulate matter emissions, noise pollution, or the use of specific materials in engine construction. Engine manufacturers and ship designers must stay informed about upcoming regulatory changes and incorporate flexibility into their designs to ensure long-term compliance and environmental sustainability.

One of the most impactful regulations is the IMO 2020 rule, which mandates a global sulfur cap of 0.5% for marine fuels. This regulation has forced ship operators to either switch to low-sulfur fuels or install exhaust gas cleaning systems (scrubbers). The integration of LS engines must take these requirements into account, as they directly affect the engine's design and performance characteristics.

Nitrogen oxide (NOx) emissions are another area of focus for environmental regulations. The IMO Tier III standards, applicable in designated Emission Control Areas (ECAs), require substantial reductions in NOx emissions compared to previous standards. This has led to the development of advanced emission control technologies, such as Selective Catalytic Reduction (SCR) systems, which must be considered when integrating LS engines into maritime applications.

Carbon dioxide (CO2) emissions are also under scrutiny, with the IMO adopting measures to reduce greenhouse gas emissions from international shipping. The Energy Efficiency Design Index (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) are two key initiatives aimed at improving the energy efficiency of vessels. These regulations impact the design and operation of LS engines, requiring manufacturers to focus on fuel efficiency and alternative fuel compatibility.

The increasing focus on environmental sustainability has led to the exploration of alternative fuels in maritime applications. Liquefied Natural Gas (LNG), biofuels, and hydrogen are being considered as potential replacements for traditional marine fuels. The integration of LS engines must account for the possibility of using these alternative fuels, which may require modifications to engine design and fuel delivery systems.

Ballast water management regulations, while not directly related to engine emissions, also impact the overall environmental performance of vessels. The Ballast Water Management Convention requires ships to manage their ballast water to prevent the spread of invasive aquatic species. This regulation indirectly affects engine integration by influencing the overall design and power requirements of vessels.

As environmental regulations continue to evolve, the integration of LS engines in maritime applications must remain adaptable. Future regulations may focus on particulate matter emissions, noise pollution, or the use of specific materials in engine construction. Engine manufacturers and ship designers must stay informed about upcoming regulatory changes and incorporate flexibility into their designs to ensure long-term compliance and environmental sustainability.

Cost-Benefit Analysis of LS Marine Integration

The integration of LS engines in maritime applications presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for LS engine integration are typically higher than traditional marine propulsion systems. This includes expenses for engine procurement, modification of existing vessel structures, and installation of supporting systems. However, these upfront costs are often offset by long-term operational benefits.

Fuel efficiency is a primary advantage of LS engines in marine applications. These engines can achieve up to 15-20% better fuel economy compared to conventional marine engines, resulting in significant cost savings over the vessel's lifetime. This improved efficiency translates to reduced fuel consumption and lower operating expenses, particularly beneficial for vessels with high annual usage rates.

Maintenance costs represent another area of potential savings. LS engines, designed for automotive applications, often have more readily available and less expensive spare parts compared to specialized marine engines. This can lead to reduced maintenance expenses and shorter downtime periods for repairs, contributing to overall cost-effectiveness.

Environmental compliance is an increasingly important factor in the maritime industry. LS engines generally produce lower emissions, helping vessels meet stringent environmental regulations without the need for extensive exhaust after-treatment systems. This can result in cost savings related to compliance and potential fines avoidance.

The versatility of LS engines allows for easier integration of hybrid and electric propulsion systems, potentially future-proofing vessels against evolving environmental standards. While this adaptability may require additional initial investment, it can provide long-term benefits in terms of operational flexibility and regulatory compliance.

Crew training and familiarization represent a cost factor that should not be overlooked. The transition to LS engines may necessitate additional training for engineering crews, potentially increasing short-term operational costs. However, the widespread use of LS engines in automotive applications means that a larger pool of technicians is familiar with these systems, potentially reducing long-term labor costs for maintenance and repairs.

In conclusion, while the initial costs of integrating LS engines in maritime applications can be substantial, the long-term benefits in fuel efficiency, maintenance costs, and environmental compliance often outweigh these expenses. The cost-benefit analysis should consider the specific vessel type, operational profile, and regulatory environment to determine the most advantageous implementation strategy.

Fuel efficiency is a primary advantage of LS engines in marine applications. These engines can achieve up to 15-20% better fuel economy compared to conventional marine engines, resulting in significant cost savings over the vessel's lifetime. This improved efficiency translates to reduced fuel consumption and lower operating expenses, particularly beneficial for vessels with high annual usage rates.

Maintenance costs represent another area of potential savings. LS engines, designed for automotive applications, often have more readily available and less expensive spare parts compared to specialized marine engines. This can lead to reduced maintenance expenses and shorter downtime periods for repairs, contributing to overall cost-effectiveness.

Environmental compliance is an increasingly important factor in the maritime industry. LS engines generally produce lower emissions, helping vessels meet stringent environmental regulations without the need for extensive exhaust after-treatment systems. This can result in cost savings related to compliance and potential fines avoidance.

The versatility of LS engines allows for easier integration of hybrid and electric propulsion systems, potentially future-proofing vessels against evolving environmental standards. While this adaptability may require additional initial investment, it can provide long-term benefits in terms of operational flexibility and regulatory compliance.

Crew training and familiarization represent a cost factor that should not be overlooked. The transition to LS engines may necessitate additional training for engineering crews, potentially increasing short-term operational costs. However, the widespread use of LS engines in automotive applications means that a larger pool of technicians is familiar with these systems, potentially reducing long-term labor costs for maintenance and repairs.

In conclusion, while the initial costs of integrating LS engines in maritime applications can be substantial, the long-term benefits in fuel efficiency, maintenance costs, and environmental compliance often outweigh these expenses. The cost-benefit analysis should consider the specific vessel type, operational profile, and regulatory environment to determine the most advantageous implementation strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!