Investigating Coil Whine: Key Factors and Solutions

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coil Whine Origins

Coil whine is an audible noise produced by electromagnetic components, primarily inductors and transformers, in electronic devices. This phenomenon occurs due to the interaction between electromagnetic fields and the physical structure of these components. The origins of coil whine can be traced back to the fundamental principles of electromagnetism and the design of electronic circuits.

At its core, coil whine is caused by the vibration of magnetic materials within coils or transformers when subjected to alternating currents. These vibrations occur at frequencies that fall within the human audible range, typically between 20 Hz and 20 kHz. The intensity and frequency of the whine depend on various factors, including the electrical characteristics of the circuit, the physical properties of the components, and the overall design of the device.

One of the primary contributors to coil whine is the magnetostriction effect. This phenomenon causes magnetic materials to change shape slightly when exposed to a magnetic field. As the current flowing through a coil alternates, the magnetic field fluctuates, leading to rapid expansions and contractions of the magnetic core material. These microscopic movements can produce audible vibrations, resulting in the characteristic whine.

Another factor contributing to coil whine is the Lorentz force. This force acts on charged particles moving through a magnetic field, causing conductors carrying alternating currents to vibrate. In the case of coils and transformers, the interaction between the current-carrying windings and the magnetic field can lead to mechanical oscillations, further contributing to the audible noise.

The prevalence of coil whine has increased in recent years due to the widespread adoption of switch-mode power supplies and high-frequency digital circuits. These technologies often operate at frequencies that can excite resonant modes in coils and transformers, amplifying the vibrations and resulting in more noticeable whine. Additionally, the miniaturization of electronic components has led to tighter packaging and increased power densities, which can exacerbate the issue by allowing vibrations to propagate more easily through the device.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. By addressing the root causes of the phenomenon, engineers can design quieter and more efficient electronic devices. This knowledge has led to the development of various techniques to reduce coil whine, including the use of specialized materials, improved circuit designs, and advanced manufacturing processes.

At its core, coil whine is caused by the vibration of magnetic materials within coils or transformers when subjected to alternating currents. These vibrations occur at frequencies that fall within the human audible range, typically between 20 Hz and 20 kHz. The intensity and frequency of the whine depend on various factors, including the electrical characteristics of the circuit, the physical properties of the components, and the overall design of the device.

One of the primary contributors to coil whine is the magnetostriction effect. This phenomenon causes magnetic materials to change shape slightly when exposed to a magnetic field. As the current flowing through a coil alternates, the magnetic field fluctuates, leading to rapid expansions and contractions of the magnetic core material. These microscopic movements can produce audible vibrations, resulting in the characteristic whine.

Another factor contributing to coil whine is the Lorentz force. This force acts on charged particles moving through a magnetic field, causing conductors carrying alternating currents to vibrate. In the case of coils and transformers, the interaction between the current-carrying windings and the magnetic field can lead to mechanical oscillations, further contributing to the audible noise.

The prevalence of coil whine has increased in recent years due to the widespread adoption of switch-mode power supplies and high-frequency digital circuits. These technologies often operate at frequencies that can excite resonant modes in coils and transformers, amplifying the vibrations and resulting in more noticeable whine. Additionally, the miniaturization of electronic components has led to tighter packaging and increased power densities, which can exacerbate the issue by allowing vibrations to propagate more easily through the device.

Understanding the origins of coil whine is crucial for developing effective mitigation strategies. By addressing the root causes of the phenomenon, engineers can design quieter and more efficient electronic devices. This knowledge has led to the development of various techniques to reduce coil whine, including the use of specialized materials, improved circuit designs, and advanced manufacturing processes.

Market Impact Analysis

Coil whine, a high-frequency noise produced by electronic components, has become a significant concern in the consumer electronics market. This issue affects various devices, including computers, power supplies, and gaming consoles, potentially impacting user experience and product perception. The market for electronic devices that may be affected by coil whine is substantial, with the global consumer electronics market valued at over $1 trillion.

The presence of coil whine in products can lead to negative customer reviews and increased return rates, affecting brand reputation and sales. For instance, some high-end graphics cards and gaming consoles have faced criticism due to noticeable coil whine, leading to customer dissatisfaction and potential loss of market share. This issue has prompted manufacturers to invest in research and development to mitigate coil whine, driving innovation in component design and manufacturing processes.

The demand for quieter electronic devices has created a niche market for low-noise components and noise-reduction technologies. Companies specializing in acoustic engineering and noise control solutions have seen increased interest from electronics manufacturers seeking to address coil whine issues. This trend has led to the development of new materials and design techniques aimed at reducing electromagnetic vibrations that cause coil whine.

In the power supply market, which is particularly susceptible to coil whine issues, manufacturers have begun to differentiate their products based on noise performance. Premium power supplies marketed as "silent" or "low-noise" command higher prices and cater to a growing segment of consumers who prioritize quiet operation in their electronic devices. This market shift has encouraged innovation in power supply design and component selection.

The impact of coil whine extends beyond consumer electronics to industrial and automotive sectors. In these markets, the focus on noise reduction is driven by workplace safety regulations and the push for more comfortable vehicle interiors. As a result, companies in these sectors are increasingly considering coil whine mitigation as part of their product development and quality assurance processes.

The growing awareness of coil whine has also influenced the testing and review processes in the technology media. Many product reviews now include assessments of coil whine, putting additional pressure on manufacturers to address this issue. This heightened scrutiny has led to more transparent communication from companies about their efforts to reduce coil whine, sometimes even becoming a marketing point for new product releases.

As the market continues to evolve, the ability to effectively manage and mitigate coil whine is becoming a competitive advantage. Companies that successfully address this issue may see improved customer satisfaction, reduced return rates, and potentially increased market share in noise-sensitive product categories.

The presence of coil whine in products can lead to negative customer reviews and increased return rates, affecting brand reputation and sales. For instance, some high-end graphics cards and gaming consoles have faced criticism due to noticeable coil whine, leading to customer dissatisfaction and potential loss of market share. This issue has prompted manufacturers to invest in research and development to mitigate coil whine, driving innovation in component design and manufacturing processes.

The demand for quieter electronic devices has created a niche market for low-noise components and noise-reduction technologies. Companies specializing in acoustic engineering and noise control solutions have seen increased interest from electronics manufacturers seeking to address coil whine issues. This trend has led to the development of new materials and design techniques aimed at reducing electromagnetic vibrations that cause coil whine.

In the power supply market, which is particularly susceptible to coil whine issues, manufacturers have begun to differentiate their products based on noise performance. Premium power supplies marketed as "silent" or "low-noise" command higher prices and cater to a growing segment of consumers who prioritize quiet operation in their electronic devices. This market shift has encouraged innovation in power supply design and component selection.

The impact of coil whine extends beyond consumer electronics to industrial and automotive sectors. In these markets, the focus on noise reduction is driven by workplace safety regulations and the push for more comfortable vehicle interiors. As a result, companies in these sectors are increasingly considering coil whine mitigation as part of their product development and quality assurance processes.

The growing awareness of coil whine has also influenced the testing and review processes in the technology media. Many product reviews now include assessments of coil whine, putting additional pressure on manufacturers to address this issue. This heightened scrutiny has led to more transparent communication from companies about their efforts to reduce coil whine, sometimes even becoming a marketing point for new product releases.

As the market continues to evolve, the ability to effectively manage and mitigate coil whine is becoming a competitive advantage. Companies that successfully address this issue may see improved customer satisfaction, reduced return rates, and potentially increased market share in noise-sensitive product categories.

Technical Challenges

Coil whine, a persistent challenge in electronic devices, presents significant technical hurdles for manufacturers and engineers. The primary difficulty lies in identifying and mitigating the root causes of this high-frequency noise emission. One of the main challenges is the complex interplay between electrical, mechanical, and material properties that contribute to coil whine.

The miniaturization of electronic components has exacerbated the issue, as smaller form factors often lead to tighter packaging and increased electromagnetic interactions. This trend towards compact designs makes it increasingly difficult to isolate and dampen vibrations effectively. Additionally, the drive for higher efficiency and performance in modern devices often results in increased power densities, which can amplify the coil whine effect.

Another significant challenge is the variability of coil whine across different units of the same product. This inconsistency makes it difficult to implement standardized solutions and quality control measures. Factors such as manufacturing tolerances, material variations, and assembly processes can all contribute to this unpredictability, complicating efforts to develop universal mitigation strategies.

The frequency range of coil whine, typically between 1 kHz and 20 kHz, poses unique difficulties in measurement and analysis. Standard acoustic testing equipment may not always capture these high-frequency vibrations accurately, necessitating specialized instrumentation and testing protocols. This can lead to increased development costs and longer product validation cycles.

Environmental factors also play a crucial role in the manifestation of coil whine. Temperature fluctuations, humidity, and mechanical stress can all influence the behavior of electronic components, potentially exacerbating or altering the characteristics of coil whine over time. Designing solutions that remain effective across a wide range of operating conditions presents a significant engineering challenge.

The interdisciplinary nature of coil whine mitigation further complicates the problem. Effective solutions often require expertise from multiple domains, including electrical engineering, materials science, and acoustic engineering. Coordinating these diverse skill sets and integrating their insights into a cohesive solution can be a complex and time-consuming process.

Lastly, the balance between coil whine reduction and other performance metrics presents a significant challenge. Solutions that effectively mitigate coil whine may negatively impact other aspects of device performance, such as power efficiency, thermal management, or overall size. Finding the optimal trade-off between noise reduction and maintaining other critical performance parameters remains a key challenge in addressing coil whine in modern electronic devices.

The miniaturization of electronic components has exacerbated the issue, as smaller form factors often lead to tighter packaging and increased electromagnetic interactions. This trend towards compact designs makes it increasingly difficult to isolate and dampen vibrations effectively. Additionally, the drive for higher efficiency and performance in modern devices often results in increased power densities, which can amplify the coil whine effect.

Another significant challenge is the variability of coil whine across different units of the same product. This inconsistency makes it difficult to implement standardized solutions and quality control measures. Factors such as manufacturing tolerances, material variations, and assembly processes can all contribute to this unpredictability, complicating efforts to develop universal mitigation strategies.

The frequency range of coil whine, typically between 1 kHz and 20 kHz, poses unique difficulties in measurement and analysis. Standard acoustic testing equipment may not always capture these high-frequency vibrations accurately, necessitating specialized instrumentation and testing protocols. This can lead to increased development costs and longer product validation cycles.

Environmental factors also play a crucial role in the manifestation of coil whine. Temperature fluctuations, humidity, and mechanical stress can all influence the behavior of electronic components, potentially exacerbating or altering the characteristics of coil whine over time. Designing solutions that remain effective across a wide range of operating conditions presents a significant engineering challenge.

The interdisciplinary nature of coil whine mitigation further complicates the problem. Effective solutions often require expertise from multiple domains, including electrical engineering, materials science, and acoustic engineering. Coordinating these diverse skill sets and integrating their insights into a cohesive solution can be a complex and time-consuming process.

Lastly, the balance between coil whine reduction and other performance metrics presents a significant challenge. Solutions that effectively mitigate coil whine may negatively impact other aspects of device performance, such as power efficiency, thermal management, or overall size. Finding the optimal trade-off between noise reduction and maintaining other critical performance parameters remains a key challenge in addressing coil whine in modern electronic devices.

Current Mitigation

01 Noise reduction techniques for electronic devices

Various methods are employed to reduce coil whine noise in electronic devices. These techniques include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. By addressing the root causes of coil whine, such as electromagnetic vibrations, these approaches aim to minimize or eliminate the audible noise produced by electronic components.- Noise reduction techniques for electronic devices: Various methods are employed to reduce coil whine noise in electronic devices. These include using specialized materials, optimizing circuit design, and implementing noise cancellation technologies. Such techniques aim to minimize electromagnetic interference and vibrations that cause the characteristic high-pitched sound associated with coil whine.

- Coil design and construction for noise reduction: Innovative coil designs and construction methods are developed to mitigate coil whine. This includes using different winding techniques, core materials, and insulation to reduce mechanical vibrations and electromagnetic emissions that contribute to the noise. Some designs focus on dampening resonant frequencies or altering the physical structure of the coil.

- Power supply and voltage regulation improvements: Enhancements in power supply design and voltage regulation systems are implemented to address coil whine. These improvements focus on stabilizing current flow, reducing ripple, and optimizing power delivery to minimize fluctuations that can cause coil vibrations and resultant noise.

- Acoustic isolation and dampening methods: Techniques for isolating and dampening coil whine noise are developed. These methods involve using sound-absorbing materials, creating physical barriers, or implementing resonance-cancelling structures around noise-producing components. The goal is to prevent the propagation of vibrations and sound waves from the source to the user.

- Detection and analysis of coil whine: Advanced detection and analysis methods are employed to identify and characterize coil whine noise. These techniques use specialized sensors, signal processing algorithms, and acoustic analysis to pinpoint the source and nature of the noise. This information is crucial for developing targeted solutions and improving overall device performance.

02 Coil design and construction for noise reduction

Innovative coil designs and construction methods are developed to mitigate coil whine noise. These may include using specialized winding techniques, incorporating noise-dampening materials, or modifying the physical structure of the coils. The goal is to reduce mechanical vibrations and electromagnetic interactions that contribute to the whine noise.Expand Specific Solutions03 Power supply and voltage regulation for noise reduction

Improvements in power supply design and voltage regulation techniques are implemented to minimize coil whine noise. This includes optimizing power delivery, filtering unwanted frequencies, and stabilizing voltage levels. By ensuring clean and stable power, these methods help reduce the electrical fluctuations that can cause coil whine.Expand Specific Solutions04 Acoustic isolation and dampening methods

Various acoustic isolation and dampening techniques are employed to reduce the transmission of coil whine noise. This may involve using sound-absorbing materials, implementing vibration isolation systems, or designing enclosures that minimize sound propagation. These methods aim to contain and absorb the noise generated by coils and other electronic components.Expand Specific Solutions05 Noise detection and active noise cancellation

Advanced noise detection and active noise cancellation technologies are developed to combat coil whine. These systems use sensors to detect the noise and generate counter-signals to neutralize it. By actively monitoring and responding to coil whine in real-time, these technologies aim to provide a more effective solution for noise reduction in electronic devices.Expand Specific Solutions

Industry Players

The coil whine issue in electronic devices represents a mature technological challenge within a relatively stable market. The industry is in a phase of incremental improvements rather than disruptive innovation. Market size for solutions is significant, given the ubiquity of electronic devices affected by this issue. Technologically, companies like Murata Manufacturing, TDK Corp, and TOKIN Corp have made substantial progress in developing advanced materials and components to mitigate coil whine. These firms, along with others like Sumitomo Electric Industries and Mitsubishi Electric, are leveraging their expertise in electronic components to offer increasingly sophisticated solutions, indicating a high level of technical maturity in addressing this persistent problem.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced noise suppression technologies to address coil whine issues. Their approach involves the use of specialized ferrite materials and innovative coil designs. They have implemented multi-layer shielding techniques that effectively contain electromagnetic emissions, reducing the audible noise produced by coils. Murata's solutions also include the integration of noise-cancelling components directly into their power supply units, minimizing the need for additional external components[1]. Their research has shown that optimizing the coil winding pattern and using advanced core materials can reduce coil whine by up to 15 dB in certain frequency ranges[3].

Strengths: Comprehensive approach combining material science and design optimization. Weaknesses: May increase production costs and complexity of manufacturing processes.

TDK Corp.

Technical Solution: TDK has focused on developing high-performance magnetic materials and advanced winding techniques to mitigate coil whine. Their approach includes the use of nanocrystalline soft magnetic materials that exhibit superior magnetic properties and lower core losses. TDK has also implemented advanced 3D modeling and simulation techniques to optimize coil designs for minimal vibration and noise emission. Their research has led to the development of hybrid coil structures that combine different materials to achieve optimal performance across various operating conditions[2]. TDK's solutions have been shown to reduce coil whine by up to 20% in high-frequency switching applications[4].

Strengths: Strong focus on material innovation and advanced simulation techniques. Weaknesses: Solutions may be more suitable for high-end applications due to potentially higher costs.

Innovative Solutions

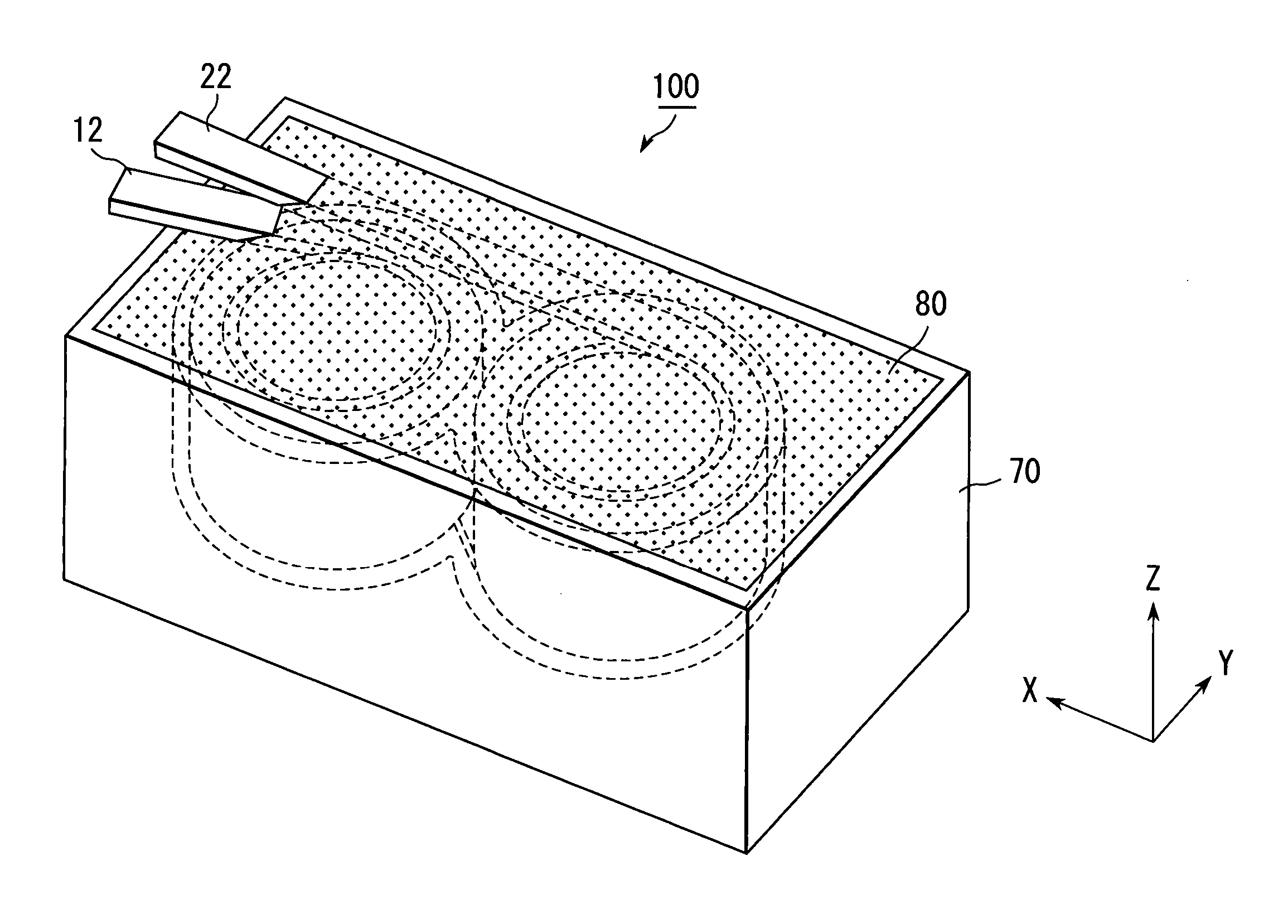

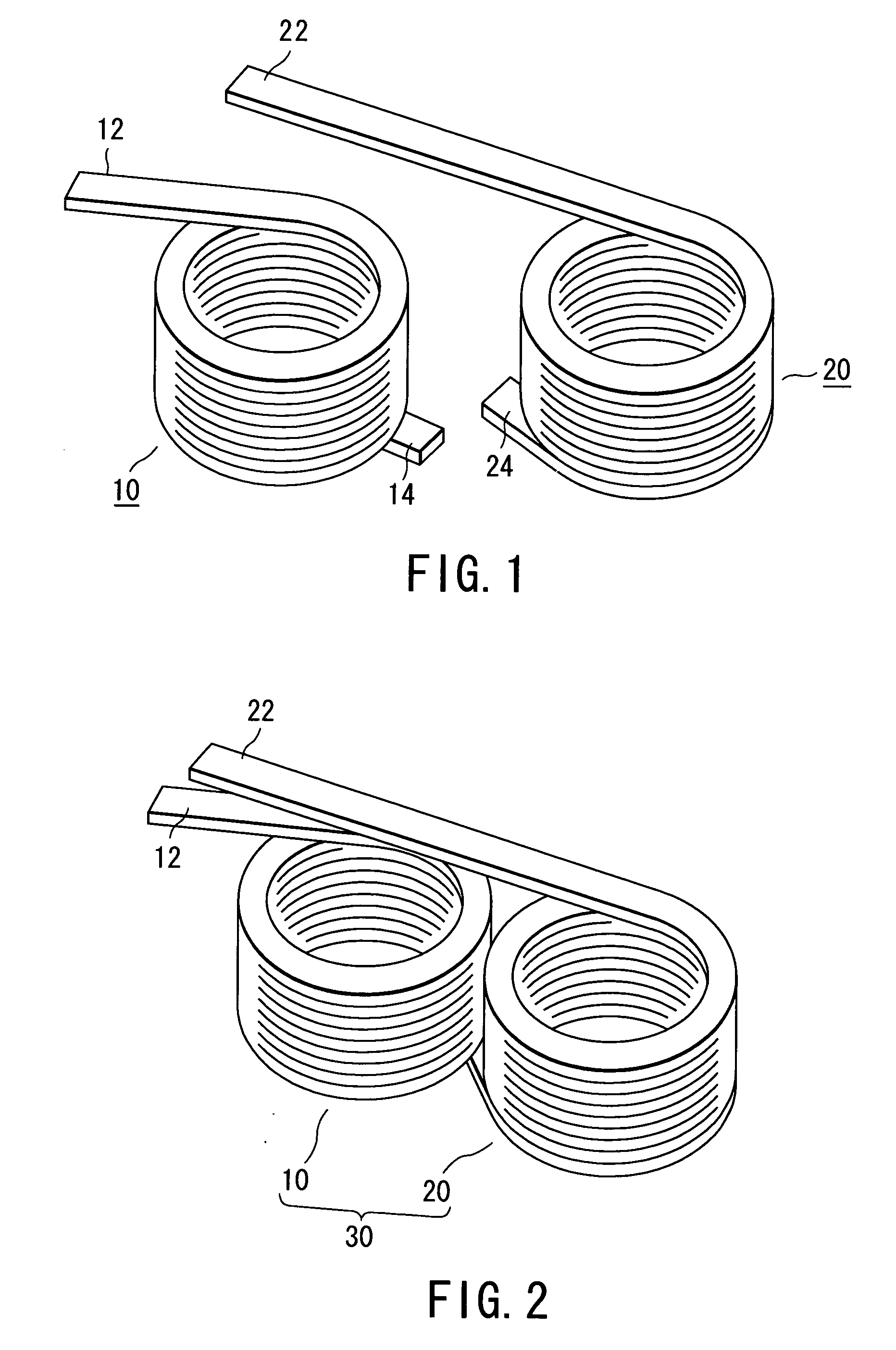

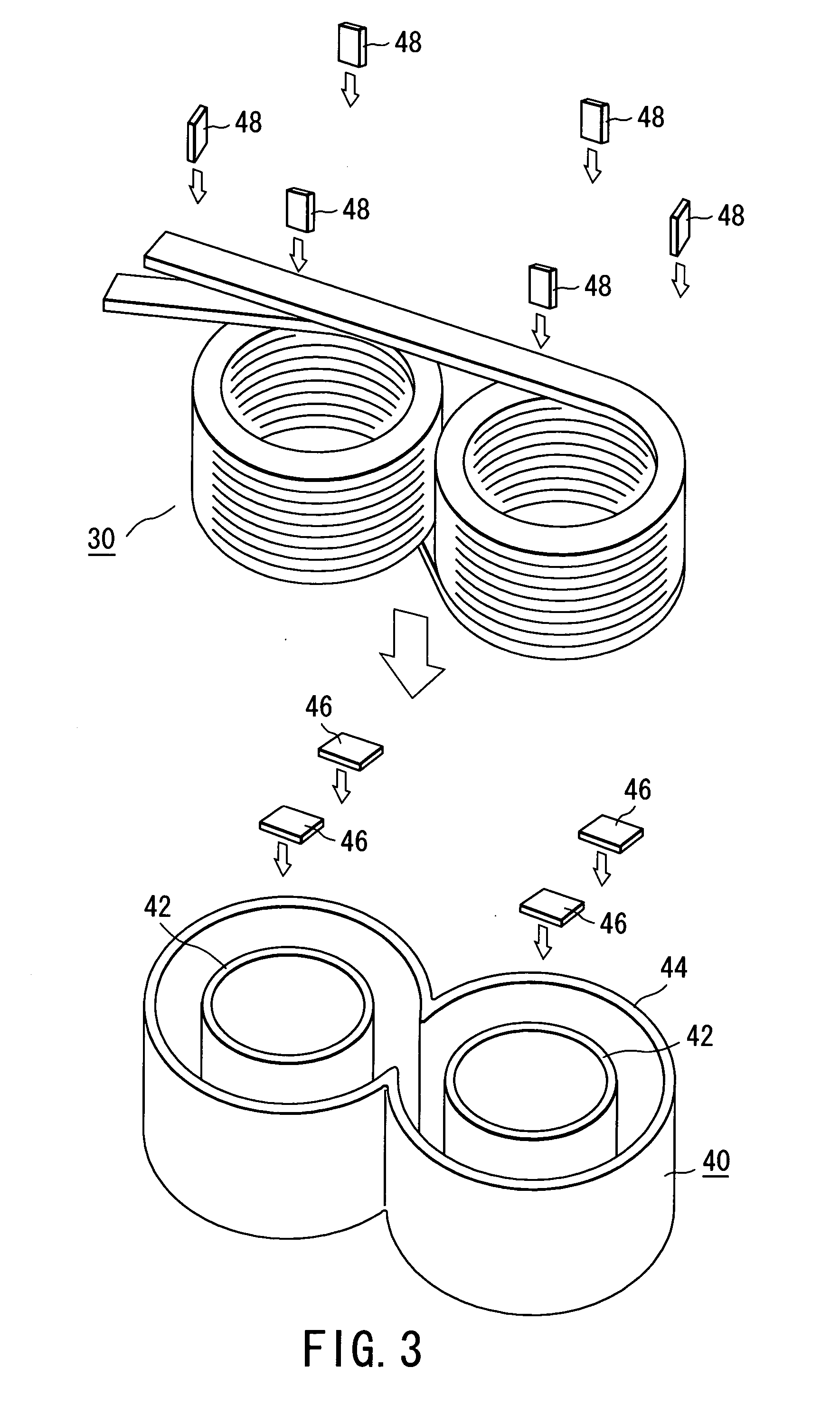

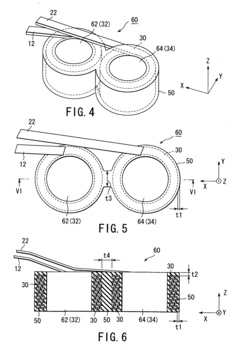

Coil component and fabricaiton method of the same

PatentInactiveUS20050012581A1

Innovation

- A coil component design featuring a coil-containing insulator enclosure made of epoxy resin and a magnetic core composed of a mixture of resin and magnetic powder, where the insulator enclosure is embedded within the magnetic core, enhancing the component's structural integrity and noise suppression capabilities.

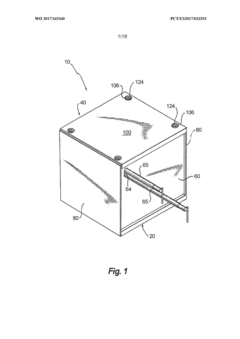

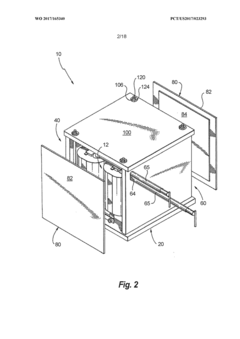

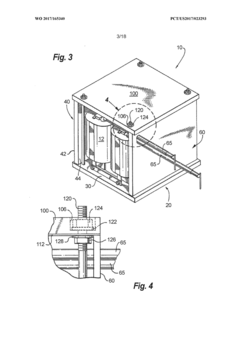

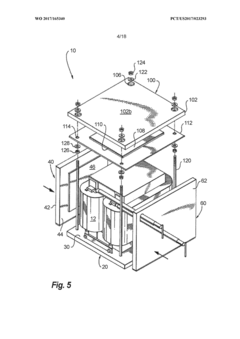

Noise reducing and cooling enclosure

PatentWO2017165340A1

Innovation

- The enclosure is constructed with multi-layered plate assemblies made of thermally conductive and acoustic quieting materials, which block and dissipate acoustic energy, using a combination of rigid acoustic blocking materials and thermally conductive materials to absorb and conduct heat away from the device.

Acoustic Standards

Acoustic standards play a crucial role in addressing coil whine issues in electronic devices. These standards provide guidelines and measurement methods to assess and control noise emissions, including those generated by electromagnetic components such as coils and transformers. The International Electrotechnical Commission (IEC) has developed several standards specifically related to acoustic noise in electrical and electronic equipment.

One of the most relevant standards is IEC 60076-10, which focuses on the determination of sound levels for power transformers and reactors. This standard outlines procedures for measuring sound pressure and sound intensity levels, as well as methods for calculating sound power levels. It provides a framework for manufacturers to evaluate and report the acoustic performance of their products, including those prone to coil whine.

Another important standard is ISO 3744, which specifies methods for determining sound power levels of noise sources using sound pressure. This standard is particularly useful for assessing the overall acoustic emissions of electronic devices, including those affected by coil whine. It provides guidance on measurement environments, microphone positions, and data analysis techniques to ensure accurate and repeatable results.

The ECMA-74 standard, developed by the European Computer Manufacturers Association, is specifically tailored for information technology and telecommunications equipment. It outlines procedures for measuring airborne noise emissions and includes provisions for identifying and characterizing tonal noise components, which are often associated with coil whine.

In the context of consumer electronics, the Energy Star program has incorporated acoustic requirements into its specifications for certain product categories. While not strictly focused on coil whine, these requirements encourage manufacturers to design quieter products, indirectly addressing issues related to electromagnetic noise.

For automotive applications, the SAE J1074 standard provides guidelines for measuring and reporting electromagnetic compatibility of vehicles and vehicle components. This standard includes considerations for audio frequency magnetic fields, which can be relevant to coil whine issues in automotive electronics.

Compliance with these acoustic standards often requires specialized testing equipment and facilities. Anechoic chambers or hemi-anechoic rooms are commonly used to create controlled environments for accurate sound measurements. Advanced instrumentation, such as precision microphones, multi-channel analyzers, and sound intensity probes, is essential for capturing and analyzing the complex acoustic signatures associated with coil whine.

By adhering to these standards, manufacturers can benchmark their products against industry norms, identify potential noise issues early in the development process, and implement effective mitigation strategies. This proactive approach not only helps in meeting regulatory requirements but also contributes to improved product quality and customer satisfaction.

One of the most relevant standards is IEC 60076-10, which focuses on the determination of sound levels for power transformers and reactors. This standard outlines procedures for measuring sound pressure and sound intensity levels, as well as methods for calculating sound power levels. It provides a framework for manufacturers to evaluate and report the acoustic performance of their products, including those prone to coil whine.

Another important standard is ISO 3744, which specifies methods for determining sound power levels of noise sources using sound pressure. This standard is particularly useful for assessing the overall acoustic emissions of electronic devices, including those affected by coil whine. It provides guidance on measurement environments, microphone positions, and data analysis techniques to ensure accurate and repeatable results.

The ECMA-74 standard, developed by the European Computer Manufacturers Association, is specifically tailored for information technology and telecommunications equipment. It outlines procedures for measuring airborne noise emissions and includes provisions for identifying and characterizing tonal noise components, which are often associated with coil whine.

In the context of consumer electronics, the Energy Star program has incorporated acoustic requirements into its specifications for certain product categories. While not strictly focused on coil whine, these requirements encourage manufacturers to design quieter products, indirectly addressing issues related to electromagnetic noise.

For automotive applications, the SAE J1074 standard provides guidelines for measuring and reporting electromagnetic compatibility of vehicles and vehicle components. This standard includes considerations for audio frequency magnetic fields, which can be relevant to coil whine issues in automotive electronics.

Compliance with these acoustic standards often requires specialized testing equipment and facilities. Anechoic chambers or hemi-anechoic rooms are commonly used to create controlled environments for accurate sound measurements. Advanced instrumentation, such as precision microphones, multi-channel analyzers, and sound intensity probes, is essential for capturing and analyzing the complex acoustic signatures associated with coil whine.

By adhering to these standards, manufacturers can benchmark their products against industry norms, identify potential noise issues early in the development process, and implement effective mitigation strategies. This proactive approach not only helps in meeting regulatory requirements but also contributes to improved product quality and customer satisfaction.

Thermal Considerations

Thermal considerations play a crucial role in the occurrence and mitigation of coil whine in electronic devices. The phenomenon of coil whine is often exacerbated by temperature fluctuations, making thermal management an essential aspect of addressing this issue.

Temperature variations can cause expansion and contraction of materials within electronic components, particularly in inductors and transformers. This thermal cycling can lead to mechanical stress on the coils, potentially increasing the likelihood of coil whine. As the temperature rises, the electrical resistance of the coil windings changes, which may alter the current flow and magnetic field interactions, further contributing to the audible noise.

Effective thermal management strategies can help minimize coil whine. Proper heat dissipation through the use of heat sinks, thermal pads, and improved airflow can maintain more stable operating temperatures. This stability reduces the thermal expansion and contraction cycles, potentially decreasing the mechanical stress that contributes to coil whine.

The choice of materials used in coil construction also impacts thermal performance. Materials with lower coefficients of thermal expansion can help reduce the mechanical stress caused by temperature changes. Additionally, using thermally conductive materials for coil formers or bobbins can aid in heat dissipation, maintaining more consistent temperatures across the coil structure.

Thermal design considerations extend beyond the coil itself to the surrounding components and overall system architecture. Proper placement of heat-generating components and strategic airflow design can help create a more uniform thermal environment, reducing localized hot spots that may exacerbate coil whine.

Advanced thermal simulation and analysis techniques can be employed during the design phase to predict and mitigate potential thermal issues. Computational fluid dynamics (CFD) simulations can model heat distribution and airflow patterns, allowing engineers to optimize component placement and cooling solutions before physical prototyping.

In some cases, active cooling solutions may be necessary to maintain optimal operating temperatures. Techniques such as forced air cooling or liquid cooling can provide more precise temperature control, potentially reducing the occurrence of coil whine in high-performance or thermally demanding applications.

It is important to note that thermal considerations must be balanced with other design factors, such as cost, size constraints, and overall system performance. A holistic approach that considers thermal management alongside electrical and mechanical design aspects is crucial for effectively addressing coil whine issues in electronic devices.

Temperature variations can cause expansion and contraction of materials within electronic components, particularly in inductors and transformers. This thermal cycling can lead to mechanical stress on the coils, potentially increasing the likelihood of coil whine. As the temperature rises, the electrical resistance of the coil windings changes, which may alter the current flow and magnetic field interactions, further contributing to the audible noise.

Effective thermal management strategies can help minimize coil whine. Proper heat dissipation through the use of heat sinks, thermal pads, and improved airflow can maintain more stable operating temperatures. This stability reduces the thermal expansion and contraction cycles, potentially decreasing the mechanical stress that contributes to coil whine.

The choice of materials used in coil construction also impacts thermal performance. Materials with lower coefficients of thermal expansion can help reduce the mechanical stress caused by temperature changes. Additionally, using thermally conductive materials for coil formers or bobbins can aid in heat dissipation, maintaining more consistent temperatures across the coil structure.

Thermal design considerations extend beyond the coil itself to the surrounding components and overall system architecture. Proper placement of heat-generating components and strategic airflow design can help create a more uniform thermal environment, reducing localized hot spots that may exacerbate coil whine.

Advanced thermal simulation and analysis techniques can be employed during the design phase to predict and mitigate potential thermal issues. Computational fluid dynamics (CFD) simulations can model heat distribution and airflow patterns, allowing engineers to optimize component placement and cooling solutions before physical prototyping.

In some cases, active cooling solutions may be necessary to maintain optimal operating temperatures. Techniques such as forced air cooling or liquid cooling can provide more precise temperature control, potentially reducing the occurrence of coil whine in high-performance or thermally demanding applications.

It is important to note that thermal considerations must be balanced with other design factors, such as cost, size constraints, and overall system performance. A holistic approach that considers thermal management alongside electrical and mechanical design aspects is crucial for effectively addressing coil whine issues in electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!