Investigation of the Role of Linker Length in the Flexibility of MOFs

AUG 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Linker Length Background and Objectives

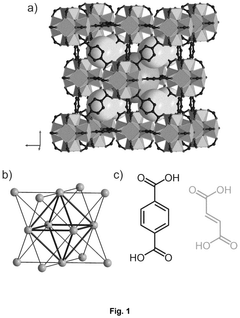

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials with exceptional versatility and potential applications across various fields. The investigation of linker length in MOFs represents a critical area of research that aims to understand and manipulate the flexibility and properties of these materials. This study is rooted in the fundamental understanding that the organic linkers connecting metal nodes in MOFs play a crucial role in determining their structural and functional characteristics.

The evolution of MOF technology has seen a growing interest in tailoring the properties of these materials through precise control of their molecular architecture. Linker length has been identified as a key parameter that can significantly influence the pore size, shape, and overall framework flexibility. As researchers delve deeper into this aspect, the objective is to establish a comprehensive understanding of how variations in linker length correlate with changes in MOF behavior and performance.

The primary goal of this investigation is to elucidate the relationship between linker length and MOF flexibility. This involves exploring how different linker lengths affect the dynamic behavior of MOFs, including their ability to undergo structural transformations in response to external stimuli such as pressure, temperature, or guest molecule adsorption. Understanding these dynamics is crucial for designing MOFs with specific functionalities and optimizing their performance in various applications.

Another important objective is to develop predictive models that can guide the rational design of MOFs with tailored flexibility. By systematically studying the impact of linker length on framework properties, researchers aim to establish design principles that can be applied to create MOFs with precisely controlled flexibility characteristics. This knowledge is essential for advancing MOF technology and expanding its potential applications in areas such as gas storage, separation processes, and sensing technologies.

Furthermore, this research seeks to explore the limits and possibilities of MOF flexibility as influenced by linker length. This includes investigating the maximum extent of framework expansion and contraction that can be achieved through linker modification, as well as identifying any potential trade-offs between flexibility and other desirable properties such as stability or selectivity. By pushing the boundaries of MOF design, researchers hope to unlock new functionalities and applications for these versatile materials.

In the broader context of materials science and chemistry, this investigation contributes to the fundamental understanding of structure-property relationships in porous materials. The insights gained from studying linker length effects in MOFs may also have implications for other classes of materials, potentially leading to new design strategies for creating adaptive and responsive structures across various technological domains.

The evolution of MOF technology has seen a growing interest in tailoring the properties of these materials through precise control of their molecular architecture. Linker length has been identified as a key parameter that can significantly influence the pore size, shape, and overall framework flexibility. As researchers delve deeper into this aspect, the objective is to establish a comprehensive understanding of how variations in linker length correlate with changes in MOF behavior and performance.

The primary goal of this investigation is to elucidate the relationship between linker length and MOF flexibility. This involves exploring how different linker lengths affect the dynamic behavior of MOFs, including their ability to undergo structural transformations in response to external stimuli such as pressure, temperature, or guest molecule adsorption. Understanding these dynamics is crucial for designing MOFs with specific functionalities and optimizing their performance in various applications.

Another important objective is to develop predictive models that can guide the rational design of MOFs with tailored flexibility. By systematically studying the impact of linker length on framework properties, researchers aim to establish design principles that can be applied to create MOFs with precisely controlled flexibility characteristics. This knowledge is essential for advancing MOF technology and expanding its potential applications in areas such as gas storage, separation processes, and sensing technologies.

Furthermore, this research seeks to explore the limits and possibilities of MOF flexibility as influenced by linker length. This includes investigating the maximum extent of framework expansion and contraction that can be achieved through linker modification, as well as identifying any potential trade-offs between flexibility and other desirable properties such as stability or selectivity. By pushing the boundaries of MOF design, researchers hope to unlock new functionalities and applications for these versatile materials.

In the broader context of materials science and chemistry, this investigation contributes to the fundamental understanding of structure-property relationships in porous materials. The insights gained from studying linker length effects in MOFs may also have implications for other classes of materials, potentially leading to new design strategies for creating adaptive and responsive structures across various technological domains.

Market Analysis for Flexible MOFs

The market for flexible Metal-Organic Frameworks (MOFs) is experiencing significant growth, driven by their unique properties and diverse applications across various industries. Flexible MOFs, characterized by their ability to undergo structural changes in response to external stimuli, offer advantages over traditional rigid MOFs in areas such as gas storage, separation, and sensing.

In the energy sector, flexible MOFs show promise for enhanced gas storage and separation applications. The market for natural gas storage and transportation is particularly interested in these materials due to their potential to increase storage capacity and improve efficiency. Additionally, the growing focus on hydrogen as a clean energy carrier has created opportunities for flexible MOFs in hydrogen storage systems.

The environmental sector represents another key market for flexible MOFs. With increasing global emphasis on carbon capture and storage (CCS) technologies, these materials are being explored for their potential to selectively adsorb CO2 from industrial emissions. The adaptability of flexible MOFs to different gas mixtures and environmental conditions makes them attractive candidates for next-generation CCS systems.

In the pharmaceutical industry, flexible MOFs are gaining attention for drug delivery applications. Their ability to encapsulate and release drug molecules in response to specific triggers offers potential for targeted and controlled drug release systems. This market segment is expected to grow as research progresses and regulatory pathways become clearer.

The electronics industry is also exploring flexible MOFs for sensor applications. Their responsiveness to various stimuli, including temperature, pressure, and chemical species, makes them suitable for developing advanced sensing devices. This market is likely to expand as miniaturization and integration of sensors in smart devices continue to advance.

Despite the promising outlook, challenges remain in scaling up production and ensuring long-term stability of flexible MOFs. The market is currently dominated by research and development activities, with commercial applications still in early stages. However, collaborations between academic institutions and industry players are accelerating the transition from lab-scale to industrial-scale production.

The global market for MOFs, including flexible variants, is projected to grow significantly in the coming years. While specific market size data for flexible MOFs is limited due to their emerging nature, the overall MOF market is expected to expand as applications in gas storage, separation, and sensing mature. Regions with strong research capabilities and industrial bases, such as North America, Europe, and parts of Asia, are likely to lead in market development and adoption of flexible MOF technologies.

In the energy sector, flexible MOFs show promise for enhanced gas storage and separation applications. The market for natural gas storage and transportation is particularly interested in these materials due to their potential to increase storage capacity and improve efficiency. Additionally, the growing focus on hydrogen as a clean energy carrier has created opportunities for flexible MOFs in hydrogen storage systems.

The environmental sector represents another key market for flexible MOFs. With increasing global emphasis on carbon capture and storage (CCS) technologies, these materials are being explored for their potential to selectively adsorb CO2 from industrial emissions. The adaptability of flexible MOFs to different gas mixtures and environmental conditions makes them attractive candidates for next-generation CCS systems.

In the pharmaceutical industry, flexible MOFs are gaining attention for drug delivery applications. Their ability to encapsulate and release drug molecules in response to specific triggers offers potential for targeted and controlled drug release systems. This market segment is expected to grow as research progresses and regulatory pathways become clearer.

The electronics industry is also exploring flexible MOFs for sensor applications. Their responsiveness to various stimuli, including temperature, pressure, and chemical species, makes them suitable for developing advanced sensing devices. This market is likely to expand as miniaturization and integration of sensors in smart devices continue to advance.

Despite the promising outlook, challenges remain in scaling up production and ensuring long-term stability of flexible MOFs. The market is currently dominated by research and development activities, with commercial applications still in early stages. However, collaborations between academic institutions and industry players are accelerating the transition from lab-scale to industrial-scale production.

The global market for MOFs, including flexible variants, is projected to grow significantly in the coming years. While specific market size data for flexible MOFs is limited due to their emerging nature, the overall MOF market is expected to expand as applications in gas storage, separation, and sensing mature. Regions with strong research capabilities and industrial bases, such as North America, Europe, and parts of Asia, are likely to lead in market development and adoption of flexible MOF technologies.

Current Challenges in MOF Flexibility

The flexibility of Metal-Organic Frameworks (MOFs) presents several challenges that researchers are currently grappling with. One of the primary issues is the complex relationship between linker length and framework flexibility. While longer linkers generally contribute to increased flexibility, the precise mechanisms and limits of this relationship are not fully understood. This complexity is further compounded by the interplay between linker length and other structural factors, such as metal node geometry and framework topology.

Another significant challenge lies in accurately predicting and controlling the degree of flexibility in MOFs. The multitude of variables involved, including linker composition, metal center coordination, and environmental conditions, makes it difficult to develop reliable models for flexibility prediction. This unpredictability hampers the rational design of MOFs with specific flexible properties for targeted applications.

The characterization of MOF flexibility also poses considerable difficulties. Traditional characterization techniques often struggle to capture the dynamic nature of flexible MOFs, particularly in situ or under operating conditions. This limitation hinders our understanding of the structural changes that occur during adsorption, desorption, or other stimuli-responsive processes.

Furthermore, the scalability of flexible MOFs remains a significant hurdle. While many interesting flexible MOFs have been synthesized and studied at the laboratory scale, translating these materials to industrial-scale production while maintaining their flexible properties is challenging. Issues such as defect formation, loss of crystallinity, and reduced flexibility in bulk samples need to be addressed.

The long-term stability of flexible MOFs is another area of concern. The repeated structural changes associated with flexibility can lead to framework degradation over time, potentially limiting the lifespan and practical applicability of these materials. Understanding and mitigating these degradation mechanisms is crucial for the development of durable, flexible MOFs.

Lastly, the integration of flexible MOFs into functional devices and systems presents its own set of challenges. The dynamic nature of these materials can complicate their incorporation into existing technologies, requiring novel engineering solutions and device designs to fully leverage their unique properties.

Another significant challenge lies in accurately predicting and controlling the degree of flexibility in MOFs. The multitude of variables involved, including linker composition, metal center coordination, and environmental conditions, makes it difficult to develop reliable models for flexibility prediction. This unpredictability hampers the rational design of MOFs with specific flexible properties for targeted applications.

The characterization of MOF flexibility also poses considerable difficulties. Traditional characterization techniques often struggle to capture the dynamic nature of flexible MOFs, particularly in situ or under operating conditions. This limitation hinders our understanding of the structural changes that occur during adsorption, desorption, or other stimuli-responsive processes.

Furthermore, the scalability of flexible MOFs remains a significant hurdle. While many interesting flexible MOFs have been synthesized and studied at the laboratory scale, translating these materials to industrial-scale production while maintaining their flexible properties is challenging. Issues such as defect formation, loss of crystallinity, and reduced flexibility in bulk samples need to be addressed.

The long-term stability of flexible MOFs is another area of concern. The repeated structural changes associated with flexibility can lead to framework degradation over time, potentially limiting the lifespan and practical applicability of these materials. Understanding and mitigating these degradation mechanisms is crucial for the development of durable, flexible MOFs.

Lastly, the integration of flexible MOFs into functional devices and systems presents its own set of challenges. The dynamic nature of these materials can complicate their incorporation into existing technologies, requiring novel engineering solutions and device designs to fully leverage their unique properties.

Existing Approaches to Tune MOF Flexibility

01 Structural flexibility of MOFs

Metal-Organic Frameworks (MOFs) exhibit structural flexibility, allowing them to respond to external stimuli such as pressure, temperature, or guest molecules. This flexibility enables MOFs to undergo reversible structural transformations, which can be utilized in various applications including gas storage, separation, and sensing.- Structural flexibility of MOFs: Metal-Organic Frameworks (MOFs) exhibit structural flexibility, allowing them to adapt to various stimuli such as pressure, temperature, or guest molecules. This flexibility enables MOFs to change their pore size and shape, leading to applications in gas storage, separation, and sensing.

- Breathing and swelling phenomena in MOFs: Some MOFs demonstrate breathing and swelling phenomena, where the framework can expand or contract in response to external stimuli. This dynamic behavior allows for reversible structural changes, enhancing their potential in applications such as controlled drug delivery and selective adsorption.

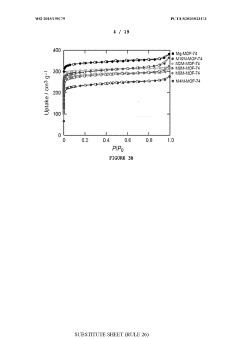

- Flexible MOFs for enhanced gas adsorption: The flexibility of MOFs can be exploited to improve gas adsorption properties. By designing MOFs with specific flexible components, researchers can create materials with increased gas uptake capacity and selectivity, particularly useful for gas storage and separation applications.

- Stimuli-responsive MOFs: MOFs can be designed to respond to various external stimuli such as light, pH, or magnetic fields. This responsiveness allows for the development of smart materials with potential applications in sensing, catalysis, and controlled release systems.

- Computational modeling of MOF flexibility: Advanced computational techniques are employed to model and predict the flexible behavior of MOFs. These simulations help researchers understand the mechanisms of flexibility and design new MOFs with tailored properties for specific applications.

02 Synthesis of flexible MOFs

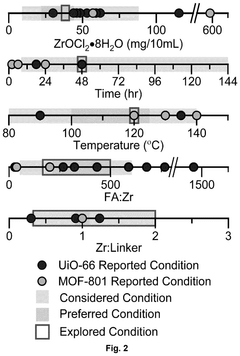

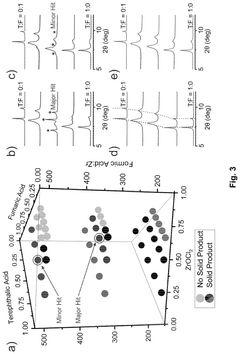

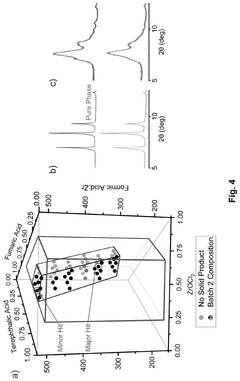

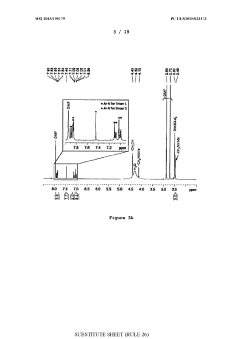

Researchers have developed various methods to synthesize flexible MOFs, including the use of specific ligands, metal centers, and synthesis conditions. These approaches aim to create MOFs with enhanced flexibility and tailored properties for specific applications, such as improved adsorption capacity or selectivity.Expand Specific Solutions03 Characterization of MOF flexibility

Advanced characterization techniques are employed to study and quantify the flexibility of MOFs. These methods include in-situ X-ray diffraction, spectroscopic techniques, and computational simulations. Such characterization helps in understanding the mechanisms of flexibility and predicting the behavior of MOFs under different conditions.Expand Specific Solutions04 Applications of flexible MOFs

The flexibility of MOFs is exploited in various applications, including gas storage and separation, catalysis, drug delivery, and sensing. The ability of flexible MOFs to change their structure in response to external stimuli makes them particularly useful for selective adsorption, controlled release of molecules, and detection of specific compounds.Expand Specific Solutions05 Enhancing MOF flexibility through functionalization

Researchers are exploring ways to enhance the flexibility of MOFs through functionalization of the organic linkers or metal nodes. This approach allows for fine-tuning of the MOF's flexibility and responsiveness to specific stimuli, leading to improved performance in targeted applications such as gas separation or chemical sensing.Expand Specific Solutions

Key Players in MOF Research and Development

The investigation into the role of linker length in MOF flexibility is currently in an early developmental stage, with growing interest from both academia and industry. The market size is expanding as researchers explore potential applications in gas storage, catalysis, and separation processes. While the technology is still maturing, several key players are advancing the field. Centre National de la Recherche Scientifique, The Regents of the University of California, and King Abdullah University of Science & Technology are leading academic institutions contributing to fundamental research. Companies like BASF Corp. and ExxonMobil Technology & Engineering Co. are exploring commercial applications, leveraging their expertise in materials science and chemical engineering to develop novel MOF structures with tailored flexibility.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has been at the forefront of investigating the role of linker length in MOF flexibility. Their research focuses on developing a systematic approach to tuning MOF properties through linker design. They have synthesized a series of MOFs with varying linker lengths, utilizing advanced characterization techniques such as in-situ X-ray diffraction and molecular dynamics simulations to understand the relationship between linker length and framework flexibility[1]. Their studies have shown that increasing linker length generally leads to enhanced framework flexibility, but this relationship is not always linear and can be influenced by other factors such as ligand geometry and metal node coordination[2]. KAUST researchers have also explored the impact of linker flexibility on gas adsorption and separation properties, demonstrating that carefully designed flexible MOFs can exhibit enhanced selectivity for certain gas molecules[3].

Strengths: Access to cutting-edge characterization techniques and computational resources. Strong interdisciplinary approach combining synthesis, characterization, and modeling. Weaknesses: May face challenges in scaling up synthesis for industrial applications.

The University of Liverpool

Technical Solution: The University of Liverpool has made significant contributions to understanding the role of linker length in MOF flexibility. Their research team has developed a series of isoreticular MOFs with systematically varied linker lengths, allowing for precise control over pore size and framework flexibility[4]. They have employed advanced in-situ characterization techniques, including synchrotron-based X-ray diffraction and spectroscopy, to study the dynamic behavior of these MOFs under different stimuli such as guest adsorption and temperature changes[5]. Their findings have revealed complex relationships between linker length, framework topology, and flexibility, demonstrating that longer linkers can lead to increased framework compliance but may also result in interpenetration or framework collapse in some cases[6]. The Liverpool team has also explored the application of these flexible MOFs in areas such as gas storage, separation, and catalysis, showcasing the potential for tuning performance through linker design.

Strengths: Expertise in MOF synthesis and advanced characterization techniques. Strong focus on structure-property relationships. Weaknesses: May face challenges in translating fundamental research into practical applications.

Innovative Linker Length Strategies

Metal-organic framework

PatentPendingUS20240336636A1

Innovation

- A three-dimensional MOF is synthesized using a single-step method with crystallographically-ordered heterolinkers of different types, allowing for precise control of window types and cage structures, enabling tailored porosity and functional properties.

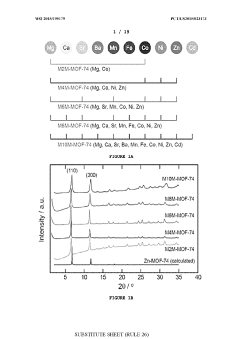

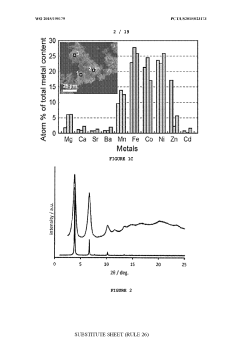

Metal organic frameworks comprising a plurality of SBUS with different metal IONS and/or a plurality of organic linking ligands with different functional groups.

PatentWO2015195179A2

Innovation

- The development of MOFs comprising a plurality of secondary building units (SBUs) linked by multiple types of organic linking ligands with varying functional groups and metal ions, allowing for customizable material properties through ratio adjustments of metal ions and functionalized ligands, enabling topologically uniform yet compositionally diverse structures.

Environmental Impact of Flexible MOFs

The environmental impact of flexible Metal-Organic Frameworks (MOFs) is a crucial consideration in their development and application. These materials, characterized by their ability to undergo structural changes in response to external stimuli, offer unique advantages in various fields, including gas storage, separation, and catalysis. However, their environmental implications must be carefully evaluated.

Flexible MOFs demonstrate enhanced adsorption and separation capabilities compared to their rigid counterparts. This increased efficiency can lead to reduced energy consumption in industrial processes, potentially lowering greenhouse gas emissions. For instance, in gas separation applications, flexible MOFs can achieve higher selectivity and capacity, resulting in more efficient purification processes and decreased energy requirements.

The adaptability of flexible MOFs also contributes to their extended lifespan and reusability. Unlike rigid structures that may degrade or lose efficiency over time, flexible MOFs can often recover their original structure after deformation, reducing the need for frequent replacement. This durability translates to reduced waste generation and resource consumption in the long term.

However, the environmental benefits of flexible MOFs must be weighed against potential drawbacks. The synthesis of these materials often involves the use of organic solvents and metal precursors, which can have negative environmental impacts if not properly managed. Additionally, the production of MOFs may require energy-intensive processes, potentially offsetting some of their operational environmental benefits.

The disposal and end-of-life management of flexible MOFs also warrant consideration. While many MOFs can be recycled or regenerated, the process may involve chemical treatments that could pose environmental risks if not handled appropriately. Furthermore, the long-term stability and potential degradation products of flexible MOFs in various environmental conditions need to be thoroughly investigated to ensure they do not introduce harmful substances into ecosystems.

In the context of linker length investigation, the environmental impact may vary depending on the specific linkers used. Longer linkers might provide greater flexibility and enhanced performance in certain applications, potentially leading to improved environmental outcomes. However, they may also require more complex synthesis procedures or result in larger pore sizes that could affect the material's stability and recyclability.

Overall, while flexible MOFs offer promising environmental benefits through improved efficiency and durability, a comprehensive life cycle assessment is essential to fully understand their net environmental impact. This evaluation should consider factors such as raw material sourcing, synthesis methods, operational efficiency, and end-of-life management to ensure that the development of flexible MOFs aligns with sustainable practices and environmental stewardship.

Flexible MOFs demonstrate enhanced adsorption and separation capabilities compared to their rigid counterparts. This increased efficiency can lead to reduced energy consumption in industrial processes, potentially lowering greenhouse gas emissions. For instance, in gas separation applications, flexible MOFs can achieve higher selectivity and capacity, resulting in more efficient purification processes and decreased energy requirements.

The adaptability of flexible MOFs also contributes to their extended lifespan and reusability. Unlike rigid structures that may degrade or lose efficiency over time, flexible MOFs can often recover their original structure after deformation, reducing the need for frequent replacement. This durability translates to reduced waste generation and resource consumption in the long term.

However, the environmental benefits of flexible MOFs must be weighed against potential drawbacks. The synthesis of these materials often involves the use of organic solvents and metal precursors, which can have negative environmental impacts if not properly managed. Additionally, the production of MOFs may require energy-intensive processes, potentially offsetting some of their operational environmental benefits.

The disposal and end-of-life management of flexible MOFs also warrant consideration. While many MOFs can be recycled or regenerated, the process may involve chemical treatments that could pose environmental risks if not handled appropriately. Furthermore, the long-term stability and potential degradation products of flexible MOFs in various environmental conditions need to be thoroughly investigated to ensure they do not introduce harmful substances into ecosystems.

In the context of linker length investigation, the environmental impact may vary depending on the specific linkers used. Longer linkers might provide greater flexibility and enhanced performance in certain applications, potentially leading to improved environmental outcomes. However, they may also require more complex synthesis procedures or result in larger pore sizes that could affect the material's stability and recyclability.

Overall, while flexible MOFs offer promising environmental benefits through improved efficiency and durability, a comprehensive life cycle assessment is essential to fully understand their net environmental impact. This evaluation should consider factors such as raw material sourcing, synthesis methods, operational efficiency, and end-of-life management to ensure that the development of flexible MOFs aligns with sustainable practices and environmental stewardship.

Scalability and Industrial Applications

The scalability and industrial applications of Metal-Organic Frameworks (MOFs) with varying linker lengths present significant opportunities and challenges. As research into the role of linker length in MOF flexibility progresses, the potential for large-scale production and diverse industrial uses becomes increasingly apparent.

In terms of scalability, MOFs with optimized linker lengths offer improved synthesis processes and enhanced structural stability. Longer linkers can create larger pore sizes, potentially increasing the material's surface area and adsorption capacity. This scalability aspect is particularly crucial for industrial applications requiring high-volume gas storage or separation processes. However, the trade-off between flexibility and stability must be carefully balanced to ensure the MOF's structural integrity during large-scale production and use.

The industrial applications of MOFs with tailored linker lengths span various sectors. In the energy industry, these materials show promise for gas storage and separation, particularly for hydrogen storage and carbon capture. The ability to fine-tune pore sizes through linker length adjustment allows for more efficient and selective gas adsorption processes. This characteristic is especially valuable in the context of clean energy initiatives and environmental protection efforts.

In the field of catalysis, MOFs with specific linker lengths can create unique reaction environments within their pores. This property is particularly beneficial for the chemical and pharmaceutical industries, where selective and efficient catalytic processes are essential. By adjusting the linker length, researchers can optimize the MOF's catalytic performance for specific reactions, potentially leading to more sustainable and cost-effective industrial processes.

The water treatment sector is another area where MOFs with varied linker lengths show significant potential. The ability to tailor pore sizes and chemical functionalities through linker modification allows for the development of highly efficient water purification systems. These materials could be used for the removal of specific contaminants or the desalination of seawater, addressing critical global challenges in water scarcity and pollution.

However, scaling up MOF production for industrial applications presents several challenges. Maintaining consistent quality and structural integrity during large-scale synthesis is crucial. Additionally, the cost-effectiveness of producing MOFs with specific linker lengths on an industrial scale needs to be carefully evaluated. The development of more efficient and economical synthesis methods is an ongoing area of research that will significantly impact the widespread industrial adoption of these materials.

As research in this field advances, the potential for customizing MOFs for specific industrial applications through linker length optimization continues to grow. This adaptability positions MOFs as versatile materials with the potential to revolutionize various industrial processes, from energy storage to environmental remediation.

In terms of scalability, MOFs with optimized linker lengths offer improved synthesis processes and enhanced structural stability. Longer linkers can create larger pore sizes, potentially increasing the material's surface area and adsorption capacity. This scalability aspect is particularly crucial for industrial applications requiring high-volume gas storage or separation processes. However, the trade-off between flexibility and stability must be carefully balanced to ensure the MOF's structural integrity during large-scale production and use.

The industrial applications of MOFs with tailored linker lengths span various sectors. In the energy industry, these materials show promise for gas storage and separation, particularly for hydrogen storage and carbon capture. The ability to fine-tune pore sizes through linker length adjustment allows for more efficient and selective gas adsorption processes. This characteristic is especially valuable in the context of clean energy initiatives and environmental protection efforts.

In the field of catalysis, MOFs with specific linker lengths can create unique reaction environments within their pores. This property is particularly beneficial for the chemical and pharmaceutical industries, where selective and efficient catalytic processes are essential. By adjusting the linker length, researchers can optimize the MOF's catalytic performance for specific reactions, potentially leading to more sustainable and cost-effective industrial processes.

The water treatment sector is another area where MOFs with varied linker lengths show significant potential. The ability to tailor pore sizes and chemical functionalities through linker modification allows for the development of highly efficient water purification systems. These materials could be used for the removal of specific contaminants or the desalination of seawater, addressing critical global challenges in water scarcity and pollution.

However, scaling up MOF production for industrial applications presents several challenges. Maintaining consistent quality and structural integrity during large-scale synthesis is crucial. Additionally, the cost-effectiveness of producing MOFs with specific linker lengths on an industrial scale needs to be carefully evaluated. The development of more efficient and economical synthesis methods is an ongoing area of research that will significantly impact the widespread industrial adoption of these materials.

As research in this field advances, the potential for customizing MOFs for specific industrial applications through linker length optimization continues to grow. This adaptability positions MOFs as versatile materials with the potential to revolutionize various industrial processes, from energy storage to environmental remediation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!