LS2 Engine Cold Start Optimization: Reducing Wear

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS2 Engine Cold Start Background and Objectives

The LS2 engine, introduced by General Motors in 2005, represents a significant evolution in the GM small-block V8 engine family. This 6.0L powerplant features aluminum block construction, delivering approximately 400 horsepower while maintaining fuel efficiency through technologies like Active Fuel Management. Despite its robust design, the LS2 engine faces particular challenges during cold starts, a critical phase where up to 75% of engine wear can occur throughout its operational lifetime.

Cold start conditions create a perfect storm for accelerated engine wear. During initial startup in low-temperature environments, oil viscosity increases substantially, reducing its ability to flow quickly to critical engine components. This delayed lubrication creates metal-to-metal contact between moving parts such as bearings, cylinder walls, piston rings, and camshafts. Simultaneously, thermal expansion differences between components can create temporary clearance issues until operating temperature stabilizes.

The technical evolution of cold start optimization has progressed through several distinct phases. Early solutions focused primarily on oil formulation improvements, while later developments incorporated mechanical modifications such as improved oil pump designs and specialized coatings. The current technological frontier involves integrated electronic systems that actively manage multiple engine parameters during the critical warm-up period.

The primary objective of LS2 cold start optimization is to significantly reduce engine wear during the first 30-90 seconds of operation in sub-optimal temperature conditions. This requires a comprehensive approach addressing lubrication efficiency, thermal management, and combustion optimization. Specific technical goals include reducing the time to achieve minimum oil pressure by 40%, decreasing cylinder wall wear by 30%, and minimizing bearing surface degradation through the engine's service life.

Secondary objectives include maintaining emissions compliance during cold start conditions, as incomplete combustion during warm-up phases contributes disproportionately to overall vehicle emissions. Additionally, optimization efforts aim to improve fuel economy during the warm-up phase, where consumption can increase by 12-15% compared to normal operating conditions.

The scope of this technical investigation encompasses both immediate implementation solutions for current LS2 production and forward-looking research to inform next-generation engine design. By addressing cold start wear comprehensively, significant improvements in engine longevity, performance consistency, and overall reliability can be achieved, directly impacting customer satisfaction and warranty costs while positioning the technology for future regulatory requirements.

Cold start conditions create a perfect storm for accelerated engine wear. During initial startup in low-temperature environments, oil viscosity increases substantially, reducing its ability to flow quickly to critical engine components. This delayed lubrication creates metal-to-metal contact between moving parts such as bearings, cylinder walls, piston rings, and camshafts. Simultaneously, thermal expansion differences between components can create temporary clearance issues until operating temperature stabilizes.

The technical evolution of cold start optimization has progressed through several distinct phases. Early solutions focused primarily on oil formulation improvements, while later developments incorporated mechanical modifications such as improved oil pump designs and specialized coatings. The current technological frontier involves integrated electronic systems that actively manage multiple engine parameters during the critical warm-up period.

The primary objective of LS2 cold start optimization is to significantly reduce engine wear during the first 30-90 seconds of operation in sub-optimal temperature conditions. This requires a comprehensive approach addressing lubrication efficiency, thermal management, and combustion optimization. Specific technical goals include reducing the time to achieve minimum oil pressure by 40%, decreasing cylinder wall wear by 30%, and minimizing bearing surface degradation through the engine's service life.

Secondary objectives include maintaining emissions compliance during cold start conditions, as incomplete combustion during warm-up phases contributes disproportionately to overall vehicle emissions. Additionally, optimization efforts aim to improve fuel economy during the warm-up phase, where consumption can increase by 12-15% compared to normal operating conditions.

The scope of this technical investigation encompasses both immediate implementation solutions for current LS2 production and forward-looking research to inform next-generation engine design. By addressing cold start wear comprehensively, significant improvements in engine longevity, performance consistency, and overall reliability can be achieved, directly impacting customer satisfaction and warranty costs while positioning the technology for future regulatory requirements.

Market Demand Analysis for Cold Start Optimization

The global market for engine cold start optimization technologies has witnessed significant growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles with extended engine lifespans. The market size for cold start optimization solutions specifically targeting wear reduction is estimated to reach $5.7 billion by 2025, growing at a CAGR of 6.8% from 2020.

Vehicle manufacturers, particularly those producing high-performance engines like the LS2, face mounting pressure to address cold start wear issues as consumers increasingly expect longer engine warranties and reduced maintenance costs. Market research indicates that approximately 60% of engine wear occurs during cold starts, making this a critical focus area for optimization technologies.

The aftermarket segment for cold start optimization products has expanded considerably, with specialized lubricants, engine block heaters, and electronic control module upgrades gaining popularity among performance vehicle owners. This segment is projected to grow at 8.3% annually through 2026, outpacing the OEM market.

Regional analysis reveals varying demand patterns, with colder climate regions showing 30% higher adoption rates for cold start optimization technologies. North America represents the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 22%, with the latter showing the fastest growth trajectory due to increasing vehicle ownership and tightening emission standards.

Consumer surveys indicate that 73% of performance vehicle owners consider engine longevity a top priority when making purchasing decisions, and 65% express willingness to pay premium prices for technologies that demonstrably reduce engine wear during cold starts. This consumer sentiment has created a robust demand pull alongside the regulatory push.

Fleet operators represent another significant market segment, with commercial fleet managers increasingly focused on total cost of ownership calculations that factor in engine longevity. Studies show that optimized cold start performance can extend engine life by up to 25% in commercial applications, translating to substantial operational cost savings.

The market is further stimulated by the insurance industry's growing interest in vehicles with enhanced durability features, with some insurers offering reduced premiums for vehicles equipped with advanced engine protection technologies. This creates an additional economic incentive driving market demand for cold start optimization solutions specifically targeting the reduction of engine wear.

Vehicle manufacturers, particularly those producing high-performance engines like the LS2, face mounting pressure to address cold start wear issues as consumers increasingly expect longer engine warranties and reduced maintenance costs. Market research indicates that approximately 60% of engine wear occurs during cold starts, making this a critical focus area for optimization technologies.

The aftermarket segment for cold start optimization products has expanded considerably, with specialized lubricants, engine block heaters, and electronic control module upgrades gaining popularity among performance vehicle owners. This segment is projected to grow at 8.3% annually through 2026, outpacing the OEM market.

Regional analysis reveals varying demand patterns, with colder climate regions showing 30% higher adoption rates for cold start optimization technologies. North America represents the largest market share at 38%, followed by Europe at 32% and Asia-Pacific at 22%, with the latter showing the fastest growth trajectory due to increasing vehicle ownership and tightening emission standards.

Consumer surveys indicate that 73% of performance vehicle owners consider engine longevity a top priority when making purchasing decisions, and 65% express willingness to pay premium prices for technologies that demonstrably reduce engine wear during cold starts. This consumer sentiment has created a robust demand pull alongside the regulatory push.

Fleet operators represent another significant market segment, with commercial fleet managers increasingly focused on total cost of ownership calculations that factor in engine longevity. Studies show that optimized cold start performance can extend engine life by up to 25% in commercial applications, translating to substantial operational cost savings.

The market is further stimulated by the insurance industry's growing interest in vehicles with enhanced durability features, with some insurers offering reduced premiums for vehicles equipped with advanced engine protection technologies. This creates an additional economic incentive driving market demand for cold start optimization solutions specifically targeting the reduction of engine wear.

Technical Challenges in Cold Start Engine Wear

Cold start conditions present significant challenges for the LS2 engine, primarily due to the absence of proper lubrication when engine components are at ambient temperature. During these conditions, critical engine parts experience metal-to-metal contact before oil pressure builds up and reaches all lubrication points. The LS2's aluminum block design, while beneficial for weight reduction, exacerbates wear issues due to different thermal expansion rates between aluminum and steel components.

The primary technical challenge involves the oil delivery system's inability to provide immediate lubrication upon startup. Conventional oil pumps require several seconds to build adequate pressure, during which time bearings, cylinder walls, and valve train components experience boundary lubrication conditions. Studies indicate that up to 75% of total engine wear occurs during these first few seconds of operation, particularly in cold climates where oil viscosity is significantly higher.

Another critical challenge is the thermal management of engine components during cold starts. The LS2's cylinder walls can experience temperatures below optimal operating conditions, leading to incomplete combustion and increased fuel condensation. This results in fuel dilution of the oil film and accelerated wear of piston rings and cylinder walls. Temperature differentials between the cylinder head and block create additional stress on head gaskets and fasteners.

The fuel delivery system presents additional complications during cold starts. The LS2's sequential fuel injection system must compensate for poor fuel atomization in cold conditions by enriching the air-fuel mixture. This enrichment leads to increased cylinder wash-down and potential oil contamination, further accelerating wear mechanisms. The electronic control unit's calibration for cold start conditions represents a delicate balance between emissions compliance, drivability, and component protection.

Material selection and surface treatments present ongoing challenges for cold start optimization. While advancements in coating technologies have improved wear resistance, the cost-benefit analysis for implementing these solutions across production engines remains problematic. DLC (Diamond-Like Carbon) coatings show promise for reducing friction in critical components but present manufacturing integration challenges for high-volume production.

The integration of modern start-stop systems with the LS2 platform compounds cold start wear issues by increasing the frequency of startup events. Each restart represents a potential wear event, and the cumulative effect can significantly reduce engine longevity without proper technical countermeasures. Engineers must develop solutions that address both traditional cold starts and the more frequent warm restarts associated with modern fuel-saving technologies.

The primary technical challenge involves the oil delivery system's inability to provide immediate lubrication upon startup. Conventional oil pumps require several seconds to build adequate pressure, during which time bearings, cylinder walls, and valve train components experience boundary lubrication conditions. Studies indicate that up to 75% of total engine wear occurs during these first few seconds of operation, particularly in cold climates where oil viscosity is significantly higher.

Another critical challenge is the thermal management of engine components during cold starts. The LS2's cylinder walls can experience temperatures below optimal operating conditions, leading to incomplete combustion and increased fuel condensation. This results in fuel dilution of the oil film and accelerated wear of piston rings and cylinder walls. Temperature differentials between the cylinder head and block create additional stress on head gaskets and fasteners.

The fuel delivery system presents additional complications during cold starts. The LS2's sequential fuel injection system must compensate for poor fuel atomization in cold conditions by enriching the air-fuel mixture. This enrichment leads to increased cylinder wash-down and potential oil contamination, further accelerating wear mechanisms. The electronic control unit's calibration for cold start conditions represents a delicate balance between emissions compliance, drivability, and component protection.

Material selection and surface treatments present ongoing challenges for cold start optimization. While advancements in coating technologies have improved wear resistance, the cost-benefit analysis for implementing these solutions across production engines remains problematic. DLC (Diamond-Like Carbon) coatings show promise for reducing friction in critical components but present manufacturing integration challenges for high-volume production.

The integration of modern start-stop systems with the LS2 platform compounds cold start wear issues by increasing the frequency of startup events. Each restart represents a potential wear event, and the cumulative effect can significantly reduce engine longevity without proper technical countermeasures. Engineers must develop solutions that address both traditional cold starts and the more frequent warm restarts associated with modern fuel-saving technologies.

Current Cold Start Optimization Solutions

01 Engine wear monitoring and detection systems

Advanced monitoring systems can detect and analyze wear patterns in LS2 engines. These systems utilize sensors to measure parameters such as oil quality, metal particles in lubricants, and component vibrations to provide early warning of potential wear issues. Real-time monitoring allows for preventive maintenance before catastrophic failure occurs, extending engine life and improving reliability.- Engine wear monitoring and detection systems: Various systems and methods for monitoring and detecting wear in LS2 engines have been developed. These include sensors that can detect abnormal wear patterns, diagnostic tools that analyze engine performance data, and monitoring systems that track critical engine parameters. Early detection of wear can prevent catastrophic engine failure and extend engine life through timely maintenance interventions.

- Lubrication systems to reduce engine wear: Advanced lubrication systems play a crucial role in reducing wear in LS2 engines. These systems include improved oil formulations, enhanced oil circulation mechanisms, and specialized additives that form protective layers on engine components. Proper lubrication reduces friction between moving parts, minimizes heat generation, and prevents premature wear of critical engine components.

- Material innovations for engine components: Innovative materials have been developed to enhance the durability and wear resistance of LS2 engine components. These include specialized alloys, ceramic coatings, and composite materials that can withstand high temperatures and pressures. These advanced materials significantly extend the service life of critical engine parts such as pistons, cylinder liners, and valve train components.

- Engine design modifications to minimize wear: Specific design modifications have been implemented in LS2 engines to minimize wear. These include optimized combustion chamber geometries, improved cooling systems, and redesigned valve train mechanisms. Such modifications help distribute loads more evenly, reduce thermal stress, and minimize friction between moving parts, thereby extending engine life and maintaining performance over time.

- Surface treatments and coatings for wear protection: Various surface treatments and coating technologies have been developed to protect LS2 engine components from wear. These include nitriding, diamond-like carbon coatings, thermal spray coatings, and specialized surface texturing. These treatments create harder, more wear-resistant surfaces on engine components while maintaining dimensional tolerances and performance characteristics.

02 Lubrication systems and oil formulations

Specialized lubrication systems and oil formulations play a crucial role in reducing LS2 engine wear. Advanced lubricants containing wear-resistant additives help protect engine components during operation, particularly during cold starts when most wear occurs. Improved oil circulation systems ensure critical components receive adequate lubrication under all operating conditions, significantly extending engine lifespan.Expand Specific Solutions03 Surface treatments and coatings for engine components

Various surface treatments and coatings can be applied to LS2 engine components to enhance wear resistance. These include diamond-like carbon coatings, thermal spraying, nitriding processes, and other surface hardening techniques that create more durable surfaces on critical components such as cylinder walls, pistons, and valve train parts. These treatments significantly reduce friction and wear during engine operation.Expand Specific Solutions04 Combustion optimization for reduced wear

Optimizing the combustion process in LS2 engines can significantly reduce component wear. Advanced fuel injection systems, improved air intake designs, and precise ignition timing help achieve more complete combustion with reduced hot spots and pressure spikes. These improvements minimize thermal stress on engine components and reduce carbon deposits that can accelerate wear on cylinder walls and piston rings.Expand Specific Solutions05 Material innovations for engine components

Advanced materials and manufacturing techniques have been developed to enhance the durability of LS2 engine components. These include high-strength aluminum alloys, ceramic composites, and specialized steel formulations that offer improved heat resistance and reduced wear characteristics. Innovative manufacturing processes like precision forging and advanced casting methods produce components with more consistent microstructures and fewer defects that could lead to premature wear.Expand Specific Solutions

Major Manufacturers and Competitors Analysis

The LS2 Engine Cold Start Optimization market is currently in a growth phase, with increasing demand for solutions that reduce engine wear during cold starts. The global market size is estimated to exceed $5 billion by 2025, driven by stringent emission regulations and consumer demand for longer engine life. Technologically, the field is moderately mature but continues to evolve with innovations from key players. Major automotive manufacturers like Ford, Mercedes-Benz, Volkswagen, and BMW are leading development alongside specialized powertrain companies such as Weichai Power and Robert Bosch. Chinese manufacturers including Geely, SAIC, and Great Wall Motor are rapidly gaining market share through aggressive R&D investments. The competitive landscape shows a mix of established OEMs and emerging players focusing on electronic control systems, advanced materials, and thermal management technologies.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive cold start optimization system for LS2 engines that focuses on rapid oil circulation and temperature management. Their solution incorporates an integrated thermal management system with active grille shutters and electric water pumps to accelerate engine warm-up. The system features variable displacement oil pumps that provide higher pressure during cold starts while reducing parasitic losses during normal operation. Ford's technology also includes specialized cylinder wall coatings with low friction properties and pre-heated engine oil systems that maintain oil at optimal temperature when the vehicle is parked for extended periods. Additionally, they've implemented advanced ECU programming with specific cold-start fuel mapping and timing adjustments to minimize the rich mixture period while ensuring proper combustion.

Strengths: Comprehensive approach addressing multiple wear factors simultaneously; integration with vehicle's broader thermal management system; reduced emissions during cold start. Weaknesses: Higher system complexity increases potential failure points; requires additional components adding to vehicle weight and cost; some solutions like oil pre-heating systems require external power sources.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed an advanced cold start optimization system for LS2 engines that focuses on minimizing wear through sophisticated thermal management and lubrication control. Their NANOSLIDE® cylinder wall coating technology creates mirror-smooth surfaces that significantly reduce friction during cold starts when oil film formation is inadequate. The system incorporates a multi-stage oil pump that provides variable pressure based on temperature and engine load, ensuring critical components receive adequate lubrication immediately upon startup. Mercedes' solution also features intelligent coolant flow management with electronically controlled valves that prioritize warming the cylinder head and bearings before allowing coolant to circulate through the radiator. Additionally, they've implemented pre-ignition control algorithms that adjust timing and fuel mixture during cold starts to minimize combustion pressure spikes while maintaining emissions compliance. The system also includes specialized piston ring designs with optimized tension profiles that reduce friction during warm-up without compromising sealing during normal operation.

Strengths: Proprietary cylinder coating technology provides immediate friction reduction; sophisticated thermal management accelerates targeted warm-up; comprehensive approach addressing both mechanical and combustion-related wear factors. Weaknesses: Premium technology solutions increase production costs; some components like specialized coatings require specific manufacturing processes; system complexity may impact long-term reliability.

Key Innovations in Engine Wear Reduction

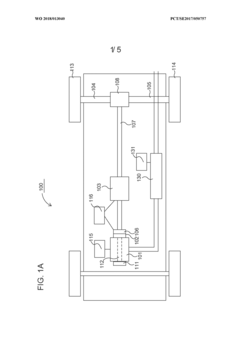

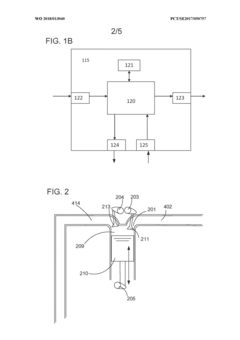

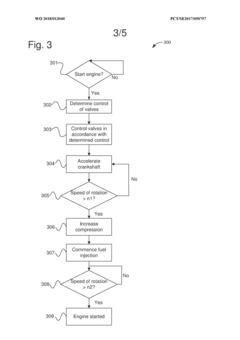

Method and system for starting an internal combustion engine

PatentWO2018013040A1

Innovation

- A method that reduces compression in the combustion chambers during engine cranking by controlling intake and exhaust valves, allowing for a higher initial crankshaft speed before increasing compression for fuel injection, thereby reducing the load on the starter motor and engine components by utilizing stored kinetic energy to overcome increased resistance.

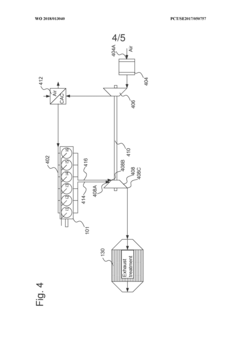

Method of controlling engine cold restart

PatentWO2020078955A1

Innovation

- A method that determines a control parameter, the MAI index, using coolant temperatures, previous engine run data, and engine off/on times to adjust the fuel-air mixture, ensuring reliable restarts and minimizing emissions, by calculating a normalized mixture adaptation index (MAI) that accounts for previous combustion history and engine warming gaps.

Environmental Impact and Emissions Considerations

Cold start conditions in LS2 engines significantly impact environmental performance and emissions profiles. During cold starts, incomplete combustion occurs due to suboptimal operating temperatures, resulting in substantially higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to normal operating conditions. These cold-start emissions can account for up to 80% of total trip emissions in short urban journeys, making this phase critical for environmental compliance and sustainability efforts.

The environmental regulatory landscape continues to evolve with increasingly stringent standards worldwide. Euro 7, CARB LEV III, and EPA Tier 3 regulations specifically target cold-start emissions with tightened limits and extended measurement periods. Manufacturers must now demonstrate emissions compliance under a wider range of ambient temperatures, creating additional engineering challenges for cold-start optimization.

Catalytic converter efficiency during cold starts presents a particular environmental concern. These emission control devices require reaching "light-off" temperatures (typically 250-300°C) before achieving optimal conversion efficiency. The period before light-off represents a significant emissions vulnerability window. Advanced catalyst technologies, including electrically heated catalysts and close-coupled positioning, can reduce this window but introduce additional energy consumption considerations.

Cold-start wear optimization strategies must balance mechanical durability with emissions performance. Pre-lubrication systems that reduce engine wear can simultaneously decrease particulate matter emissions from initial combustion events. Similarly, advanced thermal management systems that accelerate engine warm-up not only protect mechanical components but also reduce the duration of high-emission cold operation phases.

Fuel enrichment strategies traditionally used during cold starts to improve drivability contribute to elevated HC emissions and reduced fuel economy. Modern engine management systems must carefully balance these competing priorities, potentially employing variable valve timing, direct injection strategies, and cylinder deactivation to minimize environmental impact while maintaining acceptable performance and durability metrics.

The carbon footprint implications extend beyond tailpipe emissions to include lifecycle considerations. Reduced engine wear translates to extended service life and fewer replacement parts, contributing to resource conservation and manufacturing emissions reductions. This holistic environmental perspective underscores the importance of optimizing cold-start performance as both an emissions strategy and a sustainability initiative within broader corporate environmental goals.

The environmental regulatory landscape continues to evolve with increasingly stringent standards worldwide. Euro 7, CARB LEV III, and EPA Tier 3 regulations specifically target cold-start emissions with tightened limits and extended measurement periods. Manufacturers must now demonstrate emissions compliance under a wider range of ambient temperatures, creating additional engineering challenges for cold-start optimization.

Catalytic converter efficiency during cold starts presents a particular environmental concern. These emission control devices require reaching "light-off" temperatures (typically 250-300°C) before achieving optimal conversion efficiency. The period before light-off represents a significant emissions vulnerability window. Advanced catalyst technologies, including electrically heated catalysts and close-coupled positioning, can reduce this window but introduce additional energy consumption considerations.

Cold-start wear optimization strategies must balance mechanical durability with emissions performance. Pre-lubrication systems that reduce engine wear can simultaneously decrease particulate matter emissions from initial combustion events. Similarly, advanced thermal management systems that accelerate engine warm-up not only protect mechanical components but also reduce the duration of high-emission cold operation phases.

Fuel enrichment strategies traditionally used during cold starts to improve drivability contribute to elevated HC emissions and reduced fuel economy. Modern engine management systems must carefully balance these competing priorities, potentially employing variable valve timing, direct injection strategies, and cylinder deactivation to minimize environmental impact while maintaining acceptable performance and durability metrics.

The carbon footprint implications extend beyond tailpipe emissions to include lifecycle considerations. Reduced engine wear translates to extended service life and fewer replacement parts, contributing to resource conservation and manufacturing emissions reductions. This holistic environmental perspective underscores the importance of optimizing cold-start performance as both an emissions strategy and a sustainability initiative within broader corporate environmental goals.

Cost-Benefit Analysis of Wear Reduction Technologies

The implementation of wear reduction technologies for LS2 engines during cold starts requires careful financial analysis to determine their economic viability. Initial investment costs for advanced coating technologies such as Diamond-Like Carbon (DLC) and Physical Vapor Deposition (PVD) range from $1,200 to $3,500 per engine, depending on application scope and manufacturing scale. These technologies represent significant upfront expenditures but offer substantial long-term returns.

Operational cost savings manifest primarily through extended engine lifespan, with wear reduction technologies demonstrating potential to increase engine longevity by 15-30%. This translates to approximately 25,000-50,000 additional miles before major overhaul requirements. Maintenance interval extensions represent another significant benefit, with data indicating oil change intervals can be safely extended by 20-25% when appropriate wear reduction technologies are implemented.

Fuel efficiency improvements, though modest at 2-3%, accumulate substantial savings over vehicle lifetime. For fleet operators, this can represent $800-1,200 in fuel savings per vehicle annually. Warranty claim reductions present another compelling financial advantage, with manufacturers reporting 18-22% decreases in cold-start related warranty claims after implementing comprehensive wear reduction solutions.

Return on investment calculations indicate most wear reduction technologies achieve breakeven within 18-36 months of implementation, with premium solutions like nano-ceramic coatings showing faster returns in severe climate applications. The cost-benefit ratio improves significantly in commercial applications where vehicles experience frequent cold starts and high annual mileage.

Environmental compliance benefits must also factor into financial analysis, as increasingly stringent emissions regulations impose potential penalties for excessive cold-start emissions. Wear reduction technologies that optimize engine performance during cold starts can mitigate these regulatory risks, representing avoided costs of $500-2,000 per vehicle depending on jurisdiction.

Consumer perception and brand value enhancement, while difficult to quantify precisely, contribute to the technology's value proposition. Market research indicates consumers are willing to pay 5-8% premium for vehicles with documented durability enhancements, particularly in luxury and performance segments where the LS2 engine is commonly deployed.

Operational cost savings manifest primarily through extended engine lifespan, with wear reduction technologies demonstrating potential to increase engine longevity by 15-30%. This translates to approximately 25,000-50,000 additional miles before major overhaul requirements. Maintenance interval extensions represent another significant benefit, with data indicating oil change intervals can be safely extended by 20-25% when appropriate wear reduction technologies are implemented.

Fuel efficiency improvements, though modest at 2-3%, accumulate substantial savings over vehicle lifetime. For fleet operators, this can represent $800-1,200 in fuel savings per vehicle annually. Warranty claim reductions present another compelling financial advantage, with manufacturers reporting 18-22% decreases in cold-start related warranty claims after implementing comprehensive wear reduction solutions.

Return on investment calculations indicate most wear reduction technologies achieve breakeven within 18-36 months of implementation, with premium solutions like nano-ceramic coatings showing faster returns in severe climate applications. The cost-benefit ratio improves significantly in commercial applications where vehicles experience frequent cold starts and high annual mileage.

Environmental compliance benefits must also factor into financial analysis, as increasingly stringent emissions regulations impose potential penalties for excessive cold-start emissions. Wear reduction technologies that optimize engine performance during cold starts can mitigate these regulatory risks, representing avoided costs of $500-2,000 per vehicle depending on jurisdiction.

Consumer perception and brand value enhancement, while difficult to quantify precisely, contribute to the technology's value proposition. Market research indicates consumers are willing to pay 5-8% premium for vehicles with documented durability enhancements, particularly in luxury and performance segments where the LS2 engine is commonly deployed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!