Mechanical Deformation and Fracture Analysis in Sodium Metal Anodes

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Metal Anode Technology Background and Objectives

Sodium metal anodes have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The evolution of sodium battery technology can be traced back to the 1970s, when initial research focused on high-temperature sodium-sulfur and sodium-nickel chloride batteries. However, the development of room-temperature sodium-ion batteries gained momentum only in the last decade, driven by concerns about lithium resource limitations and increasing energy storage demands.

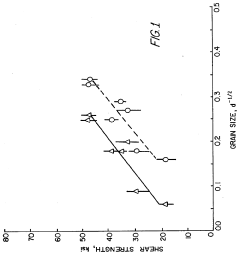

The technological trajectory of sodium metal anodes has been characterized by significant challenges related to their mechanical properties. Unlike lithium, sodium metal is inherently softer (Mohs hardness of 0.5 compared to lithium's 0.6) and more reactive, making it prone to mechanical deformation and fracture during battery cycling. These mechanical failures contribute to capacity fading, reduced cycle life, and potential safety hazards.

Recent advancements in materials science and electrochemistry have enabled researchers to better understand the mechanical behavior of sodium metal during electrochemical cycling. The correlation between mechanical properties and electrochemical performance has become a focal point in sodium battery research, with particular emphasis on understanding deformation mechanisms, crack propagation, and fracture patterns.

The primary technological objective in this field is to develop sodium metal anodes with enhanced mechanical stability that can withstand the volume changes during cycling while maintaining structural integrity. This involves understanding the fundamental mechanisms of mechanical failure in sodium metal anodes and developing strategies to mitigate these issues.

Current research trends indicate a growing interest in multidisciplinary approaches that combine electrochemistry, materials science, and mechanical engineering to address the challenges of sodium metal anodes. Advanced characterization techniques such as in-situ transmission electron microscopy, atomic force microscopy, and nanoindentation have been instrumental in visualizing and quantifying the mechanical behavior of sodium metal during cycling.

The technological goals for sodium metal anodes include achieving stable cycling performance with high Coulombic efficiency (>99%), preventing dendrite formation, minimizing volume expansion, and enhancing mechanical durability. Additionally, there is a focus on developing compatible electrolytes and interfaces that can stabilize the sodium metal surface and prevent side reactions.

Looking forward, the field is moving toward the integration of artificial intelligence and machine learning to predict mechanical failure modes and optimize anode designs. The ultimate aim is to enable sodium metal batteries that can rival or exceed the performance of lithium-ion batteries while offering advantages in cost, sustainability, and safety.

The technological trajectory of sodium metal anodes has been characterized by significant challenges related to their mechanical properties. Unlike lithium, sodium metal is inherently softer (Mohs hardness of 0.5 compared to lithium's 0.6) and more reactive, making it prone to mechanical deformation and fracture during battery cycling. These mechanical failures contribute to capacity fading, reduced cycle life, and potential safety hazards.

Recent advancements in materials science and electrochemistry have enabled researchers to better understand the mechanical behavior of sodium metal during electrochemical cycling. The correlation between mechanical properties and electrochemical performance has become a focal point in sodium battery research, with particular emphasis on understanding deformation mechanisms, crack propagation, and fracture patterns.

The primary technological objective in this field is to develop sodium metal anodes with enhanced mechanical stability that can withstand the volume changes during cycling while maintaining structural integrity. This involves understanding the fundamental mechanisms of mechanical failure in sodium metal anodes and developing strategies to mitigate these issues.

Current research trends indicate a growing interest in multidisciplinary approaches that combine electrochemistry, materials science, and mechanical engineering to address the challenges of sodium metal anodes. Advanced characterization techniques such as in-situ transmission electron microscopy, atomic force microscopy, and nanoindentation have been instrumental in visualizing and quantifying the mechanical behavior of sodium metal during cycling.

The technological goals for sodium metal anodes include achieving stable cycling performance with high Coulombic efficiency (>99%), preventing dendrite formation, minimizing volume expansion, and enhancing mechanical durability. Additionally, there is a focus on developing compatible electrolytes and interfaces that can stabilize the sodium metal surface and prevent side reactions.

Looking forward, the field is moving toward the integration of artificial intelligence and machine learning to predict mechanical failure modes and optimize anode designs. The ultimate aim is to enable sodium metal batteries that can rival or exceed the performance of lithium-ion batteries while offering advantages in cost, sustainability, and safety.

Market Analysis for Sodium-based Battery Systems

The sodium-based battery market is experiencing significant growth as an alternative to lithium-ion technologies, driven by increasing concerns about lithium supply constraints and cost volatility. Current market projections indicate that the global sodium-ion battery market could reach $500 million by 2025, with a compound annual growth rate exceeding 20% over the next decade. This growth trajectory is supported by substantial investments from both established battery manufacturers and emerging startups focused specifically on sodium battery technology.

The demand for sodium-based battery systems is particularly strong in stationary energy storage applications, where energy density requirements are less stringent than in electric vehicles. Grid-scale energy storage represents approximately 45% of the potential market for sodium-based batteries, followed by backup power systems at 30% and consumer electronics at 15%. The remaining market share is distributed across specialized applications including medical devices and industrial equipment.

Regional analysis reveals that China is currently leading the sodium battery market development, with over 60% of patents related to sodium metal anodes filed by Chinese entities in the past five years. European markets show increasing interest, particularly in countries with strong renewable energy integration needs such as Germany and Denmark. North American adoption remains in early stages but is accelerating through strategic research partnerships between universities and industry players.

Market barriers for sodium-based battery systems primarily relate to performance limitations, particularly the mechanical stability issues in sodium metal anodes that lead to deformation and fracture during cycling. These technical challenges directly impact commercial viability by reducing cycle life and reliability metrics that are critical for market acceptance. Consumer perception of sodium batteries as an "inferior alternative" to lithium-ion technology also presents a marketing challenge that manufacturers must overcome.

Price sensitivity analysis indicates that sodium-based systems need to achieve a 30-40% cost advantage over lithium-ion alternatives to drive widespread adoption, particularly in price-sensitive markets. Current production costs remain approximately 15% higher than target levels due to manufacturing scale limitations and ongoing research and development expenses related to solving mechanical stability issues.

The competitive landscape features both established battery manufacturers diversifying their technology portfolios and specialized startups focused exclusively on sodium battery innovation. Key market players include CATL, Faradion (acquired by Reliance Industries), Natron Energy, and NGK Insulators, with several university spin-offs entering the commercialization phase with novel approaches to addressing the mechanical deformation challenges in sodium metal anodes.

The demand for sodium-based battery systems is particularly strong in stationary energy storage applications, where energy density requirements are less stringent than in electric vehicles. Grid-scale energy storage represents approximately 45% of the potential market for sodium-based batteries, followed by backup power systems at 30% and consumer electronics at 15%. The remaining market share is distributed across specialized applications including medical devices and industrial equipment.

Regional analysis reveals that China is currently leading the sodium battery market development, with over 60% of patents related to sodium metal anodes filed by Chinese entities in the past five years. European markets show increasing interest, particularly in countries with strong renewable energy integration needs such as Germany and Denmark. North American adoption remains in early stages but is accelerating through strategic research partnerships between universities and industry players.

Market barriers for sodium-based battery systems primarily relate to performance limitations, particularly the mechanical stability issues in sodium metal anodes that lead to deformation and fracture during cycling. These technical challenges directly impact commercial viability by reducing cycle life and reliability metrics that are critical for market acceptance. Consumer perception of sodium batteries as an "inferior alternative" to lithium-ion technology also presents a marketing challenge that manufacturers must overcome.

Price sensitivity analysis indicates that sodium-based systems need to achieve a 30-40% cost advantage over lithium-ion alternatives to drive widespread adoption, particularly in price-sensitive markets. Current production costs remain approximately 15% higher than target levels due to manufacturing scale limitations and ongoing research and development expenses related to solving mechanical stability issues.

The competitive landscape features both established battery manufacturers diversifying their technology portfolios and specialized startups focused exclusively on sodium battery innovation. Key market players include CATL, Faradion (acquired by Reliance Industries), Natron Energy, and NGK Insulators, with several university spin-offs entering the commercialization phase with novel approaches to addressing the mechanical deformation challenges in sodium metal anodes.

Current Challenges in Sodium Metal Anode Mechanics

Sodium metal anodes represent a promising alternative to lithium for next-generation batteries due to sodium's abundance and lower cost. However, significant mechanical challenges impede their practical implementation. The most critical issue is the substantial volume expansion during sodiation/desodiation cycles, which can exceed 500% - considerably larger than observed in lithium systems. This extreme volume change induces severe mechanical stresses that lead to electrode pulverization and rapid capacity fading.

The inherent softness of sodium metal (with a Mohs hardness of only 0.5 compared to lithium's 0.6) exacerbates these mechanical issues. During cycling, sodium undergoes plastic deformation more readily than lithium, resulting in uneven surface morphology development. This deformation creates localized stress concentrations that serve as nucleation sites for dendrite formation - needle-like structures that grow from the anode surface toward the cathode.

Dendrite growth represents another major mechanical challenge, as these structures can eventually penetrate the separator, causing internal short circuits and catastrophic battery failure. Unlike lithium dendrites, sodium dendrites exhibit different growth mechanisms and morphologies due to sodium's distinct mechanical properties and electrochemical behavior. The lower surface energy of sodium metal promotes faster and more aggressive dendrite propagation under similar conditions.

Interfacial stability presents additional complications, as sodium metal reacts vigorously with conventional electrolytes to form a solid electrolyte interphase (SEI) layer. This SEI layer is typically more brittle and less uniform than in lithium systems, making it susceptible to cracking during volume changes. The mechanical failure of this protective layer exposes fresh sodium surfaces, triggering continuous electrolyte decomposition and accelerated capacity loss.

Stress-induced creep behavior in sodium anodes further complicates their mechanical performance. Under constant stress, sodium metal exhibits significant time-dependent deformation even at room temperature, leading to continuous morphological evolution during battery storage and operation. This creep behavior contributes to unpredictable mechanical failure modes that are difficult to model and mitigate.

Temperature sensitivity adds another dimension to these challenges, as sodium's mechanical properties change dramatically with temperature fluctuations. Near its relatively low melting point (97.8°C), sodium becomes increasingly susceptible to accelerated creep and plastic flow, limiting the operating temperature range of sodium metal batteries and creating safety concerns for applications in variable thermal environments.

Addressing these mechanical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and electrochemistry to develop robust sodium anode architectures capable of accommodating the extreme mechanical stresses inherent to sodium-based battery systems.

The inherent softness of sodium metal (with a Mohs hardness of only 0.5 compared to lithium's 0.6) exacerbates these mechanical issues. During cycling, sodium undergoes plastic deformation more readily than lithium, resulting in uneven surface morphology development. This deformation creates localized stress concentrations that serve as nucleation sites for dendrite formation - needle-like structures that grow from the anode surface toward the cathode.

Dendrite growth represents another major mechanical challenge, as these structures can eventually penetrate the separator, causing internal short circuits and catastrophic battery failure. Unlike lithium dendrites, sodium dendrites exhibit different growth mechanisms and morphologies due to sodium's distinct mechanical properties and electrochemical behavior. The lower surface energy of sodium metal promotes faster and more aggressive dendrite propagation under similar conditions.

Interfacial stability presents additional complications, as sodium metal reacts vigorously with conventional electrolytes to form a solid electrolyte interphase (SEI) layer. This SEI layer is typically more brittle and less uniform than in lithium systems, making it susceptible to cracking during volume changes. The mechanical failure of this protective layer exposes fresh sodium surfaces, triggering continuous electrolyte decomposition and accelerated capacity loss.

Stress-induced creep behavior in sodium anodes further complicates their mechanical performance. Under constant stress, sodium metal exhibits significant time-dependent deformation even at room temperature, leading to continuous morphological evolution during battery storage and operation. This creep behavior contributes to unpredictable mechanical failure modes that are difficult to model and mitigate.

Temperature sensitivity adds another dimension to these challenges, as sodium's mechanical properties change dramatically with temperature fluctuations. Near its relatively low melting point (97.8°C), sodium becomes increasingly susceptible to accelerated creep and plastic flow, limiting the operating temperature range of sodium metal batteries and creating safety concerns for applications in variable thermal environments.

Addressing these mechanical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and electrochemistry to develop robust sodium anode architectures capable of accommodating the extreme mechanical stresses inherent to sodium-based battery systems.

Current Approaches to Mitigate Mechanical Deformation

01 Protective coatings for sodium metal anodes

Various protective coatings can be applied to sodium metal anodes to prevent mechanical deformation and fracture during cycling. These coatings act as barriers against electrolyte corrosion while maintaining sodium ion conductivity. Materials such as polymers, ceramics, and composite layers can effectively mitigate volume changes during charge-discharge cycles, thereby enhancing the structural integrity and preventing dendrite formation that leads to mechanical failure.- Protective coatings for sodium metal anodes: Various protective coatings can be applied to sodium metal anodes to prevent mechanical deformation and fracture during cycling. These coatings act as barriers against electrolyte corrosion while maintaining sodium ion conductivity. The protective layers can include artificial solid electrolyte interphase films, polymer coatings, or inorganic materials that accommodate volume changes during charging and discharging, thereby reducing stress-induced fractures and extending anode lifespan.

- Structural design modifications for sodium anodes: Innovative structural designs can mitigate mechanical failures in sodium metal anodes. These include 3D architectures, porous structures, and composite frameworks that provide void spaces to accommodate volume expansion during sodium plating/stripping. Such designs distribute mechanical stress more evenly throughout the anode structure, preventing localized deformation that leads to fracture and dendrite formation, ultimately improving the mechanical stability and electrochemical performance.

- Electrolyte formulations to improve anode stability: Specialized electrolyte formulations can significantly reduce mechanical deformation and fracture of sodium metal anodes. Additives that form stable interfaces on the sodium surface help prevent uneven sodium deposition and dendrite growth. Solvents and salt combinations that promote uniform ion transport and deposition behavior contribute to more homogeneous mechanical stress distribution across the anode surface, reducing localized strain that leads to fracturing.

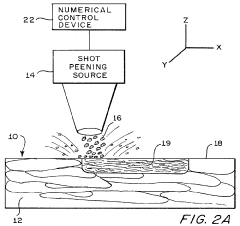

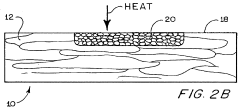

- Manufacturing processes for improved mechanical integrity: Advanced manufacturing techniques can enhance the mechanical properties of sodium metal anodes. Methods such as controlled deposition, rolling processes with specific pressure and temperature parameters, and specialized heat treatments can create sodium anodes with preferred crystallographic orientations and grain structures. These manufacturing approaches result in anodes with greater resistance to deformation and fracture during electrochemical cycling.

- Analytical methods for studying sodium anode failure mechanisms: Various analytical techniques are employed to understand the mechanical deformation and fracture mechanisms of sodium metal anodes. In-situ characterization methods, including microscopy, spectroscopy, and mechanical testing, provide insights into how sodium anodes fail under operational conditions. Computational modeling and simulation approaches help predict stress distribution, crack propagation, and failure points, enabling the design of more mechanically robust sodium anode systems.

02 Structural design modifications for sodium anodes

Innovative structural designs can significantly improve the mechanical stability of sodium metal anodes. These designs include 3D architectures, porous frameworks, and specially engineered current collectors that accommodate volume expansion during cycling. By providing mechanical support and controlled spaces for sodium deposition, these structures help distribute stress more evenly, reducing localized deformation and preventing catastrophic fracture of the anode material.Expand Specific Solutions03 Electrolyte formulations to enhance sodium anode stability

Specialized electrolyte formulations can significantly impact the mechanical properties of sodium metal anodes. Additives that form stable solid electrolyte interphases (SEI) help prevent continuous electrolyte decomposition and maintain anode surface integrity. Certain solvents and salt combinations promote uniform sodium deposition, reducing stress concentration points that lead to fracture. These formulations effectively control the interface reactions that contribute to mechanical degradation.Expand Specific Solutions04 Temperature and pressure control systems

Operating conditions significantly affect the mechanical behavior of sodium metal anodes. Advanced temperature and pressure control systems can be implemented to maintain optimal conditions that minimize mechanical stress. By regulating these parameters during battery operation, thermal expansion differences can be reduced, and more uniform sodium deposition can be achieved. These control systems help prevent the formation of stress points that lead to cracking and deformation.Expand Specific Solutions05 Manufacturing processes for improved mechanical properties

Specialized manufacturing techniques can enhance the mechanical properties of sodium metal anodes. Methods such as controlled deposition, rolling processes with specific parameters, and heat treatment protocols can create sodium anodes with improved grain structure and reduced internal stress. These manufacturing approaches result in anodes with greater resistance to deformation and fracture during electrochemical cycling, extending battery life and improving safety.Expand Specific Solutions

Key Industry Players in Sodium Battery Development

The sodium metal anode market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size for sodium-based battery technologies is projected to expand rapidly as demand for alternatives to lithium-ion batteries increases. Technologically, mechanical deformation and fracture analysis in sodium metal anodes remains at the developmental stage, with academic institutions leading fundamental research while companies pursue practical applications. Contemporary Amperex Technology Co. (CATL) is advancing commercial sodium-ion battery systems, while Bloom Energy explores sodium-based energy storage solutions. Research collaborations between universities (Xiamen University, Louisiana State University) and industry partners are accelerating progress toward addressing key challenges of sodium metal's mechanical instability, with potential breakthroughs expected as materials science innovations continue to emerge.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive mechanical deformation and fracture analysis framework specifically for sodium metal anodes in sodium-ion batteries. Their approach combines in-situ optical microscopy, electron microscopy, and mechanical testing to understand the unique deformation mechanisms of sodium metal during cycling. CATL's research has revealed that sodium metal experiences significant creep behavior at room temperature due to its low melting point (97.8°C), which leads to continuous deformation under stress. Their proprietary "Gradient Structure Design" technology creates engineered interfaces that accommodate volume changes and mechanical stress during sodium plating/stripping cycles. This design incorporates elastomeric interlayers with gradient mechanical properties that effectively distribute stress and prevent crack propagation. CATL has also implemented computational modeling using finite element analysis to predict fracture patterns and optimize anode structures before physical prototyping.

Strengths: Industry-leading manufacturing scale allows for rapid implementation of research findings into commercial products. Their gradient structure design effectively mitigates mechanical failure modes specific to sodium metal. Weaknesses: The approach requires complex manufacturing processes that may increase production costs compared to conventional lithium-ion batteries. The long-term stability of their engineered interfaces under extreme temperature conditions remains challenging.

INNOLITH TECHNOLOGY AG

Technical Solution: Innolith has pioneered an innovative approach to sodium metal anode mechanical stability through their "Controlled Deformation Framework" technology. Their solution addresses the fundamental challenge of sodium's high ductility and low mechanical strength by implementing a multi-scale reinforcement strategy. At the microscale, they've developed a proprietary ceramic-polymer composite scaffold that provides structural support while maintaining ionic conductivity. This scaffold features engineered porosity that accommodates sodium's volumetric changes during cycling while preventing uncontrolled deformation. Innolith's approach incorporates real-time stress monitoring using embedded piezoelectric sensors that detect early signs of mechanical failure. Their fracture analysis methodology combines acoustic emission detection with post-mortem metallographic examination to identify failure modes. Additionally, they've developed specialized electrolyte additives that form mechanically robust solid electrolyte interphase (SEI) layers that resist fracture propagation during cycling.

Strengths: Their multi-scale reinforcement strategy effectively addresses sodium's inherent mechanical limitations while maintaining electrochemical performance. The real-time monitoring system provides valuable data for predictive maintenance. Weaknesses: The complex composite scaffold increases manufacturing complexity and potentially raises production costs. The technology is relatively new and lacks extensive long-term cycling validation in commercial-scale cells.

Critical Fracture Mechanics Patents and Literature

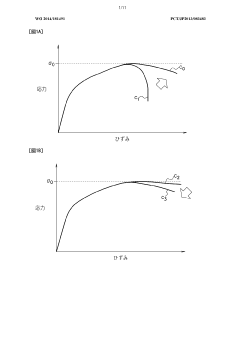

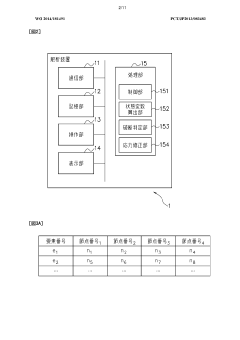

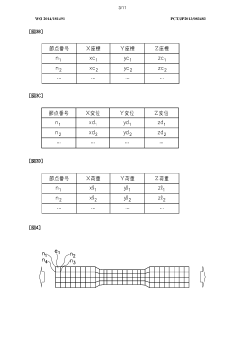

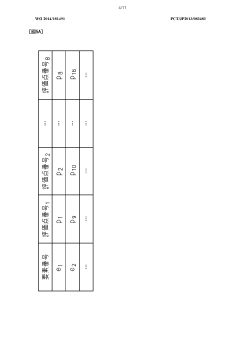

Deformation analysis device, deformation analysis method, and program

PatentWO2014181491A1

Innovation

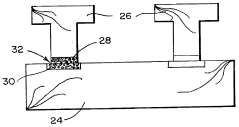

- A deformation analysis device and method that calculates stress considering stiffness reduction, using continuum damage mechanics to gradually reduce the rigidity of fractured elements rather than erasing them, allowing for more accurate simulation of material behavior post-fracture.

Method for diffusion bonding of metals and alloys using mechanical deformation

PatentInactiveUS4969593A

Innovation

- A two-phase method involving cold working mechanical deformation followed by heat treatment to produce a fine-grained microstructure on the surface of alloy materials, allowing for enhanced diffusion bonding by disrupting surface oxides and improving contact between mating pieces, applicable to materials of any shape or size.

Safety Standards and Testing Protocols for Sodium Batteries

The development of safety standards and testing protocols for sodium batteries represents a critical aspect of their commercialization pathway. Current safety evaluation frameworks, largely derived from lithium-ion battery systems, require significant adaptation to address the unique properties of sodium metal anodes, particularly their mechanical deformation and fracture behaviors.

International organizations including IEC, UL, and ISO have begun establishing preliminary safety guidelines for sodium-based energy storage systems, though these remain in early development stages compared to their lithium counterparts. The mechanical integrity testing protocols specifically designed for sodium metal anodes are notably underdeveloped, creating a regulatory gap that impedes industry advancement.

Mechanical safety testing for sodium batteries must account for their distinctive characteristics, including sodium's lower melting point (97.8°C versus lithium's 180.5°C), higher reactivity with moisture, and different mechanical properties. Current protocols typically include crush tests, penetration tests, and vibration resistance evaluations, but these require modification to address sodium's unique deformation mechanisms and failure modes.

Thermal runaway testing represents another critical safety protocol area requiring sodium-specific adaptations. The different thermal expansion coefficients and phase change behaviors of sodium metal necessitate revised temperature thresholds and safety margins in testing procedures. Accelerated aging tests must also be recalibrated to account for sodium's distinctive creep behavior and mechanical degradation pathways.

Electrochemical stability testing protocols need enhancement to monitor the unique interface dynamics between sodium metal anodes and electrolytes, particularly focusing on dendrite formation patterns and mechanical stress distribution during cycling. The correlation between mechanical deformation and electrochemical performance requires specialized in-situ monitoring techniques not currently standardized.

Several research institutions, including Argonne National Laboratory and the Battery Safety Testing Centers in Germany and Japan, are developing sodium-specific testing methodologies. These emerging protocols incorporate advanced imaging techniques like in-situ X-ray tomography to visualize mechanical deformation in real-time, providing crucial data for safety standard development.

Industry stakeholders have identified the need for harmonized global standards to accelerate sodium battery commercialization. The development of these standards requires collaborative efforts between academic researchers focusing on fundamental mechanical behaviors, regulatory bodies establishing safety thresholds, and industry partners validating practical implementation approaches.

International organizations including IEC, UL, and ISO have begun establishing preliminary safety guidelines for sodium-based energy storage systems, though these remain in early development stages compared to their lithium counterparts. The mechanical integrity testing protocols specifically designed for sodium metal anodes are notably underdeveloped, creating a regulatory gap that impedes industry advancement.

Mechanical safety testing for sodium batteries must account for their distinctive characteristics, including sodium's lower melting point (97.8°C versus lithium's 180.5°C), higher reactivity with moisture, and different mechanical properties. Current protocols typically include crush tests, penetration tests, and vibration resistance evaluations, but these require modification to address sodium's unique deformation mechanisms and failure modes.

Thermal runaway testing represents another critical safety protocol area requiring sodium-specific adaptations. The different thermal expansion coefficients and phase change behaviors of sodium metal necessitate revised temperature thresholds and safety margins in testing procedures. Accelerated aging tests must also be recalibrated to account for sodium's distinctive creep behavior and mechanical degradation pathways.

Electrochemical stability testing protocols need enhancement to monitor the unique interface dynamics between sodium metal anodes and electrolytes, particularly focusing on dendrite formation patterns and mechanical stress distribution during cycling. The correlation between mechanical deformation and electrochemical performance requires specialized in-situ monitoring techniques not currently standardized.

Several research institutions, including Argonne National Laboratory and the Battery Safety Testing Centers in Germany and Japan, are developing sodium-specific testing methodologies. These emerging protocols incorporate advanced imaging techniques like in-situ X-ray tomography to visualize mechanical deformation in real-time, providing crucial data for safety standard development.

Industry stakeholders have identified the need for harmonized global standards to accelerate sodium battery commercialization. The development of these standards requires collaborative efforts between academic researchers focusing on fundamental mechanical behaviors, regulatory bodies establishing safety thresholds, and industry partners validating practical implementation approaches.

Environmental Impact and Sustainability Assessment

The environmental impact of sodium metal anodes extends beyond their performance characteristics, encompassing the entire lifecycle from raw material extraction to disposal. Sodium's abundance in the Earth's crust (approximately 2.8%, making it the sixth most abundant element) presents a significant sustainability advantage over lithium, which occurs at merely 0.002%. This abundance translates to lower environmental degradation from mining activities and reduced geopolitical tensions associated with resource scarcity.

The extraction processes for sodium compounds require substantially less water compared to lithium extraction, which is particularly significant in water-stressed regions. Conventional lithium extraction can consume up to 500,000 gallons of water per ton of lithium, while sodium extraction methods typically use 50-70% less water. Additionally, sodium processing generates fewer toxic byproducts, reducing the environmental remediation costs associated with production facilities.

When considering the mechanical deformation and fracture challenges in sodium metal anodes, environmental implications become apparent. The dendrite formation and subsequent fracturing that occurs during cycling necessitates more frequent battery replacement, potentially increasing electronic waste. However, innovations in mechanical stabilization techniques that extend sodium anode lifespans could significantly reduce this environmental burden.

Carbon footprint analyses reveal that sodium-based battery production emits approximately 20-30% less CO2 equivalent compared to lithium-ion counterparts, primarily due to reduced energy requirements during material processing and lower transportation emissions from more distributed supply chains. This advantage becomes particularly relevant when scaling to grid-level storage applications.

Recycling considerations present both challenges and opportunities. The reactive nature of sodium metal complicates end-of-life handling, but recent advances in controlled deactivation processes have improved recycling feasibility. Current recovery rates for sodium from spent batteries reach 60-70%, compared to 50-60% for lithium, suggesting a potential sustainability advantage as recycling technologies mature.

From a regulatory perspective, sodium-based energy storage technologies face fewer restrictions under frameworks like the EU's Battery Directive and the U.S. Critical Materials Strategy, potentially accelerating their market adoption. This regulatory advantage, combined with sodium's inherent abundance, positions mechanical innovations in sodium anodes as environmentally strategic research directions that align with global sustainability goals and circular economy principles.

The extraction processes for sodium compounds require substantially less water compared to lithium extraction, which is particularly significant in water-stressed regions. Conventional lithium extraction can consume up to 500,000 gallons of water per ton of lithium, while sodium extraction methods typically use 50-70% less water. Additionally, sodium processing generates fewer toxic byproducts, reducing the environmental remediation costs associated with production facilities.

When considering the mechanical deformation and fracture challenges in sodium metal anodes, environmental implications become apparent. The dendrite formation and subsequent fracturing that occurs during cycling necessitates more frequent battery replacement, potentially increasing electronic waste. However, innovations in mechanical stabilization techniques that extend sodium anode lifespans could significantly reduce this environmental burden.

Carbon footprint analyses reveal that sodium-based battery production emits approximately 20-30% less CO2 equivalent compared to lithium-ion counterparts, primarily due to reduced energy requirements during material processing and lower transportation emissions from more distributed supply chains. This advantage becomes particularly relevant when scaling to grid-level storage applications.

Recycling considerations present both challenges and opportunities. The reactive nature of sodium metal complicates end-of-life handling, but recent advances in controlled deactivation processes have improved recycling feasibility. Current recovery rates for sodium from spent batteries reach 60-70%, compared to 50-60% for lithium, suggesting a potential sustainability advantage as recycling technologies mature.

From a regulatory perspective, sodium-based energy storage technologies face fewer restrictions under frameworks like the EU's Battery Directive and the U.S. Critical Materials Strategy, potentially accelerating their market adoption. This regulatory advantage, combined with sodium's inherent abundance, positions mechanical innovations in sodium anodes as environmentally strategic research directions that align with global sustainability goals and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!