Thermal Runaway Prevention in Sodium Metal Batteries

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Battery Thermal Runaway Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of sodium metal batteries (SMBs) dates back to the 1970s, but significant research momentum has only been gained in the past decade. This renewed interest stems from the increasing demand for sustainable energy storage solutions and concerns about lithium supply chain vulnerabilities.

Thermal runaway, a catastrophic failure mechanism in batteries, represents one of the most critical safety challenges for sodium metal batteries. This phenomenon occurs when exothermic reactions within the battery trigger a self-accelerating temperature increase, potentially leading to fire or explosion. In sodium metal batteries, thermal runaway presents unique challenges due to sodium's high reactivity with electrolytes and lower melting point (97.8°C) compared to lithium (180.5°C).

The evolution of thermal runaway prevention technologies in sodium batteries has progressed through several stages. Early research focused on solid electrolytes as physical barriers, followed by flame-retardant electrolyte additives. Recent advancements include smart battery management systems and novel cell designs incorporating thermal fuses and phase-change materials for heat dissipation.

Current technological trends indicate a shift toward multi-layered safety approaches that combine materials innovation with advanced monitoring systems. The integration of artificial intelligence for predictive thermal management represents the cutting edge of this field, allowing for early detection of potential thermal events before they escalate.

The primary objectives of thermal runaway prevention research in sodium metal batteries include developing electrolytes with wider electrochemical stability windows, designing safer anode-electrolyte interfaces, creating advanced thermal management systems, and establishing comprehensive safety standards specific to sodium battery chemistry.

Industry projections suggest that solving thermal runaway challenges could accelerate sodium battery commercialization, potentially reducing energy storage costs by 30-40% compared to current lithium-ion technologies. This would significantly impact grid storage applications and electric vehicle markets, particularly in regions with limited lithium resources.

Academic and industrial research aims to achieve sodium metal batteries with thermal stability up to 150°C without performance degradation, representing a substantial improvement over current systems that typically become unstable above 80°C. Meeting these objectives would position sodium metal batteries as a viable, safe alternative for large-scale energy storage applications where cost and safety are paramount considerations.

Thermal runaway, a catastrophic failure mechanism in batteries, represents one of the most critical safety challenges for sodium metal batteries. This phenomenon occurs when exothermic reactions within the battery trigger a self-accelerating temperature increase, potentially leading to fire or explosion. In sodium metal batteries, thermal runaway presents unique challenges due to sodium's high reactivity with electrolytes and lower melting point (97.8°C) compared to lithium (180.5°C).

The evolution of thermal runaway prevention technologies in sodium batteries has progressed through several stages. Early research focused on solid electrolytes as physical barriers, followed by flame-retardant electrolyte additives. Recent advancements include smart battery management systems and novel cell designs incorporating thermal fuses and phase-change materials for heat dissipation.

Current technological trends indicate a shift toward multi-layered safety approaches that combine materials innovation with advanced monitoring systems. The integration of artificial intelligence for predictive thermal management represents the cutting edge of this field, allowing for early detection of potential thermal events before they escalate.

The primary objectives of thermal runaway prevention research in sodium metal batteries include developing electrolytes with wider electrochemical stability windows, designing safer anode-electrolyte interfaces, creating advanced thermal management systems, and establishing comprehensive safety standards specific to sodium battery chemistry.

Industry projections suggest that solving thermal runaway challenges could accelerate sodium battery commercialization, potentially reducing energy storage costs by 30-40% compared to current lithium-ion technologies. This would significantly impact grid storage applications and electric vehicle markets, particularly in regions with limited lithium resources.

Academic and industrial research aims to achieve sodium metal batteries with thermal stability up to 150°C without performance degradation, representing a substantial improvement over current systems that typically become unstable above 80°C. Meeting these objectives would position sodium metal batteries as a viable, safe alternative for large-scale energy storage applications where cost and safety are paramount considerations.

Market Analysis for Safe Sodium Metal Battery Technologies

The global market for sodium metal batteries is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the sodium battery sector is expanding at a compound annual growth rate of approximately 5-7%, with projections suggesting a market size reaching several billion dollars by 2030. This growth trajectory is primarily fueled by the inherent advantages of sodium-based technologies, including abundant raw material availability and lower production costs compared to lithium-ion alternatives.

Safety concerns, particularly thermal runaway prevention, represent a critical market driver. Industry surveys reveal that energy storage system purchasers consistently rank safety as a top-three consideration in procurement decisions. This prioritization has created a distinct market segment specifically for enhanced safety technologies in sodium metal batteries, estimated to comprise about 15-20% of the total sodium battery market value.

Regional market analysis shows varying adoption patterns. European markets demonstrate the strongest demand for safety-enhanced sodium battery technologies, influenced by stringent regulatory frameworks and heightened consumer awareness. The Asia-Pacific region, particularly China and South Korea, leads in manufacturing capacity but shows growing interest in premium safety features as urban energy storage applications increase.

Application-specific market segments reveal divergent requirements. Grid-scale energy storage applications prioritize long-term safety reliability and cost-effectiveness, creating demand for passive thermal management systems. In contrast, the emerging electric mobility sector emphasizes rapid-response safety mechanisms and compact thermal management solutions that don't compromise energy density.

Consumer electronics represents a smaller but growing market segment for sodium metal batteries with enhanced thermal safety features. This segment values miniaturized safety systems that maintain the form factor advantages of sodium technology while addressing consumer safety concerns.

Market competition analysis indicates that established battery manufacturers are increasingly investing in sodium battery safety research, with several major players filing patents specifically addressing thermal runaway prevention. Simultaneously, specialized startups focused exclusively on battery safety technologies are gaining traction, attracting significant venture capital investment.

The pricing premium for enhanced safety features in sodium batteries currently ranges between 10-25% above standard configurations, though this premium is expected to decrease as manufacturing scales and technologies mature. Market research indicates consumers and industrial buyers demonstrate willingness to pay this premium, particularly for critical applications where failure risks are unacceptable.

Safety concerns, particularly thermal runaway prevention, represent a critical market driver. Industry surveys reveal that energy storage system purchasers consistently rank safety as a top-three consideration in procurement decisions. This prioritization has created a distinct market segment specifically for enhanced safety technologies in sodium metal batteries, estimated to comprise about 15-20% of the total sodium battery market value.

Regional market analysis shows varying adoption patterns. European markets demonstrate the strongest demand for safety-enhanced sodium battery technologies, influenced by stringent regulatory frameworks and heightened consumer awareness. The Asia-Pacific region, particularly China and South Korea, leads in manufacturing capacity but shows growing interest in premium safety features as urban energy storage applications increase.

Application-specific market segments reveal divergent requirements. Grid-scale energy storage applications prioritize long-term safety reliability and cost-effectiveness, creating demand for passive thermal management systems. In contrast, the emerging electric mobility sector emphasizes rapid-response safety mechanisms and compact thermal management solutions that don't compromise energy density.

Consumer electronics represents a smaller but growing market segment for sodium metal batteries with enhanced thermal safety features. This segment values miniaturized safety systems that maintain the form factor advantages of sodium technology while addressing consumer safety concerns.

Market competition analysis indicates that established battery manufacturers are increasingly investing in sodium battery safety research, with several major players filing patents specifically addressing thermal runaway prevention. Simultaneously, specialized startups focused exclusively on battery safety technologies are gaining traction, attracting significant venture capital investment.

The pricing premium for enhanced safety features in sodium batteries currently ranges between 10-25% above standard configurations, though this premium is expected to decrease as manufacturing scales and technologies mature. Market research indicates consumers and industrial buyers demonstrate willingness to pay this premium, particularly for critical applications where failure risks are unacceptable.

Current Challenges in Sodium Battery Thermal Stability

Sodium metal batteries (SMBs) face significant thermal stability challenges that impede their widespread commercial adoption. The primary concern is the high reactivity of sodium metal with electrolytes, which can trigger thermal runaway events under various conditions. Unlike their lithium counterparts, sodium batteries exhibit unique thermal behavior due to sodium's lower melting point (97.8°C compared to lithium's 180.5°C), creating additional safety concerns during operation.

The formation of dendrites represents one of the most critical challenges in sodium battery thermal stability. These needle-like structures grow during charging cycles and can penetrate the separator, causing internal short circuits that rapidly generate heat. This localized heating can initiate a cascade of exothermic reactions, potentially leading to catastrophic thermal runaway events. Research indicates that sodium dendrites form more rapidly and with different morphologies than lithium dendrites, complicating mitigation strategies.

Electrolyte decomposition presents another significant thermal stability challenge. Conventional organic electrolytes used in sodium batteries have narrow electrochemical stability windows and begin decomposing at elevated temperatures, releasing flammable gases and generating additional heat. This decomposition accelerates as temperature increases, creating a dangerous positive feedback loop. Recent studies have shown that the solid electrolyte interphase (SEI) formed in sodium systems is generally less stable than in lithium batteries, providing inadequate protection against continuous electrolyte decomposition.

The thermal conductivity limitations of battery components further exacerbate stability issues. Poor heat dissipation within the cell structure allows hotspots to develop, particularly in larger format cells intended for grid storage applications. These thermal gradients can lead to uneven sodium plating/stripping and accelerated degradation in specific regions of the battery, creating localized failure points that may trigger broader thermal events.

Environmental factors also significantly impact sodium battery thermal stability. Exposure to high ambient temperatures can accelerate side reactions and reduce the effectiveness of thermal management systems. Additionally, mechanical stresses from thermal expansion and contraction during cycling can compromise cell integrity, potentially exposing reactive sodium metal to air or moisture if seals fail.

Current battery management systems (BMS) struggle to accurately predict and prevent thermal events in sodium batteries due to the complex and sometimes unpredictable nature of sodium's thermal behavior. The traditional thermal models developed for lithium-ion systems require substantial modification to account for sodium's unique properties, including its lower melting point and different reaction kinetics with common battery materials.

The formation of dendrites represents one of the most critical challenges in sodium battery thermal stability. These needle-like structures grow during charging cycles and can penetrate the separator, causing internal short circuits that rapidly generate heat. This localized heating can initiate a cascade of exothermic reactions, potentially leading to catastrophic thermal runaway events. Research indicates that sodium dendrites form more rapidly and with different morphologies than lithium dendrites, complicating mitigation strategies.

Electrolyte decomposition presents another significant thermal stability challenge. Conventional organic electrolytes used in sodium batteries have narrow electrochemical stability windows and begin decomposing at elevated temperatures, releasing flammable gases and generating additional heat. This decomposition accelerates as temperature increases, creating a dangerous positive feedback loop. Recent studies have shown that the solid electrolyte interphase (SEI) formed in sodium systems is generally less stable than in lithium batteries, providing inadequate protection against continuous electrolyte decomposition.

The thermal conductivity limitations of battery components further exacerbate stability issues. Poor heat dissipation within the cell structure allows hotspots to develop, particularly in larger format cells intended for grid storage applications. These thermal gradients can lead to uneven sodium plating/stripping and accelerated degradation in specific regions of the battery, creating localized failure points that may trigger broader thermal events.

Environmental factors also significantly impact sodium battery thermal stability. Exposure to high ambient temperatures can accelerate side reactions and reduce the effectiveness of thermal management systems. Additionally, mechanical stresses from thermal expansion and contraction during cycling can compromise cell integrity, potentially exposing reactive sodium metal to air or moisture if seals fail.

Current battery management systems (BMS) struggle to accurately predict and prevent thermal events in sodium batteries due to the complex and sometimes unpredictable nature of sodium's thermal behavior. The traditional thermal models developed for lithium-ion systems require substantial modification to account for sodium's unique properties, including its lower melting point and different reaction kinetics with common battery materials.

Existing Thermal Runaway Mitigation Strategies

01 Thermal management systems for sodium metal batteries

Various thermal management systems are designed to prevent thermal runaway in sodium metal batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that can detect and respond to abnormal temperature increases. Advanced thermal management systems incorporate phase change materials and specialized cooling channels to efficiently remove excess heat from battery cells, maintaining optimal operating temperatures and preventing the cascade of exothermic reactions that lead to thermal runaway.- Thermal management systems for sodium metal batteries: Various thermal management systems have been developed to prevent thermal runaway in sodium metal batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that can detect and respond to temperature increases. Advanced thermal management systems incorporate phase change materials and specialized cooling channels to efficiently remove heat from battery cells during operation, thereby reducing the risk of thermal runaway events.

- Electrolyte additives and modifications for thermal stability: Specialized electrolyte formulations can significantly improve the thermal stability of sodium metal batteries. These formulations include flame-retardant additives, ionic liquids, and solid-state electrolytes that are less prone to thermal decomposition. Modified electrolytes can form stable interfaces with the sodium metal anode, preventing dendrite formation and subsequent short circuits that often lead to thermal runaway. These electrolyte systems maintain their integrity at elevated temperatures, providing an additional safety barrier.

- Protective coatings and separator technologies: Advanced separator technologies and protective coatings play a crucial role in preventing thermal runaway in sodium metal batteries. These include ceramic-reinforced separators, polymer-based protective layers, and composite membranes that maintain structural integrity at high temperatures. Some designs incorporate self-healing materials that can repair minor damage and prevent the propagation of thermal events. These technologies create physical barriers between battery components, reducing the risk of internal short circuits.

- Battery management systems and safety mechanisms: Sophisticated battery management systems (BMS) have been developed to monitor and control sodium metal batteries to prevent thermal runaway. These systems incorporate real-time temperature monitoring, voltage regulation, and current limiting features. Some designs include pressure relief mechanisms, thermal fuses, and emergency shutdown protocols that activate when abnormal conditions are detected. Advanced BMS can predict potential thermal events based on battery performance data and take preventive actions before critical conditions are reached.

- Novel electrode designs and materials: Innovative electrode designs and materials have been developed to enhance the thermal stability of sodium metal batteries. These include structured sodium metal anodes, composite cathode materials with improved thermal conductivity, and current collectors designed to dissipate heat efficiently. Some approaches involve the use of sodium alloys instead of pure sodium metal to reduce reactivity. Advanced manufacturing techniques create electrodes with optimized porosity and surface structures that minimize localized heating during battery operation.

02 Electrolyte additives and formulations for thermal stability

Specialized electrolyte formulations can significantly improve the thermal stability of sodium metal batteries. These formulations include flame-retardant additives, thermal stabilizers, and compounds that form protective interfaces between the sodium metal and electrolyte. By modifying the electrolyte composition, researchers have developed systems that suppress dendrite formation, reduce reactivity with sodium metal, and increase the temperature threshold at which thermal decomposition occurs, thereby enhancing safety against thermal runaway events.Expand Specific Solutions03 Protective separator and electrode designs

Advanced separator and electrode designs play a crucial role in preventing thermal runaway in sodium metal batteries. These include multi-layer separators with thermal shutdown properties, ceramic-reinforced membranes that maintain structural integrity at high temperatures, and electrode architectures that minimize sodium dendrite formation. Some designs incorporate heat-resistant materials that create physical barriers to prevent internal short circuits, while others feature self-healing components that can repair minor damage before it escalates to catastrophic failure.Expand Specific Solutions04 Battery management systems for early detection and prevention

Sophisticated battery management systems (BMS) are developed specifically for sodium metal batteries to monitor and prevent thermal runaway conditions. These systems employ advanced algorithms to analyze battery parameters in real-time, detecting early warning signs of potential thermal events. The BMS can implement protective measures such as current limitation, load disconnection, or emergency cooling activation when abnormal conditions are detected. Some systems also incorporate artificial intelligence to learn from operational data and improve predictive capabilities for identifying potential safety risks.Expand Specific Solutions05 Cell and pack-level safety mechanisms

Various safety mechanisms are integrated at both cell and pack levels to mitigate thermal runaway risks in sodium metal batteries. These include pressure relief valves that vent gases before dangerous pressures build up, thermal fuses that disconnect electrical pathways at critical temperatures, and intumescent materials that expand to isolate overheating cells. Pack-level designs feature physical barriers between cells to prevent propagation of thermal events, and some incorporate fire-suppression systems that automatically activate when thermal runaway is detected, containing the damage to affected cells.Expand Specific Solutions

Key Industry Players in Sodium Battery Safety Solutions

The thermal runaway prevention in sodium metal batteries market is in an early growth stage, characterized by increasing R&D investments but limited commercial deployment. The global market is projected to expand significantly as sodium batteries emerge as a cost-effective alternative to lithium-ion technology, with an estimated CAGR of 12-15% through 2030. Leading players demonstrate varying levels of technological maturity: CATL and LG Energy Solution are advancing commercial solutions, while Tesla and IBM focus on innovative safety mechanisms. Aspen Aerogels has developed specialized thermal barrier materials, and ProLogium is pioneering solid-state electrolyte solutions. Academic-industry collaborations, particularly involving Nanjing Tech University, are accelerating thermal management breakthroughs, indicating a dynamic competitive landscape with significant growth potential.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a multi-layered thermal management system specifically for sodium metal batteries that combines physical barriers and chemical suppressants. Their approach includes a proprietary thermal interface material with high thermal conductivity (>5 W/m·K) that efficiently dissipates heat from hotspots. The system incorporates flame-retardant separators infused with ceramic particles that maintain structural integrity up to 300°C. CATL's solution also features a phase-change material layer that absorbs excess heat during temperature spikes, effectively delaying thermal propagation by up to 15 minutes compared to conventional systems. Their battery management system employs predictive algorithms that can detect early signs of thermal anomalies and trigger preventive measures before runaway conditions develop.

Strengths: Industry-leading thermal conductivity materials and comprehensive multi-layer protection approach. Integration with advanced BMS provides early detection capabilities. Weaknesses: The multi-layered system adds weight and volume to battery packs, potentially reducing energy density. Higher manufacturing complexity increases production costs.

Prologium Technology Co. Ltd.

Technical Solution: ProLogium has pioneered solid-state electrolyte technology for sodium metal batteries that fundamentally addresses thermal runaway risks. Their ceramic-based solid electrolyte eliminates the flammable liquid components typically responsible for thermal events. The proprietary solid electrolyte maintains stability at temperatures exceeding 300°C and prevents dendrite formation that often triggers short circuits in conventional batteries. ProLogium's design incorporates a bipolar stacking architecture that reduces internal resistance by approximately 60%, minimizing heat generation during operation. Their batteries feature a self-regulating thermal fuse mechanism that physically disconnects cells when temperature thresholds are exceeded, preventing cascade failures across the battery pack. Recent testing demonstrated that their sodium metal batteries maintained structural integrity even after nail penetration tests that typically cause catastrophic failure in conventional systems.

Strengths: Inherently safer solid-state design eliminates the primary cause of thermal runaway. Higher thermal stability threshold provides greater safety margins. Weaknesses: Manufacturing scale-up challenges for solid-state technology. Higher production costs compared to conventional liquid electrolyte systems. Lower ionic conductivity at room temperature may affect performance.

Critical Patents in Sodium Battery Safety Mechanisms

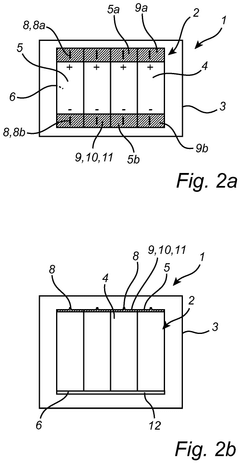

Battery module comprising a thermal runaway reaction inhibitor

PatentPendingEP4621970A1

Innovation

- A battery module with a thermal suppressant liner containing a thermal runaway reaction inhibitor, such as silica-trifluoroacetyl powder, Mg(OH)2, bicarbonate powder, or sodium sulfite, embedded in a polymer-based liner material, covers the venting areas or cell tabs to suppress the thermal runaway reaction by releasing the inhibitor upon detection, breaking the chain reaction and preventing further damage.

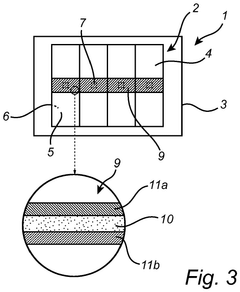

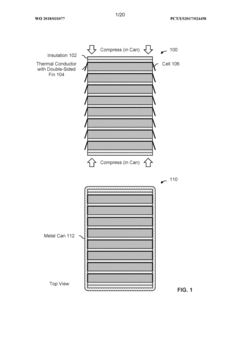

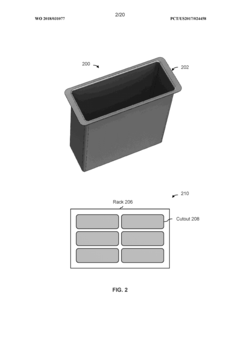

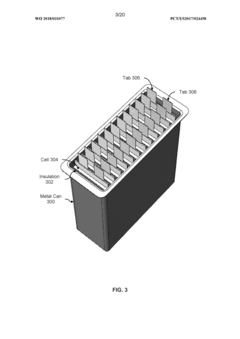

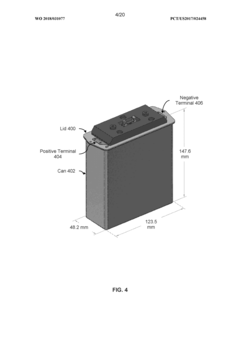

Battery with compression and prevention of thermal runaway propagation features

PatentWO2018031077A1

Innovation

- A battery design featuring a metal can with compressed pouch cells, layered insulation, and thermal conductors with fins to prevent heat spread and apply pressure, enhancing thermal insulation and heat dissipation while maintaining cell performance.

Safety Standards and Regulatory Framework

The regulatory landscape for sodium metal batteries is evolving rapidly as this technology advances toward commercialization. Currently, most safety standards and regulations have been developed primarily for lithium-ion batteries, creating a significant gap in the regulatory framework specifically addressing sodium-based energy storage systems. Organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are beginning to adapt existing standards to accommodate the unique characteristics and thermal runaway risks associated with sodium metal batteries.

Key safety standards applicable to sodium metal batteries include IEC 62619 for industrial applications and UL 1973 for stationary energy storage. However, these standards require modification to address the specific thermal behaviors of sodium metal, which differs significantly from lithium in terms of reactivity with moisture and thermal conductivity properties. The UN Transportation Testing standards (UN 38.3) also need adaptation to properly evaluate sodium battery safety during shipping and handling.

Regulatory bodies in major markets are taking different approaches to sodium battery safety certification. The European Union, through its Battery Directive and upcoming Battery Regulation, is developing specific provisions for emerging battery chemistries including sodium-based systems. In the United States, the Department of Energy and the Consumer Product Safety Commission are collaborating on new safety protocols specifically targeting thermal runaway prevention in next-generation batteries.

China, as a leading manufacturer of battery technologies, has established the GB/T 36276 standard which includes some provisions applicable to sodium batteries, though more specific regulations are under development. Japan's regulatory framework through METI (Ministry of Economy, Trade and Industry) has begun incorporating sodium battery safety requirements into its electrical appliance safety laws.

A critical gap in current regulations is the lack of standardized testing protocols for thermal runaway prevention systems in sodium metal batteries. Industry stakeholders are advocating for the development of specific test methods that account for sodium's unique thermal characteristics, including its lower melting point (97.8°C compared to lithium's 180.5°C) and different thermal propagation behaviors.

Compliance with these evolving regulations presents both challenges and opportunities for manufacturers. Early engagement with regulatory bodies during product development can help shape appropriate standards while ensuring market access. Companies demonstrating robust thermal runaway prevention systems may gain competitive advantages as safety becomes an increasingly important differentiator in the energy storage market.

Key safety standards applicable to sodium metal batteries include IEC 62619 for industrial applications and UL 1973 for stationary energy storage. However, these standards require modification to address the specific thermal behaviors of sodium metal, which differs significantly from lithium in terms of reactivity with moisture and thermal conductivity properties. The UN Transportation Testing standards (UN 38.3) also need adaptation to properly evaluate sodium battery safety during shipping and handling.

Regulatory bodies in major markets are taking different approaches to sodium battery safety certification. The European Union, through its Battery Directive and upcoming Battery Regulation, is developing specific provisions for emerging battery chemistries including sodium-based systems. In the United States, the Department of Energy and the Consumer Product Safety Commission are collaborating on new safety protocols specifically targeting thermal runaway prevention in next-generation batteries.

China, as a leading manufacturer of battery technologies, has established the GB/T 36276 standard which includes some provisions applicable to sodium batteries, though more specific regulations are under development. Japan's regulatory framework through METI (Ministry of Economy, Trade and Industry) has begun incorporating sodium battery safety requirements into its electrical appliance safety laws.

A critical gap in current regulations is the lack of standardized testing protocols for thermal runaway prevention systems in sodium metal batteries. Industry stakeholders are advocating for the development of specific test methods that account for sodium's unique thermal characteristics, including its lower melting point (97.8°C compared to lithium's 180.5°C) and different thermal propagation behaviors.

Compliance with these evolving regulations presents both challenges and opportunities for manufacturers. Early engagement with regulatory bodies during product development can help shape appropriate standards while ensuring market access. Companies demonstrating robust thermal runaway prevention systems may gain competitive advantages as safety becomes an increasingly important differentiator in the energy storage market.

Environmental Impact and Sustainability Considerations

The environmental impact of sodium metal batteries represents a significant advantage over conventional lithium-ion technologies. Sodium resources are approximately 1,000 times more abundant than lithium in the Earth's crust, with widespread global distribution that reduces geopolitical supply risks. This abundance translates to lower environmental degradation from mining operations and decreased pressure on ecologically sensitive areas where lithium is traditionally extracted.

When addressing thermal runaway prevention in sodium metal batteries, environmental considerations must be integrated into safety solution designs. Many conventional thermal management systems rely on materials with high environmental footprints, such as synthetic flame retardants or rare earth elements. Developing bio-based or recyclable thermal management materials can significantly reduce the life-cycle environmental impact while maintaining safety standards.

The manufacturing processes for thermal safety components must also be evaluated through sustainability metrics. Energy-intensive production of ceramic separators or specialized electrolyte additives can offset the inherent environmental benefits of sodium technology. Implementation of green chemistry principles in the development of thermal runaway prevention solutions ensures alignment with broader sustainability goals.

End-of-life management presents both challenges and opportunities for sodium battery thermal safety systems. Thermal management components often contain materials that complicate recycling processes. Designing these components for easy disassembly and material recovery can enhance the circular economy potential of sodium batteries. Current research indicates that sodium battery materials can achieve recycling rates of up to 90% when properly designed for disassembly.

Carbon footprint analysis of various thermal runaway prevention strategies reveals significant variations. Physical protection methods typically show lower environmental impacts than chemical approaches that rely on synthesized compounds. For instance, phase change materials derived from bio-based sources for thermal management can reduce the carbon footprint by approximately 40% compared to conventional synthetic alternatives.

Water consumption represents another critical environmental consideration, particularly as battery production scales. Thermal management systems that require water-intensive manufacturing processes contribute to resource strain in water-stressed regions. Dry manufacturing processes for safety components can reduce water usage by up to 70% compared to conventional wet processes, significantly enhancing the sustainability profile of sodium battery technologies.

When addressing thermal runaway prevention in sodium metal batteries, environmental considerations must be integrated into safety solution designs. Many conventional thermal management systems rely on materials with high environmental footprints, such as synthetic flame retardants or rare earth elements. Developing bio-based or recyclable thermal management materials can significantly reduce the life-cycle environmental impact while maintaining safety standards.

The manufacturing processes for thermal safety components must also be evaluated through sustainability metrics. Energy-intensive production of ceramic separators or specialized electrolyte additives can offset the inherent environmental benefits of sodium technology. Implementation of green chemistry principles in the development of thermal runaway prevention solutions ensures alignment with broader sustainability goals.

End-of-life management presents both challenges and opportunities for sodium battery thermal safety systems. Thermal management components often contain materials that complicate recycling processes. Designing these components for easy disassembly and material recovery can enhance the circular economy potential of sodium batteries. Current research indicates that sodium battery materials can achieve recycling rates of up to 90% when properly designed for disassembly.

Carbon footprint analysis of various thermal runaway prevention strategies reveals significant variations. Physical protection methods typically show lower environmental impacts than chemical approaches that rely on synthesized compounds. For instance, phase change materials derived from bio-based sources for thermal management can reduce the carbon footprint by approximately 40% compared to conventional synthetic alternatives.

Water consumption represents another critical environmental consideration, particularly as battery production scales. Thermal management systems that require water-intensive manufacturing processes contribute to resource strain in water-stressed regions. Dry manufacturing processes for safety components can reduce water usage by up to 70% compared to conventional wet processes, significantly enhancing the sustainability profile of sodium battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!