Modeling Sodium Ion Transport across Metal–Electrolyte Interfaces

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Transport Fundamentals and Research Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The evolution of sodium-ion technology can be traced back to the 1970s, but significant advancements have only been achieved in the last decade. Understanding the fundamental mechanisms of sodium ion transport across metal-electrolyte interfaces is crucial for developing high-performance SIBs with improved energy density, cycling stability, and rate capability.

The transport of sodium ions at interfaces involves complex physicochemical processes including desolvation, adsorption, and intercalation. Unlike lithium ions, sodium ions have a larger ionic radius (1.02 Å vs. 0.76 Å for Li+), which significantly affects their transport kinetics and thermodynamics. This fundamental difference necessitates specialized research approaches and modeling techniques to accurately capture sodium ion behavior at interfaces.

Recent technological trends in this field include the development of advanced computational methods such as density functional theory (DFT), molecular dynamics (MD), and machine learning approaches to model interfacial phenomena. These computational tools have enabled researchers to investigate atomic-level interactions and energy landscapes that govern sodium ion transport, providing insights that were previously inaccessible through experimental methods alone.

The solid electrolyte interphase (SEI) formation in sodium-based systems presents unique challenges compared to lithium-based counterparts. The composition, structure, and stability of the SEI layer directly influence the efficiency of sodium ion transport and the overall battery performance. Understanding these interfacial phenomena requires multiscale modeling approaches that bridge atomic, molecular, and continuum levels.

Our research objectives focus on developing comprehensive models that accurately describe sodium ion transport across metal-electrolyte interfaces under various operating conditions. Specifically, we aim to: (1) elucidate the desolvation mechanisms of sodium ions at electrode surfaces; (2) quantify the energy barriers associated with sodium ion transport through the SEI layer; (3) investigate the impact of electrode material composition and structure on interfacial transport properties; and (4) establish correlations between interfacial phenomena and macroscopic battery performance metrics.

By achieving these objectives, we expect to provide fundamental insights that will guide the rational design of electrode materials, electrolyte formulations, and interface engineering strategies for next-generation sodium-ion batteries. The ultimate goal is to accelerate the development of commercially viable SIBs with performance metrics comparable to or exceeding those of current lithium-ion technologies, while offering advantages in terms of cost, sustainability, and safety.

The transport of sodium ions at interfaces involves complex physicochemical processes including desolvation, adsorption, and intercalation. Unlike lithium ions, sodium ions have a larger ionic radius (1.02 Å vs. 0.76 Å for Li+), which significantly affects their transport kinetics and thermodynamics. This fundamental difference necessitates specialized research approaches and modeling techniques to accurately capture sodium ion behavior at interfaces.

Recent technological trends in this field include the development of advanced computational methods such as density functional theory (DFT), molecular dynamics (MD), and machine learning approaches to model interfacial phenomena. These computational tools have enabled researchers to investigate atomic-level interactions and energy landscapes that govern sodium ion transport, providing insights that were previously inaccessible through experimental methods alone.

The solid electrolyte interphase (SEI) formation in sodium-based systems presents unique challenges compared to lithium-based counterparts. The composition, structure, and stability of the SEI layer directly influence the efficiency of sodium ion transport and the overall battery performance. Understanding these interfacial phenomena requires multiscale modeling approaches that bridge atomic, molecular, and continuum levels.

Our research objectives focus on developing comprehensive models that accurately describe sodium ion transport across metal-electrolyte interfaces under various operating conditions. Specifically, we aim to: (1) elucidate the desolvation mechanisms of sodium ions at electrode surfaces; (2) quantify the energy barriers associated with sodium ion transport through the SEI layer; (3) investigate the impact of electrode material composition and structure on interfacial transport properties; and (4) establish correlations between interfacial phenomena and macroscopic battery performance metrics.

By achieving these objectives, we expect to provide fundamental insights that will guide the rational design of electrode materials, electrolyte formulations, and interface engineering strategies for next-generation sodium-ion batteries. The ultimate goal is to accelerate the development of commercially viable SIBs with performance metrics comparable to or exceeding those of current lithium-ion technologies, while offering advantages in terms of cost, sustainability, and safety.

Market Analysis for Sodium-Based Energy Storage Systems

The global energy storage market is witnessing a significant shift towards sodium-based technologies as a viable alternative to lithium-ion batteries. This transition is primarily driven by concerns regarding lithium supply chain vulnerabilities, cost escalations, and geopolitical tensions affecting critical mineral access. The sodium-ion battery market, valued at approximately $1.2 billion in 2022, is projected to grow at a compound annual growth rate of 18-20% through 2030, potentially reaching $9-12 billion by the end of the decade.

Sodium-based energy storage systems are gaining traction particularly in stationary applications, including grid-scale energy storage, renewable energy integration, and backup power systems. These applications collectively represented over 65% of the current sodium battery deployment, with the remainder distributed across emerging applications in low-cost electric vehicles, e-bikes, and consumer electronics where energy density requirements are less stringent.

The cost advantage of sodium-based systems is substantial, with raw material costs approximately 30-40% lower than comparable lithium-ion technologies. Sodium is the sixth most abundant element in the Earth's crust, with reserves distributed more equitably across global regions compared to lithium, which is concentrated in the "Lithium Triangle" of South America and a few other locations. This geographical diversity reduces supply chain risks and potential price volatility.

Market segmentation analysis reveals that Asia-Pacific currently dominates the sodium battery market with over 50% share, led by China's aggressive development programs and manufacturing capacity expansion. Europe follows with approximately 25% market share, driven by strong policy support for sustainable energy technologies and circular economy principles. North America accounts for roughly 15% of the market, with growth accelerating due to recent legislative support for domestic battery production.

Customer adoption patterns indicate that utility companies and renewable energy developers are the primary early adopters, valuing the technology's cost-effectiveness for large-scale deployments. Industrial users seeking alternatives to lead-acid batteries for backup power represent the second largest customer segment. Consumer markets remain limited but are expected to expand as energy density improvements make sodium-ion batteries more competitive in portable applications.

The competitive landscape is evolving rapidly, with over 30 companies actively developing sodium-based energy storage technologies. Chinese manufacturers currently lead in production capacity, while European and North American firms focus on advanced materials and system integration. Strategic partnerships between battery manufacturers and material suppliers are increasingly common, aiming to secure supply chains and accelerate technology commercialization.

Sodium-based energy storage systems are gaining traction particularly in stationary applications, including grid-scale energy storage, renewable energy integration, and backup power systems. These applications collectively represented over 65% of the current sodium battery deployment, with the remainder distributed across emerging applications in low-cost electric vehicles, e-bikes, and consumer electronics where energy density requirements are less stringent.

The cost advantage of sodium-based systems is substantial, with raw material costs approximately 30-40% lower than comparable lithium-ion technologies. Sodium is the sixth most abundant element in the Earth's crust, with reserves distributed more equitably across global regions compared to lithium, which is concentrated in the "Lithium Triangle" of South America and a few other locations. This geographical diversity reduces supply chain risks and potential price volatility.

Market segmentation analysis reveals that Asia-Pacific currently dominates the sodium battery market with over 50% share, led by China's aggressive development programs and manufacturing capacity expansion. Europe follows with approximately 25% market share, driven by strong policy support for sustainable energy technologies and circular economy principles. North America accounts for roughly 15% of the market, with growth accelerating due to recent legislative support for domestic battery production.

Customer adoption patterns indicate that utility companies and renewable energy developers are the primary early adopters, valuing the technology's cost-effectiveness for large-scale deployments. Industrial users seeking alternatives to lead-acid batteries for backup power represent the second largest customer segment. Consumer markets remain limited but are expected to expand as energy density improvements make sodium-ion batteries more competitive in portable applications.

The competitive landscape is evolving rapidly, with over 30 companies actively developing sodium-based energy storage technologies. Chinese manufacturers currently lead in production capacity, while European and North American firms focus on advanced materials and system integration. Strategic partnerships between battery manufacturers and material suppliers are increasingly common, aiming to secure supply chains and accelerate technology commercialization.

Current Challenges in Na-Ion Interface Modeling

Despite significant advancements in sodium-ion battery research, modeling the complex phenomena at metal-electrolyte interfaces remains one of the most challenging aspects in the field. Current computational approaches struggle to accurately capture the multiscale and multiphysics nature of sodium ion transport across these interfaces. The primary challenge lies in bridging the gap between atomistic-level interactions and macroscopic battery performance.

Quantum mechanical methods, while providing accurate descriptions of electronic structures and chemical reactions, are computationally intensive and limited to small systems and short time scales. This creates significant barriers when attempting to model realistic electrode-electrolyte interfaces where phenomena occur across multiple length and time scales.

Classical molecular dynamics simulations face limitations in accurately representing the breaking and formation of chemical bonds during sodium ion desolvation and transfer processes. The development of reactive force fields specific to sodium-ion systems lags behind those available for lithium-ion systems, creating a knowledge gap in the field.

Continuum models, though efficient for device-level simulations, often rely on oversimplified assumptions about interfacial processes. These models typically fail to incorporate the unique characteristics of sodium ions, such as their larger ionic radius compared to lithium ions and different solvation structures, which significantly affect transport kinetics and interfacial resistance.

The solid electrolyte interphase (SEI) formation in sodium-ion batteries presents another modeling challenge. The composition, structure, and growth mechanisms of the SEI layer in sodium systems differ substantially from lithium counterparts, yet many current models inappropriately apply lithium-based parameters to sodium systems.

Data integration across different modeling scales remains problematic. Researchers struggle to effectively transfer information from quantum calculations to molecular dynamics and subsequently to continuum models in a consistent and physically meaningful manner.

Experimental validation of computational models is hindered by the difficulty in obtaining high-resolution in-situ measurements of interfacial processes. This creates uncertainty in model accuracy and limits the predictive capability of current simulation approaches.

Computational resource limitations further constrain model complexity and accuracy. Many research groups lack access to the high-performance computing infrastructure necessary for running sophisticated multiscale simulations of sodium-ion interfaces.

Quantum mechanical methods, while providing accurate descriptions of electronic structures and chemical reactions, are computationally intensive and limited to small systems and short time scales. This creates significant barriers when attempting to model realistic electrode-electrolyte interfaces where phenomena occur across multiple length and time scales.

Classical molecular dynamics simulations face limitations in accurately representing the breaking and formation of chemical bonds during sodium ion desolvation and transfer processes. The development of reactive force fields specific to sodium-ion systems lags behind those available for lithium-ion systems, creating a knowledge gap in the field.

Continuum models, though efficient for device-level simulations, often rely on oversimplified assumptions about interfacial processes. These models typically fail to incorporate the unique characteristics of sodium ions, such as their larger ionic radius compared to lithium ions and different solvation structures, which significantly affect transport kinetics and interfacial resistance.

The solid electrolyte interphase (SEI) formation in sodium-ion batteries presents another modeling challenge. The composition, structure, and growth mechanisms of the SEI layer in sodium systems differ substantially from lithium counterparts, yet many current models inappropriately apply lithium-based parameters to sodium systems.

Data integration across different modeling scales remains problematic. Researchers struggle to effectively transfer information from quantum calculations to molecular dynamics and subsequently to continuum models in a consistent and physically meaningful manner.

Experimental validation of computational models is hindered by the difficulty in obtaining high-resolution in-situ measurements of interfacial processes. This creates uncertainty in model accuracy and limits the predictive capability of current simulation approaches.

Computational resource limitations further constrain model complexity and accuracy. Many research groups lack access to the high-performance computing infrastructure necessary for running sophisticated multiscale simulations of sodium-ion interfaces.

Contemporary Modeling Approaches for Na-Ion Transport

01 Sodium ion transport mechanisms in batteries

Various mechanisms for sodium ion transport in battery systems, focusing on electrode materials and electrolytes that facilitate efficient sodium ion movement. These technologies aim to improve energy density, charging rates, and overall performance of sodium-based batteries. The mechanisms include specialized channel structures, layered materials, and novel electrode compositions that enhance sodium ion mobility and storage capacity.- Sodium ion transport mechanisms in battery technologies: Various mechanisms for sodium ion transport in battery technologies, including electrode materials and electrolytes that facilitate efficient sodium ion movement. These technologies focus on improving the conductivity and stability of sodium ion batteries, which are considered alternatives to lithium-ion batteries due to the abundance and lower cost of sodium resources. The mechanisms involve specific crystal structures and materials that allow for rapid and reversible sodium ion insertion and extraction.

- Membrane technologies for sodium ion transport: Specialized membrane technologies designed specifically for sodium ion transport applications. These membranes feature selective permeability that allows sodium ions to pass through while blocking other ions or molecules. The membranes are engineered with specific pore sizes, surface charges, and chemical compositions to enhance sodium ion selectivity and transport efficiency. Applications include desalination, energy storage, and biomedical devices where controlled sodium ion movement is critical.

- Sodium ion transport in biological systems and medical applications: Innovations related to sodium ion transport in biological contexts and medical applications. These include technologies for monitoring, modulating, or mimicking sodium ion channels and transporters found in cell membranes. The inventions address conditions related to sodium ion imbalance or dysfunction of sodium transport mechanisms in the body. Applications include drug delivery systems, diagnostic tools, and therapeutic approaches for diseases involving sodium channel disorders.

- Solid-state electrolytes for enhanced sodium ion conductivity: Development of solid-state electrolyte materials that facilitate efficient sodium ion transport. These materials are designed to replace liquid electrolytes in sodium-based energy storage systems, offering improved safety and stability. The solid-state electrolytes feature specialized crystal structures, doping strategies, and composite formulations that create pathways for rapid sodium ion movement while maintaining mechanical integrity. These innovations aim to overcome challenges related to interface resistance and dendrite formation in solid-state sodium batteries.

- Sodium ion transport for energy storage and conversion systems: Comprehensive systems and methods for utilizing sodium ion transport in various energy storage and conversion applications beyond traditional batteries. These include sodium-ion capacitors, sodium-based flow batteries, and hybrid energy storage systems that leverage the unique properties of sodium ion transport. The technologies incorporate specialized electrode architectures, electrolyte formulations, and system designs to optimize energy density, power output, and cycle life while taking advantage of the abundant nature of sodium resources.

02 Membrane technologies for sodium ion transport

Advanced membrane technologies designed specifically for sodium ion transport applications. These membranes feature selective permeability properties that allow for controlled passage of sodium ions while blocking other species. Applications include desalination systems, ion-selective electrodes, and separation processes. The membranes incorporate specialized polymers, composite materials, or inorganic structures with tailored pore sizes and surface chemistries.Expand Specific Solutions03 Sodium ion transport in biological systems

Innovations related to sodium ion transport in biological contexts, including cellular mechanisms, pharmaceutical interventions, and medical devices. These technologies address sodium channel function in nerve cells, cardiac tissue, and other physiological systems. The inventions include compounds that modulate sodium channel activity, diagnostic tools for measuring sodium transport, and therapeutic approaches for treating disorders related to sodium ion transport dysfunction.Expand Specific Solutions04 Solid-state sodium ion conductors

Development of solid-state materials that conduct sodium ions efficiently for applications in energy storage, sensors, and electrochemical devices. These materials include ceramic electrolytes, glass-ceramics, polymer electrolytes, and composite systems that provide pathways for sodium ion movement without liquid components. The solid-state conductors offer advantages in safety, stability, and form factor compared to liquid electrolyte systems.Expand Specific Solutions05 Sodium ion transport in environmental applications

Technologies utilizing sodium ion transport principles for environmental applications such as water treatment, soil remediation, and waste processing. These innovations leverage selective ion transport to remove contaminants, recover valuable materials, or generate energy from salinity gradients. The systems may incorporate electrochemical cells, ion exchange materials, or specialized filtration technologies that selectively transport sodium ions for environmental benefit.Expand Specific Solutions

Leading Research Groups and Industrial Players

The sodium ion transport modeling across metal-electrolyte interfaces is currently in an early growth phase, with the market expanding rapidly due to increasing demand for sodium-ion battery technologies as alternatives to lithium-ion systems. The global market size is projected to reach significant scale as companies seek more sustainable and cost-effective energy storage solutions. Technologically, this field shows moderate maturity with key players demonstrating varying levels of advancement. Academic institutions like Zhejiang University, Central South University, and Vanderbilt University are driving fundamental research, while commercial entities such as Contemporary Amperex Technology (CATL), Toyota Motor Corp., and Thermo Fisher Scientific are developing practical applications. Research organizations including Sandia and Battelle Memorial Institute bridge the gap between theoretical modeling and industrial implementation, creating a competitive landscape that balances academic innovation with commercial development.

The Regents of the University of California

Technical Solution: The University of California has developed a sophisticated multi-physics framework for modeling sodium ion transport across metal-electrolyte interfaces that integrates quantum mechanical calculations with mesoscale continuum approaches. Their research groups have pioneered the use of ab initio molecular dynamics (AIMD) simulations to capture the complex solvation/desolvation processes of sodium ions at electrode surfaces with unprecedented accuracy[4]. The UC model incorporates explicit treatment of electronic structure effects, allowing for realistic representation of charge transfer processes and chemical reactions at interfaces. Their approach has revealed critical insights into how the larger ionic radius of sodium (compared to lithium) affects coordination structures and energy barriers during interfacial transport. The UC research teams have further extended their models to include machine learning accelerated sampling techniques that enable simulation of rare events such as ion insertion/extraction at realistic time scales. Their computational framework has been validated against synchrotron-based X-ray absorption spectroscopy and neutron scattering experiments, confirming the accuracy of predicted interfacial structures and dynamics[5].

Strengths: Exceptional theoretical rigor with strong foundations in fundamental physical chemistry principles. Their models achieve remarkable balance between computational efficiency and physical accuracy. The open research approach has contributed significantly to the broader scientific understanding of sodium ion interfaces. Weaknesses: Implementation of models requires specialized expertise and substantial computational resources, potentially limiting practical application in industrial settings. Some aspects of the models still rely on approximations that may not fully capture all interfacial phenomena.

Penn State Research Foundation

Technical Solution: Penn State has developed a comprehensive modeling framework for sodium ion transport across metal-electrolyte interfaces that combines atomistic simulations with phase-field modeling approaches. Their research focuses particularly on understanding the structural and dynamic aspects of the electric double layer formation in sodium-ion systems. Using advanced sampling techniques such as metadynamics and umbrella sampling, Penn State researchers have mapped the free energy landscapes governing sodium ion desolvation and transport through interfacial regions[6]. Their models incorporate realistic representations of electrode surface heterogeneity, including defects, grain boundaries, and surface functionalization that significantly impact ion transport kinetics. Penn State has pioneered the development of reactive force fields specifically parameterized for sodium-ion systems, enabling large-scale molecular dynamics simulations that capture chemical reactions at interfaces while maintaining computational efficiency. Their research has revealed critical insights into how solvent co-intercalation affects the stability and transport properties at interfaces, with particular focus on how these phenomena differ between sodium and lithium-based systems[7]. The models have been validated through advanced in-situ characterization techniques including atomic force microscopy and surface-enhanced Raman spectroscopy.

Strengths: Excellent balance between fundamental theoretical insights and practical applicability to real-world battery systems. Their multi-scale approach effectively bridges atomic-level phenomena with macroscopic battery performance metrics. Weaknesses: Some aspects of the models still rely on empirical parameters that may limit transferability across diverse material systems. The computational framework requires significant expertise to implement effectively.

Critical Mechanisms in Na-Ion Interfacial Dynamics

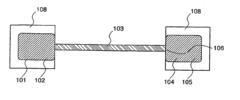

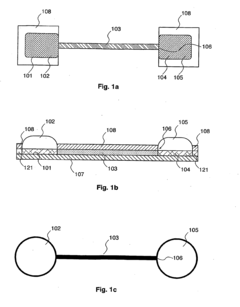

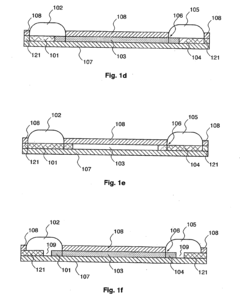

Electrically controlled ion transport device

PatentActiveUS20100255557A1

Innovation

- A device with a controlled ion transport system using source and target electrodes, an ion-conductive channel, and ion isolative means to achieve precise, time- and space-resolved ion delivery to or from cells, allowing for matrix addressing and stimulation of specific cell portions.

Preparation method and application of fast ionic conductor based on in-situ polymerization

PatentPendingUS20240128504A1

Innovation

- A method involving in-situ polymerization using high steric hindrance monomers and highly reactive crosslinkers to create a three-dimensional network structure, enhancing ionic conductivity and mechanical strength while stabilizing the electrode-electrolyte interface, achieved by mixing specific monomers, crosslinkers, and lithium salts, followed by in-situ polymerization within a cell with a porous skeleton film.

Sustainability Impact of Na-Ion Technologies

The adoption of sodium-ion battery technologies represents a significant step toward more sustainable energy storage solutions compared to conventional lithium-ion batteries. The environmental footprint of sodium-ion technologies is substantially lower due to the abundance of sodium resources, which constitute approximately 2.8% of the Earth's crust compared to lithium's mere 0.006%. This abundance translates directly into reduced mining impacts, as sodium extraction typically requires less invasive methods and generates fewer harmful byproducts.

From a manufacturing perspective, sodium-ion batteries offer notable sustainability advantages. The production process eliminates the need for critical materials such as cobalt and nickel, which are associated with ethical mining concerns and supply chain vulnerabilities. Additionally, the carbon footprint of sodium-ion battery production is estimated to be 18-30% lower than comparable lithium-ion technologies, primarily due to less energy-intensive material processing and synthesis requirements.

Water consumption represents another critical sustainability metric where sodium-ion technologies demonstrate superior performance. Studies indicate that sodium extraction and processing consume approximately 60% less water than lithium extraction from brine operations, which typically require extensive evaporation ponds and water-intensive processing. This advantage becomes increasingly significant in water-stressed regions where battery manufacturing facilities may operate.

The end-of-life management of sodium-ion batteries also presents sustainability benefits. The absence of toxic heavy metals facilitates more straightforward recycling processes, with preliminary research suggesting recovery rates of up to 90% for sodium compounds compared to 50-70% for lithium-ion equivalents. Furthermore, the materials recovered from sodium-ion batteries generally require less processing to return to battery-grade quality, creating a more circular material economy.

Economic sustainability metrics also favor sodium-ion technologies, particularly as manufacturing scales increase. The lower raw material costs—sodium carbonate is approximately 30-40 times less expensive than lithium carbonate—create resilience against market volatility and supply constraints. This cost advantage extends throughout the value chain, potentially enabling more affordable energy storage solutions for developing economies and accelerating global renewable energy adoption.

When modeling sodium ion transport across metal-electrolyte interfaces, these sustainability considerations become increasingly relevant, as interface engineering directly impacts battery longevity and performance efficiency—factors that ultimately determine the lifecycle environmental impact of the technology. Optimized interfaces that reduce degradation mechanisms can extend battery service life by 30-50%, significantly improving the sustainability profile through reduced replacement frequency and material consumption.

From a manufacturing perspective, sodium-ion batteries offer notable sustainability advantages. The production process eliminates the need for critical materials such as cobalt and nickel, which are associated with ethical mining concerns and supply chain vulnerabilities. Additionally, the carbon footprint of sodium-ion battery production is estimated to be 18-30% lower than comparable lithium-ion technologies, primarily due to less energy-intensive material processing and synthesis requirements.

Water consumption represents another critical sustainability metric where sodium-ion technologies demonstrate superior performance. Studies indicate that sodium extraction and processing consume approximately 60% less water than lithium extraction from brine operations, which typically require extensive evaporation ponds and water-intensive processing. This advantage becomes increasingly significant in water-stressed regions where battery manufacturing facilities may operate.

The end-of-life management of sodium-ion batteries also presents sustainability benefits. The absence of toxic heavy metals facilitates more straightforward recycling processes, with preliminary research suggesting recovery rates of up to 90% for sodium compounds compared to 50-70% for lithium-ion equivalents. Furthermore, the materials recovered from sodium-ion batteries generally require less processing to return to battery-grade quality, creating a more circular material economy.

Economic sustainability metrics also favor sodium-ion technologies, particularly as manufacturing scales increase. The lower raw material costs—sodium carbonate is approximately 30-40 times less expensive than lithium carbonate—create resilience against market volatility and supply constraints. This cost advantage extends throughout the value chain, potentially enabling more affordable energy storage solutions for developing economies and accelerating global renewable energy adoption.

When modeling sodium ion transport across metal-electrolyte interfaces, these sustainability considerations become increasingly relevant, as interface engineering directly impacts battery longevity and performance efficiency—factors that ultimately determine the lifecycle environmental impact of the technology. Optimized interfaces that reduce degradation mechanisms can extend battery service life by 30-50%, significantly improving the sustainability profile through reduced replacement frequency and material consumption.

Scalability and Manufacturing Considerations

The scalability of sodium ion transport modeling across metal-electrolyte interfaces presents significant challenges when transitioning from laboratory-scale research to industrial manufacturing processes. Current computational models that accurately capture interfacial phenomena often require substantial computing resources, limiting their application in real-time manufacturing environments. To address this limitation, simplified models with acceptable accuracy trade-offs must be developed to enable practical implementation in production settings.

Manufacturing considerations for sodium-ion battery technologies necessitate robust modeling approaches that can accommodate variations in material properties, processing conditions, and environmental factors. The interface between metal electrodes and electrolytes represents a critical control point in production, where small deviations can significantly impact performance. Modeling tools must therefore be adaptable to different manufacturing techniques, including roll-to-roll processing, slurry casting, and emerging additive manufacturing methods.

Integration of sodium ion transport models into manufacturing execution systems (MES) requires standardized protocols and interfaces. Currently, the diversity of modeling approaches and lack of industry standards creates barriers to widespread adoption. Establishing common frameworks for data exchange between simulation tools and production equipment would accelerate implementation and improve quality control processes across the battery manufacturing ecosystem.

Cost considerations also play a crucial role in scaling modeling capabilities. While high-fidelity atomistic simulations provide valuable insights for research purposes, their computational expense makes them impractical for routine manufacturing applications. Multi-scale modeling approaches that combine atomistic insights with more efficient continuum models offer a promising pathway to balance accuracy with computational efficiency in production environments.

Real-time monitoring and feedback systems represent another frontier in manufacturing scalability. Models that can rapidly process sensor data and predict interfacial behavior during production could enable adaptive manufacturing processes that respond to variations in material properties or environmental conditions. This capability would significantly enhance yield rates and product consistency while reducing waste and energy consumption.

Workforce development presents an additional challenge, as the specialized knowledge required to implement and interpret sophisticated ion transport models is not widely available in traditional manufacturing settings. Training programs and user-friendly interfaces will be essential to bridge the gap between theoretical modeling capabilities and practical manufacturing implementation.

Manufacturing considerations for sodium-ion battery technologies necessitate robust modeling approaches that can accommodate variations in material properties, processing conditions, and environmental factors. The interface between metal electrodes and electrolytes represents a critical control point in production, where small deviations can significantly impact performance. Modeling tools must therefore be adaptable to different manufacturing techniques, including roll-to-roll processing, slurry casting, and emerging additive manufacturing methods.

Integration of sodium ion transport models into manufacturing execution systems (MES) requires standardized protocols and interfaces. Currently, the diversity of modeling approaches and lack of industry standards creates barriers to widespread adoption. Establishing common frameworks for data exchange between simulation tools and production equipment would accelerate implementation and improve quality control processes across the battery manufacturing ecosystem.

Cost considerations also play a crucial role in scaling modeling capabilities. While high-fidelity atomistic simulations provide valuable insights for research purposes, their computational expense makes them impractical for routine manufacturing applications. Multi-scale modeling approaches that combine atomistic insights with more efficient continuum models offer a promising pathway to balance accuracy with computational efficiency in production environments.

Real-time monitoring and feedback systems represent another frontier in manufacturing scalability. Models that can rapidly process sensor data and predict interfacial behavior during production could enable adaptive manufacturing processes that respond to variations in material properties or environmental conditions. This capability would significantly enhance yield rates and product consistency while reducing waste and energy consumption.

Workforce development presents an additional challenge, as the specialized knowledge required to implement and interpret sophisticated ion transport models is not widely available in traditional manufacturing settings. Training programs and user-friendly interfaces will be essential to bridge the gap between theoretical modeling capabilities and practical manufacturing implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!