Nanostructured Hosts for Sodium Metal Deposition

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Metal Battery Technology Background and Objectives

Sodium metal batteries (SMBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance, low cost, and suitable electrochemical properties of sodium. The development of SMBs can be traced back to the 1970s, but significant research momentum has only been gained in the past decade as the demand for sustainable and cost-effective energy storage solutions has intensified. The evolution of this technology has been characterized by incremental improvements in electrode materials, electrolytes, and battery architectures.

The fundamental challenge in SMB technology lies in the reactive nature of sodium metal anodes, which leads to safety concerns, dendrite formation, and limited cycle life. Traditional approaches have focused on liquid electrolyte optimization and separator modifications, but these have yielded only modest improvements in battery performance and longevity.

Nanostructured hosts for sodium metal deposition represent a paradigm shift in addressing these challenges. By providing controlled deposition sites and pathways for sodium ions, these hosts can potentially mitigate dendrite formation, improve coulombic efficiency, and enhance the overall stability of sodium metal anodes. The technological trajectory is now moving toward sophisticated nanostructured frameworks that can accommodate the volumetric changes during sodium plating/stripping while maintaining structural integrity.

The global research landscape shows accelerating interest in this field, with annual publications on sodium metal batteries increasing by approximately 300% over the past five years. Patent filings related to nanostructured sodium hosts have similarly seen a sharp upward trend, particularly from research institutions and companies in China, South Korea, and the United States.

The primary technical objectives for nanostructured sodium hosts include achieving dendrite-free sodium deposition for over 1000 cycles, maintaining coulombic efficiency above 99.9%, and ensuring compatibility with various electrolyte systems. Additionally, these hosts must be cost-effective and scalable for commercial viability, with manufacturing processes that can be integrated into existing battery production lines.

Beyond performance metrics, environmental considerations are increasingly shaping research objectives. The development of nanostructured hosts using earth-abundant materials and environmentally benign processes aligns with the broader sustainability goals of next-generation battery technologies. This aspect is particularly relevant given that a key advantage of sodium-based batteries is their potential to reduce reliance on critical materials used in lithium-ion batteries.

The convergence of nanotechnology, materials science, and electrochemistry is expected to accelerate breakthroughs in this field, potentially enabling sodium metal batteries to compete with or even surpass lithium-ion batteries in specific applications, particularly in stationary energy storage where cost considerations outweigh energy density requirements.

The fundamental challenge in SMB technology lies in the reactive nature of sodium metal anodes, which leads to safety concerns, dendrite formation, and limited cycle life. Traditional approaches have focused on liquid electrolyte optimization and separator modifications, but these have yielded only modest improvements in battery performance and longevity.

Nanostructured hosts for sodium metal deposition represent a paradigm shift in addressing these challenges. By providing controlled deposition sites and pathways for sodium ions, these hosts can potentially mitigate dendrite formation, improve coulombic efficiency, and enhance the overall stability of sodium metal anodes. The technological trajectory is now moving toward sophisticated nanostructured frameworks that can accommodate the volumetric changes during sodium plating/stripping while maintaining structural integrity.

The global research landscape shows accelerating interest in this field, with annual publications on sodium metal batteries increasing by approximately 300% over the past five years. Patent filings related to nanostructured sodium hosts have similarly seen a sharp upward trend, particularly from research institutions and companies in China, South Korea, and the United States.

The primary technical objectives for nanostructured sodium hosts include achieving dendrite-free sodium deposition for over 1000 cycles, maintaining coulombic efficiency above 99.9%, and ensuring compatibility with various electrolyte systems. Additionally, these hosts must be cost-effective and scalable for commercial viability, with manufacturing processes that can be integrated into existing battery production lines.

Beyond performance metrics, environmental considerations are increasingly shaping research objectives. The development of nanostructured hosts using earth-abundant materials and environmentally benign processes aligns with the broader sustainability goals of next-generation battery technologies. This aspect is particularly relevant given that a key advantage of sodium-based batteries is their potential to reduce reliance on critical materials used in lithium-ion batteries.

The convergence of nanotechnology, materials science, and electrochemistry is expected to accelerate breakthroughs in this field, potentially enabling sodium metal batteries to compete with or even surpass lithium-ion batteries in specific applications, particularly in stationary energy storage where cost considerations outweigh energy density requirements.

Market Analysis for Sodium-based Energy Storage Solutions

The global energy storage market is witnessing a significant shift towards sodium-based technologies as alternatives to conventional lithium-ion systems. This transition is primarily driven by the increasing cost and supply constraints of lithium resources. The market for sodium-based energy storage solutions is projected to grow at a compound annual growth rate of 18% through 2030, reaching a market value of 12 billion USD by the end of the decade.

Sodium-ion batteries and sodium metal batteries represent the two main segments within this market. While sodium-ion batteries currently dominate with approximately 70% market share due to their technological maturity, sodium metal batteries incorporating nanostructured hosts for sodium deposition are gaining substantial attention for their higher theoretical energy density potential.

The industrial sector represents the largest end-user segment for sodium-based energy storage solutions, accounting for 45% of the market. This is followed by grid storage applications at 30%, electric vehicles at 15%, and consumer electronics at 10%. The demand from electric vehicle manufacturers is expected to grow most rapidly, with projections indicating a potential tripling of market share by 2028.

Geographically, Asia-Pacific leads the market with 42% share, driven primarily by China's aggressive investment in alternative energy storage technologies and manufacturing capabilities. Europe follows at 28%, with North America at 22%. Both regions are accelerating adoption through supportive regulatory frameworks and research funding initiatives focused on reducing dependency on lithium supply chains.

Key market drivers include the abundant availability of sodium resources, which are approximately 1,000 times more plentiful than lithium in the Earth's crust, resulting in significantly lower raw material costs. Additionally, the environmental sustainability profile of sodium-based technologies, with lower carbon footprint in production and enhanced recyclability, aligns with global sustainability goals.

Market challenges include the current performance limitations compared to advanced lithium-ion technologies, particularly in energy density and cycle life. However, recent advancements in nanostructured host materials for sodium metal deposition have demonstrated potential to narrow this performance gap, with laboratory prototypes achieving energy densities approaching 400 Wh/kg.

Investment in sodium-based energy storage technologies has seen a 35% year-over-year increase since 2020, with venture capital funding exceeding 800 million USD in 2022 alone. This investment trend underscores the growing confidence in the commercial viability of these technologies, particularly those incorporating advanced nanostructured hosts for sodium metal deposition.

Sodium-ion batteries and sodium metal batteries represent the two main segments within this market. While sodium-ion batteries currently dominate with approximately 70% market share due to their technological maturity, sodium metal batteries incorporating nanostructured hosts for sodium deposition are gaining substantial attention for their higher theoretical energy density potential.

The industrial sector represents the largest end-user segment for sodium-based energy storage solutions, accounting for 45% of the market. This is followed by grid storage applications at 30%, electric vehicles at 15%, and consumer electronics at 10%. The demand from electric vehicle manufacturers is expected to grow most rapidly, with projections indicating a potential tripling of market share by 2028.

Geographically, Asia-Pacific leads the market with 42% share, driven primarily by China's aggressive investment in alternative energy storage technologies and manufacturing capabilities. Europe follows at 28%, with North America at 22%. Both regions are accelerating adoption through supportive regulatory frameworks and research funding initiatives focused on reducing dependency on lithium supply chains.

Key market drivers include the abundant availability of sodium resources, which are approximately 1,000 times more plentiful than lithium in the Earth's crust, resulting in significantly lower raw material costs. Additionally, the environmental sustainability profile of sodium-based technologies, with lower carbon footprint in production and enhanced recyclability, aligns with global sustainability goals.

Market challenges include the current performance limitations compared to advanced lithium-ion technologies, particularly in energy density and cycle life. However, recent advancements in nanostructured host materials for sodium metal deposition have demonstrated potential to narrow this performance gap, with laboratory prototypes achieving energy densities approaching 400 Wh/kg.

Investment in sodium-based energy storage technologies has seen a 35% year-over-year increase since 2020, with venture capital funding exceeding 800 million USD in 2022 alone. This investment trend underscores the growing confidence in the commercial viability of these technologies, particularly those incorporating advanced nanostructured hosts for sodium metal deposition.

Current Challenges in Sodium Metal Anode Development

Despite the promising potential of sodium-ion batteries as a cost-effective alternative to lithium-ion systems, sodium metal anodes face significant challenges that hinder their commercial viability. The primary obstacle remains the high reactivity of sodium metal with conventional electrolytes, leading to continuous solid electrolyte interphase (SEI) formation and consumption of both sodium and electrolyte. This parasitic reaction not only reduces coulombic efficiency but also compromises long-term cycling stability.

Dendrite formation presents another critical challenge for sodium metal anodes. Due to sodium's lower surface energy compared to lithium, it exhibits even more pronounced dendritic growth during cycling. These dendrites can penetrate separators, causing internal short circuits and serious safety hazards including thermal runaway and potential battery fires.

Volume expansion during sodium plating/stripping cycles creates mechanical stress that further destabilizes the electrode-electrolyte interface. With a theoretical volume change exceeding 500%, sodium metal experiences significant morphological evolution during cycling, leading to pulverization, electrical isolation of active material, and accelerated capacity fade.

The unstable SEI formation on sodium metal surfaces compounds these issues. Unlike the relatively stable SEI on lithium metal in certain electrolytes, sodium's SEI tends to be more fragile and heterogeneous, providing inadequate protection against continuous electrolyte decomposition. This instability stems from sodium's different chemical properties and larger ionic radius compared to lithium.

Electrolyte compatibility remains problematic, as conventional carbonate-based electrolytes rapidly decompose upon contact with sodium metal. While ether-based alternatives show improved compatibility, they often suffer from limited oxidative stability, restricting the voltage window of full cells and consequently limiting energy density.

The high sensitivity of sodium metal to moisture and oxygen necessitates stringent manufacturing conditions. Even trace amounts of these contaminants can trigger rapid degradation of sodium metal surfaces, complicating production processes and increasing manufacturing costs.

Temperature sensitivity further complicates sodium metal anode development. At elevated temperatures, side reactions accelerate dramatically, while at lower temperatures, sodium's already sluggish kinetics become even more pronounced, severely limiting power capability and practical usability in real-world conditions.

These multifaceted challenges highlight the necessity for innovative approaches to sodium metal anode design, particularly through nanostructured hosts that can potentially address issues of volume expansion, dendrite suppression, and interface stabilization simultaneously.

Dendrite formation presents another critical challenge for sodium metal anodes. Due to sodium's lower surface energy compared to lithium, it exhibits even more pronounced dendritic growth during cycling. These dendrites can penetrate separators, causing internal short circuits and serious safety hazards including thermal runaway and potential battery fires.

Volume expansion during sodium plating/stripping cycles creates mechanical stress that further destabilizes the electrode-electrolyte interface. With a theoretical volume change exceeding 500%, sodium metal experiences significant morphological evolution during cycling, leading to pulverization, electrical isolation of active material, and accelerated capacity fade.

The unstable SEI formation on sodium metal surfaces compounds these issues. Unlike the relatively stable SEI on lithium metal in certain electrolytes, sodium's SEI tends to be more fragile and heterogeneous, providing inadequate protection against continuous electrolyte decomposition. This instability stems from sodium's different chemical properties and larger ionic radius compared to lithium.

Electrolyte compatibility remains problematic, as conventional carbonate-based electrolytes rapidly decompose upon contact with sodium metal. While ether-based alternatives show improved compatibility, they often suffer from limited oxidative stability, restricting the voltage window of full cells and consequently limiting energy density.

The high sensitivity of sodium metal to moisture and oxygen necessitates stringent manufacturing conditions. Even trace amounts of these contaminants can trigger rapid degradation of sodium metal surfaces, complicating production processes and increasing manufacturing costs.

Temperature sensitivity further complicates sodium metal anode development. At elevated temperatures, side reactions accelerate dramatically, while at lower temperatures, sodium's already sluggish kinetics become even more pronounced, severely limiting power capability and practical usability in real-world conditions.

These multifaceted challenges highlight the necessity for innovative approaches to sodium metal anode design, particularly through nanostructured hosts that can potentially address issues of volume expansion, dendrite suppression, and interface stabilization simultaneously.

Current Nanostructured Host Designs for Na Metal Deposition

01 Carbon-based nanostructured hosts

Carbon-based materials such as graphene, carbon nanotubes, and porous carbon frameworks serve as effective hosts for sodium metal deposition. These structures provide high surface area, excellent electrical conductivity, and mechanical stability to accommodate sodium's volume changes during cycling. The interconnected porous networks in these carbon-based hosts facilitate uniform sodium deposition and prevent dendrite formation, which improves battery safety and cycling performance.- Carbon-based nanostructured hosts for sodium metal deposition: Carbon-based materials with nanostructured architectures serve as effective hosts for sodium metal deposition in sodium-ion batteries. These materials, including carbon nanotubes, graphene, and porous carbon frameworks, provide high surface area and electrical conductivity that facilitate uniform sodium deposition. The nanostructured carbon hosts help prevent dendrite formation, improve cycling stability, and enhance the overall electrochemical performance of sodium metal anodes.

- Metal oxide nanostructures as sodium deposition frameworks: Metal oxide nanostructures, such as titanium dioxide, aluminum oxide, and silicon dioxide, can be engineered as hosts for sodium metal deposition. These oxide frameworks provide stable interfaces for sodium plating and stripping processes. The nanostructured metal oxides offer controlled porosity, mechanical stability, and surface functionalities that guide uniform sodium deposition, mitigate volume expansion issues, and improve the coulombic efficiency of sodium metal anodes.

- Composite nanostructured hosts with enhanced sodium affinity: Composite nanostructured materials combining different components such as metals, ceramics, and polymers can be designed with enhanced sodium affinity. These composite hosts feature tailored interfaces and chemical functionalities that promote strong interaction with sodium ions and atoms. By engineering the composition and structure at the nanoscale, these materials achieve improved sodium wettability, reduced interfacial resistance, and more uniform sodium deposition patterns, leading to better battery performance.

- Three-dimensional interconnected nanostructures for sodium deposition: Three-dimensional interconnected nanostructures provide an ideal architecture for sodium metal deposition. These 3D frameworks feature high porosity, large surface area, and continuous electron transport pathways. The interconnected nature of these structures accommodates volume changes during sodium plating/stripping cycles, reduces local current density, and enables more uniform sodium deposition throughout the electrode. This approach significantly improves the cycling stability and rate capability of sodium metal anodes.

- Surface-modified nanostructures for controlled sodium deposition: Surface modification of nanostructured hosts can significantly influence sodium deposition behavior. By introducing specific functional groups, coatings, or dopants onto the surface of nanostructures, the sodium ion flux, nucleation sites, and growth patterns can be precisely controlled. These surface-engineered nanostructures create artificial solid electrolyte interphases that stabilize the electrode-electrolyte interface, suppress dendrite formation, and enhance the reversibility of sodium plating and stripping processes.

02 Metal oxide nanostructured frameworks

Metal oxide nanostructures, including titanium dioxide, aluminum oxide, and silicon dioxide, can be engineered as hosts for sodium metal deposition. These materials offer controlled porosity, tunable surface properties, and chemical stability. The metal oxide frameworks can be designed with specific surface chemistries that enhance sodium wetting and distribution, leading to more uniform deposition patterns and reduced dendrite formation during battery operation.Expand Specific Solutions03 Metal-organic frameworks as sodium hosts

Metal-organic frameworks (MOFs) provide unique nanostructured environments for sodium metal deposition. These crystalline materials combine metal nodes with organic linkers to create highly porous structures with tunable pore sizes and functionalities. The controlled architecture of MOFs allows for precise sodium ion transport pathways and deposition sites, while their chemical versatility enables optimization for sodium battery applications through modification of the organic linkers or metal centers.Expand Specific Solutions04 Polymer-based nanostructured matrices

Polymer-based nanostructured matrices offer flexible and adaptable frameworks for sodium metal deposition. These materials can be engineered with specific functional groups that interact favorably with sodium ions, directing their deposition in a controlled manner. The elasticity of polymer matrices accommodates the volume changes during sodium plating and stripping, while their versatile chemistry allows for incorporation of conductive additives to enhance electron transport throughout the host structure.Expand Specific Solutions05 Composite nanostructured hosts

Composite nanostructured hosts combine multiple materials to create synergistic properties for sodium metal deposition. These hybrids typically integrate conductive components (like carbon) with mechanically robust or chemically active materials (such as ceramics or polymers). The resulting composite structures offer enhanced sodium wetting, improved mechanical stability, and better control over the sodium deposition process. The interfaces between different materials in these composites can also serve as preferential nucleation sites for uniform sodium growth.Expand Specific Solutions

Leading Research Groups and Companies in Na-Metal Battery Field

The nanostructured hosts for sodium metal deposition technology landscape is currently in an early growth phase, characterized by significant academic research with emerging commercial interest. The market size remains relatively modest but is expanding rapidly due to increasing demand for sodium-based energy storage alternatives to lithium-ion batteries. From a technical maturity perspective, the field is still evolving, with key players including academic institutions (University of California, MIT, Rice University) leading fundamental research, while established companies (3M Innovative Properties, Nanosys) focus on materials development and commercialization. Research organizations (Chinese Academy of Sciences, CEA) are bridging fundamental science with applications. The competitive landscape shows a balanced distribution between academic innovation and industrial development, with increasing patent activity suggesting the technology is approaching commercial viability, though significant challenges in scalability and performance optimization remain.

The Regents of the University of California

Technical Solution: The University of California has pioneered innovative nanostructured host materials for sodium metal anodes, focusing on hierarchical porous frameworks that enable stable sodium deposition. Their technology utilizes biomass-derived carbon scaffolds with tailored surface chemistry and pore structures specifically optimized for sodium ion transport and deposition. These materials feature interconnected macro/meso/microporous architectures that effectively distribute sodium ions during plating, preventing localized accumulation that leads to dendrite formation. UC researchers have demonstrated that their carbon-based hosts can be functionalized with heteroatoms (N, S, O) to create polarized sites that guide uniform sodium nucleation. Recent advancements include the development of composite structures incorporating ceramic nanoparticles (TiO2, Al2O3) within the carbon framework to further enhance mechanical stability and sodium affinity, achieving Coulombic efficiencies exceeding 99.5% over extended cycling.

Strengths: Highly sustainable approach using renewable biomass precursors; excellent sodium wettability and distribution properties; demonstrated scalability potential through simple fabrication methods. Weaknesses: Some designs show increased interfacial resistance over extended cycling; mechanical integrity challenges under extreme fast charging conditions; optimization still needed for low-temperature performance.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed sophisticated nanostructured host materials for sodium metal anodes based on hierarchical carbon frameworks with precisely engineered surface chemistry. Their approach utilizes nitrogen-rich carbon nanomaterials derived from metal-organic frameworks (MOFs) that create uniform sodium nucleation sites across the host structure. These materials feature interconnected porous architectures with optimized pore size distributions (macro/meso/micropores) that facilitate sodium ion transport while physically constraining dendrite growth. CAS researchers have demonstrated that their carbon hosts can be further enhanced through heteroatom doping (N, S, P) to create polarized sites with strong sodium affinity, effectively reducing the nucleation barrier and promoting uniform deposition. Recent innovations include the development of composite structures incorporating ceramic nanoparticles (SiO2, Al2O3) within the carbon framework to enhance mechanical stability and sodium wettability, achieving remarkable cycling performance with over 1000 stable cycles at practical current densities.

Strengths: Excellent sodium wettability properties ensuring uniform deposition; scalable synthesis methods compatible with industrial production; superior dendrite suppression through combined physical/chemical mechanisms. Weaknesses: Some designs show increased interfacial resistance after extended cycling; performance degradation under extreme temperature conditions; further optimization needed for ultra-fast charging applications.

Key Patents and Research on Sodium Metal Hosting Materials

Method for depositing nanoparticles on a nanostructured metal oxide substrate

PatentInactiveUS9393591B2

Innovation

- A method involving the use of a bifunctional coupling agent with a phosphonic function to functionalize the nanostructured metal oxide substrate before grafting nanoparticles, allowing for controlled size, shape, and composition, and enhancing colloidal stability, using phosphonic acid effectively even in harsh conditions.

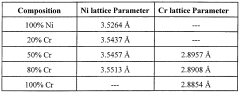

Nanostructured metals, metal alloys, metal carbides and metal alloy carbides and chemical synthesis thereof

PatentWO1998024576A1

Innovation

- A chemical synthetic method involving a starting solution of metal salts in a solvent, with a reducing agent added via atomization to control nucleation and growth, followed by filtration, passivation, and heat treatment, and optionally carburization to produce nanostructured metals, metal alloys, and metal carbides like nickel/chromium and nickel chromium carbide.

Sustainability and Resource Considerations for Na-based Batteries

The sustainability advantages of sodium-based batteries represent a significant driver for their development and adoption. Unlike lithium, sodium is abundantly available in the Earth's crust (2.6% vs. 0.002% for lithium) and oceans, making it substantially more accessible and geographically distributed. This abundance translates to lower extraction costs and reduced geopolitical supply risks compared to lithium resources, which are concentrated in regions like South America, Australia, and China.

The environmental footprint of sodium extraction and processing is considerably smaller than that of lithium. Traditional lithium extraction methods, particularly from salt flats, consume vast amounts of water—approximately 2 million liters per ton of lithium—often in water-stressed regions. In contrast, sodium can be obtained from seawater or common salt (NaCl) through less resource-intensive processes, resulting in lower carbon emissions and reduced ecosystem disruption.

When considering nanostructured hosts for sodium metal deposition, sustainability extends beyond raw material availability to manufacturing processes. Current fabrication methods for advanced nanostructured materials often involve energy-intensive processes and potentially toxic chemicals. Research indicates that more sustainable approaches, such as biomass-derived carbon frameworks and water-based synthesis routes, can reduce environmental impact while maintaining electrochemical performance.

End-of-life considerations also favor sodium-based systems. The recycling infrastructure for sodium batteries could potentially be less complex than for lithium-ion batteries due to the lower economic value of recovered materials, which paradoxically may encourage more comprehensive recycling systems focused on environmental benefits rather than material recovery economics.

The transition to nanostructured sodium hosts presents opportunities for circular economy approaches. For instance, carbon-based nanostructured hosts can be derived from agricultural waste or sustainable biomass sources, creating value chains that reduce waste while providing high-performance battery materials. Recent studies demonstrate that such bio-derived nanostructured hosts can achieve comparable performance to synthetic alternatives while significantly reducing environmental impact.

Energy requirements for sodium processing are approximately 30% lower than those for lithium, further enhancing the sustainability profile of Na-based batteries. This energy advantage, combined with sodium's abundance, positions Na-based batteries with nanostructured hosts as a promising technology pathway for large-scale energy storage applications where resource sustainability is prioritized over energy density considerations.

The environmental footprint of sodium extraction and processing is considerably smaller than that of lithium. Traditional lithium extraction methods, particularly from salt flats, consume vast amounts of water—approximately 2 million liters per ton of lithium—often in water-stressed regions. In contrast, sodium can be obtained from seawater or common salt (NaCl) through less resource-intensive processes, resulting in lower carbon emissions and reduced ecosystem disruption.

When considering nanostructured hosts for sodium metal deposition, sustainability extends beyond raw material availability to manufacturing processes. Current fabrication methods for advanced nanostructured materials often involve energy-intensive processes and potentially toxic chemicals. Research indicates that more sustainable approaches, such as biomass-derived carbon frameworks and water-based synthesis routes, can reduce environmental impact while maintaining electrochemical performance.

End-of-life considerations also favor sodium-based systems. The recycling infrastructure for sodium batteries could potentially be less complex than for lithium-ion batteries due to the lower economic value of recovered materials, which paradoxically may encourage more comprehensive recycling systems focused on environmental benefits rather than material recovery economics.

The transition to nanostructured sodium hosts presents opportunities for circular economy approaches. For instance, carbon-based nanostructured hosts can be derived from agricultural waste or sustainable biomass sources, creating value chains that reduce waste while providing high-performance battery materials. Recent studies demonstrate that such bio-derived nanostructured hosts can achieve comparable performance to synthetic alternatives while significantly reducing environmental impact.

Energy requirements for sodium processing are approximately 30% lower than those for lithium, further enhancing the sustainability profile of Na-based batteries. This energy advantage, combined with sodium's abundance, positions Na-based batteries with nanostructured hosts as a promising technology pathway for large-scale energy storage applications where resource sustainability is prioritized over energy density considerations.

Safety and Performance Benchmarking of Nanostructured Na Hosts

Safety and performance benchmarking of nanostructured sodium hosts represents a critical aspect in the development of next-generation sodium-based energy storage systems. Establishing standardized testing protocols is essential for meaningful comparisons across different nanostructured host materials and designs. Current benchmarking approaches typically evaluate several key parameters including cycling stability, Coulombic efficiency, rate capability, and dendrite suppression effectiveness.

The safety assessment of nanostructured Na hosts primarily focuses on thermal stability, mechanical integrity, and chemical compatibility with electrolytes. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) are commonly employed to determine thermal runaway thresholds and decomposition behaviors. Recent studies have demonstrated that carbon-based nanostructured hosts with optimized porosity exhibit superior thermal stability compared to metallic frameworks, with exothermic reactions typically delayed until temperatures exceed 150°C.

Mechanical stability testing involves evaluating the host's resistance to volume changes during sodium plating/stripping cycles. Nanoindentation techniques and in-situ TEM observations have revealed that 3D interconnected structures with hierarchical porosity generally outperform 2D planar designs. The benchmark for mechanical stability is currently set by graphene-based aerogels, which can accommodate volumetric changes exceeding 300% while maintaining structural integrity beyond 500 cycles.

Electrochemical performance benchmarks focus on several critical metrics. Current density capability serves as a primary indicator, with state-of-the-art nanostructured hosts achieving stable cycling at 5-10 mA/cm². Coulombic efficiency represents another crucial parameter, with the industry benchmark now approaching 99.9% for advanced carbon-based frameworks incorporating heteroatom doping. Cycle life expectations have also evolved, with leading nanostructured hosts demonstrating stable performance for 1000+ cycles at moderate current densities.

Dendrite suppression capability is quantified through a combination of electrochemical impedance spectroscopy (EIS), post-mortem SEM analysis, and short-circuit time measurements. The benchmark for dendrite resistance continues to improve, with recent metal-organic framework (MOF) derived hosts demonstrating stable cycling for over 2000 hours without short-circuiting under practical testing conditions.

Standardization efforts are currently underway to establish industry-wide protocols for benchmarking nanostructured Na hosts, with particular emphasis on accelerated testing methodologies that can reliably predict long-term performance. These initiatives aim to bridge the gap between laboratory demonstrations and commercial viability by ensuring that performance metrics translate to real-world operating conditions.

The safety assessment of nanostructured Na hosts primarily focuses on thermal stability, mechanical integrity, and chemical compatibility with electrolytes. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) are commonly employed to determine thermal runaway thresholds and decomposition behaviors. Recent studies have demonstrated that carbon-based nanostructured hosts with optimized porosity exhibit superior thermal stability compared to metallic frameworks, with exothermic reactions typically delayed until temperatures exceed 150°C.

Mechanical stability testing involves evaluating the host's resistance to volume changes during sodium plating/stripping cycles. Nanoindentation techniques and in-situ TEM observations have revealed that 3D interconnected structures with hierarchical porosity generally outperform 2D planar designs. The benchmark for mechanical stability is currently set by graphene-based aerogels, which can accommodate volumetric changes exceeding 300% while maintaining structural integrity beyond 500 cycles.

Electrochemical performance benchmarks focus on several critical metrics. Current density capability serves as a primary indicator, with state-of-the-art nanostructured hosts achieving stable cycling at 5-10 mA/cm². Coulombic efficiency represents another crucial parameter, with the industry benchmark now approaching 99.9% for advanced carbon-based frameworks incorporating heteroatom doping. Cycle life expectations have also evolved, with leading nanostructured hosts demonstrating stable performance for 1000+ cycles at moderate current densities.

Dendrite suppression capability is quantified through a combination of electrochemical impedance spectroscopy (EIS), post-mortem SEM analysis, and short-circuit time measurements. The benchmark for dendrite resistance continues to improve, with recent metal-organic framework (MOF) derived hosts demonstrating stable cycling for over 2000 hours without short-circuiting under practical testing conditions.

Standardization efforts are currently underway to establish industry-wide protocols for benchmarking nanostructured Na hosts, with particular emphasis on accelerated testing methodologies that can reliably predict long-term performance. These initiatives aim to bridge the gap between laboratory demonstrations and commercial viability by ensuring that performance metrics translate to real-world operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!