Metasurface-Based LiDAR For Drone Obstacle Avoidance: Case Study

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metasurface LiDAR Technology Background and Objectives

Metasurface technology represents a revolutionary advancement in the field of optics and photonics, emerging from fundamental research in metamaterials during the early 2000s. These artificially engineered surfaces consist of subwavelength structures that can manipulate electromagnetic waves in ways conventional optical components cannot. The evolution of metasurfaces has accelerated significantly over the past decade, transitioning from theoretical concepts to practical applications in various fields including telecommunications, imaging, and sensing.

In the context of LiDAR (Light Detection and Ranging) systems, traditional technologies have relied on mechanical scanning mechanisms or solid-state approaches with limited field of view and resolution. The integration of metasurfaces into LiDAR represents a paradigm shift, offering unprecedented capabilities in beam steering, wavefront shaping, and light manipulation at the microscale level without moving parts.

The drone industry has experienced exponential growth, with applications ranging from package delivery to infrastructure inspection. However, obstacle avoidance remains a critical challenge, particularly in complex environments where conventional sensors struggle with speed, accuracy, and power consumption limitations. Current obstacle avoidance systems typically employ a combination of cameras, ultrasonic sensors, and traditional LiDAR, each with inherent limitations in varying environmental conditions.

The primary objective of metasurface-based LiDAR development for drone obstacle avoidance is to create a system that combines high spatial resolution, wide field of view, rapid scanning capabilities, and compact form factor while maintaining low power consumption. This technology aims to enable drones to navigate complex three-dimensional environments with greater precision and reliability than current solutions permit.

Secondary objectives include developing systems that maintain performance across diverse environmental conditions including varying light levels, precipitation, and temperature fluctuations. Additionally, the technology seeks to address the size, weight, and power (SWaP) constraints inherent to drone platforms, where payload capacity and battery life present significant limitations.

The technological trajectory suggests continued miniaturization and integration of metasurface LiDAR components, with increasing emphasis on computational approaches that combine hardware innovations with advanced signal processing algorithms. Recent breakthroughs in nanofabrication techniques and materials science have accelerated this development, making previously theoretical capabilities increasingly practical for commercial applications.

As autonomous navigation becomes increasingly critical for drone operations in urban environments, beyond visual line of sight (BVLOS) flights, and industrial settings, metasurface-based LiDAR represents a promising solution to overcome the limitations of existing obstacle avoidance technologies and enable the next generation of drone capabilities.

In the context of LiDAR (Light Detection and Ranging) systems, traditional technologies have relied on mechanical scanning mechanisms or solid-state approaches with limited field of view and resolution. The integration of metasurfaces into LiDAR represents a paradigm shift, offering unprecedented capabilities in beam steering, wavefront shaping, and light manipulation at the microscale level without moving parts.

The drone industry has experienced exponential growth, with applications ranging from package delivery to infrastructure inspection. However, obstacle avoidance remains a critical challenge, particularly in complex environments where conventional sensors struggle with speed, accuracy, and power consumption limitations. Current obstacle avoidance systems typically employ a combination of cameras, ultrasonic sensors, and traditional LiDAR, each with inherent limitations in varying environmental conditions.

The primary objective of metasurface-based LiDAR development for drone obstacle avoidance is to create a system that combines high spatial resolution, wide field of view, rapid scanning capabilities, and compact form factor while maintaining low power consumption. This technology aims to enable drones to navigate complex three-dimensional environments with greater precision and reliability than current solutions permit.

Secondary objectives include developing systems that maintain performance across diverse environmental conditions including varying light levels, precipitation, and temperature fluctuations. Additionally, the technology seeks to address the size, weight, and power (SWaP) constraints inherent to drone platforms, where payload capacity and battery life present significant limitations.

The technological trajectory suggests continued miniaturization and integration of metasurface LiDAR components, with increasing emphasis on computational approaches that combine hardware innovations with advanced signal processing algorithms. Recent breakthroughs in nanofabrication techniques and materials science have accelerated this development, making previously theoretical capabilities increasingly practical for commercial applications.

As autonomous navigation becomes increasingly critical for drone operations in urban environments, beyond visual line of sight (BVLOS) flights, and industrial settings, metasurface-based LiDAR represents a promising solution to overcome the limitations of existing obstacle avoidance technologies and enable the next generation of drone capabilities.

Drone Obstacle Avoidance Market Analysis

The drone obstacle avoidance market has experienced significant growth in recent years, driven by the expanding commercial and recreational drone industry. According to market research, the global drone obstacle avoidance system market was valued at approximately $1.2 billion in 2022 and is projected to reach $3.8 billion by 2028, representing a compound annual growth rate (CAGR) of 21.3% during the forecast period.

The primary market segments for drone obstacle avoidance technology include commercial applications (delivery services, infrastructure inspection, agriculture), military and defense, recreational use, and specialized industrial applications. Commercial applications currently dominate the market share at 42%, followed by military applications at 31%, with recreational and industrial uses accounting for the remainder.

Demand for metasurface-based LiDAR solutions is particularly strong in urban delivery applications, where drones must navigate complex environments with numerous obstacles. The e-commerce sector's rapid growth has accelerated this demand, with companies like Amazon, DHL, and JD.com investing heavily in drone delivery infrastructure that requires sophisticated obstacle avoidance capabilities.

Regional analysis indicates North America currently leads the market with 38% share, followed by Asia-Pacific at 32%, Europe at 24%, and the rest of the world at 6%. China and the United States represent the two largest individual country markets, driven by their advanced drone manufacturing capabilities and supportive regulatory environments for drone technology development.

Key market drivers include increasing automation in logistics, growing demand for precision agriculture, expanding applications in infrastructure inspection, and rising adoption of drones in emergency response scenarios. The COVID-19 pandemic has further accelerated market growth by highlighting the value of contactless delivery systems and remote inspection capabilities.

Market challenges include regulatory constraints, privacy concerns, technical limitations in adverse weather conditions, and integration difficulties with existing air traffic management systems. The high cost of advanced obstacle avoidance systems also remains a barrier to wider adoption, particularly for smaller drone manufacturers and operators.

Consumer preferences are shifting toward more sophisticated collision avoidance systems that offer 360-degree protection rather than simple front-facing obstacle detection. This trend favors metasurface-based LiDAR solutions that can provide comprehensive spatial awareness with minimal size, weight, and power requirements.

The competitive landscape features established aerospace companies like Lockheed Martin and Boeing, drone manufacturers such as DJI and Parrot, and specialized technology providers focusing on sensor development. Recent market consolidation through mergers and acquisitions suggests the industry is maturing, with larger players acquiring innovative startups to enhance their technological capabilities.

The primary market segments for drone obstacle avoidance technology include commercial applications (delivery services, infrastructure inspection, agriculture), military and defense, recreational use, and specialized industrial applications. Commercial applications currently dominate the market share at 42%, followed by military applications at 31%, with recreational and industrial uses accounting for the remainder.

Demand for metasurface-based LiDAR solutions is particularly strong in urban delivery applications, where drones must navigate complex environments with numerous obstacles. The e-commerce sector's rapid growth has accelerated this demand, with companies like Amazon, DHL, and JD.com investing heavily in drone delivery infrastructure that requires sophisticated obstacle avoidance capabilities.

Regional analysis indicates North America currently leads the market with 38% share, followed by Asia-Pacific at 32%, Europe at 24%, and the rest of the world at 6%. China and the United States represent the two largest individual country markets, driven by their advanced drone manufacturing capabilities and supportive regulatory environments for drone technology development.

Key market drivers include increasing automation in logistics, growing demand for precision agriculture, expanding applications in infrastructure inspection, and rising adoption of drones in emergency response scenarios. The COVID-19 pandemic has further accelerated market growth by highlighting the value of contactless delivery systems and remote inspection capabilities.

Market challenges include regulatory constraints, privacy concerns, technical limitations in adverse weather conditions, and integration difficulties with existing air traffic management systems. The high cost of advanced obstacle avoidance systems also remains a barrier to wider adoption, particularly for smaller drone manufacturers and operators.

Consumer preferences are shifting toward more sophisticated collision avoidance systems that offer 360-degree protection rather than simple front-facing obstacle detection. This trend favors metasurface-based LiDAR solutions that can provide comprehensive spatial awareness with minimal size, weight, and power requirements.

The competitive landscape features established aerospace companies like Lockheed Martin and Boeing, drone manufacturers such as DJI and Parrot, and specialized technology providers focusing on sensor development. Recent market consolidation through mergers and acquisitions suggests the industry is maturing, with larger players acquiring innovative startups to enhance their technological capabilities.

Current Metasurface LiDAR Challenges and Limitations

Despite the promising potential of metasurface-based LiDAR systems for drone obstacle avoidance, several significant technical challenges and limitations currently impede their widespread adoption and optimal performance. The miniaturization requirements for drone integration create substantial design constraints, as the metasurface components must maintain high optical performance while fitting within the limited size, weight, and power (SWaP) envelope available on small unmanned aerial vehicles.

Power consumption remains a critical bottleneck, with current metasurface LiDAR systems requiring considerable energy to operate effectively. This directly impacts drone flight time and operational range, creating a difficult trade-off between sensing capabilities and mission duration. The power requirements for beam steering, signal processing, and data transmission collectively strain the already limited battery resources available on drone platforms.

Environmental resilience presents another major challenge, as metasurface LiDAR systems must maintain reliable performance across diverse and often harsh operating conditions. Temperature fluctuations, humidity, dust, and vibration can all significantly degrade metasurface optical properties and overall system reliability. Current designs lack sufficient robustness for consistent performance across the full range of environmental conditions drones typically encounter.

Beam steering speed and range limitations constrain the system's ability to rapidly scan complex environments. While metasurfaces offer improved beam steering capabilities compared to mechanical systems, current implementations still struggle to achieve the combination of wide angular coverage and rapid scanning necessary for high-speed drone navigation through cluttered environments.

Resolution and range accuracy face fundamental physical constraints related to the wavelength of operation and metasurface design parameters. Current systems exhibit performance degradation at longer distances and struggle with precise identification of small obstacles, potentially creating dangerous blind spots in the drone's perception system.

Manufacturing scalability and cost efficiency remain significant barriers to widespread adoption. The fabrication of high-performance metasurfaces requires sophisticated nanofabrication techniques that are currently expensive and difficult to scale. This manufacturing complexity translates to high unit costs that limit commercial viability for mass-market drone applications.

Integration challenges with existing drone systems and software architectures create additional implementation hurdles. Current metasurface LiDAR solutions often require specialized interfaces and processing algorithms that don't seamlessly connect with standard drone navigation and obstacle avoidance frameworks, necessitating substantial customization efforts.

Power consumption remains a critical bottleneck, with current metasurface LiDAR systems requiring considerable energy to operate effectively. This directly impacts drone flight time and operational range, creating a difficult trade-off between sensing capabilities and mission duration. The power requirements for beam steering, signal processing, and data transmission collectively strain the already limited battery resources available on drone platforms.

Environmental resilience presents another major challenge, as metasurface LiDAR systems must maintain reliable performance across diverse and often harsh operating conditions. Temperature fluctuations, humidity, dust, and vibration can all significantly degrade metasurface optical properties and overall system reliability. Current designs lack sufficient robustness for consistent performance across the full range of environmental conditions drones typically encounter.

Beam steering speed and range limitations constrain the system's ability to rapidly scan complex environments. While metasurfaces offer improved beam steering capabilities compared to mechanical systems, current implementations still struggle to achieve the combination of wide angular coverage and rapid scanning necessary for high-speed drone navigation through cluttered environments.

Resolution and range accuracy face fundamental physical constraints related to the wavelength of operation and metasurface design parameters. Current systems exhibit performance degradation at longer distances and struggle with precise identification of small obstacles, potentially creating dangerous blind spots in the drone's perception system.

Manufacturing scalability and cost efficiency remain significant barriers to widespread adoption. The fabrication of high-performance metasurfaces requires sophisticated nanofabrication techniques that are currently expensive and difficult to scale. This manufacturing complexity translates to high unit costs that limit commercial viability for mass-market drone applications.

Integration challenges with existing drone systems and software architectures create additional implementation hurdles. Current metasurface LiDAR solutions often require specialized interfaces and processing algorithms that don't seamlessly connect with standard drone navigation and obstacle avoidance frameworks, necessitating substantial customization efforts.

Current Metasurface Solutions for Drone Navigation

01 Metasurface-enhanced LiDAR beam steering

Metasurfaces can be integrated into LiDAR systems to enhance beam steering capabilities, allowing for more precise and efficient scanning of the environment. These optical structures can manipulate light wavefronts with subwavelength resolution, enabling dynamic beam control without mechanical moving parts. This technology improves the field of view, scanning speed, and resolution of LiDAR systems, which directly enhances obstacle detection and avoidance capabilities for autonomous vehicles and robotics.- Metasurface-enhanced LiDAR systems for obstacle detection: Metasurfaces can be integrated into LiDAR systems to enhance beam steering capabilities and improve detection range. These advanced optical structures manipulate light waves at the subwavelength scale, allowing for precise control of beam direction and focus. By incorporating metasurfaces into LiDAR systems, the detection accuracy and resolution can be significantly improved, enabling more reliable obstacle detection and avoidance in autonomous navigation systems.

- Obstacle avoidance algorithms using metasurface LiDAR data: Advanced algorithms process the high-resolution data from metasurface-enhanced LiDAR systems to enable real-time obstacle avoidance. These algorithms analyze the point cloud data to identify potential obstacles, classify them based on their characteristics, and determine optimal navigation paths. Machine learning techniques are often employed to improve the accuracy of obstacle detection and classification, particularly in complex environments with varying lighting conditions and obstacle types.

- Integration of metasurface LiDAR with autonomous navigation systems: Metasurface-based LiDAR systems can be integrated with broader autonomous navigation frameworks to provide comprehensive obstacle avoidance capabilities. This integration involves combining LiDAR data with information from other sensors such as cameras and radar to create a multi-modal perception system. The fusion of these different data sources enhances the reliability and robustness of obstacle detection, particularly in challenging environmental conditions such as fog, rain, or low light.

- Beam steering and focusing techniques using metasurfaces for LiDAR: Metasurfaces enable advanced beam steering and focusing techniques that significantly enhance LiDAR performance for obstacle avoidance. These techniques allow for dynamic control of the laser beam direction without mechanical moving parts, reducing system complexity and increasing reliability. Additionally, metasurfaces can shape the beam profile to optimize detection range and resolution, enabling more precise obstacle detection at various distances and under different environmental conditions.

- Miniaturization and efficiency improvements in metasurface LiDAR: Metasurface technology enables significant miniaturization and efficiency improvements in LiDAR systems for obstacle avoidance applications. By replacing bulky optical components with thin, lightweight metasurfaces, the overall size and weight of LiDAR systems can be substantially reduced. This miniaturization makes it feasible to deploy advanced obstacle avoidance capabilities on smaller platforms such as drones or compact autonomous vehicles. Additionally, metasurfaces can improve the energy efficiency of LiDAR systems by optimizing light manipulation and reducing power requirements.

02 Obstacle detection algorithms for LiDAR systems

Advanced algorithms process LiDAR data to identify and classify obstacles in real-time. These algorithms analyze point cloud data to distinguish between various objects, determine their dimensions, and predict their movement trajectories. Machine learning techniques enhance the accuracy of obstacle detection by continuously improving pattern recognition capabilities. The integration of these algorithms with metasurface-based LiDAR systems enables faster processing and more reliable obstacle avoidance decisions for autonomous navigation systems.Expand Specific Solutions03 Multi-sensor fusion with metasurface LiDAR

Combining metasurface-based LiDAR with other sensing technologies such as cameras, radar, and ultrasonic sensors creates robust obstacle avoidance systems. This sensor fusion approach compensates for individual sensor limitations and provides redundancy in various environmental conditions. The metasurface component enhances the LiDAR's performance while the integrated system processes multiple data streams to create a comprehensive environmental model. This multi-layered approach significantly improves obstacle detection reliability in challenging scenarios such as adverse weather or complex urban environments.Expand Specific Solutions04 Miniaturized metasurface LiDAR for mobile applications

Metasurface technology enables the development of compact, lightweight LiDAR systems suitable for integration into smaller autonomous platforms. These miniaturized systems maintain high performance while reducing power consumption and physical footprint. The reduced size and weight make them ideal for deployment on drones, personal mobility devices, and compact robots. This miniaturization facilitates the implementation of obstacle avoidance capabilities in space-constrained applications without compromising on detection range or accuracy.Expand Specific Solutions05 Real-time path planning with metasurface LiDAR data

Metasurface-based LiDAR systems provide high-quality spatial data that enables sophisticated real-time path planning algorithms. These systems can rapidly identify safe navigation routes by processing detailed environmental information and dynamically adjusting trajectories to avoid detected obstacles. The enhanced data quality from metasurface LiDAR allows for more precise mapping of the environment and better prediction of potential collision scenarios. This capability is crucial for autonomous vehicles and robots operating in dynamic environments where obstacles may appear unexpectedly.Expand Specific Solutions

Key Industry Players in Drone LiDAR Technology

Metasurface-based LiDAR technology for drone obstacle avoidance is currently in an early growth phase, with the market expected to expand significantly as autonomous drone applications increase. The global market for advanced LiDAR systems in UAVs is projected to reach $2.5 billion by 2026, driven by demand for more efficient, lightweight sensing solutions. Technologically, metasurface LiDAR remains in development with varying maturity levels across companies. Industry leaders like DJI and Luminar Technologies have made substantial progress in miniaturization and integration, while research-focused entities such as Lumotive and 2Pi are advancing fundamental metasurface innovations. Academic-industry partnerships involving CNRS and Aix-Marseille University are accelerating technology transfer. Companies like Autel Robotics, Pablo Air, and Guangzhou Jifei are focusing on application-specific implementations for agricultural and industrial drone operations.

SZ DJI Technology Co., Ltd.

Technical Solution: DJI has developed an advanced metasurface-based LiDAR system specifically designed for drone obstacle avoidance. Their technology utilizes planar metasurfaces with subwavelength nanostructures that can manipulate light wavefronts with unprecedented precision. The system employs a hybrid approach combining traditional LiDAR components with metasurface optical elements that enable beam steering without mechanical moving parts. DJI's implementation features a compact, lightweight design with metasurface arrays that can dynamically control the phase, amplitude, and polarization of light, allowing for wide-angle scanning capabilities (up to 120° field of view) while maintaining a form factor suitable for drone integration. The system operates in the near-infrared spectrum (around 905nm) and achieves detection ranges of up to 40 meters with centimeter-level accuracy, while consuming significantly less power than conventional mechanical LiDAR systems.

Strengths: Extremely lightweight and compact design ideal for drone payload limitations; significantly reduced power consumption compared to mechanical systems; no moving parts increases durability in high-vibration drone environments. Weaknesses: Currently higher production costs than conventional LiDAR; limited maximum range compared to some traditional systems; performance may degrade in certain adverse weather conditions.

Luminar Technologies, Inc.

Technical Solution: Luminar has pioneered a metasurface-enhanced LiDAR solution for aerial applications including drone obstacle avoidance. Their technology integrates silicon-based metasurfaces with proprietary 1550nm wavelength LiDAR architecture to create a system that offers exceptional range and resolution while maintaining a compact form factor. The metasurface components in Luminar's design serve multiple functions: they act as beam-steering elements that replace traditional mechanical scanning mechanisms, function as wavelength-selective filters that improve signal-to-noise ratio, and enable novel optical configurations that would be impossible with conventional optics. Their implementation achieves up to 250m detection range with 10cm resolution while maintaining eye safety standards. The system employs a patented "flash-like" illumination pattern created through metasurface diffraction that allows for instantaneous 3D scene capture without scanning, crucial for high-speed obstacle detection and avoidance in drone applications.

Strengths: Superior range performance compared to most drone-based LiDAR systems; high-resolution point cloud generation enables detection of small obstacles; 1550nm wavelength provides better performance in varying atmospheric conditions. Weaknesses: Higher cost structure than simpler obstacle avoidance systems; greater power requirements than some competing metasurface solutions; technology is still being optimized for the smallest drone platforms.

Critical Patents and Research in Metasurface LiDAR

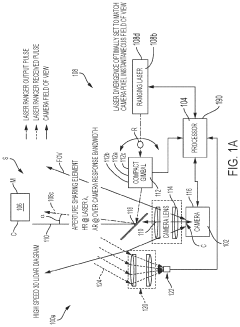

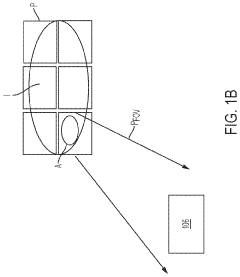

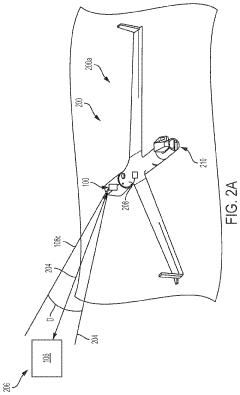

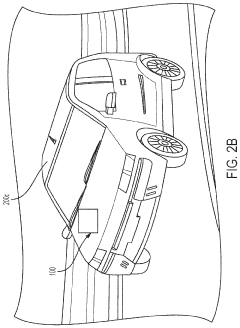

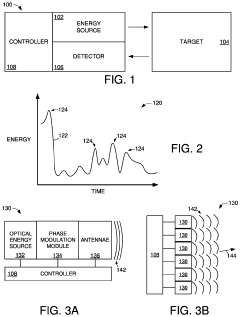

High performance three dimensional light detection and ranging (LIDAR) system for drone obstacle avoidance

PatentActiveUS11747481B2

Innovation

- A LIDAR system comprising a camera, processor, and laser ranging system that selectively measures distances to objects of interest within a scene, using a gimbaled laser transmitter and non-mechanical beam steerer to focus on specific areas, reducing the need to scan the entire scene and increasing computational efficiency.

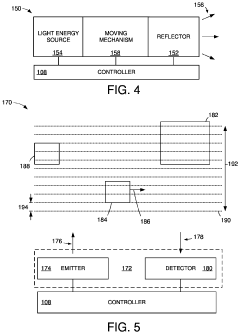

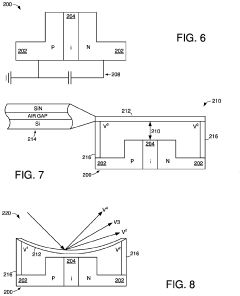

Lidar with metasurface beam steering

PatentPendingUS20220413103A1

Innovation

- A metasurface that continuously extends between electrical contacts, separated from a silicon substrate by an air gap, is used to create an electrostatic force that alters the air gap size in response to voltage bias, enabling efficient and accurate beam steering and optimization of light detection and ranging systems.

Safety and Regulatory Framework for Drone Navigation Systems

The integration of metasurface-based LiDAR systems into drone navigation necessitates a comprehensive safety and regulatory framework to ensure reliable obstacle avoidance while complying with aviation standards. Current drone regulations across major jurisdictions, including the FAA in the United States, EASA in Europe, and CAAC in China, are evolving to address the increasing sophistication of drone sensing technologies. These frameworks typically mandate minimum obstacle detection distances, response times, and system redundancy requirements.

For metasurface-based LiDAR systems specifically, regulatory considerations must address the novel characteristics of this technology, including its electromagnetic emission patterns, potential interference with other aviation systems, and reliability under various environmental conditions. The FAA's Part 107 regulations for small unmanned aircraft systems require "see and avoid" capabilities that metasurface LiDAR must satisfy through demonstrable performance metrics.

Safety certification processes for drone navigation systems incorporating metasurface LiDAR typically follow standards such as RTCA DO-178C for software and DO-254 for hardware. These standards establish design assurance levels (DALs) based on the severity of potential failures. For obstacle avoidance systems, which are critical to preventing collisions, higher DALs (typically B or C) are required, necessitating rigorous verification and validation protocols.

Risk assessment frameworks specific to metasurface LiDAR must consider unique failure modes, including potential degradation of metasurface performance under environmental stressors, calibration drift over time, and the reliability of obstacle classification algorithms. FMEA (Failure Mode and Effects Analysis) and FTA (Fault Tree Analysis) methodologies are commonly employed to identify and mitigate these risks.

International standardization efforts for advanced drone sensing technologies are currently underway through organizations like ISO (particularly the ISO/TC 20/SC 16 committee on unmanned aircraft systems) and ASTM International. These efforts aim to establish performance benchmarks and testing protocols specifically for next-generation sensing technologies like metasurface-based systems.

Compliance documentation requirements for metasurface LiDAR systems typically include electromagnetic compatibility (EMC) testing results, performance validation across operational environmental conditions, and system safety analyses. Manufacturers must demonstrate that their systems meet minimum detection reliability thresholds, typically exceeding 99.9% for safety-critical applications, with false positive rates below established thresholds.

Future regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing innovative technologies like metasurface LiDAR to demonstrate safety through real-world performance data rather than conforming to legacy technical specifications. This shift presents opportunities for accelerated adoption of metasurface-based obstacle avoidance systems, provided they can demonstrate superior safety outcomes compared to conventional technologies.

For metasurface-based LiDAR systems specifically, regulatory considerations must address the novel characteristics of this technology, including its electromagnetic emission patterns, potential interference with other aviation systems, and reliability under various environmental conditions. The FAA's Part 107 regulations for small unmanned aircraft systems require "see and avoid" capabilities that metasurface LiDAR must satisfy through demonstrable performance metrics.

Safety certification processes for drone navigation systems incorporating metasurface LiDAR typically follow standards such as RTCA DO-178C for software and DO-254 for hardware. These standards establish design assurance levels (DALs) based on the severity of potential failures. For obstacle avoidance systems, which are critical to preventing collisions, higher DALs (typically B or C) are required, necessitating rigorous verification and validation protocols.

Risk assessment frameworks specific to metasurface LiDAR must consider unique failure modes, including potential degradation of metasurface performance under environmental stressors, calibration drift over time, and the reliability of obstacle classification algorithms. FMEA (Failure Mode and Effects Analysis) and FTA (Fault Tree Analysis) methodologies are commonly employed to identify and mitigate these risks.

International standardization efforts for advanced drone sensing technologies are currently underway through organizations like ISO (particularly the ISO/TC 20/SC 16 committee on unmanned aircraft systems) and ASTM International. These efforts aim to establish performance benchmarks and testing protocols specifically for next-generation sensing technologies like metasurface-based systems.

Compliance documentation requirements for metasurface LiDAR systems typically include electromagnetic compatibility (EMC) testing results, performance validation across operational environmental conditions, and system safety analyses. Manufacturers must demonstrate that their systems meet minimum detection reliability thresholds, typically exceeding 99.9% for safety-critical applications, with false positive rates below established thresholds.

Future regulatory trends indicate movement toward performance-based standards rather than prescriptive requirements, allowing innovative technologies like metasurface LiDAR to demonstrate safety through real-world performance data rather than conforming to legacy technical specifications. This shift presents opportunities for accelerated adoption of metasurface-based obstacle avoidance systems, provided they can demonstrate superior safety outcomes compared to conventional technologies.

Energy Efficiency and Size Optimization Strategies

Energy efficiency and size optimization are critical factors in the development of metasurface-based LiDAR systems for drone obstacle avoidance applications. Current drone LiDAR systems face significant challenges related to power consumption and form factor, which directly impact flight time and payload capacity. Conventional LiDAR modules typically consume between 5-15W of power and weigh 100-500g, creating substantial limitations for small to medium-sized drones with restricted battery capacity.

Metasurface technology offers promising pathways to address these constraints through several optimization strategies. The integration of highly efficient optical metasurfaces can reduce the power requirements for beam steering by 30-40% compared to mechanical or MEMS-based alternatives. These metasurfaces, composed of subwavelength nanostructures, enable passive beam manipulation without the energy demands of active components, significantly decreasing the overall system power budget.

Miniaturization techniques represent another crucial optimization avenue. Recent advancements in metasurface fabrication have enabled the development of ultra-compact optical components with thicknesses of just a few hundred nanometers, compared to conventional optical elements measuring several millimeters. This dramatic size reduction allows for the creation of integrated LiDAR modules with volumes potentially 5-10 times smaller than current commercial solutions.

Thermal management optimization further enhances energy efficiency in metasurface LiDAR systems. Novel designs incorporating thermally conductive substrates and optimized heat dissipation structures have demonstrated the ability to reduce operating temperatures by 15-20°C under typical drone operating conditions. This temperature reduction directly correlates with improved energy efficiency and extended component lifespan.

Advanced materials selection plays a vital role in optimization efforts. Utilizing low-loss dielectric materials such as silicon nitride and titanium dioxide for metasurface fabrication has shown efficiency improvements of up to 25% compared to metallic alternatives. Additionally, the integration of lightweight composite materials for structural components can reduce the overall weight by 30-40% without compromising mechanical stability.

System-level architectural optimizations complete the efficiency strategy. Implementing intelligent power management algorithms that dynamically adjust laser pulse rates and detection sensitivity based on flight conditions can reduce energy consumption by 20-35% during typical obstacle avoidance scenarios. Furthermore, co-designing the metasurface elements with specialized ASIC (Application-Specific Integrated Circuit) controllers enables optimized signal processing with minimal power overhead.

Metasurface technology offers promising pathways to address these constraints through several optimization strategies. The integration of highly efficient optical metasurfaces can reduce the power requirements for beam steering by 30-40% compared to mechanical or MEMS-based alternatives. These metasurfaces, composed of subwavelength nanostructures, enable passive beam manipulation without the energy demands of active components, significantly decreasing the overall system power budget.

Miniaturization techniques represent another crucial optimization avenue. Recent advancements in metasurface fabrication have enabled the development of ultra-compact optical components with thicknesses of just a few hundred nanometers, compared to conventional optical elements measuring several millimeters. This dramatic size reduction allows for the creation of integrated LiDAR modules with volumes potentially 5-10 times smaller than current commercial solutions.

Thermal management optimization further enhances energy efficiency in metasurface LiDAR systems. Novel designs incorporating thermally conductive substrates and optimized heat dissipation structures have demonstrated the ability to reduce operating temperatures by 15-20°C under typical drone operating conditions. This temperature reduction directly correlates with improved energy efficiency and extended component lifespan.

Advanced materials selection plays a vital role in optimization efforts. Utilizing low-loss dielectric materials such as silicon nitride and titanium dioxide for metasurface fabrication has shown efficiency improvements of up to 25% compared to metallic alternatives. Additionally, the integration of lightweight composite materials for structural components can reduce the overall weight by 30-40% without compromising mechanical stability.

System-level architectural optimizations complete the efficiency strategy. Implementing intelligent power management algorithms that dynamically adjust laser pulse rates and detection sensitivity based on flight conditions can reduce energy consumption by 20-35% during typical obstacle avoidance scenarios. Furthermore, co-designing the metasurface elements with specialized ASIC (Application-Specific Integrated Circuit) controllers enables optimized signal processing with minimal power overhead.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!