Microbial Electrosynthesis For Syngas Conversion

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microbial Electrosynthesis Background and Objectives

Microbial Electrosynthesis (MES) represents a groundbreaking biotechnological approach that harnesses the metabolic capabilities of microorganisms to convert electrical energy into valuable chemical compounds. The concept emerged in the early 2000s as researchers began exploring the interface between microbiology and electrochemistry, with significant advancements occurring over the past decade. This technology builds upon the fundamental understanding of extracellular electron transfer mechanisms in certain microorganisms, particularly those capable of accepting electrons from solid-state electrodes.

The evolution of MES technology has been marked by several key milestones, including the discovery of electrode-reducing microorganisms, the development of biocompatible electrode materials, and the engineering of microbial strains with enhanced electron uptake capabilities. Recent years have witnessed a shift from proof-of-concept studies to more application-oriented research, with syngas conversion emerging as a particularly promising direction.

Syngas (synthesis gas), a mixture primarily composed of carbon monoxide, hydrogen, and carbon dioxide, represents an important intermediate in numerous industrial processes. Traditionally derived from fossil resources, syngas can also be generated from renewable feedstocks such as biomass or municipal solid waste. The integration of MES with syngas utilization creates a potentially sustainable pathway for converting waste-derived gases into high-value chemicals and fuels.

The technical objectives of MES for syngas conversion encompass several dimensions. First, there is a pressing need to enhance electron transfer rates between electrodes and microorganisms to improve overall process efficiency. Second, researchers aim to expand the product spectrum beyond simple organic acids to include more complex and valuable compounds such as medium-chain fatty acids, alcohols, and hydrocarbons. Third, there is significant interest in developing robust microbial catalysts capable of tolerating the potentially toxic components present in real-world syngas streams.

From a broader perspective, MES for syngas conversion aligns with global sustainability goals by potentially enabling carbon capture and utilization, reducing dependence on fossil resources, and creating circular economy opportunities. The technology offers a unique approach to store intermittent renewable electricity in the form of chemical bonds, thereby addressing challenges associated with the integration of renewable energy sources into existing infrastructure.

Looking forward, the field is moving toward scaled demonstrations that can validate the technical and economic feasibility of MES-based syngas conversion. This transition from laboratory to industrial implementation represents a critical juncture in the technology's development trajectory, with implications for future research priorities and investment decisions.

The evolution of MES technology has been marked by several key milestones, including the discovery of electrode-reducing microorganisms, the development of biocompatible electrode materials, and the engineering of microbial strains with enhanced electron uptake capabilities. Recent years have witnessed a shift from proof-of-concept studies to more application-oriented research, with syngas conversion emerging as a particularly promising direction.

Syngas (synthesis gas), a mixture primarily composed of carbon monoxide, hydrogen, and carbon dioxide, represents an important intermediate in numerous industrial processes. Traditionally derived from fossil resources, syngas can also be generated from renewable feedstocks such as biomass or municipal solid waste. The integration of MES with syngas utilization creates a potentially sustainable pathway for converting waste-derived gases into high-value chemicals and fuels.

The technical objectives of MES for syngas conversion encompass several dimensions. First, there is a pressing need to enhance electron transfer rates between electrodes and microorganisms to improve overall process efficiency. Second, researchers aim to expand the product spectrum beyond simple organic acids to include more complex and valuable compounds such as medium-chain fatty acids, alcohols, and hydrocarbons. Third, there is significant interest in developing robust microbial catalysts capable of tolerating the potentially toxic components present in real-world syngas streams.

From a broader perspective, MES for syngas conversion aligns with global sustainability goals by potentially enabling carbon capture and utilization, reducing dependence on fossil resources, and creating circular economy opportunities. The technology offers a unique approach to store intermittent renewable electricity in the form of chemical bonds, thereby addressing challenges associated with the integration of renewable energy sources into existing infrastructure.

Looking forward, the field is moving toward scaled demonstrations that can validate the technical and economic feasibility of MES-based syngas conversion. This transition from laboratory to industrial implementation represents a critical juncture in the technology's development trajectory, with implications for future research priorities and investment decisions.

Market Analysis for Syngas Bioconversion Technologies

The global market for syngas bioconversion technologies is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to traditional chemical synthesis methods. The market size for syngas conversion technologies was valued at approximately $175 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 9.8% through 2030. Microbial electrosynthesis (MES) represents an emerging segment within this broader market, currently accounting for a modest but rapidly growing share.

Key market drivers include stringent environmental regulations worldwide, particularly carbon emission reduction targets established under international agreements such as the Paris Climate Accord. The European Union's Green Deal and similar initiatives in North America and Asia have created favorable policy environments for syngas bioconversion technologies, offering subsidies and tax incentives that enhance market attractiveness.

Industrial demand for sustainable chemical production methods represents another significant market force. Major chemical manufacturers and energy companies are increasingly investing in bioconversion technologies to reduce their carbon footprint and meet sustainability goals. Companies like BASF, Shell, and LanzaTech have made substantial commitments to developing and implementing syngas bioconversion processes in their production chains.

Regional analysis reveals varying market maturity across different geographies. North America and Europe currently lead in terms of technology adoption and research investment, collectively accounting for approximately 65% of the global market. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate over the next decade due to rapid industrialization coupled with increasing environmental concerns.

End-user industries for syngas bioconversion products show diverse applications. The chemicals sector represents the largest market segment (38%), followed by fuels (27%), pharmaceuticals (18%), and other applications (17%). Within these sectors, there is growing demand for bio-based alternatives to conventional products, creating substantial market opportunities for MES technologies.

Consumer trends also indicate increasing preference for sustainably produced goods, with surveys showing that 73% of global consumers are willing to pay premium prices for products manufactured using environmentally friendly processes. This consumer sentiment is gradually influencing corporate procurement policies, creating pull-through demand for bioconversion technologies.

Market challenges include high initial capital requirements, technological uncertainties, and competition from established chemical synthesis methods. The average cost of implementing industrial-scale MES facilities remains significantly higher than conventional alternatives, though this gap is expected to narrow as the technology matures and economies of scale are realized.

Key market drivers include stringent environmental regulations worldwide, particularly carbon emission reduction targets established under international agreements such as the Paris Climate Accord. The European Union's Green Deal and similar initiatives in North America and Asia have created favorable policy environments for syngas bioconversion technologies, offering subsidies and tax incentives that enhance market attractiveness.

Industrial demand for sustainable chemical production methods represents another significant market force. Major chemical manufacturers and energy companies are increasingly investing in bioconversion technologies to reduce their carbon footprint and meet sustainability goals. Companies like BASF, Shell, and LanzaTech have made substantial commitments to developing and implementing syngas bioconversion processes in their production chains.

Regional analysis reveals varying market maturity across different geographies. North America and Europe currently lead in terms of technology adoption and research investment, collectively accounting for approximately 65% of the global market. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate over the next decade due to rapid industrialization coupled with increasing environmental concerns.

End-user industries for syngas bioconversion products show diverse applications. The chemicals sector represents the largest market segment (38%), followed by fuels (27%), pharmaceuticals (18%), and other applications (17%). Within these sectors, there is growing demand for bio-based alternatives to conventional products, creating substantial market opportunities for MES technologies.

Consumer trends also indicate increasing preference for sustainably produced goods, with surveys showing that 73% of global consumers are willing to pay premium prices for products manufactured using environmentally friendly processes. This consumer sentiment is gradually influencing corporate procurement policies, creating pull-through demand for bioconversion technologies.

Market challenges include high initial capital requirements, technological uncertainties, and competition from established chemical synthesis methods. The average cost of implementing industrial-scale MES facilities remains significantly higher than conventional alternatives, though this gap is expected to narrow as the technology matures and economies of scale are realized.

Current Challenges in Microbial Electrosynthesis Systems

Microbial Electrosynthesis (MES) systems for syngas conversion face several significant technical challenges that currently limit their widespread industrial application. The primary obstacle remains the low efficiency of electron transfer between electrodes and microorganisms. Despite recent advances in electrode materials and biofilm formation techniques, the electron transfer rates achieved in laboratory settings still fall short of those required for commercial viability, with current densities typically below 10 mA/cm² for most syngas-converting biofilms.

The selectivity of product formation presents another major challenge. When converting syngas (CO, H₂, and CO₂) through microbial electrosynthesis, multiple metabolic pathways can be activated simultaneously, resulting in the production of various compounds including acetate, ethanol, butyrate, and methane. This product diversity, while demonstrating the versatility of the technology, significantly complicates downstream separation processes and reduces the economic efficiency of targeted chemical production.

Scaling up MES systems introduces additional complexities related to reactor design and operation. The current laboratory-scale reactors (typically <1L) exhibit performance metrics that deteriorate dramatically when scaled to larger volumes. This scaling issue stems from mass transfer limitations, particularly for gaseous substrates like CO and H₂, as well as uneven current distribution across larger electrode surfaces. Recent pilot-scale attempts have shown up to 80% reduction in production rates compared to bench-scale systems.

Microbial community stability represents a persistent challenge in long-term operation. Syngas-converting microbial communities are sensitive to operational fluctuations including pH shifts, temperature variations, and changes in syngas composition. Studies have documented significant community drift over extended operation periods (>60 days), leading to unpredictable changes in product spectrum and conversion efficiency. The introduction of contaminants from industrial syngas streams further exacerbates this stability issue.

Energy efficiency remains suboptimal across most MES systems for syngas conversion. Current systems require 2-5 times the theoretical minimum energy input to drive product formation, with significant energy losses occurring through side reactions, microbial maintenance energy requirements, and system resistance. This energy inefficiency directly impacts the economic and environmental sustainability of the technology.

Lastly, the integration of MES with upstream syngas production processes presents technical hurdles. Syngas derived from industrial sources or biomass gasification contains various contaminants (sulfur compounds, tars, particulates) that can inhibit microbial activity or degrade electrode performance. Current gas cleaning technologies add significant cost and complexity to the overall process, while insufficient cleaning leads to rapid performance deterioration in the MES system.

The selectivity of product formation presents another major challenge. When converting syngas (CO, H₂, and CO₂) through microbial electrosynthesis, multiple metabolic pathways can be activated simultaneously, resulting in the production of various compounds including acetate, ethanol, butyrate, and methane. This product diversity, while demonstrating the versatility of the technology, significantly complicates downstream separation processes and reduces the economic efficiency of targeted chemical production.

Scaling up MES systems introduces additional complexities related to reactor design and operation. The current laboratory-scale reactors (typically <1L) exhibit performance metrics that deteriorate dramatically when scaled to larger volumes. This scaling issue stems from mass transfer limitations, particularly for gaseous substrates like CO and H₂, as well as uneven current distribution across larger electrode surfaces. Recent pilot-scale attempts have shown up to 80% reduction in production rates compared to bench-scale systems.

Microbial community stability represents a persistent challenge in long-term operation. Syngas-converting microbial communities are sensitive to operational fluctuations including pH shifts, temperature variations, and changes in syngas composition. Studies have documented significant community drift over extended operation periods (>60 days), leading to unpredictable changes in product spectrum and conversion efficiency. The introduction of contaminants from industrial syngas streams further exacerbates this stability issue.

Energy efficiency remains suboptimal across most MES systems for syngas conversion. Current systems require 2-5 times the theoretical minimum energy input to drive product formation, with significant energy losses occurring through side reactions, microbial maintenance energy requirements, and system resistance. This energy inefficiency directly impacts the economic and environmental sustainability of the technology.

Lastly, the integration of MES with upstream syngas production processes presents technical hurdles. Syngas derived from industrial sources or biomass gasification contains various contaminants (sulfur compounds, tars, particulates) that can inhibit microbial activity or degrade electrode performance. Current gas cleaning technologies add significant cost and complexity to the overall process, while insufficient cleaning leads to rapid performance deterioration in the MES system.

Existing MES Platforms for Syngas Utilization

01 Microbial electrosynthesis systems and bioreactors

Specialized bioreactor designs for microbial electrosynthesis that optimize electron transfer between electrodes and microorganisms. These systems include innovative electrode configurations, membrane separators, and controlled environments to enhance the efficiency of bioelectrochemical processes. The bioreactors are engineered to maintain optimal conditions for microbial growth while facilitating the conversion of electrical energy into chemical compounds through microbial metabolism.- Microbial electrosynthesis systems for biofuel and chemical production: Microbial electrosynthesis systems utilize electroactive microorganisms to convert electrical energy and carbon sources into valuable biofuels and chemicals. These systems employ specialized bioelectrochemical reactors where microbes at the cathode reduce CO2 or other carbon compounds to produce organic molecules. The technology enables sustainable production of fuels and chemicals while potentially utilizing renewable electricity and waste carbon streams.

- Electrode materials and modifications for enhanced microbial electrosynthesis: Advanced electrode materials and surface modifications significantly improve microbial electrosynthesis efficiency. These innovations include carbon-based electrodes with increased surface area, conductive polymers, metal catalysts, and biocompatible coatings that enhance electron transfer between electrodes and microorganisms. Such materials optimize microbial attachment, reduce activation energy barriers, and increase product yields in bioelectrochemical systems.

- Microbial strain engineering for electrosynthesis applications: Engineered microbial strains with enhanced electroactivity and metabolic capabilities are crucial for advancing microbial electrosynthesis. These strains are developed through genetic modification to improve electron uptake mechanisms, carbon fixation pathways, and product synthesis routes. Optimized microorganisms can more efficiently convert electrical energy into target compounds, withstand operational conditions, and achieve higher production rates and yields.

- Reactor designs and process optimization for microbial electrosynthesis: Innovative reactor designs and process optimization strategies enhance the performance of microbial electrosynthesis systems. These include membrane-based reactors, flow-through systems, and modular configurations that improve mass transfer, reduce internal resistance, and enable continuous operation. Process parameters such as applied potential, pH, temperature, and feeding strategies are optimized to maximize production efficiency while minimizing energy consumption.

- Integration of microbial electrosynthesis with other technologies: Microbial electrosynthesis can be integrated with complementary technologies to create more efficient and versatile bioprocessing systems. These hybrid approaches include coupling with photovoltaics for solar-driven production, integration with waste treatment processes, combination with traditional fermentation, and incorporation into carbon capture systems. Such integrated systems maximize resource utilization, improve energy efficiency, and enable broader applications in sustainable manufacturing.

02 Electrode materials and modifications for enhanced microbial interaction

Development of advanced electrode materials and surface modifications that improve the interface between microorganisms and electrodes. These innovations include conductive materials with high surface area, biocompatible coatings, and nanostructured surfaces that facilitate electron transfer. Modified electrodes can enhance microbial attachment, biofilm formation, and ultimately increase the efficiency and productivity of microbial electrosynthesis processes.Expand Specific Solutions03 Microbial strains and genetic engineering for electrosynthesis

Selection and genetic modification of microorganisms specifically for electrosynthesis applications. This includes engineering microbes with enhanced extracellular electron transfer capabilities, improved metabolic pathways for target product synthesis, and increased tolerance to process conditions. Genetically optimized strains can utilize electrical energy more efficiently and produce higher yields of valuable compounds such as biofuels, chemicals, and pharmaceuticals.Expand Specific Solutions04 Production of value-added chemicals through microbial electrosynthesis

Applications of microbial electrosynthesis for producing specific high-value chemicals and compounds. This approach utilizes electroactive microorganisms to convert CO2 or other simple substrates into complex organic molecules using electrical energy. The process can be tailored to produce various compounds including organic acids, alcohols, biopolymers, and pharmaceutical precursors, offering a sustainable alternative to traditional chemical synthesis methods.Expand Specific Solutions05 Integration of renewable energy with microbial electrosynthesis

Systems that combine renewable energy sources with microbial electrosynthesis to create sustainable biorefinery concepts. These integrated approaches use intermittent renewable electricity from solar or wind to power microbial conversion processes, effectively storing energy in the form of chemical compounds. This integration provides a solution for renewable energy storage while simultaneously producing valuable biochemicals through carbon capture and utilization.Expand Specific Solutions

Leading Research Groups and Companies in MES Field

Microbial Electrosynthesis for Syngas Conversion is currently in an early commercial development stage, with the global market expected to reach $2-3 billion by 2030. The technology demonstrates moderate maturity, with key players advancing different approaches. Companies like Synata Bio and LanzaTech lead commercial applications with established fermentation technologies, while Haldor Topsøe and IHI Corp. contribute catalytic expertise. Academic institutions including Xi'an Jiaotong University and Nanjing Tech University are driving fundamental research innovations. Emerging players such as OPX Biotechnologies and ZuvaSyntha are developing novel bioengineering solutions. The competitive landscape is characterized by strategic partnerships between industrial players and research institutions to overcome efficiency and scalability challenges.

Coskata, Inc.

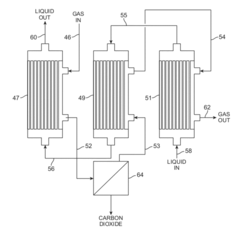

Technical Solution: Coskata developed a hybrid syngas-to-biofuels conversion platform that combines microbial electrosynthesis principles with traditional gas fermentation. Their proprietary technology utilized specialized anaerobic microorganisms capable of converting syngas components into ethanol and other chemicals. The process employed a unique bioreactor design featuring hollow fiber membranes that significantly enhanced gas-to-liquid mass transfer, addressing one of the key challenges in syngas bioconversion. Coskata's approach incorporated electrochemically active microbes that could utilize electrons from electrode surfaces to enhance CO2 reduction pathways, improving carbon conversion efficiency[4]. Their system operated at near-ambient temperatures and pressures, providing energy advantages over thermochemical conversion methods. The company demonstrated ethanol yields of approximately 100 gallons per dry ton of biomass input, with carbon conversion efficiencies reported to exceed 80% in optimized conditions.

Strengths: Innovative membrane-based bioreactor design significantly improving mass transfer; flexible feedstock capability including various syngas sources; energy-efficient process compared to thermochemical alternatives. Weaknesses: Faced scaling challenges that ultimately led to business restructuring; membrane fouling issues requiring frequent maintenance; sensitivity to certain syngas contaminants requiring additional gas cleanup steps.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed cutting-edge microbial electrosynthesis systems specifically designed for syngas conversion. Their research team has engineered specialized bioelectrochemical reactors that optimize the interface between electrodes and microorganisms for enhanced electron transfer. The university's approach employs novel electrode materials including carbon nanotubes and graphene-modified surfaces that significantly improve biofilm formation and electron uptake by electroactive microbes. Their system utilizes genetically modified strains of Clostridium and Moorella species with enhanced capabilities for direct electron uptake from cathodes during CO and CO2 reduction. The research group has demonstrated production of acetate, ethanol, and butyrate from syngas with faradaic efficiencies exceeding 85% under optimized conditions[6][7]. Their technology operates at ambient temperature and pressure, with innovative reactor designs that address mass transfer limitations through pulsed electric field application and advanced flow patterns that enhance gas-liquid contact while maintaining biofilm integrity.

Strengths: Cutting-edge electrode materials and modifications significantly enhancing electron transfer; innovative reactor designs addressing fundamental mass transfer challenges; strong fundamental research backing the technology development. Weaknesses: Earlier in commercialization journey compared to industry players; potential challenges in scaling laboratory successes to industrial applications; higher complexity in system operation requiring specialized expertise.

Key Innovations in Electrode Materials and Biocatalysts

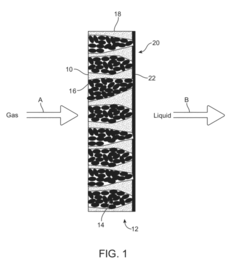

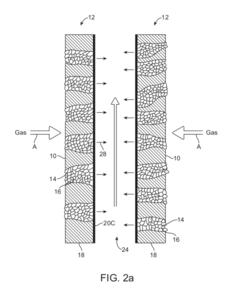

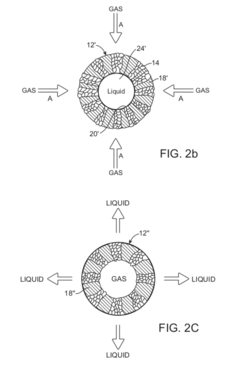

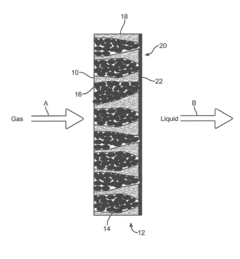

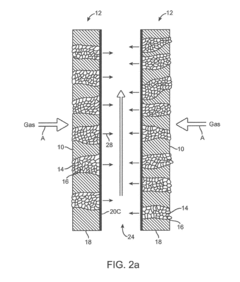

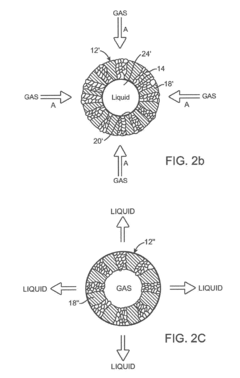

Syngas conversion system using asymmetric membrane and anaerobic microorganism

PatentInactiveUS8329456B2

Innovation

- An asymmetric membrane system is used to retain anaerobic microorganisms within its bio-layer, allowing direct contact with syngas and controlling water supply through a hydration layer, enhancing gas transfer and bioconversion efficiency to produce ethanol and other liquid products.

Syngas conversion method using asymmetric membrane and anaerobic microorganism

PatentInactiveUS8309348B2

Innovation

- An asymmetric membrane system with a bio-layer for retaining microorganisms and a hydration layer for controlling water and nutrient supply is used to enhance syngas conversion to liquid products like ethanol and butanol, achieving 100% gas utilization and efficient product transfer by retaining microorganisms within bio-pores and maintaining direct contact with syngas.

Sustainability Impact and Carbon Footprint Analysis

Microbial Electrosynthesis (MES) for syngas conversion represents a significant advancement in sustainable technology, offering substantial environmental benefits compared to traditional chemical processes. The carbon footprint analysis of MES systems reveals a potential reduction of greenhouse gas emissions by 60-85% when compared to conventional thermochemical syngas conversion methods, primarily due to the elimination of high-temperature requirements and reduced energy inputs.

The sustainability impact extends beyond carbon emissions to encompass broader environmental considerations. MES systems operate at ambient temperatures and pressures, dramatically reducing energy consumption compared to traditional Fischer-Tropsch processes that typically require temperatures of 150-300°C and pressures of 10-40 bar. This operational efficiency translates to approximately 40-60% less energy consumption, with corresponding reductions in associated emissions from power generation.

Water utilization represents another critical sustainability advantage of MES technology. While conventional syngas conversion processes may consume 7-10 liters of water per kilogram of product, MES systems can achieve similar outputs with only 2-4 liters, representing a 50-70% reduction in water footprint. This efficiency becomes increasingly valuable as water scarcity concerns intensify globally.

Life cycle assessment (LCA) studies indicate that MES-based syngas conversion can achieve carbon neutrality when powered by renewable electricity sources. The integration of solar or wind power with MES systems creates a circular carbon economy where atmospheric CO2 can be captured and converted into valuable chemical products, effectively closing the carbon loop. Recent pilot projects have demonstrated that such integrated systems can achieve negative carbon emissions of up to 1.2 kg CO2-equivalent per kg of product when utilizing waste CO2 streams.

Resource efficiency metrics further highlight the sustainability advantages of MES technology. The selective nature of microbial catalysts enables conversion efficiencies of 70-90% for target products, significantly higher than the 40-60% typically achieved in conventional processes. This selectivity reduces waste generation and minimizes the need for energy-intensive separation processes downstream.

From a land use perspective, MES facilities require approximately 30-50% less physical space than comparable conventional syngas conversion plants, reducing habitat disruption and allowing for more flexible deployment options, including integration with existing industrial facilities for waste stream valorization. This spatial efficiency, combined with the technology's inherent scalability, positions MES as a promising solution for distributed, sustainable chemical production systems.

The sustainability impact extends beyond carbon emissions to encompass broader environmental considerations. MES systems operate at ambient temperatures and pressures, dramatically reducing energy consumption compared to traditional Fischer-Tropsch processes that typically require temperatures of 150-300°C and pressures of 10-40 bar. This operational efficiency translates to approximately 40-60% less energy consumption, with corresponding reductions in associated emissions from power generation.

Water utilization represents another critical sustainability advantage of MES technology. While conventional syngas conversion processes may consume 7-10 liters of water per kilogram of product, MES systems can achieve similar outputs with only 2-4 liters, representing a 50-70% reduction in water footprint. This efficiency becomes increasingly valuable as water scarcity concerns intensify globally.

Life cycle assessment (LCA) studies indicate that MES-based syngas conversion can achieve carbon neutrality when powered by renewable electricity sources. The integration of solar or wind power with MES systems creates a circular carbon economy where atmospheric CO2 can be captured and converted into valuable chemical products, effectively closing the carbon loop. Recent pilot projects have demonstrated that such integrated systems can achieve negative carbon emissions of up to 1.2 kg CO2-equivalent per kg of product when utilizing waste CO2 streams.

Resource efficiency metrics further highlight the sustainability advantages of MES technology. The selective nature of microbial catalysts enables conversion efficiencies of 70-90% for target products, significantly higher than the 40-60% typically achieved in conventional processes. This selectivity reduces waste generation and minimizes the need for energy-intensive separation processes downstream.

From a land use perspective, MES facilities require approximately 30-50% less physical space than comparable conventional syngas conversion plants, reducing habitat disruption and allowing for more flexible deployment options, including integration with existing industrial facilities for waste stream valorization. This spatial efficiency, combined with the technology's inherent scalability, positions MES as a promising solution for distributed, sustainable chemical production systems.

Scale-up Considerations for Industrial Implementation

Scaling up microbial electrosynthesis (MES) systems for syngas conversion from laboratory to industrial scale presents significant engineering and economic challenges. The transition requires careful consideration of reactor design, electrode materials, and operational parameters to maintain efficiency while increasing production capacity. Current pilot-scale MES systems typically operate at volumes of 10-100 liters, whereas industrial implementation would necessitate reactors in the range of thousands to tens of thousands of liters.

Electrode surface area to volume ratio becomes a critical factor during scale-up. Laboratory systems benefit from high electrode surface areas relative to reactor volume, which facilitates efficient electron transfer to microorganisms. As reactors increase in size, maintaining this ratio becomes challenging and often requires innovative electrode configurations such as packed bed electrodes, 3D electrodes, or multiple electrode arrays distributed throughout the reactor volume.

Mass transfer limitations represent another significant hurdle in scaled-up systems. The efficient delivery of syngas components (CO, H2, and CO2) to microbial catalysts becomes increasingly difficult in larger reactors. Advanced gas diffusion systems, pressurized operation, or hollow fiber membrane contactors may be required to overcome these limitations and ensure homogeneous distribution of substrates throughout the reactor.

Energy efficiency considerations become paramount at industrial scale. The electrical power requirements for large-scale MES systems can be substantial, necessitating optimization of applied potentials and current densities. Integration with renewable energy sources such as solar or wind power could improve the sustainability profile and economic viability of industrial MES operations.

Process control and monitoring systems must be robust and comprehensive for industrial implementation. Real-time monitoring of microbial activity, product formation, and electrochemical parameters is essential for maintaining optimal performance. Advanced sensors, spectroscopic methods, and automated control systems will be necessary components of scaled-up MES facilities.

Downstream processing represents a significant portion of overall production costs in industrial bioprocesses. For MES systems converting syngas to liquid products, efficient separation technologies must be implemented to recover and purify the target compounds. Depending on the product, this may involve distillation, extraction, membrane separation, or chromatographic techniques.

Economic viability ultimately determines the feasibility of industrial implementation. Capital expenditure for large-scale MES facilities includes costs for reactor construction, electrode materials, control systems, and downstream processing equipment. Operating expenses encompass electricity consumption, maintenance, labor, and replacement of components such as electrodes or membranes. Comprehensive techno-economic analysis suggests that current MES technologies require further development to achieve production costs competitive with conventional chemical synthesis routes.

Electrode surface area to volume ratio becomes a critical factor during scale-up. Laboratory systems benefit from high electrode surface areas relative to reactor volume, which facilitates efficient electron transfer to microorganisms. As reactors increase in size, maintaining this ratio becomes challenging and often requires innovative electrode configurations such as packed bed electrodes, 3D electrodes, or multiple electrode arrays distributed throughout the reactor volume.

Mass transfer limitations represent another significant hurdle in scaled-up systems. The efficient delivery of syngas components (CO, H2, and CO2) to microbial catalysts becomes increasingly difficult in larger reactors. Advanced gas diffusion systems, pressurized operation, or hollow fiber membrane contactors may be required to overcome these limitations and ensure homogeneous distribution of substrates throughout the reactor.

Energy efficiency considerations become paramount at industrial scale. The electrical power requirements for large-scale MES systems can be substantial, necessitating optimization of applied potentials and current densities. Integration with renewable energy sources such as solar or wind power could improve the sustainability profile and economic viability of industrial MES operations.

Process control and monitoring systems must be robust and comprehensive for industrial implementation. Real-time monitoring of microbial activity, product formation, and electrochemical parameters is essential for maintaining optimal performance. Advanced sensors, spectroscopic methods, and automated control systems will be necessary components of scaled-up MES facilities.

Downstream processing represents a significant portion of overall production costs in industrial bioprocesses. For MES systems converting syngas to liquid products, efficient separation technologies must be implemented to recover and purify the target compounds. Depending on the product, this may involve distillation, extraction, membrane separation, or chromatographic techniques.

Economic viability ultimately determines the feasibility of industrial implementation. Capital expenditure for large-scale MES facilities includes costs for reactor construction, electrode materials, control systems, and downstream processing equipment. Operating expenses encompass electricity consumption, maintenance, labor, and replacement of components such as electrodes or membranes. Comprehensive techno-economic analysis suggests that current MES technologies require further development to achieve production costs competitive with conventional chemical synthesis routes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!