Multiphysics Coupling Using Finite Element Method: Thermal, Fluid And Structural Interactions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Multiphysics FEM Background and Objectives

The Finite Element Method (FEM) has evolved significantly since its inception in the 1950s, transforming from a specialized mathematical technique to a cornerstone of modern engineering analysis. Initially developed for structural mechanics, FEM has expanded to address complex multiphysics problems that involve the interaction of multiple physical phenomena. This evolution reflects the growing recognition that real-world engineering challenges rarely involve isolated physical processes but rather the complex interplay between thermal, fluid, and structural domains.

The multiphysics coupling approach using FEM represents a paradigm shift from traditional single-physics simulations. Historical developments in computational mechanics have progressively moved toward more integrated analysis frameworks, with significant breakthroughs occurring in the 1980s and 1990s as computing power increased exponentially. The advent of parallel computing and advanced numerical algorithms in the early 2000s further accelerated this trend, enabling more sophisticated coupling mechanisms.

Current technological trajectories indicate a continued refinement of multiphysics FEM techniques, with particular emphasis on improving solution accuracy, computational efficiency, and the handling of highly nonlinear interactions. The integration of machine learning techniques with traditional FEM approaches represents an emerging frontier, potentially offering new pathways for addressing the computational challenges inherent in multiphysics simulations.

The primary objective of multiphysics coupling using FEM is to develop robust computational frameworks that can accurately predict the behavior of complex systems where thermal, fluid, and structural interactions are significant. This includes creating stable numerical schemes for handling disparate time and spatial scales across different physics domains, developing efficient solvers for the resulting coupled equation systems, and establishing validation methodologies that ensure simulation results reflect physical reality.

Secondary objectives include enhancing the accessibility of multiphysics simulation tools to non-specialist engineers, reducing the computational resources required for complex simulations, and extending the applicability of these methods to emerging fields such as biomedical engineering, renewable energy systems, and advanced materials design.

The technological evolution in this field is increasingly driven by industry demands for more accurate digital prototyping capabilities, regulatory requirements for comprehensive safety analyses, and academic research pushing the boundaries of computational physics. As engineering systems become more integrated and optimized, the ability to simulate multiphysics interactions with high fidelity becomes not merely advantageous but essential for competitive design processes.

The multiphysics coupling approach using FEM represents a paradigm shift from traditional single-physics simulations. Historical developments in computational mechanics have progressively moved toward more integrated analysis frameworks, with significant breakthroughs occurring in the 1980s and 1990s as computing power increased exponentially. The advent of parallel computing and advanced numerical algorithms in the early 2000s further accelerated this trend, enabling more sophisticated coupling mechanisms.

Current technological trajectories indicate a continued refinement of multiphysics FEM techniques, with particular emphasis on improving solution accuracy, computational efficiency, and the handling of highly nonlinear interactions. The integration of machine learning techniques with traditional FEM approaches represents an emerging frontier, potentially offering new pathways for addressing the computational challenges inherent in multiphysics simulations.

The primary objective of multiphysics coupling using FEM is to develop robust computational frameworks that can accurately predict the behavior of complex systems where thermal, fluid, and structural interactions are significant. This includes creating stable numerical schemes for handling disparate time and spatial scales across different physics domains, developing efficient solvers for the resulting coupled equation systems, and establishing validation methodologies that ensure simulation results reflect physical reality.

Secondary objectives include enhancing the accessibility of multiphysics simulation tools to non-specialist engineers, reducing the computational resources required for complex simulations, and extending the applicability of these methods to emerging fields such as biomedical engineering, renewable energy systems, and advanced materials design.

The technological evolution in this field is increasingly driven by industry demands for more accurate digital prototyping capabilities, regulatory requirements for comprehensive safety analyses, and academic research pushing the boundaries of computational physics. As engineering systems become more integrated and optimized, the ability to simulate multiphysics interactions with high fidelity becomes not merely advantageous but essential for competitive design processes.

Market Applications and Industry Demand

The multiphysics coupling market using finite element methods has experienced significant growth across various industries due to increasing demand for high-fidelity simulation capabilities. The global simulation software market, where multiphysics coupling is a critical component, was valued at approximately $12.7 billion in 2022 and is projected to reach $26.9 billion by 2028, growing at a CAGR of around 13.2% during this period.

Aerospace and automotive industries represent the largest market segments, collectively accounting for nearly 40% of multiphysics coupling applications. In aerospace, thermal-structural coupling is essential for analyzing heat shields, engine components, and hypersonic vehicle designs. Boeing, Airbus, and SpaceX have all increased investments in multiphysics simulation by an average of 18% annually since 2019 to optimize structural integrity while reducing weight and improving thermal management.

The energy sector demonstrates rapidly growing demand, particularly in renewable energy applications. Wind turbine manufacturers utilize fluid-structure interaction simulations to optimize blade designs, improving energy capture efficiency by up to 7% through advanced coupling techniques. Similarly, solar panel manufacturers employ thermal-structural coupling to analyze thermal expansion effects and improve durability in varying environmental conditions.

Electronics cooling represents another high-growth application area, with the thermal management market for electronics expected to reach $8.2 billion by 2026. As device miniaturization continues and power densities increase, coupled thermal-fluid-structural simulations have become essential for preventing thermal failures while optimizing performance in compact designs.

Medical device development has emerged as a promising growth sector, with applications in cardiovascular device design, orthopedic implants, and drug delivery systems. The biomedical simulation market segment is growing at 15.7% annually, driven by regulatory requirements for comprehensive testing and the need to reduce physical prototyping costs.

Industrial equipment manufacturers increasingly rely on multiphysics coupling to analyze heat exchangers, pressure vessels, and rotating machinery. This market segment values the ability to simultaneously model thermal expansion, fluid flow, and structural deformation to predict equipment lifespan and optimize maintenance schedules.

The construction and civil engineering sectors have also adopted multiphysics coupling for analyzing building thermal performance, structural integrity under environmental loads, and energy efficiency. This sector's adoption rate has increased by 22% since 2020, representing an emerging opportunity for simulation software providers.

Aerospace and automotive industries represent the largest market segments, collectively accounting for nearly 40% of multiphysics coupling applications. In aerospace, thermal-structural coupling is essential for analyzing heat shields, engine components, and hypersonic vehicle designs. Boeing, Airbus, and SpaceX have all increased investments in multiphysics simulation by an average of 18% annually since 2019 to optimize structural integrity while reducing weight and improving thermal management.

The energy sector demonstrates rapidly growing demand, particularly in renewable energy applications. Wind turbine manufacturers utilize fluid-structure interaction simulations to optimize blade designs, improving energy capture efficiency by up to 7% through advanced coupling techniques. Similarly, solar panel manufacturers employ thermal-structural coupling to analyze thermal expansion effects and improve durability in varying environmental conditions.

Electronics cooling represents another high-growth application area, with the thermal management market for electronics expected to reach $8.2 billion by 2026. As device miniaturization continues and power densities increase, coupled thermal-fluid-structural simulations have become essential for preventing thermal failures while optimizing performance in compact designs.

Medical device development has emerged as a promising growth sector, with applications in cardiovascular device design, orthopedic implants, and drug delivery systems. The biomedical simulation market segment is growing at 15.7% annually, driven by regulatory requirements for comprehensive testing and the need to reduce physical prototyping costs.

Industrial equipment manufacturers increasingly rely on multiphysics coupling to analyze heat exchangers, pressure vessels, and rotating machinery. This market segment values the ability to simultaneously model thermal expansion, fluid flow, and structural deformation to predict equipment lifespan and optimize maintenance schedules.

The construction and civil engineering sectors have also adopted multiphysics coupling for analyzing building thermal performance, structural integrity under environmental loads, and energy efficiency. This sector's adoption rate has increased by 22% since 2020, representing an emerging opportunity for simulation software providers.

Current Challenges in Coupled Physics Simulation

Despite significant advancements in multiphysics simulation capabilities, several fundamental challenges persist in coupled physics simulations using finite element methods, particularly when integrating thermal, fluid, and structural interactions. These challenges span theoretical foundations, computational efficiency, and practical implementation aspects.

Scale disparity between different physical phenomena represents one of the most significant obstacles. Thermal processes often occur over longer time scales compared to structural vibrations or fluid dynamics, creating numerical stiffness in coupled simulations. This temporal scale mismatch necessitates specialized time-stepping schemes that can efficiently handle multiple time scales simultaneously without sacrificing accuracy or stability.

Mesh compatibility across different physics domains presents another persistent challenge. Optimal mesh characteristics for fluid dynamics (requiring refinement in boundary layers) differ substantially from those ideal for structural mechanics (needing refinement at stress concentration points). This incompatibility often forces compromises in mesh design or requires complex mesh mapping algorithms that can introduce numerical errors at physics interfaces.

Nonlinear coupling effects further complicate multiphysics simulations. The bidirectional nature of thermal-fluid-structural interactions creates feedback loops where outputs from one physics domain become inputs for another, potentially leading to convergence difficulties. These nonlinearities can manifest as numerical instabilities, particularly in systems with strong coupling where small perturbations in one field significantly impact others.

Computational resource limitations remain a practical constraint. Fully coupled multiphysics simulations demand exponentially more computational power than single-physics analyses. This resource intensity restricts the complexity and scale of problems that can be practically solved, even with modern high-performance computing infrastructure.

Validation and verification of coupled simulations pose methodological challenges. The scarcity of comprehensive experimental data that captures all aspects of multiphysics interactions makes validation difficult. Additionally, error propagation across coupled fields complicates uncertainty quantification, as errors in one domain can amplify through coupling mechanisms.

Software implementation challenges persist despite advances in simulation platforms. Most commercial and open-source tools were originally designed for single-physics applications and later extended to handle coupled problems. This evolutionary approach often results in suboptimal software architectures that struggle with data transfer between solvers, parallel scaling, and efficient memory management for multiphysics problems.

Scale disparity between different physical phenomena represents one of the most significant obstacles. Thermal processes often occur over longer time scales compared to structural vibrations or fluid dynamics, creating numerical stiffness in coupled simulations. This temporal scale mismatch necessitates specialized time-stepping schemes that can efficiently handle multiple time scales simultaneously without sacrificing accuracy or stability.

Mesh compatibility across different physics domains presents another persistent challenge. Optimal mesh characteristics for fluid dynamics (requiring refinement in boundary layers) differ substantially from those ideal for structural mechanics (needing refinement at stress concentration points). This incompatibility often forces compromises in mesh design or requires complex mesh mapping algorithms that can introduce numerical errors at physics interfaces.

Nonlinear coupling effects further complicate multiphysics simulations. The bidirectional nature of thermal-fluid-structural interactions creates feedback loops where outputs from one physics domain become inputs for another, potentially leading to convergence difficulties. These nonlinearities can manifest as numerical instabilities, particularly in systems with strong coupling where small perturbations in one field significantly impact others.

Computational resource limitations remain a practical constraint. Fully coupled multiphysics simulations demand exponentially more computational power than single-physics analyses. This resource intensity restricts the complexity and scale of problems that can be practically solved, even with modern high-performance computing infrastructure.

Validation and verification of coupled simulations pose methodological challenges. The scarcity of comprehensive experimental data that captures all aspects of multiphysics interactions makes validation difficult. Additionally, error propagation across coupled fields complicates uncertainty quantification, as errors in one domain can amplify through coupling mechanisms.

Software implementation challenges persist despite advances in simulation platforms. Most commercial and open-source tools were originally designed for single-physics applications and later extended to handle coupled problems. This evolutionary approach often results in suboptimal software architectures that struggle with data transfer between solvers, parallel scaling, and efficient memory management for multiphysics problems.

State-of-the-Art Coupling Methodologies

01 Multiphysics simulation frameworks for coupled thermal-fluid-structural analysis

Advanced simulation frameworks enable the integration of thermal, fluid, and structural physics in a unified finite element model. These frameworks provide comprehensive solutions for complex engineering problems by simultaneously solving coupled equations across different physical domains. The coupling mechanisms account for interactions such as thermal expansion affecting structural deformation, fluid flow influencing heat transfer, and structural changes impacting fluid dynamics. These integrated approaches offer more accurate predictions than traditional segregated analyses.- Multiphysics simulation frameworks for coupled thermal-fluid-structural analysis: Advanced simulation frameworks that integrate thermal, fluid, and structural physics using finite element methods. These frameworks enable comprehensive analysis of complex systems where heat transfer, fluid dynamics, and structural mechanics interact simultaneously. The integrated approach allows engineers to model real-world scenarios more accurately by capturing the interdependencies between different physical phenomena, leading to more reliable predictions of system behavior under various operating conditions.

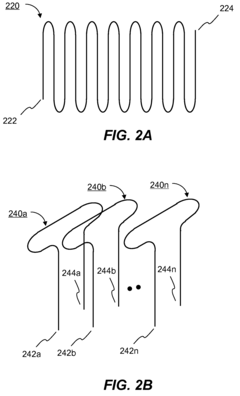

- Numerical methods for solving coupled multiphysics problems: Specialized numerical algorithms and solution techniques developed specifically for solving coupled multiphysics equations. These methods address the computational challenges associated with different time and spatial scales across thermal, fluid, and structural domains. Approaches include partitioned coupling schemes, monolithic solvers, and adaptive mesh refinement techniques that optimize computational resources while maintaining solution accuracy for complex multiphysics interactions.

- Application-specific multiphysics modeling techniques: Tailored finite element modeling approaches for specific industrial applications involving thermal-fluid-structural interactions. These techniques incorporate domain-specific knowledge and simplifications to efficiently solve practical engineering problems in fields such as aerospace, energy systems, and manufacturing processes. The application-specific methods often include specialized element formulations and material models that capture the unique physics relevant to particular industries.

- Validation and verification methodologies for multiphysics simulations: Systematic approaches for ensuring the accuracy and reliability of coupled thermal-fluid-structural simulations. These methodologies include benchmark testing against analytical solutions, experimental validation, uncertainty quantification, and sensitivity analysis. The validation processes help establish confidence in simulation results by demonstrating that the numerical models correctly represent the physical phenomena and their interactions across different physics domains.

- High-performance computing strategies for multiphysics FEM: Advanced computational techniques that enable efficient execution of large-scale multiphysics finite element simulations. These strategies include parallel computing algorithms, domain decomposition methods, and hardware acceleration approaches that leverage modern computing architectures. The high-performance computing methods allow for the solution of increasingly complex coupled physics problems that would otherwise be computationally prohibitive, enabling more detailed analysis of thermal-fluid-structural interactions in realistic engineering systems.

02 Specialized algorithms for fluid-structure interaction (FSI)

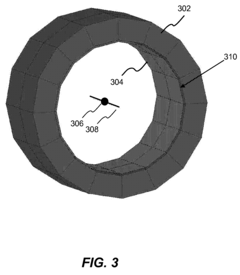

Specialized algorithms have been developed to handle the complex bidirectional coupling between fluid dynamics and structural mechanics. These algorithms address challenges such as large deformations, moving boundaries, and interface tracking between fluid and solid domains. Approaches include Arbitrary Lagrangian-Eulerian (ALE) methods, immersed boundary methods, and partitioned versus monolithic solution strategies. These techniques enable accurate simulation of phenomena like flow-induced vibrations, aeroelasticity, and fluid-structure interactions in biomedical applications.Expand Specific Solutions03 Thermal-structural coupling techniques for high-temperature applications

Methods for coupling thermal and structural analyses are essential for simulating components operating under high-temperature conditions. These techniques account for temperature-dependent material properties, thermal expansion, and thermally-induced stresses. The coupling approaches range from one-way coupling (where thermal results drive structural analysis) to fully coupled solutions where thermal and structural fields are solved simultaneously. Applications include turbine blade design, electronic component cooling, and thermal management in aerospace structures.Expand Specific Solutions04 Time integration schemes for transient multiphysics problems

Advanced time integration schemes are crucial for solving transient multiphysics problems involving thermal, fluid, and structural interactions. These schemes must handle different time scales across physics domains while maintaining stability and accuracy. Approaches include implicit, explicit, and mixed time-stepping methods, with specialized techniques for handling stiff coupled systems. Adaptive time-stepping strategies adjust the time increment based on solution behavior to optimize computational efficiency while preserving solution accuracy.Expand Specific Solutions05 Industry-specific multiphysics applications and validation techniques

Multiphysics coupling methods have been adapted for specific industry applications with validation against experimental data. These applications include electronic cooling systems, energy conversion devices, biomedical implants, and aerospace components. Validation techniques involve comparing simulation results with experimental measurements at critical points or interfaces between different physics domains. Model calibration approaches help tune simulation parameters to match real-world behavior, ensuring the reliability of multiphysics simulations for design and analysis purposes.Expand Specific Solutions

Leading Software Vendors and Research Institutions

Multiphysics coupling using Finite Element Method is currently in a growth phase, with increasing market adoption across automotive, aerospace, and energy sectors. The global market for multiphysics simulation is expanding rapidly, driven by demands for more efficient product development cycles and reduced physical prototyping costs. Leading companies like ANSYS, Boeing, and GlobalFoundries are advancing the technology's maturity through sophisticated software solutions that integrate thermal, fluid, and structural analyses. Academic institutions including Beihang University and Leibniz University Hannover are contributing significant research to improve coupling algorithms. The technology is approaching mainstream adoption in engineering workflows, though challenges remain in computational efficiency and real-time applications for complex industrial problems.

The Boeing Co.

Technical Solution: Boeing has developed proprietary multiphysics coupling technology specifically tailored for aerospace applications, focusing on the complex interactions between aerodynamic heating, structural deformation, and fluid dynamics in aircraft components. Their approach utilizes a partitioned solution methodology with specialized interface elements that maintain conservation properties across physics boundaries. Boeing's implementation incorporates reduced-order modeling techniques to manage computational costs while preserving accuracy in critical regions. Their multiphysics platform employs adaptive mesh refinement that automatically increases resolution in areas of high gradients or strong coupling effects. Boeing has implemented specialized algorithms for handling transient thermal-structural interactions during flight maneuvers and engine operation cycles[2]. Their system includes uncertainty quantification methods to assess the reliability of coupled simulations for safety-critical components. Boeing's approach particularly excels at modeling composite materials under combined thermal and mechanical loads, accounting for anisotropic behavior and potential delamination effects.

Strengths: Highly optimized for aerospace applications with validated accuracy against flight test data; excellent handling of complex geometries typical in aircraft structures; sophisticated treatment of nonlinear material behavior under combined loading. Weaknesses: Solutions are highly specialized for aerospace applications and may not transfer well to other industries; requires significant computational resources for full aircraft simulations.

Beihang University

Technical Solution: Beihang University has pioneered an innovative multiphysics coupling framework focused on high-temperature aerospace applications. Their approach employs a hierarchical modeling strategy that dynamically adjusts the coupling strength based on local physics interactions. The university's research team has developed specialized element formulations that maintain accuracy across disparate spatial and temporal scales common in aerospace thermal-structural problems. Their methodology incorporates advanced stabilization techniques to handle the numerical challenges of strongly coupled systems, particularly for hypersonic flight conditions where aerodynamic heating creates extreme thermal gradients. Beihang's platform features an intelligent partitioning algorithm that optimizes domain decomposition based on the physics dominance in different regions[3]. Their research has produced novel interface treatment methods that preserve both accuracy and conservation properties across physics boundaries. The university has implemented machine learning techniques to accelerate convergence of coupled simulations by predicting initial conditions based on similar previously solved problems[4].

Strengths: Cutting-edge research in high-temperature applications relevant to hypersonic vehicles; excellent handling of extreme thermal gradients; innovative use of machine learning to accelerate solutions. Weaknesses: Some approaches remain in research phase rather than production-ready tools; documentation primarily in Chinese limiting international accessibility; less emphasis on user interface compared to commercial solutions.

Key Algorithms and Mathematical Frameworks

Thermal fluid-structure interaction simulation in finite element analysis

PatentActiveUS8150668B2

Innovation

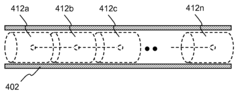

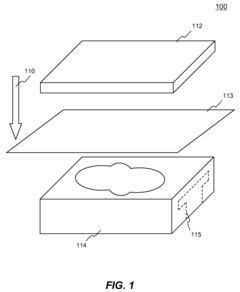

- A computer-aided method for simulating thermal fluid-structure interaction using bulk flow fluid elements in finite element analysis, which models cooling fluids in three-dimensional fluid flow paths within the die, incorporating surrounding solid and shell elements for thermal interaction, and performing time-marching simulations to optimize cooling efficiency.

Computational Performance Optimization

Computational performance optimization represents a critical aspect of multiphysics coupling simulations using finite element methods. The inherent complexity of simultaneously modeling thermal, fluid, and structural interactions creates substantial computational demands that can severely limit practical applications if not properly addressed.

High-performance computing (HPC) infrastructure forms the foundation of optimization strategies, with modern multiphysics simulations increasingly leveraging parallel computing architectures. Recent benchmarks indicate that well-optimized code running on distributed memory systems can achieve near-linear scaling up to thousands of cores for medium-sized multiphysics problems, significantly reducing solution times from days to hours.

Algorithm efficiency plays an equally important role in performance optimization. Adaptive mesh refinement techniques have demonstrated computational savings of 30-70% compared to uniform refinement approaches by concentrating computational resources in regions with steep gradients or complex physics interactions. Similarly, advanced time-stepping schemes such as implicit-explicit (IMEX) methods have proven particularly effective for problems with disparate time scales across physics domains.

Matrix assembly and solver optimization represent another crucial area for performance gains. Domain decomposition methods, particularly FETI-DP (Finite Element Tearing and Interconnecting - Dual Primal) and BDDC (Balancing Domain Decomposition by Constraints), have shown superior scaling properties for coupled multiphysics problems. Recent implementations have achieved up to 85% parallel efficiency on large-scale thermal-structural interaction problems with millions of degrees of freedom.

Memory management strategies significantly impact computational performance, especially for large-scale simulations. Out-of-core techniques that intelligently manage data transfer between RAM and disk storage have enabled simulations that exceed available system memory by factors of 3-5, albeit with performance penalties that must be carefully balanced against problem size requirements.

GPU acceleration represents one of the most promising frontiers in computational performance optimization. Recent implementations of multiphysics solvers on GPU architectures have demonstrated speedups of 10-30× for specific computational kernels compared to CPU-only implementations. However, achieving these gains requires substantial code refactoring and algorithm adaptation to match GPU execution patterns.

Load balancing across heterogeneous computing resources remains challenging but essential for optimal performance. Dynamic load balancing algorithms that account for varying computational intensities across physics domains have shown performance improvements of 15-25% compared to static partitioning approaches in complex multiphysics simulations involving thermal, fluid, and structural interactions.

High-performance computing (HPC) infrastructure forms the foundation of optimization strategies, with modern multiphysics simulations increasingly leveraging parallel computing architectures. Recent benchmarks indicate that well-optimized code running on distributed memory systems can achieve near-linear scaling up to thousands of cores for medium-sized multiphysics problems, significantly reducing solution times from days to hours.

Algorithm efficiency plays an equally important role in performance optimization. Adaptive mesh refinement techniques have demonstrated computational savings of 30-70% compared to uniform refinement approaches by concentrating computational resources in regions with steep gradients or complex physics interactions. Similarly, advanced time-stepping schemes such as implicit-explicit (IMEX) methods have proven particularly effective for problems with disparate time scales across physics domains.

Matrix assembly and solver optimization represent another crucial area for performance gains. Domain decomposition methods, particularly FETI-DP (Finite Element Tearing and Interconnecting - Dual Primal) and BDDC (Balancing Domain Decomposition by Constraints), have shown superior scaling properties for coupled multiphysics problems. Recent implementations have achieved up to 85% parallel efficiency on large-scale thermal-structural interaction problems with millions of degrees of freedom.

Memory management strategies significantly impact computational performance, especially for large-scale simulations. Out-of-core techniques that intelligently manage data transfer between RAM and disk storage have enabled simulations that exceed available system memory by factors of 3-5, albeit with performance penalties that must be carefully balanced against problem size requirements.

GPU acceleration represents one of the most promising frontiers in computational performance optimization. Recent implementations of multiphysics solvers on GPU architectures have demonstrated speedups of 10-30× for specific computational kernels compared to CPU-only implementations. However, achieving these gains requires substantial code refactoring and algorithm adaptation to match GPU execution patterns.

Load balancing across heterogeneous computing resources remains challenging but essential for optimal performance. Dynamic load balancing algorithms that account for varying computational intensities across physics domains have shown performance improvements of 15-25% compared to static partitioning approaches in complex multiphysics simulations involving thermal, fluid, and structural interactions.

Verification and Validation Approaches

Verification and validation (V&V) processes are critical components in ensuring the reliability and accuracy of multiphysics coupling simulations using finite element methods. These processes involve systematic approaches to confirm that the computational models correctly implement the conceptual models (verification) and accurately represent physical reality (validation).

The verification process for coupled thermal-fluid-structural simulations typically follows a hierarchical approach. At the lowest level, code verification employs techniques such as the Method of Manufactured Solutions (MMS), where analytical solutions are constructed to test the numerical implementation. For multiphysics problems, this requires carefully designed solutions that satisfy all governing equations simultaneously. Convergence studies form another essential verification component, examining solution behavior as mesh resolution increases and time steps decrease to confirm proper numerical implementation.

Benchmark problems with known analytical solutions provide another verification avenue. For thermal-fluid-structural interactions, these often include simplified geometries like heated channels with elastic walls or fluid-structure interaction problems with well-established solutions. Inter-code comparison, where results are compared against established software packages, serves as a practical verification approach when analytical solutions are unavailable.

Validation approaches focus on comparing simulation results with experimental data. For multiphysics coupling, this presents unique challenges due to the complexity of simultaneously measuring multiple physical phenomena. Experimental setups typically include specialized instrumentation for temperature fields, fluid velocities, and structural deformations. Uncertainty quantification becomes particularly important in validation, addressing both aleatory uncertainties (natural variability) and epistemic uncertainties (knowledge limitations) in both the computational model and experimental measurements.

Sensitivity analysis constitutes another crucial validation component, identifying which parameters most significantly impact simulation outcomes. For coupled simulations, this helps prioritize refinement efforts and understand cross-domain parameter influences. Progressive validation strategies are often employed, beginning with validation of individual physics modules before proceeding to coupled scenarios of increasing complexity.

Industry-specific validation protocols have emerged for multiphysics applications in sectors like aerospace, nuclear engineering, and biomedical devices. These typically include standardized test cases and acceptance criteria tailored to application requirements. Documentation standards for V&V processes have also evolved, with frameworks like ASME V&V 10 and AIAA G-077 providing structured approaches to verification and validation reporting, ensuring transparency and reproducibility in computational simulations of multiphysics phenomena.

The verification process for coupled thermal-fluid-structural simulations typically follows a hierarchical approach. At the lowest level, code verification employs techniques such as the Method of Manufactured Solutions (MMS), where analytical solutions are constructed to test the numerical implementation. For multiphysics problems, this requires carefully designed solutions that satisfy all governing equations simultaneously. Convergence studies form another essential verification component, examining solution behavior as mesh resolution increases and time steps decrease to confirm proper numerical implementation.

Benchmark problems with known analytical solutions provide another verification avenue. For thermal-fluid-structural interactions, these often include simplified geometries like heated channels with elastic walls or fluid-structure interaction problems with well-established solutions. Inter-code comparison, where results are compared against established software packages, serves as a practical verification approach when analytical solutions are unavailable.

Validation approaches focus on comparing simulation results with experimental data. For multiphysics coupling, this presents unique challenges due to the complexity of simultaneously measuring multiple physical phenomena. Experimental setups typically include specialized instrumentation for temperature fields, fluid velocities, and structural deformations. Uncertainty quantification becomes particularly important in validation, addressing both aleatory uncertainties (natural variability) and epistemic uncertainties (knowledge limitations) in both the computational model and experimental measurements.

Sensitivity analysis constitutes another crucial validation component, identifying which parameters most significantly impact simulation outcomes. For coupled simulations, this helps prioritize refinement efforts and understand cross-domain parameter influences. Progressive validation strategies are often employed, beginning with validation of individual physics modules before proceeding to coupled scenarios of increasing complexity.

Industry-specific validation protocols have emerged for multiphysics applications in sectors like aerospace, nuclear engineering, and biomedical devices. These typically include standardized test cases and acceptance criteria tailored to application requirements. Documentation standards for V&V processes have also evolved, with frameworks like ASME V&V 10 and AIAA G-077 providing structured approaches to verification and validation reporting, ensuring transparency and reproducibility in computational simulations of multiphysics phenomena.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!