Nitinol's Effectiveness in Stress Proofing Structural Elements

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Background and Objectives

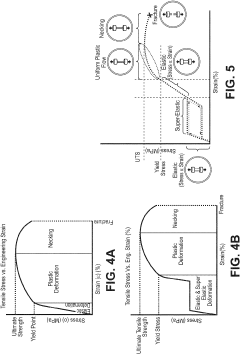

Nitinol, an acronym for Nickel Titanium Naval Ordnance Laboratory, is a remarkable shape memory alloy that has revolutionized various industries since its discovery in the 1960s. This unique material, composed primarily of nickel and titanium, exhibits exceptional properties that make it particularly suitable for stress-proofing structural elements.

The development of Nitinol can be traced back to its accidental discovery by William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory. Initially, the focus was on its shape memory properties, but researchers soon recognized its potential for stress-related applications due to its superelastic behavior and high fatigue resistance.

Over the years, Nitinol has undergone significant advancements in terms of composition, manufacturing processes, and application techniques. The evolution of this technology has been driven by the growing demand for materials that can withstand extreme stress conditions while maintaining structural integrity.

The primary objective of utilizing Nitinol in stress-proofing structural elements is to enhance the overall durability, reliability, and performance of various systems and components. By leveraging Nitinol's unique properties, engineers aim to develop structures that can withstand higher levels of stress, recover from deformation, and exhibit improved fatigue resistance compared to conventional materials.

One of the key technological trends in Nitinol development is the fine-tuning of its composition and heat treatment processes to optimize its mechanical properties for specific applications. Researchers are continuously exploring ways to enhance Nitinol's stress-strain characteristics, transformation temperatures, and cyclic stability to meet the demanding requirements of different industries.

Another significant trend is the integration of Nitinol with other materials and advanced manufacturing techniques, such as 3D printing and composite structures. These innovations are opening up new possibilities for creating complex, stress-resistant structures that were previously unattainable with traditional materials and manufacturing methods.

The future trajectory of Nitinol technology in stress-proofing applications is expected to focus on several key areas. These include developing new alloy compositions with improved properties, enhancing the material's compatibility with other structural elements, and expanding its application range to cover a broader spectrum of stress-related challenges across various industries.

As research in this field progresses, the goal is to push the boundaries of what is possible in terms of stress resistance and structural performance. This ongoing development is likely to lead to breakthroughs in areas such as aerospace, civil engineering, and medical devices, where the ability to withstand and manage stress is crucial for safety and functionality.

The development of Nitinol can be traced back to its accidental discovery by William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory. Initially, the focus was on its shape memory properties, but researchers soon recognized its potential for stress-related applications due to its superelastic behavior and high fatigue resistance.

Over the years, Nitinol has undergone significant advancements in terms of composition, manufacturing processes, and application techniques. The evolution of this technology has been driven by the growing demand for materials that can withstand extreme stress conditions while maintaining structural integrity.

The primary objective of utilizing Nitinol in stress-proofing structural elements is to enhance the overall durability, reliability, and performance of various systems and components. By leveraging Nitinol's unique properties, engineers aim to develop structures that can withstand higher levels of stress, recover from deformation, and exhibit improved fatigue resistance compared to conventional materials.

One of the key technological trends in Nitinol development is the fine-tuning of its composition and heat treatment processes to optimize its mechanical properties for specific applications. Researchers are continuously exploring ways to enhance Nitinol's stress-strain characteristics, transformation temperatures, and cyclic stability to meet the demanding requirements of different industries.

Another significant trend is the integration of Nitinol with other materials and advanced manufacturing techniques, such as 3D printing and composite structures. These innovations are opening up new possibilities for creating complex, stress-resistant structures that were previously unattainable with traditional materials and manufacturing methods.

The future trajectory of Nitinol technology in stress-proofing applications is expected to focus on several key areas. These include developing new alloy compositions with improved properties, enhancing the material's compatibility with other structural elements, and expanding its application range to cover a broader spectrum of stress-related challenges across various industries.

As research in this field progresses, the goal is to push the boundaries of what is possible in terms of stress resistance and structural performance. This ongoing development is likely to lead to breakthroughs in areas such as aerospace, civil engineering, and medical devices, where the ability to withstand and manage stress is crucial for safety and functionality.

Market Demand Analysis

The market demand for Nitinol in stress-proofing structural elements has been steadily growing across various industries. This shape memory alloy's unique properties, including superelasticity and shape memory effect, make it particularly attractive for applications requiring high stress resistance and durability.

In the aerospace sector, there is a significant demand for Nitinol-based components in aircraft structures. The material's ability to withstand extreme temperature variations and high stress levels while maintaining its shape and performance characteristics has led to increased adoption in critical aerospace applications. This trend is expected to continue as the industry seeks lighter, more efficient, and more resilient materials for next-generation aircraft.

The automotive industry has also shown growing interest in Nitinol for stress-proofing structural elements. As vehicle manufacturers strive to improve fuel efficiency and safety, the use of Nitinol in impact-absorbing structures and lightweight components has gained traction. The material's superelastic properties allow for better energy absorption during collisions, potentially enhancing passenger safety.

In civil engineering, Nitinol's potential for seismic protection and structural reinforcement has sparked considerable interest. The material's ability to absorb and dissipate energy makes it valuable for earthquake-resistant building designs. As urban areas in seismically active regions continue to expand, the demand for Nitinol-based solutions in construction is projected to rise.

The medical device industry represents another significant market for Nitinol in stress-proofing applications. The material's biocompatibility, coupled with its stress-resistant properties, makes it ideal for implantable devices and surgical instruments. The growing prevalence of minimally invasive procedures and the need for durable, long-lasting medical implants are driving the demand for Nitinol in this sector.

The oil and gas industry has also recognized the benefits of Nitinol in stress-proofing structural elements for deep-sea exploration and drilling operations. The material's resistance to corrosion and ability to withstand high pressures make it suitable for use in offshore platforms and subsea equipment.

As global infrastructure development continues, particularly in emerging economies, the demand for advanced materials like Nitinol is expected to grow. The material's potential to enhance the longevity and resilience of bridges, buildings, and other critical infrastructure components is likely to drive its adoption in large-scale construction projects.

While the market for Nitinol in stress-proofing applications is expanding, challenges such as high production costs and limited manufacturing capabilities may impact its widespread adoption. However, ongoing research and development efforts aimed at improving production processes and reducing costs are expected to address these limitations and further boost market growth in the coming years.

In the aerospace sector, there is a significant demand for Nitinol-based components in aircraft structures. The material's ability to withstand extreme temperature variations and high stress levels while maintaining its shape and performance characteristics has led to increased adoption in critical aerospace applications. This trend is expected to continue as the industry seeks lighter, more efficient, and more resilient materials for next-generation aircraft.

The automotive industry has also shown growing interest in Nitinol for stress-proofing structural elements. As vehicle manufacturers strive to improve fuel efficiency and safety, the use of Nitinol in impact-absorbing structures and lightweight components has gained traction. The material's superelastic properties allow for better energy absorption during collisions, potentially enhancing passenger safety.

In civil engineering, Nitinol's potential for seismic protection and structural reinforcement has sparked considerable interest. The material's ability to absorb and dissipate energy makes it valuable for earthquake-resistant building designs. As urban areas in seismically active regions continue to expand, the demand for Nitinol-based solutions in construction is projected to rise.

The medical device industry represents another significant market for Nitinol in stress-proofing applications. The material's biocompatibility, coupled with its stress-resistant properties, makes it ideal for implantable devices and surgical instruments. The growing prevalence of minimally invasive procedures and the need for durable, long-lasting medical implants are driving the demand for Nitinol in this sector.

The oil and gas industry has also recognized the benefits of Nitinol in stress-proofing structural elements for deep-sea exploration and drilling operations. The material's resistance to corrosion and ability to withstand high pressures make it suitable for use in offshore platforms and subsea equipment.

As global infrastructure development continues, particularly in emerging economies, the demand for advanced materials like Nitinol is expected to grow. The material's potential to enhance the longevity and resilience of bridges, buildings, and other critical infrastructure components is likely to drive its adoption in large-scale construction projects.

While the market for Nitinol in stress-proofing applications is expanding, challenges such as high production costs and limited manufacturing capabilities may impact its widespread adoption. However, ongoing research and development efforts aimed at improving production processes and reducing costs are expected to address these limitations and further boost market growth in the coming years.

Current State and Challenges

The current state of Nitinol's application in stress-proofing structural elements is characterized by significant advancements and persistent challenges. Globally, researchers and engineers have made substantial progress in harnessing Nitinol's unique properties, particularly its superelasticity and shape memory effect, for enhancing the resilience of various structural components.

In the United States and Europe, Nitinol has found widespread use in aerospace and civil engineering applications. The material's ability to absorb and dissipate energy has led to its integration in seismic damping systems for buildings and bridges. However, the high cost of Nitinol production and processing remains a significant barrier to its broader adoption in large-scale structural applications.

Japan and China have emerged as leaders in developing innovative Nitinol-based composites for structural reinforcement. These composites aim to combine Nitinol's stress-resistant properties with the strength and affordability of traditional materials. Despite promising results in laboratory settings, scaling these solutions for commercial use presents ongoing challenges, particularly in terms of manufacturing consistency and long-term durability.

One of the primary technical hurdles facing Nitinol implementation is the complexity of its thermomechanical behavior. The material's performance is highly sensitive to temperature variations and loading conditions, making it challenging to predict and control its behavior in diverse environmental settings. This unpredictability has limited Nitinol's application in critical structural elements where consistent performance is paramount.

Another significant challenge lies in the joining and integration of Nitinol with other structural materials. Traditional welding and fastening methods often compromise Nitinol's unique properties, necessitating the development of specialized techniques. While progress has been made in this area, particularly in the medical device industry, transferring these methods to large-scale structural applications remains problematic.

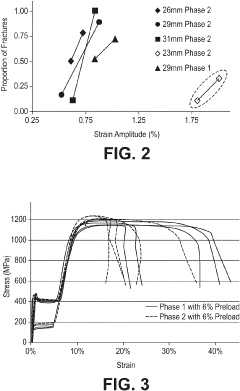

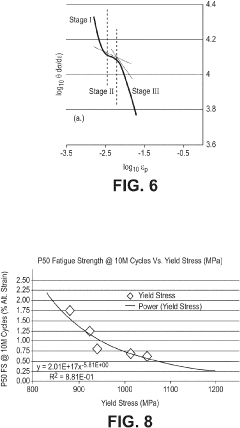

The long-term fatigue behavior of Nitinol in structural applications is another area of ongoing research and concern. While the material exhibits excellent fatigue resistance in certain conditions, its performance under complex, long-duration loading scenarios typical in structural engineering is not fully understood. This knowledge gap has led to conservative design approaches, potentially underutilizing Nitinol's capabilities.

Geographically, the development and application of Nitinol technology in structural engineering show distinct patterns. North America and Europe lead in research and high-end applications, while Asia, particularly China, is rapidly advancing in manufacturing capabilities and novel composite developments. However, the global distribution of Nitinol expertise remains uneven, with significant knowledge concentrations in a few technological hubs.

In the United States and Europe, Nitinol has found widespread use in aerospace and civil engineering applications. The material's ability to absorb and dissipate energy has led to its integration in seismic damping systems for buildings and bridges. However, the high cost of Nitinol production and processing remains a significant barrier to its broader adoption in large-scale structural applications.

Japan and China have emerged as leaders in developing innovative Nitinol-based composites for structural reinforcement. These composites aim to combine Nitinol's stress-resistant properties with the strength and affordability of traditional materials. Despite promising results in laboratory settings, scaling these solutions for commercial use presents ongoing challenges, particularly in terms of manufacturing consistency and long-term durability.

One of the primary technical hurdles facing Nitinol implementation is the complexity of its thermomechanical behavior. The material's performance is highly sensitive to temperature variations and loading conditions, making it challenging to predict and control its behavior in diverse environmental settings. This unpredictability has limited Nitinol's application in critical structural elements where consistent performance is paramount.

Another significant challenge lies in the joining and integration of Nitinol with other structural materials. Traditional welding and fastening methods often compromise Nitinol's unique properties, necessitating the development of specialized techniques. While progress has been made in this area, particularly in the medical device industry, transferring these methods to large-scale structural applications remains problematic.

The long-term fatigue behavior of Nitinol in structural applications is another area of ongoing research and concern. While the material exhibits excellent fatigue resistance in certain conditions, its performance under complex, long-duration loading scenarios typical in structural engineering is not fully understood. This knowledge gap has led to conservative design approaches, potentially underutilizing Nitinol's capabilities.

Geographically, the development and application of Nitinol technology in structural engineering show distinct patterns. North America and Europe lead in research and high-end applications, while Asia, particularly China, is rapidly advancing in manufacturing capabilities and novel composite developments. However, the global distribution of Nitinol expertise remains uneven, with significant knowledge concentrations in a few technological hubs.

Existing Nitinol Applications

01 Heat treatment processes for stress-proofing Nitinol

Various heat treatment processes can be applied to Nitinol to improve its stress resistance and shape memory properties. These processes may include annealing, aging, and controlled cooling techniques. By carefully controlling temperature and time parameters, the microstructure of Nitinol can be optimized to enhance its stress-proofing characteristics.- Heat treatment processes for Nitinol stress-proofing: Various heat treatment processes are employed to stress-proof Nitinol, including annealing, shape-setting, and aging treatments. These processes help to optimize the material's properties, improve its fatigue resistance, and stabilize its shape memory and superelastic behavior.

- Surface modification techniques for Nitinol: Surface modification techniques are used to enhance the stress-proofing of Nitinol. These may include electropolishing, passivation, or coating applications to improve corrosion resistance, reduce surface defects, and increase biocompatibility for medical applications.

- Mechanical processing for Nitinol stress-proofing: Mechanical processing methods such as cold working, shot peening, and laser shock peening are utilized to induce compressive stresses in Nitinol surfaces. These processes can improve fatigue life, wear resistance, and overall mechanical properties of Nitinol components.

- Composition control and alloying for improved stress resistance: Careful control of Nitinol composition and alloying with other elements can enhance its stress-proofing characteristics. This includes adjusting the Nickel-Titanium ratio and adding ternary elements to optimize transformation temperatures and mechanical properties.

- Testing and characterization methods for Nitinol stress-proofing: Various testing and characterization methods are employed to evaluate the effectiveness of stress-proofing treatments on Nitinol. These include fatigue testing, differential scanning calorimetry, and in-situ stress analysis techniques to assess material performance under different loading conditions.

02 Surface modification techniques for Nitinol stress-proofing

Surface modification methods can be employed to enhance the stress resistance of Nitinol. These techniques may include chemical treatments, coatings, or mechanical processes that alter the surface properties of the material. Such modifications can improve corrosion resistance, reduce friction, and enhance overall stress-proofing performance of Nitinol components.Expand Specific Solutions03 Stress-proofing through alloy composition optimization

The stress-proofing properties of Nitinol can be improved by optimizing its alloy composition. This may involve adjusting the ratio of nickel to titanium or incorporating small amounts of other elements. By fine-tuning the composition, the material's phase transformation temperatures and mechanical properties can be tailored to enhance stress resistance.Expand Specific Solutions04 Mechanical processing for Nitinol stress-proofing

Various mechanical processing techniques can be applied to Nitinol to improve its stress-proofing characteristics. These may include cold working, shape setting, and specialized forming methods. Such processes can induce beneficial changes in the material's microstructure and properties, enhancing its resistance to stress and fatigue.Expand Specific Solutions05 Testing and quality control methods for stress-proofed Nitinol

Specialized testing and quality control methods are crucial for ensuring the effectiveness of stress-proofing treatments on Nitinol. These may include fatigue testing, stress-strain analysis, and microstructural examination. Advanced techniques such as in-situ testing and non-destructive evaluation can be employed to assess the stress-proofing performance of Nitinol components.Expand Specific Solutions

Key Industry Players

The competitive landscape for Nitinol's effectiveness in stress proofing structural elements is in a growth phase, with increasing market size and technological advancements. The market is driven by applications in various industries, including medical devices, aerospace, and automotive. Key players like W. L. Gore & Associates, Medtronic, and Abbott Laboratories are investing heavily in R&D to improve Nitinol's properties and expand its applications. Universities such as South China University of Technology and St. Louis University are contributing to the technology's development through research collaborations. The technology's maturity is advancing, with companies like Shape Change Technologies and Memry Corp. specializing in Nitinol production and fabrication, indicating a growing ecosystem of suppliers and manufacturers in this field.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has pioneered the use of Nitinol in their medical devices, particularly in endovascular stent-grafts. Their technology focuses on leveraging Nitinol's shape memory and superelastic properties to create devices that can withstand the dynamic stresses of the cardiovascular system[1]. Gore has developed a unique braiding technique for Nitinol wires, which allows for the creation of flexible yet strong structural elements[2]. This approach enhances the stress distribution across the device, improving its overall durability and resistance to fatigue. Additionally, Gore has implemented advanced surface treatments to enhance the corrosion resistance of their Nitinol components, further improving their long-term performance under stress[3].

Strengths: Innovative braiding techniques, improved stress distribution, and enhanced corrosion resistance. Weaknesses: Limited to specific medical applications and potentially higher costs due to specialized manufacturing.

Medtronic, Inc.

Technical Solution: Medtronic has developed advanced Nitinol-based stents and implants for cardiovascular applications. Their technology utilizes the superelastic properties of Nitinol to create self-expanding stents that can withstand cyclic loading in blood vessels[1]. The company has implemented a proprietary heat treatment process to optimize the stress-strain behavior of Nitinol, enhancing its fatigue resistance in structural elements[2]. Medtronic's approach involves creating a microstructure in the Nitinol that allows for better distribution of stress, reducing the likelihood of material failure under repeated loading conditions[3]. They have also developed surface modification techniques to improve the biocompatibility and corrosion resistance of Nitinol implants, further enhancing their effectiveness in stress-proofing applications[4].

Strengths: Superior fatigue resistance, optimized stress-strain behavior, and enhanced biocompatibility. Weaknesses: High production costs and complex manufacturing processes.

Core Nitinol Innovations

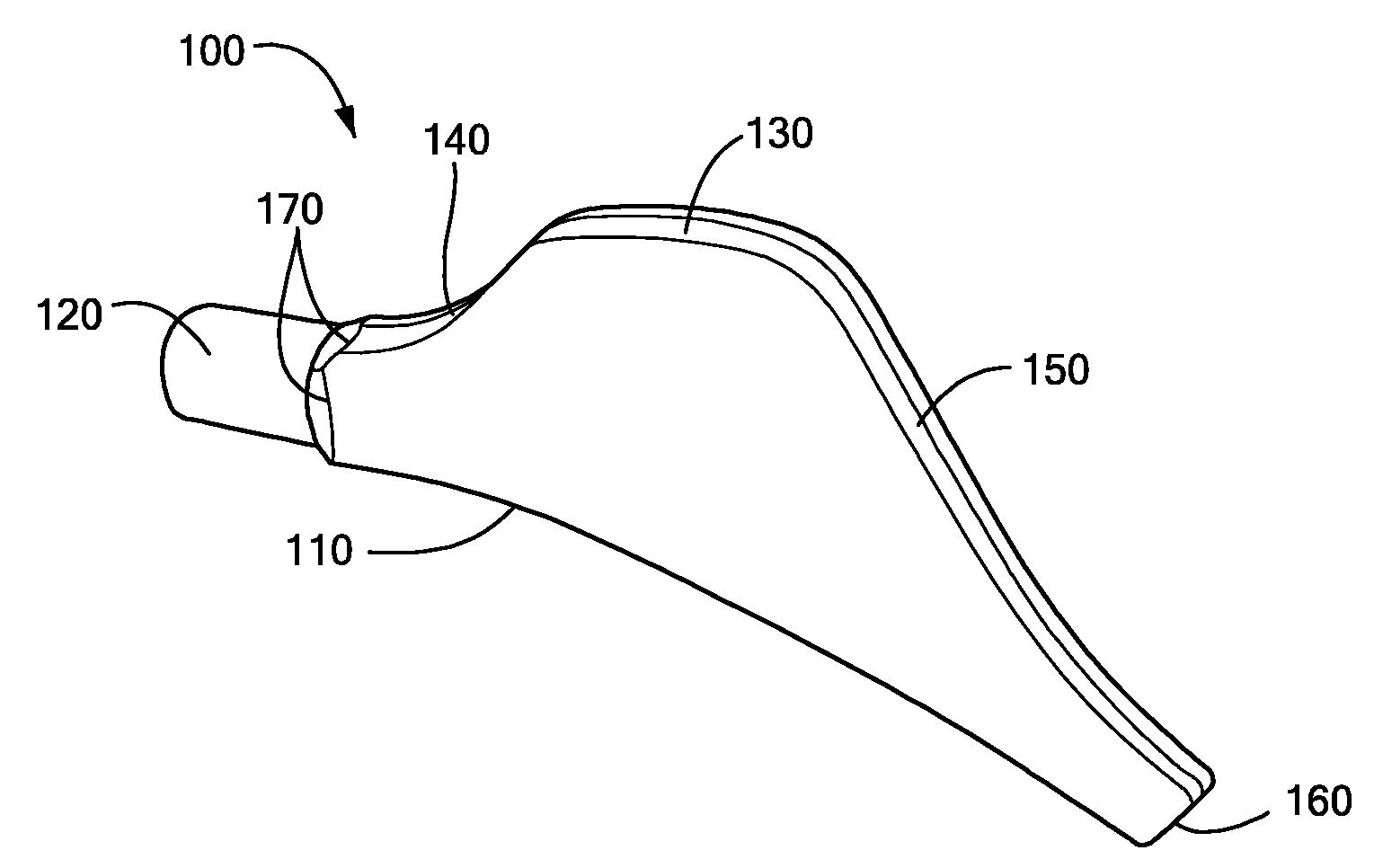

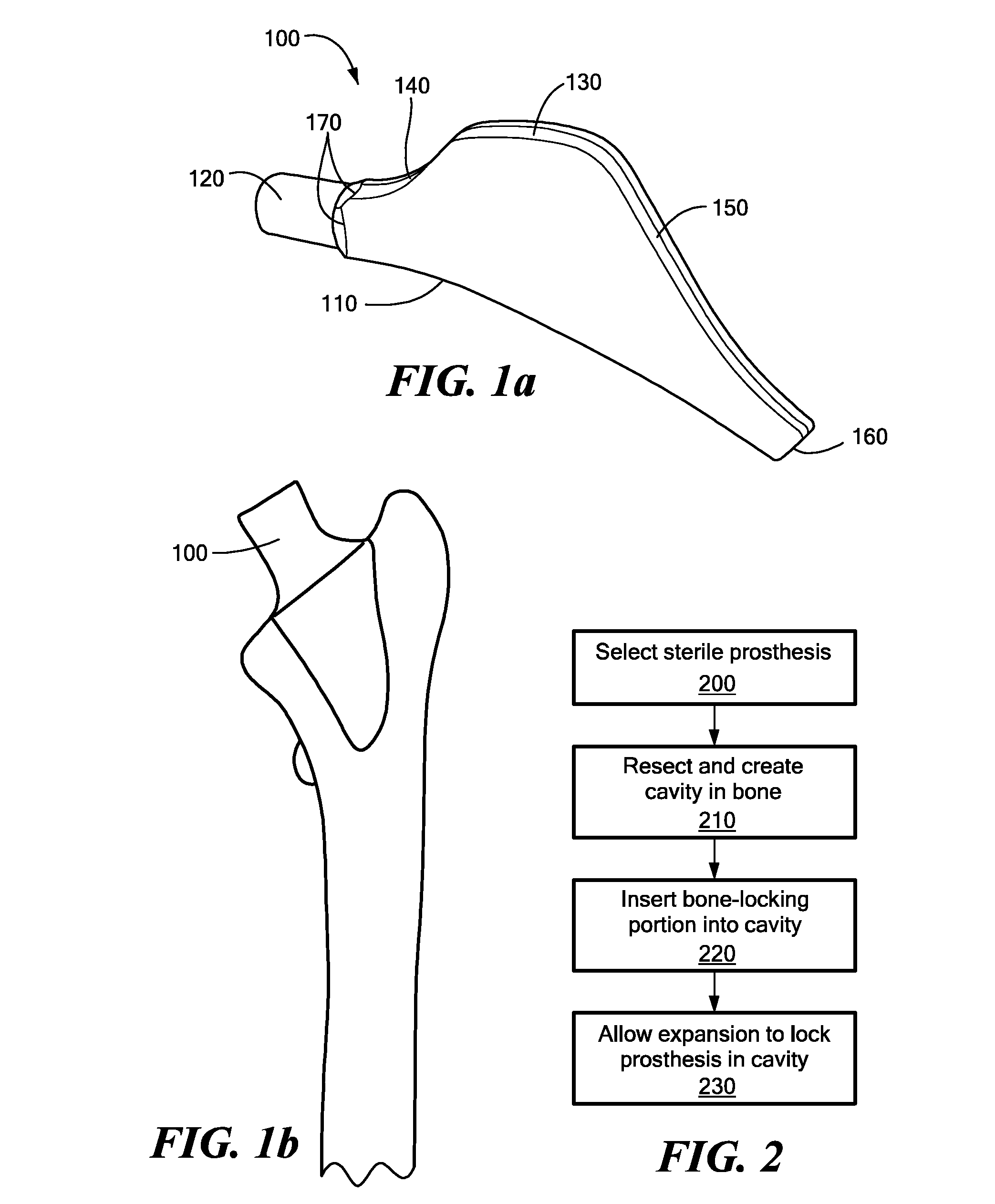

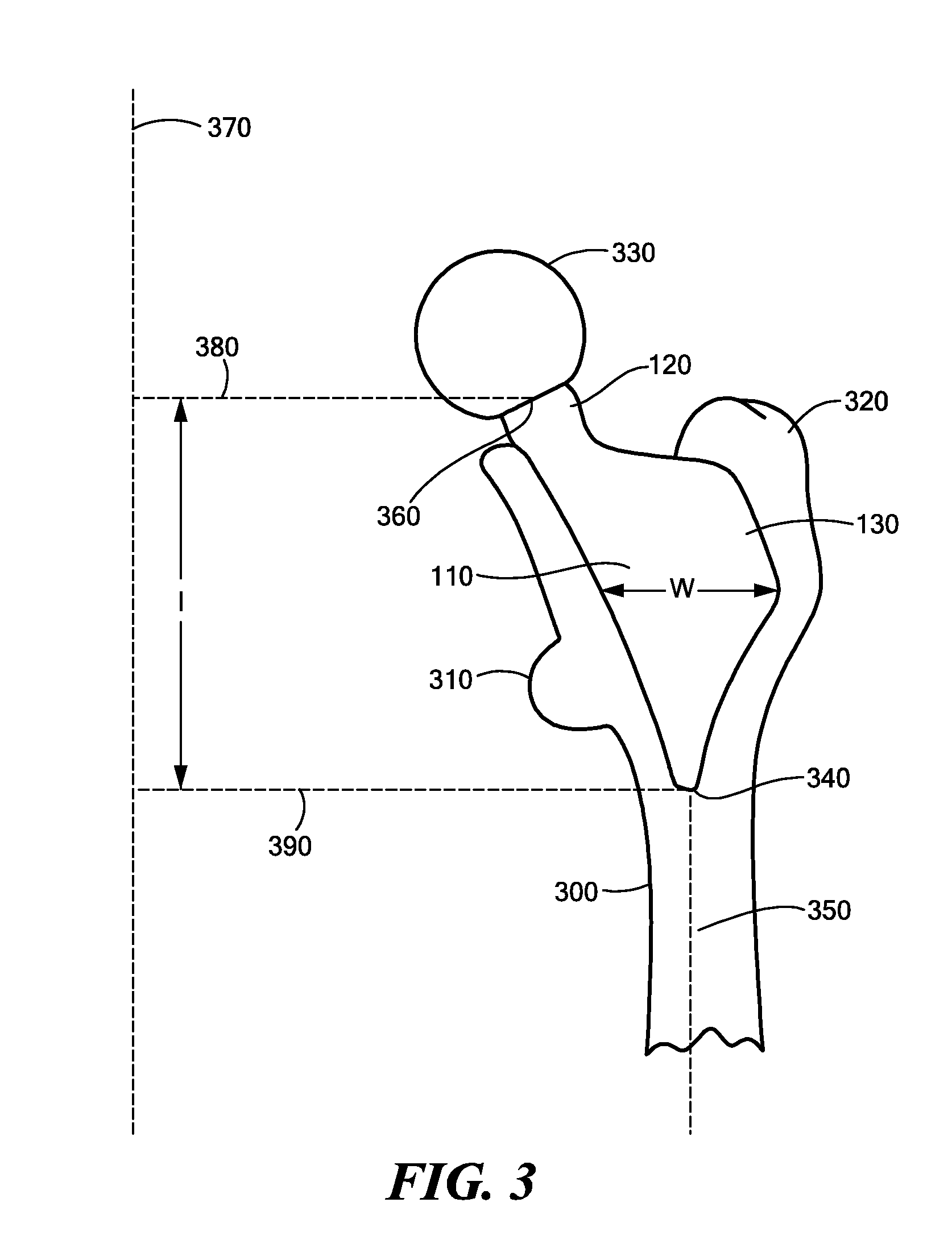

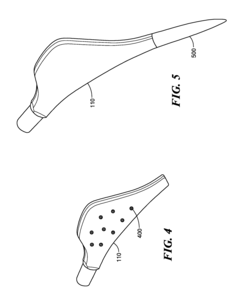

Proximally Self-Locking Long Bone Prosthesis

PatentInactiveUS20080262629A1

Innovation

- A femoral prosthesis with an expandable bone-locking portion made of shape-memory material, such as Nitinol, that expands to create a locking force upon temperature increase, providing primary stability and excluding debris, and a deformable gap-filling material to enhance sealing and stability, allowing for reduced weight-bearing recovery time and increased long-term stability.

Shape memory articles and methods for controlling properties

PatentPendingUS20230364297A1

Innovation

- The process involves promoting or inhibiting the formation of an intermediate R-phase in SMAs like nitinol by altering composition, grain size, geometry, and heat treatment to manipulate mechanical properties such as modulus and ductility, allowing for tailored fatigue performance and stiffness in medical devices.

Material Cost and Scalability

The cost and scalability of Nitinol present significant challenges for its widespread adoption in stress-proofing structural elements. As a shape memory alloy, Nitinol's unique properties come at a premium price, with raw material costs substantially higher than traditional structural materials like steel or aluminum. This elevated cost is primarily due to the complex manufacturing process required to produce Nitinol with precise composition and properties.

The production of Nitinol involves careful control of the nickel-titanium ratio and subsequent heat treatments to achieve the desired shape memory and superelastic characteristics. This process demands specialized equipment and expertise, contributing to the overall expense. Additionally, the limited number of suppliers capable of producing high-quality Nitinol further impacts its cost and availability.

Scalability issues arise from both the production process and the material's inherent properties. The manufacturing of Nitinol is typically done in smaller batches compared to conventional materials, making it challenging to achieve economies of scale. This limitation affects the ability to reduce costs through large-scale production, a crucial factor for widespread implementation in structural applications.

Furthermore, the unique properties of Nitinol that make it attractive for stress-proofing also complicate its integration into existing structural design and manufacturing processes. Engineers and manufacturers must develop new techniques and tools to effectively work with Nitinol, adding to the overall cost and complexity of implementation.

Despite these challenges, ongoing research and development efforts are focused on improving the cost-effectiveness and scalability of Nitinol production. Advancements in manufacturing technologies, such as powder metallurgy and additive manufacturing, show promise in reducing production costs and increasing scalability. These methods could potentially allow for more efficient use of raw materials and enable the production of complex Nitinol structures with less waste.

The development of new alloy compositions that maintain Nitinol's beneficial properties while using more abundant or less expensive elements is another area of active research. Such innovations could significantly impact the material's cost structure and availability, potentially opening up new applications in structural engineering.

As the demand for advanced materials in structural applications grows, there is increasing pressure to overcome these cost and scalability challenges. The future adoption of Nitinol in stress-proofing structural elements will likely depend on continued technological advancements and the ability to demonstrate clear cost-benefit advantages over traditional materials in specific high-value applications.

The production of Nitinol involves careful control of the nickel-titanium ratio and subsequent heat treatments to achieve the desired shape memory and superelastic characteristics. This process demands specialized equipment and expertise, contributing to the overall expense. Additionally, the limited number of suppliers capable of producing high-quality Nitinol further impacts its cost and availability.

Scalability issues arise from both the production process and the material's inherent properties. The manufacturing of Nitinol is typically done in smaller batches compared to conventional materials, making it challenging to achieve economies of scale. This limitation affects the ability to reduce costs through large-scale production, a crucial factor for widespread implementation in structural applications.

Furthermore, the unique properties of Nitinol that make it attractive for stress-proofing also complicate its integration into existing structural design and manufacturing processes. Engineers and manufacturers must develop new techniques and tools to effectively work with Nitinol, adding to the overall cost and complexity of implementation.

Despite these challenges, ongoing research and development efforts are focused on improving the cost-effectiveness and scalability of Nitinol production. Advancements in manufacturing technologies, such as powder metallurgy and additive manufacturing, show promise in reducing production costs and increasing scalability. These methods could potentially allow for more efficient use of raw materials and enable the production of complex Nitinol structures with less waste.

The development of new alloy compositions that maintain Nitinol's beneficial properties while using more abundant or less expensive elements is another area of active research. Such innovations could significantly impact the material's cost structure and availability, potentially opening up new applications in structural engineering.

As the demand for advanced materials in structural applications grows, there is increasing pressure to overcome these cost and scalability challenges. The future adoption of Nitinol in stress-proofing structural elements will likely depend on continued technological advancements and the ability to demonstrate clear cost-benefit advantages over traditional materials in specific high-value applications.

Environmental Impact Assessment

The environmental impact assessment of Nitinol's use in stress-proofing structural elements reveals both potential benefits and concerns. Nitinol, a nickel-titanium alloy known for its shape memory and superelastic properties, offers unique advantages in structural engineering applications. However, its production and application processes require careful consideration of environmental factors.

The manufacturing of Nitinol involves energy-intensive processes, including vacuum or inert gas melting, which contribute to greenhouse gas emissions. The extraction and processing of nickel and titanium, the primary components of Nitinol, also have significant environmental footprints. Mining operations for these metals can lead to habitat disruption, soil erosion, and water pollution if not properly managed.

On the positive side, Nitinol's durability and ability to withstand stress without permanent deformation can lead to longer-lasting structures. This increased lifespan potentially reduces the need for frequent replacements or repairs, thereby minimizing the overall environmental impact associated with construction and maintenance activities. Additionally, Nitinol's unique properties allow for more efficient designs, potentially reducing the amount of material needed in certain applications.

The use of Nitinol in stress-proofing structural elements may also contribute to improved energy efficiency in buildings and infrastructure. Its ability to adapt to temperature changes and absorb vibrations can enhance the overall performance of structures, potentially leading to reduced energy consumption for heating, cooling, and maintenance.

However, the end-of-life management of Nitinol-containing structures presents challenges. While the alloy is recyclable, the separation and recovery processes for nickel and titanium can be complex and energy-intensive. Proper recycling infrastructure and protocols need to be established to ensure that Nitinol components are effectively reclaimed and reused, minimizing waste and environmental impact.

The potential release of nickel during the use phase or improper disposal of Nitinol-containing products raises concerns about soil and water contamination. Nickel is known to be potentially harmful to ecosystems and human health in high concentrations. Therefore, careful monitoring and management of Nitinol applications are necessary to prevent environmental contamination.

In conclusion, while Nitinol offers promising benefits for stress-proofing structural elements, its environmental impact is multifaceted. Balancing the advantages of improved structural performance and longevity against the environmental costs of production and end-of-life management is crucial. Future research and development should focus on optimizing manufacturing processes, improving recycling techniques, and exploring more sustainable alternatives to mitigate the environmental impact of Nitinol use in structural applications.

The manufacturing of Nitinol involves energy-intensive processes, including vacuum or inert gas melting, which contribute to greenhouse gas emissions. The extraction and processing of nickel and titanium, the primary components of Nitinol, also have significant environmental footprints. Mining operations for these metals can lead to habitat disruption, soil erosion, and water pollution if not properly managed.

On the positive side, Nitinol's durability and ability to withstand stress without permanent deformation can lead to longer-lasting structures. This increased lifespan potentially reduces the need for frequent replacements or repairs, thereby minimizing the overall environmental impact associated with construction and maintenance activities. Additionally, Nitinol's unique properties allow for more efficient designs, potentially reducing the amount of material needed in certain applications.

The use of Nitinol in stress-proofing structural elements may also contribute to improved energy efficiency in buildings and infrastructure. Its ability to adapt to temperature changes and absorb vibrations can enhance the overall performance of structures, potentially leading to reduced energy consumption for heating, cooling, and maintenance.

However, the end-of-life management of Nitinol-containing structures presents challenges. While the alloy is recyclable, the separation and recovery processes for nickel and titanium can be complex and energy-intensive. Proper recycling infrastructure and protocols need to be established to ensure that Nitinol components are effectively reclaimed and reused, minimizing waste and environmental impact.

The potential release of nickel during the use phase or improper disposal of Nitinol-containing products raises concerns about soil and water contamination. Nickel is known to be potentially harmful to ecosystems and human health in high concentrations. Therefore, careful monitoring and management of Nitinol applications are necessary to prevent environmental contamination.

In conclusion, while Nitinol offers promising benefits for stress-proofing structural elements, its environmental impact is multifaceted. Balancing the advantages of improved structural performance and longevity against the environmental costs of production and end-of-life management is crucial. Future research and development should focus on optimizing manufacturing processes, improving recycling techniques, and exploring more sustainable alternatives to mitigate the environmental impact of Nitinol use in structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!