Nitinol-Based Actuators for Miniature Satellite Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Actuators in Space: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of space technology, particularly in the development of actuators for miniature satellite systems. This shape memory alloy (SMA) possesses unique properties that make it exceptionally suitable for space applications, including its ability to remember and return to a predetermined shape when heated.

The evolution of satellite technology has been marked by a continuous drive towards miniaturization, with CubeSats and other small satellite platforms gaining prominence in recent years. This trend has created a demand for compact, lightweight, and efficient actuator systems that can operate reliably in the harsh environment of space. Nitinol-based actuators have emerged as a promising solution to meet these requirements.

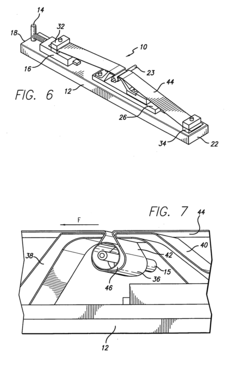

The primary objective of research on Nitinol-based actuators for miniature satellite systems is to harness the material's shape memory and superelastic properties to create robust, low-power actuation mechanisms. These actuators are envisioned to perform various functions in satellites, such as deploying solar panels, adjusting antennas, and controlling attitude determination and control systems (ADCS).

One of the key advantages of Nitinol actuators is their high power-to-weight ratio, which is crucial in space applications where every gram matters. Additionally, their ability to operate without complex mechanical components reduces the risk of failure and enhances overall system reliability. The simplicity of Nitinol actuators also contributes to reduced manufacturing costs and improved scalability for mass production of small satellites.

Research in this field aims to overcome several challenges, including optimizing the actuation speed, improving energy efficiency, and enhancing the long-term stability of Nitinol actuators in the space environment. Scientists and engineers are exploring various designs and configurations to maximize the performance of these actuators while minimizing their power consumption and thermal management requirements.

The development of Nitinol-based actuators for space applications is part of a broader trend towards smart materials and adaptive structures in aerospace engineering. This research not only promises to revolutionize satellite design but also has potential applications in other space systems, such as deployable structures for space habitats and robotic exploration missions.

As the space industry continues to evolve, with an increasing focus on small satellites and constellations, the advancement of Nitinol actuator technology is expected to play a crucial role in enabling new capabilities and mission concepts. The ongoing research in this field seeks to push the boundaries of what is possible in satellite miniaturization and functionality, paving the way for more efficient, versatile, and cost-effective space exploration and utilization.

The evolution of satellite technology has been marked by a continuous drive towards miniaturization, with CubeSats and other small satellite platforms gaining prominence in recent years. This trend has created a demand for compact, lightweight, and efficient actuator systems that can operate reliably in the harsh environment of space. Nitinol-based actuators have emerged as a promising solution to meet these requirements.

The primary objective of research on Nitinol-based actuators for miniature satellite systems is to harness the material's shape memory and superelastic properties to create robust, low-power actuation mechanisms. These actuators are envisioned to perform various functions in satellites, such as deploying solar panels, adjusting antennas, and controlling attitude determination and control systems (ADCS).

One of the key advantages of Nitinol actuators is their high power-to-weight ratio, which is crucial in space applications where every gram matters. Additionally, their ability to operate without complex mechanical components reduces the risk of failure and enhances overall system reliability. The simplicity of Nitinol actuators also contributes to reduced manufacturing costs and improved scalability for mass production of small satellites.

Research in this field aims to overcome several challenges, including optimizing the actuation speed, improving energy efficiency, and enhancing the long-term stability of Nitinol actuators in the space environment. Scientists and engineers are exploring various designs and configurations to maximize the performance of these actuators while minimizing their power consumption and thermal management requirements.

The development of Nitinol-based actuators for space applications is part of a broader trend towards smart materials and adaptive structures in aerospace engineering. This research not only promises to revolutionize satellite design but also has potential applications in other space systems, such as deployable structures for space habitats and robotic exploration missions.

As the space industry continues to evolve, with an increasing focus on small satellites and constellations, the advancement of Nitinol actuator technology is expected to play a crucial role in enabling new capabilities and mission concepts. The ongoing research in this field seeks to push the boundaries of what is possible in satellite miniaturization and functionality, paving the way for more efficient, versatile, and cost-effective space exploration and utilization.

Market Analysis for Miniature Satellite Actuators

The market for miniature satellite actuators, particularly those based on Nitinol technology, is experiencing significant growth driven by the increasing demand for small satellite systems in various space applications. The global small satellite market is projected to reach $7.53 billion by 2022, with a compound annual growth rate (CAGR) of 20.28% from 2017 to 2022. This growth is primarily fueled by the rising adoption of small satellites for Earth observation, communication, and scientific research purposes.

Nitinol-based actuators are gaining traction in the miniature satellite market due to their unique properties, including shape memory effect and superelasticity. These characteristics make them ideal for deployment mechanisms, attitude control systems, and other critical functions in small satellite platforms. The demand for Nitinol actuators is expected to grow in parallel with the small satellite market, as they offer advantages such as compact size, low power consumption, and high reliability.

The market for miniature satellite actuators is segmented based on satellite size, with nanosatellites (1-10 kg) and microsatellites (10-100 kg) being the primary focus areas for Nitinol-based actuators. These satellite categories are witnessing rapid adoption across commercial, government, and academic sectors, driving the demand for advanced actuator technologies.

Geographically, North America dominates the miniature satellite actuator market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of technological advancements and market share, with major aerospace companies and startups investing heavily in small satellite technologies. Europe is also a significant player, with countries like the United Kingdom, France, and Germany contributing to the market growth through their space programs and commercial initiatives.

The commercial sector is expected to be the fastest-growing segment for miniature satellite actuators, driven by the increasing number of private companies entering the space industry. These companies are developing innovative small satellite constellations for applications such as global internet coverage, Earth imaging, and asset tracking, creating a substantial demand for advanced actuator technologies.

Key market trends include the development of multi-functional actuators that can perform multiple tasks within a single device, reducing overall satellite mass and complexity. Additionally, there is a growing focus on improving the reliability and longevity of actuators to meet the demanding requirements of long-duration space missions.

Challenges in the market include the need for standardization of actuator interfaces and performance metrics, as well as the development of more efficient power management systems to support the operation of Nitinol-based actuators in power-constrained small satellite platforms. Despite these challenges, the market for miniature satellite actuators, particularly those based on Nitinol technology, is poised for substantial growth in the coming years, driven by the expanding small satellite ecosystem and the continuous innovation in actuator design and performance.

Nitinol-based actuators are gaining traction in the miniature satellite market due to their unique properties, including shape memory effect and superelasticity. These characteristics make them ideal for deployment mechanisms, attitude control systems, and other critical functions in small satellite platforms. The demand for Nitinol actuators is expected to grow in parallel with the small satellite market, as they offer advantages such as compact size, low power consumption, and high reliability.

The market for miniature satellite actuators is segmented based on satellite size, with nanosatellites (1-10 kg) and microsatellites (10-100 kg) being the primary focus areas for Nitinol-based actuators. These satellite categories are witnessing rapid adoption across commercial, government, and academic sectors, driving the demand for advanced actuator technologies.

Geographically, North America dominates the miniature satellite actuator market, followed by Europe and Asia-Pacific. The United States, in particular, leads in terms of technological advancements and market share, with major aerospace companies and startups investing heavily in small satellite technologies. Europe is also a significant player, with countries like the United Kingdom, France, and Germany contributing to the market growth through their space programs and commercial initiatives.

The commercial sector is expected to be the fastest-growing segment for miniature satellite actuators, driven by the increasing number of private companies entering the space industry. These companies are developing innovative small satellite constellations for applications such as global internet coverage, Earth imaging, and asset tracking, creating a substantial demand for advanced actuator technologies.

Key market trends include the development of multi-functional actuators that can perform multiple tasks within a single device, reducing overall satellite mass and complexity. Additionally, there is a growing focus on improving the reliability and longevity of actuators to meet the demanding requirements of long-duration space missions.

Challenges in the market include the need for standardization of actuator interfaces and performance metrics, as well as the development of more efficient power management systems to support the operation of Nitinol-based actuators in power-constrained small satellite platforms. Despite these challenges, the market for miniature satellite actuators, particularly those based on Nitinol technology, is poised for substantial growth in the coming years, driven by the expanding small satellite ecosystem and the continuous innovation in actuator design and performance.

Current Challenges in Nitinol-Based Space Actuators

The development of Nitinol-based actuators for miniature satellite systems faces several significant challenges that hinder their widespread adoption and optimal performance in space applications. One of the primary obstacles is the limited force output of Nitinol actuators, which restricts their ability to perform certain tasks in satellite systems. This limitation is particularly pronounced in miniature satellites where space and weight constraints are critical.

Another major challenge is the high power consumption of Nitinol actuators. In space environments, where power resources are scarce and carefully managed, the energy requirements of these actuators can be a significant drawback. This issue is compounded by the need for precise temperature control to activate the shape memory effect, which further increases power demands.

The response time of Nitinol actuators also presents a challenge for space applications. The heating and cooling cycles required for actuation can be relatively slow, limiting their usefulness in scenarios that demand rapid and precise movements. This slower response time can impact the overall agility and responsiveness of miniature satellite systems.

Durability and fatigue resistance are additional concerns for Nitinol-based actuators in space environments. The harsh conditions of space, including extreme temperature fluctuations and radiation exposure, can potentially degrade the performance and lifespan of these actuators over time. Ensuring long-term reliability is crucial for space missions, where maintenance or replacement is not feasible.

Furthermore, the complexity of controlling Nitinol actuators poses challenges in miniature satellite systems. Achieving precise and repeatable movements requires sophisticated control algorithms and sensing mechanisms, which can be difficult to implement within the constraints of small satellite platforms.

The integration of Nitinol actuators with other satellite components also presents challenges. Miniature satellites have limited space and strict mass budgets, making it difficult to incorporate actuators without compromising other essential systems. This integration challenge extends to thermal management, as the heat generated by Nitinol actuators must be effectively dissipated to prevent interference with other satellite functions.

Lastly, the space qualification of Nitinol-based actuators remains a significant hurdle. Rigorous testing and certification processes are required to ensure these actuators can withstand the launch environment and operate reliably in space. The cost and time associated with space qualification can be substantial, potentially limiting the adoption of this technology in smaller satellite missions with tighter budgets and shorter development cycles.

Another major challenge is the high power consumption of Nitinol actuators. In space environments, where power resources are scarce and carefully managed, the energy requirements of these actuators can be a significant drawback. This issue is compounded by the need for precise temperature control to activate the shape memory effect, which further increases power demands.

The response time of Nitinol actuators also presents a challenge for space applications. The heating and cooling cycles required for actuation can be relatively slow, limiting their usefulness in scenarios that demand rapid and precise movements. This slower response time can impact the overall agility and responsiveness of miniature satellite systems.

Durability and fatigue resistance are additional concerns for Nitinol-based actuators in space environments. The harsh conditions of space, including extreme temperature fluctuations and radiation exposure, can potentially degrade the performance and lifespan of these actuators over time. Ensuring long-term reliability is crucial for space missions, where maintenance or replacement is not feasible.

Furthermore, the complexity of controlling Nitinol actuators poses challenges in miniature satellite systems. Achieving precise and repeatable movements requires sophisticated control algorithms and sensing mechanisms, which can be difficult to implement within the constraints of small satellite platforms.

The integration of Nitinol actuators with other satellite components also presents challenges. Miniature satellites have limited space and strict mass budgets, making it difficult to incorporate actuators without compromising other essential systems. This integration challenge extends to thermal management, as the heat generated by Nitinol actuators must be effectively dissipated to prevent interference with other satellite functions.

Lastly, the space qualification of Nitinol-based actuators remains a significant hurdle. Rigorous testing and certification processes are required to ensure these actuators can withstand the launch environment and operate reliably in space. The cost and time associated with space qualification can be substantial, potentially limiting the adoption of this technology in smaller satellite missions with tighter budgets and shorter development cycles.

Existing Nitinol Actuator Solutions for Satellites

01 Shape memory alloy actuators

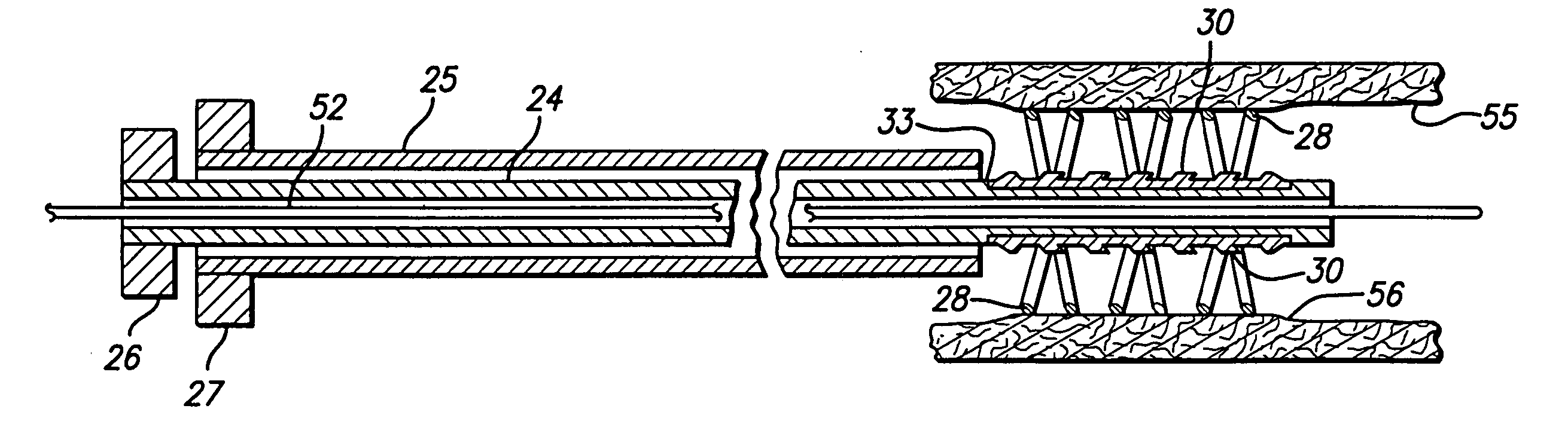

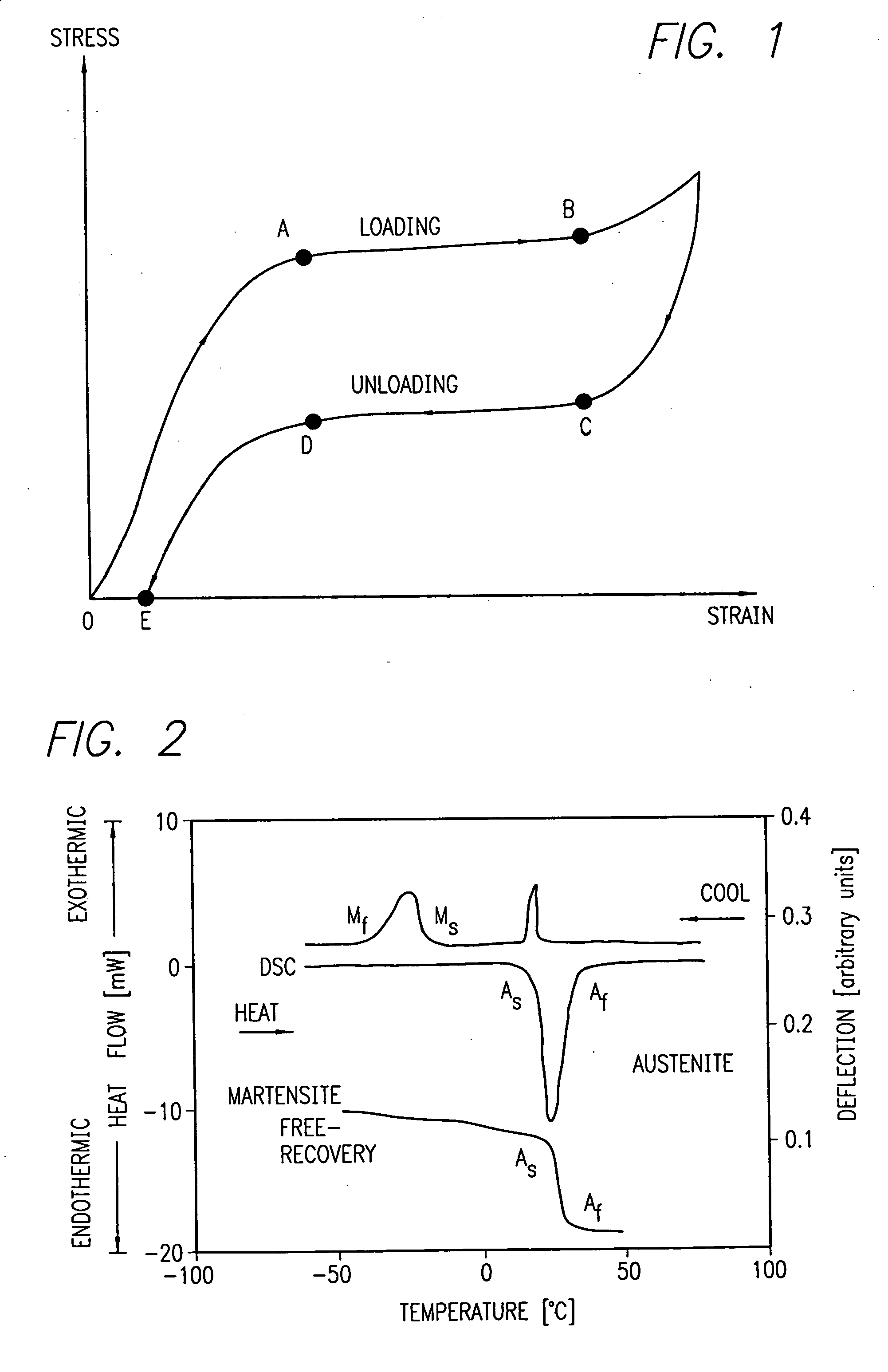

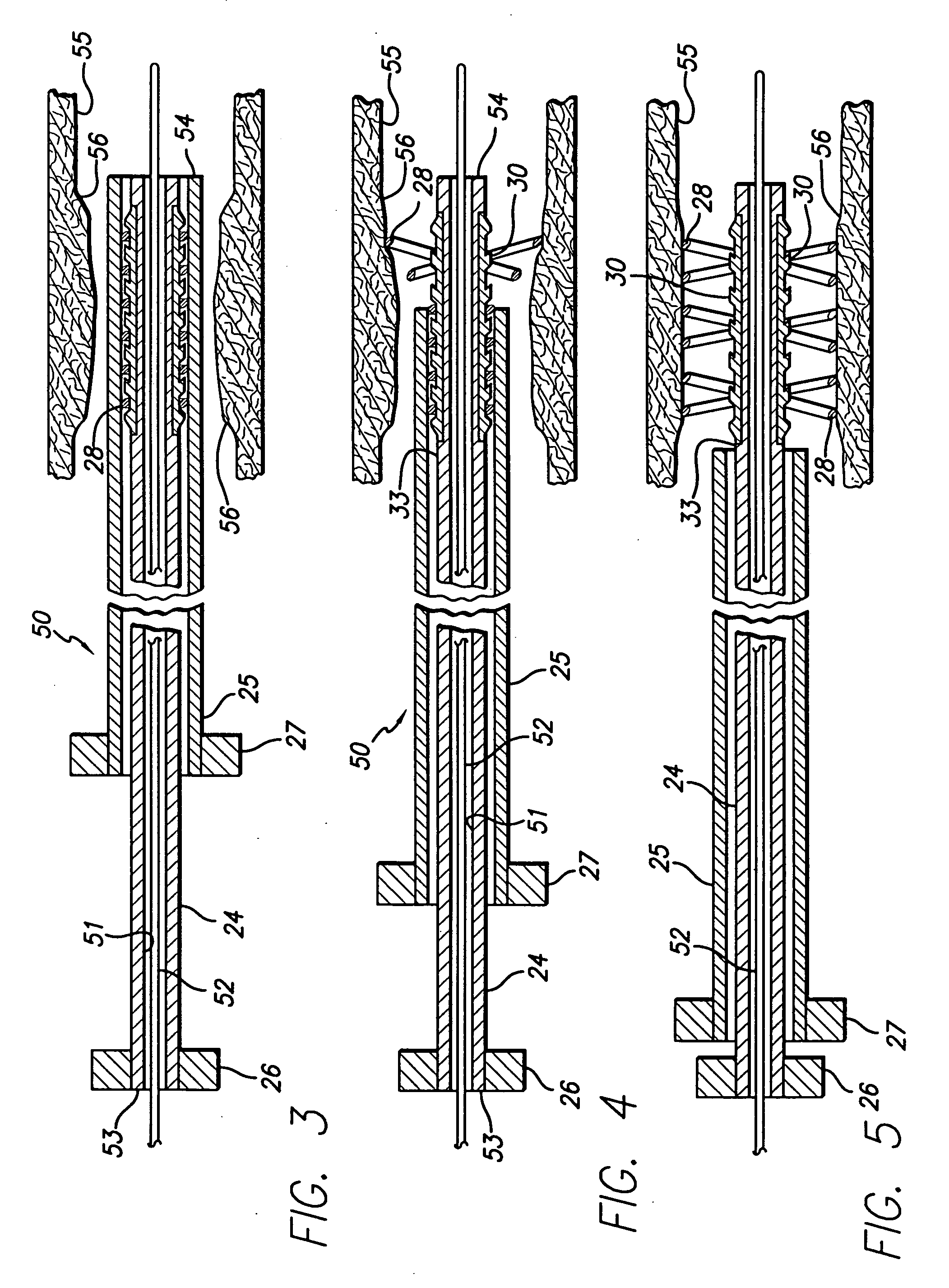

Nitinol-based actuators utilize the shape memory properties of the alloy to create motion or force. These actuators can be designed to respond to temperature changes, allowing for controlled movement in various applications such as robotics, aerospace, and medical devices.- Shape memory alloy actuators: Nitinol-based actuators utilize the shape memory properties of the alloy to create motion or force. These actuators can be designed to respond to temperature changes, allowing for controlled movement in various applications such as robotics, aerospace, and medical devices.

- Nitinol actuators in medical devices: Nitinol-based actuators are widely used in medical devices due to their biocompatibility and unique properties. They are employed in stents, guidewires, and surgical instruments, allowing for minimally invasive procedures and improved patient outcomes.

- Thermal activation of Nitinol actuators: Nitinol actuators can be activated by temperature changes, either through direct heating or by passing an electric current through the material. This thermal activation allows for precise control of the actuator's movement and force output in various applications.

- Nitinol actuators in automotive applications: Nitinol-based actuators are used in automotive systems for various purposes, including valve control, engine management, and safety features. Their compact size, reliability, and ability to operate in harsh environments make them suitable for automotive applications.

- Manufacturing and processing of Nitinol actuators: The manufacturing and processing of Nitinol-based actuators involve specialized techniques to achieve desired properties and performance. This includes heat treatment, shape setting, and surface modifications to optimize the actuator's behavior and durability.

02 Nitinol actuators in medical devices

Nitinol-based actuators are widely used in medical devices due to their biocompatibility and unique properties. They are employed in minimally invasive surgical instruments, stents, and other implantable devices, allowing for precise control and deployment within the human body.Expand Specific Solutions03 Thermal activation of Nitinol actuators

Nitinol actuators can be activated by temperature changes, utilizing the material's phase transformation properties. This allows for the design of thermally-activated devices that can perform specific functions when exposed to certain temperature ranges, such as in automotive or industrial applications.Expand Specific Solutions04 Nitinol actuators in aerospace and robotics

The unique properties of Nitinol make it suitable for use in aerospace and robotics applications. These actuators can be designed to provide precise movement, vibration damping, and adaptive structures in aircraft, spacecraft, and robotic systems.Expand Specific Solutions05 Manufacturing and processing of Nitinol actuators

The production of Nitinol-based actuators involves specialized manufacturing and processing techniques. This includes methods for shaping, heat treatment, and surface modification to optimize the performance and reliability of the actuators for specific applications.Expand Specific Solutions

Key Players in Nitinol Actuator Development

The research on Nitinol-based actuators for miniature satellite systems is in an emerging stage, with growing market potential due to increasing demand for small satellites. The technology's maturity is advancing, but still evolving. Key players include academic institutions like Beihang University, Harbin Institute of Technology, and University of Florida, alongside industry leaders such as Zhejiang Geespace Technology and Israel Aerospace Industries. These organizations are driving innovation in shape memory alloys for space applications. The competitive landscape is diverse, with collaborations between universities and aerospace companies accelerating development. As the technology progresses, we can expect increased commercialization and adoption in satellite systems.

Beihang University

Technical Solution: Beihang University has developed a novel Nitinol-based actuator system for miniature satellite applications. Their approach utilizes shape memory alloy (SMA) wires arranged in a parallel configuration to create a compact and lightweight actuator. The system employs a closed-loop control mechanism with temperature feedback to achieve precise positioning and force output. The actuator design incorporates a pre-stressed SMA wire arrangement, allowing for bidirectional actuation with a single set of wires[1]. This configuration results in a higher power-to-weight ratio compared to traditional electromagnetic actuators. The university has also implemented a unique thermal management system to optimize the heating and cooling cycles of the Nitinol wires, improving response time and energy efficiency[3].

Strengths: Compact design, high power-to-weight ratio, precise control. Weaknesses: Potential thermal management challenges in space environment, limited actuation frequency due to cooling time.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed an advanced Nitinol-based actuator system for miniature satellites, focusing on enhancing reliability and longevity in space environments. Their approach utilizes a unique composite structure that combines Nitinol wires with a carbon fiber reinforced polymer (CFRP) substrate. This design provides improved thermal stability and mechanical strength while maintaining the actuator's flexibility. The institute has implemented a novel phase transformation control technique that allows for fine-tuning of the actuator's response characteristics[2]. Additionally, they have developed a specialized coating for the Nitinol wires that mitigates atomic oxygen erosion, a common issue in low Earth orbit. The actuator system incorporates a redundant wire configuration to ensure continued operation in case of individual wire failure, significantly improving overall system reliability[4].

Strengths: Enhanced durability in space environments, improved reliability through redundancy. Weaknesses: Increased complexity and potential higher manufacturing costs.

Core Innovations in Nitinol Space Technology

Avoiding stress-induced martensitic transformation in nickle titanium alloys used in medical devices

PatentInactiveUS20070162105A1

Innovation

- A process involving heating a shape memory alloy to a temperature above its martensite deformation temperature (Md) to deform it in an austenitic state, allowing it to be deployed within a mammalian body without generating stress-induced martensite, using a hollow delivery system like a catheter to maintain the deformed shape at room temperature.

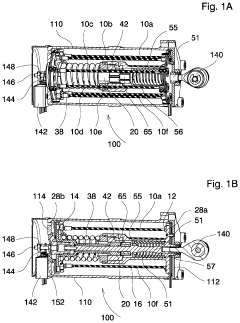

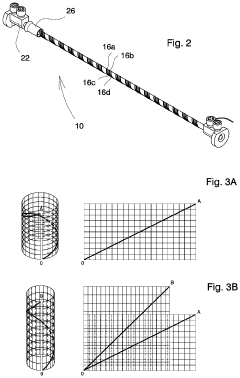

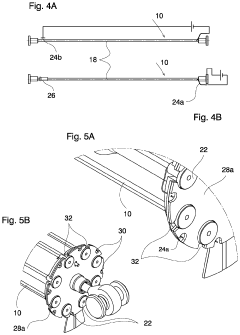

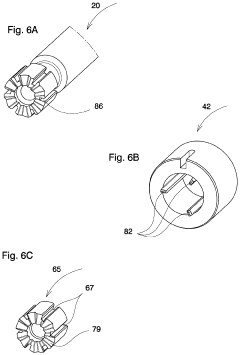

Shape memory based actuator

PatentActiveUS20210095646A1

Innovation

- A Shape Memory Material (SMM) actuator with a heating wire coiled in a circular helix configuration, where the uniform oblique angle is chosen to minimize stress on the heating wire, ensuring efficient heating and extended operational life by canceling out axial and transverse strains, and using Cu—Al—Ni alloys for improved conductivity and temperature control.

Space Debris Mitigation Strategies

Space debris mitigation strategies have become increasingly crucial in the context of miniature satellite systems, particularly those utilizing Nitinol-based actuators. As the number of small satellites in low Earth orbit continues to grow, the risk of collisions and the generation of additional debris pose significant challenges to space operations and sustainability.

One of the primary mitigation strategies involves the implementation of end-of-life disposal mechanisms. Nitinol-based actuators can play a vital role in this aspect by enabling compact and efficient deorbiting systems. These shape memory alloy actuators can be designed to deploy drag-enhancing structures, such as inflatable balloons or sail-like devices, which increase atmospheric drag and accelerate the satellite's reentry into Earth's atmosphere.

Another important strategy focuses on collision avoidance maneuvers. Miniature satellites equipped with Nitinol actuators can potentially perform precise attitude control and minor orbital adjustments to avoid potential collisions with other objects. The unique properties of Nitinol, including its high power-to-weight ratio and ability to recover its original shape after deformation, make it an attractive option for developing agile and responsive control systems in small satellite platforms.

Debris tracking and identification are also critical components of mitigation efforts. While not directly related to Nitinol actuators, the development of miniaturized sensor systems that can be integrated into small satellites may contribute to improved space situational awareness. This could potentially lead to more accurate debris mapping and prediction models, enhancing overall mitigation strategies.

The design of satellite structures that minimize the generation of debris in the event of a collision is another area where Nitinol-based technologies could contribute. The material's superelastic properties might be leveraged to create impact-resistant components or self-healing structures that reduce the likelihood of fragmentation upon impact.

Lastly, the development of active debris removal technologies represents a more proactive approach to space debris mitigation. While currently beyond the scope of most miniature satellite missions, future advancements in Nitinol-based actuators could potentially enable small satellites to participate in debris removal operations, such as capturing or de-orbiting smaller debris objects.

As research on Nitinol-based actuators for miniature satellite systems progresses, it is essential to consider these space debris mitigation strategies in the design and implementation phases. By integrating debris mitigation considerations into the development of Nitinol-based technologies, the space industry can work towards more sustainable and responsible satellite operations in increasingly congested orbital environments.

One of the primary mitigation strategies involves the implementation of end-of-life disposal mechanisms. Nitinol-based actuators can play a vital role in this aspect by enabling compact and efficient deorbiting systems. These shape memory alloy actuators can be designed to deploy drag-enhancing structures, such as inflatable balloons or sail-like devices, which increase atmospheric drag and accelerate the satellite's reentry into Earth's atmosphere.

Another important strategy focuses on collision avoidance maneuvers. Miniature satellites equipped with Nitinol actuators can potentially perform precise attitude control and minor orbital adjustments to avoid potential collisions with other objects. The unique properties of Nitinol, including its high power-to-weight ratio and ability to recover its original shape after deformation, make it an attractive option for developing agile and responsive control systems in small satellite platforms.

Debris tracking and identification are also critical components of mitigation efforts. While not directly related to Nitinol actuators, the development of miniaturized sensor systems that can be integrated into small satellites may contribute to improved space situational awareness. This could potentially lead to more accurate debris mapping and prediction models, enhancing overall mitigation strategies.

The design of satellite structures that minimize the generation of debris in the event of a collision is another area where Nitinol-based technologies could contribute. The material's superelastic properties might be leveraged to create impact-resistant components or self-healing structures that reduce the likelihood of fragmentation upon impact.

Lastly, the development of active debris removal technologies represents a more proactive approach to space debris mitigation. While currently beyond the scope of most miniature satellite missions, future advancements in Nitinol-based actuators could potentially enable small satellites to participate in debris removal operations, such as capturing or de-orbiting smaller debris objects.

As research on Nitinol-based actuators for miniature satellite systems progresses, it is essential to consider these space debris mitigation strategies in the design and implementation phases. By integrating debris mitigation considerations into the development of Nitinol-based technologies, the space industry can work towards more sustainable and responsible satellite operations in increasingly congested orbital environments.

Radiation Resistance of Nitinol Actuators

The radiation resistance of Nitinol actuators is a critical factor in their application for miniature satellite systems. Nitinol, an alloy of nickel and titanium, exhibits unique shape memory and superelastic properties, making it an attractive material for space-based actuators. However, the harsh radiation environment in space poses significant challenges to the long-term performance and reliability of these actuators.

In the context of space applications, Nitinol actuators are exposed to various types of radiation, including high-energy protons, electrons, and heavy ions. These radiation sources can cause structural damage to the material, potentially altering its shape memory and superelastic characteristics. The primary mechanisms of radiation-induced damage in Nitinol include atomic displacements, ionization, and the formation of defects within the crystal structure.

Studies have shown that the radiation resistance of Nitinol actuators is generally superior to many other materials used in space applications. The unique atomic structure and phase transformation properties of Nitinol contribute to its radiation hardness. The austenite-martensite phase transition, which is responsible for the shape memory effect, remains largely unaffected by moderate levels of radiation exposure.

However, prolonged exposure to high radiation doses can lead to cumulative effects on Nitinol actuators. These effects may include changes in transformation temperatures, reduction in recovery strain, and alterations in mechanical properties. The extent of these changes depends on factors such as radiation type, dose rate, and total accumulated dose.

To enhance the radiation resistance of Nitinol actuators for miniature satellite systems, several strategies have been explored. One approach involves the development of composite Nitinol materials, incorporating radiation-resistant elements or nanoparticles. These additives can help mitigate radiation-induced damage by acting as scattering centers or traps for radiation-induced defects.

Another promising avenue is the optimization of Nitinol's composition and microstructure. Fine-tuning the nickel-titanium ratio and introducing specific heat treatments can improve the material's radiation resistance without compromising its shape memory properties. Additionally, surface treatments and coatings have been investigated as potential methods to enhance radiation shielding for Nitinol actuators.

Ongoing research in this field focuses on developing advanced characterization techniques to better understand the effects of radiation on Nitinol at the atomic and microstructural levels. This knowledge is crucial for designing more radiation-resistant Nitinol actuators tailored for specific space environments and mission durations.

As miniature satellite systems continue to evolve, the demand for reliable and radiation-resistant actuators grows. The development of Nitinol-based actuators with enhanced radiation resistance represents a significant opportunity for advancing the capabilities and longevity of small satellites in challenging space environments.

In the context of space applications, Nitinol actuators are exposed to various types of radiation, including high-energy protons, electrons, and heavy ions. These radiation sources can cause structural damage to the material, potentially altering its shape memory and superelastic characteristics. The primary mechanisms of radiation-induced damage in Nitinol include atomic displacements, ionization, and the formation of defects within the crystal structure.

Studies have shown that the radiation resistance of Nitinol actuators is generally superior to many other materials used in space applications. The unique atomic structure and phase transformation properties of Nitinol contribute to its radiation hardness. The austenite-martensite phase transition, which is responsible for the shape memory effect, remains largely unaffected by moderate levels of radiation exposure.

However, prolonged exposure to high radiation doses can lead to cumulative effects on Nitinol actuators. These effects may include changes in transformation temperatures, reduction in recovery strain, and alterations in mechanical properties. The extent of these changes depends on factors such as radiation type, dose rate, and total accumulated dose.

To enhance the radiation resistance of Nitinol actuators for miniature satellite systems, several strategies have been explored. One approach involves the development of composite Nitinol materials, incorporating radiation-resistant elements or nanoparticles. These additives can help mitigate radiation-induced damage by acting as scattering centers or traps for radiation-induced defects.

Another promising avenue is the optimization of Nitinol's composition and microstructure. Fine-tuning the nickel-titanium ratio and introducing specific heat treatments can improve the material's radiation resistance without compromising its shape memory properties. Additionally, surface treatments and coatings have been investigated as potential methods to enhance radiation shielding for Nitinol actuators.

Ongoing research in this field focuses on developing advanced characterization techniques to better understand the effects of radiation on Nitinol at the atomic and microstructural levels. This knowledge is crucial for designing more radiation-resistant Nitinol actuators tailored for specific space environments and mission durations.

As miniature satellite systems continue to evolve, the demand for reliable and radiation-resistant actuators grows. The development of Nitinol-based actuators with enhanced radiation resistance represents a significant opportunity for advancing the capabilities and longevity of small satellites in challenging space environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!