Nitinol's Role in Designing Flexible Electronics

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Flexible Electronics: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of flexible electronics. This unique metal, discovered in the 1960s, possesses remarkable shape memory and superelastic properties, making it an ideal candidate for developing bendable and stretchable electronic devices. The evolution of Nitinol's application in flexible electronics can be traced back to the early 2000s when researchers began exploring its potential beyond traditional uses in medical devices and aerospace applications.

The primary objective of incorporating Nitinol into flexible electronics is to create devices that can withstand repeated deformation while maintaining their electrical and mechanical properties. This goal aligns with the growing demand for wearable technology, soft robotics, and adaptive electronic systems that can seamlessly integrate with the human body or complex environments. Nitinol's ability to recover its original shape after deformation, coupled with its biocompatibility, makes it particularly attractive for developing next-generation medical implants and health monitoring devices.

As the field of flexible electronics continues to expand, researchers are focusing on overcoming several key challenges associated with Nitinol integration. These include optimizing the material's electrical conductivity, enhancing its compatibility with other electronic components, and developing efficient manufacturing processes for large-scale production. The pursuit of these objectives has led to significant advancements in material science, nanotechnology, and electronic engineering.

The technological trajectory of Nitinol in flexible electronics is characterized by a series of breakthroughs in material processing and device fabrication. Early efforts concentrated on creating thin Nitinol films and wires that could be incorporated into flexible substrates. Subsequent research has focused on developing composite materials that combine Nitinol with other conductive elements to enhance overall performance. Recent innovations have explored the potential of Nitinol-based metamaterials and 3D-printed structures, opening up new possibilities for creating complex, multifunctional flexible electronic systems.

Looking ahead, the future of Nitinol in flexible electronics appears promising, with ongoing research aimed at pushing the boundaries of what is possible in terms of device flexibility, durability, and functionality. As the technology matures, we can expect to see an increasing number of commercial applications, ranging from advanced medical devices to smart textiles and adaptive aerospace components. The continued exploration of Nitinol's unique properties is likely to play a crucial role in shaping the future landscape of flexible electronics, driving innovation across multiple industries and potentially revolutionizing how we interact with technology in our daily lives.

The primary objective of incorporating Nitinol into flexible electronics is to create devices that can withstand repeated deformation while maintaining their electrical and mechanical properties. This goal aligns with the growing demand for wearable technology, soft robotics, and adaptive electronic systems that can seamlessly integrate with the human body or complex environments. Nitinol's ability to recover its original shape after deformation, coupled with its biocompatibility, makes it particularly attractive for developing next-generation medical implants and health monitoring devices.

As the field of flexible electronics continues to expand, researchers are focusing on overcoming several key challenges associated with Nitinol integration. These include optimizing the material's electrical conductivity, enhancing its compatibility with other electronic components, and developing efficient manufacturing processes for large-scale production. The pursuit of these objectives has led to significant advancements in material science, nanotechnology, and electronic engineering.

The technological trajectory of Nitinol in flexible electronics is characterized by a series of breakthroughs in material processing and device fabrication. Early efforts concentrated on creating thin Nitinol films and wires that could be incorporated into flexible substrates. Subsequent research has focused on developing composite materials that combine Nitinol with other conductive elements to enhance overall performance. Recent innovations have explored the potential of Nitinol-based metamaterials and 3D-printed structures, opening up new possibilities for creating complex, multifunctional flexible electronic systems.

Looking ahead, the future of Nitinol in flexible electronics appears promising, with ongoing research aimed at pushing the boundaries of what is possible in terms of device flexibility, durability, and functionality. As the technology matures, we can expect to see an increasing number of commercial applications, ranging from advanced medical devices to smart textiles and adaptive aerospace components. The continued exploration of Nitinol's unique properties is likely to play a crucial role in shaping the future landscape of flexible electronics, driving innovation across multiple industries and potentially revolutionizing how we interact with technology in our daily lives.

Market Demand Analysis for Nitinol-based Flexible Electronics

The market demand for Nitinol-based flexible electronics has been experiencing significant growth in recent years, driven by the increasing need for wearable devices, medical implants, and advanced consumer electronics. Nitinol, a shape memory alloy composed of nickel and titanium, offers unique properties that make it particularly suitable for flexible electronic applications.

In the wearable technology sector, the global market is projected to reach substantial value in the coming years, with a considerable portion attributed to flexible electronics. Nitinol's superelasticity and shape memory characteristics enable the development of comfortable, durable, and adaptive wearable devices. This includes fitness trackers, smart clothing, and health monitoring systems that can conform to the body's contours while maintaining functionality.

The medical device industry represents another significant market for Nitinol-based flexible electronics. The demand for minimally invasive surgical tools, implantable devices, and smart prosthetics is driving innovation in this field. Nitinol's biocompatibility and ability to change shape at body temperature make it ideal for applications such as stents, guidewires, and orthopedic implants. The aging population and increasing prevalence of chronic diseases further contribute to the growth of this market segment.

Consumer electronics is another area where Nitinol-based flexible electronics are gaining traction. As consumers demand more durable and versatile devices, manufacturers are exploring ways to incorporate flexible components into smartphones, tablets, and laptops. Nitinol's resistance to fatigue and ability to return to its original shape after deformation make it an attractive option for creating bendable displays, flexible circuit boards, and robust hinges.

The automotive industry is also showing interest in Nitinol-based flexible electronics for applications in smart surfaces, adaptive aerodynamics, and shape-morphing structures. This sector's demand is driven by the trend towards more intelligent and efficient vehicles, as well as the growing electric vehicle market.

Geographically, North America and Europe currently lead in the adoption of Nitinol-based flexible electronics, primarily due to their advanced healthcare systems and strong consumer electronics markets. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid technological advancements, increasing disposable income, and a large consumer base.

Despite the promising market outlook, challenges such as high material costs and complex manufacturing processes currently limit widespread adoption. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods and expanded applications in the future.

In the wearable technology sector, the global market is projected to reach substantial value in the coming years, with a considerable portion attributed to flexible electronics. Nitinol's superelasticity and shape memory characteristics enable the development of comfortable, durable, and adaptive wearable devices. This includes fitness trackers, smart clothing, and health monitoring systems that can conform to the body's contours while maintaining functionality.

The medical device industry represents another significant market for Nitinol-based flexible electronics. The demand for minimally invasive surgical tools, implantable devices, and smart prosthetics is driving innovation in this field. Nitinol's biocompatibility and ability to change shape at body temperature make it ideal for applications such as stents, guidewires, and orthopedic implants. The aging population and increasing prevalence of chronic diseases further contribute to the growth of this market segment.

Consumer electronics is another area where Nitinol-based flexible electronics are gaining traction. As consumers demand more durable and versatile devices, manufacturers are exploring ways to incorporate flexible components into smartphones, tablets, and laptops. Nitinol's resistance to fatigue and ability to return to its original shape after deformation make it an attractive option for creating bendable displays, flexible circuit boards, and robust hinges.

The automotive industry is also showing interest in Nitinol-based flexible electronics for applications in smart surfaces, adaptive aerodynamics, and shape-morphing structures. This sector's demand is driven by the trend towards more intelligent and efficient vehicles, as well as the growing electric vehicle market.

Geographically, North America and Europe currently lead in the adoption of Nitinol-based flexible electronics, primarily due to their advanced healthcare systems and strong consumer electronics markets. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid technological advancements, increasing disposable income, and a large consumer base.

Despite the promising market outlook, challenges such as high material costs and complex manufacturing processes currently limit widespread adoption. However, ongoing research and development efforts are focused on addressing these issues, potentially leading to more cost-effective production methods and expanded applications in the future.

Current Challenges in Nitinol Integration for Flexible Devices

The integration of Nitinol into flexible electronic devices presents several significant challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the complex manufacturing process required to incorporate Nitinol into flexible substrates. The shape memory alloy's unique properties, while beneficial for many applications, make it difficult to seamlessly integrate with traditional flexible electronics materials.

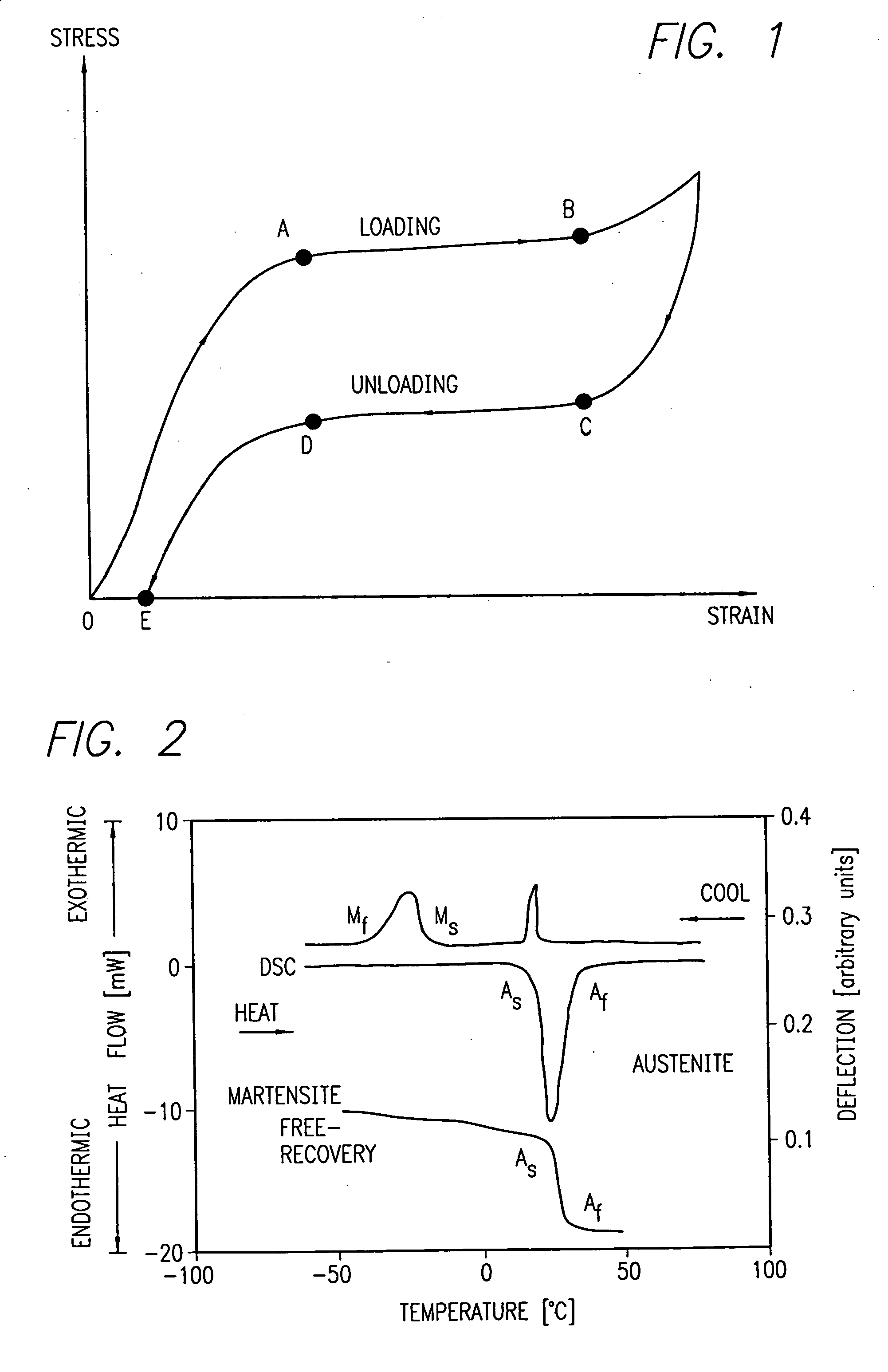

Thermal management is another critical challenge in Nitinol integration. The alloy's phase transformation, which is responsible for its shape memory and superelastic properties, is temperature-dependent. This characteristic can lead to unintended shape changes or mechanical stress in flexible devices when exposed to varying environmental temperatures. Developing effective thermal regulation systems that maintain stable operating conditions for Nitinol-based components is crucial for ensuring reliable device performance.

Compatibility issues between Nitinol and other materials used in flexible electronics pose additional hurdles. The alloy's chemical composition and surface properties may not always be compatible with common flexible substrates or conductive materials. This incompatibility can result in poor adhesion, reduced electrical conductivity, or compromised mechanical properties of the overall device. Researchers are exploring various surface modification techniques and intermediate layers to improve the interface between Nitinol and other device components.

The fatigue behavior of Nitinol in flexible electronic applications is another area of concern. While the alloy exhibits excellent fatigue resistance in many scenarios, the repeated bending and flexing inherent in flexible devices can lead to material degradation over time. Understanding and mitigating the long-term fatigue effects of Nitinol in these dynamic environments is essential for developing durable and reliable flexible electronic products.

Scalability and cost-effectiveness remain significant challenges in the widespread adoption of Nitinol in flexible electronics. The current manufacturing processes for integrating Nitinol into flexible substrates are often complex and expensive, limiting their feasibility for large-scale production. Developing more efficient and cost-effective fabrication methods is crucial for making Nitinol-based flexible electronics commercially viable.

Lastly, the biocompatibility of Nitinol in wearable or implantable flexible electronic devices presents both opportunities and challenges. While Nitinol is generally considered biocompatible, long-term studies on its effects in close contact with human tissue, especially in flexible electronic configurations, are still ongoing. Ensuring the safety and biocompatibility of Nitinol-integrated flexible devices for medical applications remains a critical area of research and development.

Thermal management is another critical challenge in Nitinol integration. The alloy's phase transformation, which is responsible for its shape memory and superelastic properties, is temperature-dependent. This characteristic can lead to unintended shape changes or mechanical stress in flexible devices when exposed to varying environmental temperatures. Developing effective thermal regulation systems that maintain stable operating conditions for Nitinol-based components is crucial for ensuring reliable device performance.

Compatibility issues between Nitinol and other materials used in flexible electronics pose additional hurdles. The alloy's chemical composition and surface properties may not always be compatible with common flexible substrates or conductive materials. This incompatibility can result in poor adhesion, reduced electrical conductivity, or compromised mechanical properties of the overall device. Researchers are exploring various surface modification techniques and intermediate layers to improve the interface between Nitinol and other device components.

The fatigue behavior of Nitinol in flexible electronic applications is another area of concern. While the alloy exhibits excellent fatigue resistance in many scenarios, the repeated bending and flexing inherent in flexible devices can lead to material degradation over time. Understanding and mitigating the long-term fatigue effects of Nitinol in these dynamic environments is essential for developing durable and reliable flexible electronic products.

Scalability and cost-effectiveness remain significant challenges in the widespread adoption of Nitinol in flexible electronics. The current manufacturing processes for integrating Nitinol into flexible substrates are often complex and expensive, limiting their feasibility for large-scale production. Developing more efficient and cost-effective fabrication methods is crucial for making Nitinol-based flexible electronics commercially viable.

Lastly, the biocompatibility of Nitinol in wearable or implantable flexible electronic devices presents both opportunities and challenges. While Nitinol is generally considered biocompatible, long-term studies on its effects in close contact with human tissue, especially in flexible electronic configurations, are still ongoing. Ensuring the safety and biocompatibility of Nitinol-integrated flexible devices for medical applications remains a critical area of research and development.

Existing Nitinol-based Solutions for Flexible Electronics

01 Shape memory properties of Nitinol

Nitinol exhibits unique shape memory properties, allowing it to return to a predetermined shape when heated. This characteristic makes it highly flexible and suitable for various applications, particularly in medical devices and aerospace industries. The material can be deformed at lower temperatures and regain its original shape when heated above its transformation temperature.- Shape memory properties of Nitinol: Nitinol exhibits unique shape memory properties, allowing it to return to a predetermined shape when heated. This characteristic enables the material to be highly flexible and adaptable, making it suitable for various applications in medical devices, aerospace, and robotics.

- Superelasticity of Nitinol: Nitinol's superelastic behavior allows it to undergo large deformations and return to its original shape without permanent damage. This property enhances its flexibility and durability, making it ideal for applications requiring repeated bending or twisting motions.

- Heat treatment and processing of Nitinol: The flexibility and mechanical properties of Nitinol can be optimized through various heat treatment and processing techniques. These methods allow for precise control over the material's transformation temperatures and mechanical behavior, tailoring its flexibility for specific applications.

- Nitinol in medical devices: Nitinol's flexibility and biocompatibility make it an excellent material for medical devices such as stents, guidewires, and orthodontic archwires. Its ability to conform to body structures and maintain its shape contributes to improved patient outcomes and device performance.

- Nitinol-based composite materials: Combining Nitinol with other materials to create composites can enhance its flexibility and other mechanical properties. These composites can be tailored to meet specific requirements in various industries, including aerospace, automotive, and consumer electronics.

02 Superelasticity of Nitinol

Nitinol demonstrates superelastic behavior, enabling it to undergo large deformations and return to its original shape upon unloading. This property allows for the creation of flexible and durable components in various applications, such as orthodontic wires, eyeglass frames, and medical stents. The superelasticity of Nitinol contributes to its ability to withstand repeated stress cycles without fatigue.Expand Specific Solutions03 Heat treatment and processing of Nitinol

The flexibility and mechanical properties of Nitinol can be tailored through various heat treatment and processing techniques. These methods include annealing, shape setting, and cold working. By controlling the temperature and duration of heat treatments, manufacturers can optimize the material's flexibility, strength, and shape memory characteristics for specific applications.Expand Specific Solutions04 Applications of Nitinol in medical devices

Nitinol's flexibility and biocompatibility make it an ideal material for various medical devices. It is commonly used in minimally invasive surgical instruments, cardiovascular stents, orthodontic archwires, and guidewires. The material's ability to navigate through complex anatomical structures while maintaining its shape and flexibility contributes to improved patient outcomes and reduced surgical complications.Expand Specific Solutions05 Nitinol in actuators and sensors

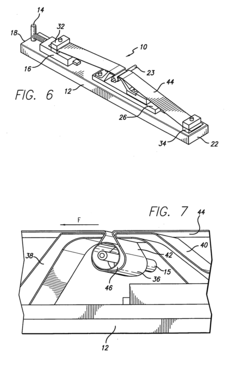

The unique properties of Nitinol make it suitable for use in actuators and sensors. Its shape memory effect and superelasticity allow for the creation of compact and efficient actuators that can generate significant force or displacement. In sensor applications, Nitinol's sensitivity to temperature changes and mechanical stress enables the development of responsive and reliable sensing devices for various industries.Expand Specific Solutions

Key Players in Nitinol and Flexible Electronics Industries

The competitive landscape for Nitinol's role in designing flexible electronics is evolving rapidly, with the market still in its early growth stage. The technology's potential applications in medical devices, consumer electronics, and aerospace industries are driving significant market expansion. While the market size is growing, it remains relatively niche compared to traditional electronics. Technologically, Nitinol's integration into flexible electronics is progressing, with companies like Boston Scientific, W. L. Gore & Associates, and Abbott Laboratories leading research and development efforts. These firms are leveraging Nitinol's unique shape memory and superelastic properties to create innovative, flexible electronic solutions. However, the technology is still maturing, with ongoing challenges in manufacturing scalability and cost-effectiveness.

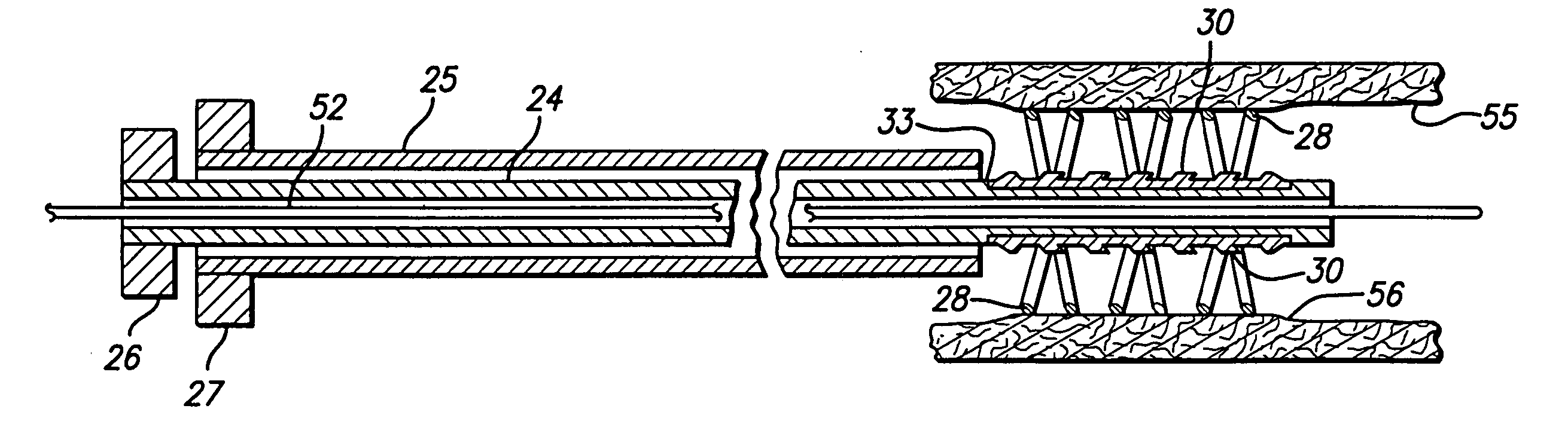

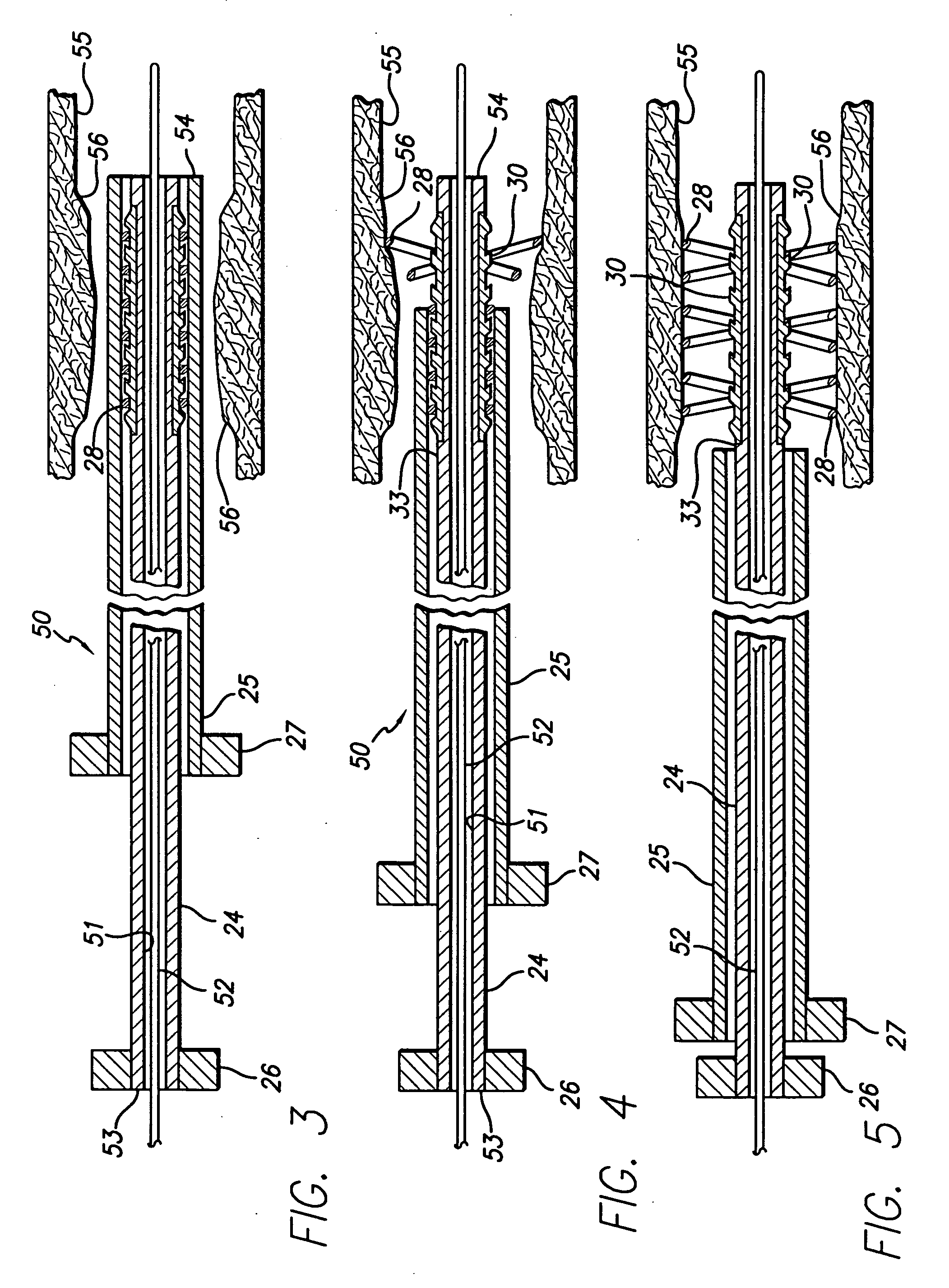

Boston Scientific Ltd.

Technical Solution: Boston Scientific has developed innovative Nitinol-based flexible electronics for medical devices. Their approach involves using Nitinol's shape memory and superelastic properties to create self-expanding stents and implantable sensors[1]. The company has integrated Nitinol wire into flexible circuit boards, allowing for devices that can conform to complex anatomical structures while maintaining electrical functionality[2]. They have also developed a proprietary surface treatment process for Nitinol that enhances its biocompatibility and reduces the risk of corrosion in physiological environments[3]. This technology has been applied in their neurostimulation devices, enabling flexible electrode arrays that can adapt to the curvature of the spinal cord or brain surface[4].

Strengths: Extensive experience in medical device applications, proprietary surface treatment technology, and integration with existing product lines. Weaknesses: Primarily focused on medical applications, potentially limiting broader flexible electronics applications.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has leveraged Nitinol in their flexible electronics designs, particularly for wearable technology and aerospace applications. Their approach combines Nitinol's unique properties with their expertise in advanced materials[1]. The company has developed a proprietary method for embedding Nitinol wires within flexible polymer matrices, creating durable and conformable electronic structures[2]. This technology has been applied in their smart fabrics, where Nitinol actuators are used to create shape-changing textiles that respond to environmental stimuli[3]. Additionally, Gore has explored the use of Nitinol-based flexible antennas for satellite communications, taking advantage of the material's ability to deploy and maintain shape in space environments[4].

Strengths: Diverse application range beyond medical devices, expertise in material integration, and established presence in aerospace and wearable markets. Weaknesses: May face challenges in miniaturization for some consumer electronics applications.

Core Innovations in Nitinol-Enabled Flexible Circuits

Ni-free beta ti alloys with share memory and super-elastic properties

PatentWO2018089028A1

Innovation

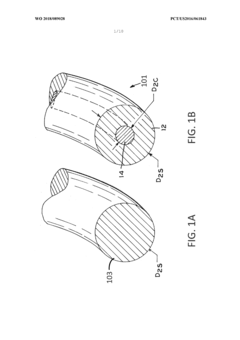

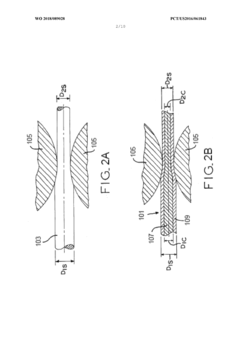

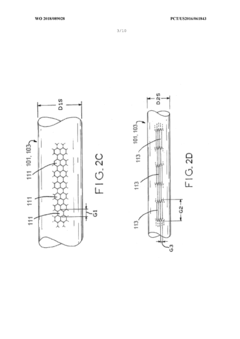

- Development of nickel-free beta-titanium alloys with compositions including 16-20 at.% hafnium or zirconium, 8-17 at.% niobium, and 0.25-6 at.% tin, which exhibit recoverable strains of at least 3.5% after deformation, utilizing niobium and tin to control beta phase stability and enhance shape memory and super-elastic properties, with hafnium and zirconium contributing to radiopacity and superelasticity.

Avoiding stress-induced martensitic transformation in nickle titanium alloys used in medical devices

PatentInactiveUS20070162105A1

Innovation

- A process involving heating a shape memory alloy to a temperature above its martensite deformation temperature (Md) to deform it in an austenitic state, allowing it to be deployed within a mammalian body without generating stress-induced martensite, using a hollow delivery system like a catheter to maintain the deformed shape at room temperature.

Environmental Impact of Nitinol in Electronics Manufacturing

The environmental impact of Nitinol in electronics manufacturing is a crucial consideration as flexible electronics become increasingly prevalent. Nitinol, an alloy of nickel and titanium, offers unique properties that make it valuable for flexible electronic applications. However, its production and use raise several environmental concerns.

The manufacturing process of Nitinol involves energy-intensive methods, contributing to greenhouse gas emissions. The extraction and refining of nickel and titanium, the primary components of Nitinol, require significant energy inputs and can lead to habitat disruption and water pollution if not properly managed. Additionally, the shape memory effect of Nitinol, which is essential for its application in flexible electronics, is achieved through heat treatment processes that further increase energy consumption.

The use of nickel in Nitinol also presents potential environmental risks. Nickel is known to be toxic to aquatic life and can accumulate in ecosystems. Improper disposal or leaching of Nitinol-containing devices could lead to the release of nickel into the environment, potentially harming local flora and fauna.

However, the durability and longevity of Nitinol-based components in flexible electronics may offset some of these environmental concerns. The material's resistance to fatigue and corrosion can lead to longer-lasting devices, potentially reducing electronic waste. This aligns with sustainability goals by extending product lifecycles and reducing the need for frequent replacements.

Recycling Nitinol presents both challenges and opportunities. While the alloy can be recycled, the process is complex due to the strong bond between nickel and titanium. Developing efficient recycling methods for Nitinol is crucial to mitigate its environmental impact and promote a circular economy in the electronics industry.

As the demand for flexible electronics grows, manufacturers are exploring ways to minimize the environmental footprint of Nitinol production. This includes researching alternative production methods that require less energy, implementing closed-loop systems to reduce waste, and investigating bio-based or more environmentally friendly shape memory materials that could potentially replace Nitinol in certain applications.

The electronics industry is also focusing on designing products with end-of-life considerations in mind. This approach involves creating flexible electronic devices that are easier to disassemble and recycle, potentially reducing the environmental impact of Nitinol-containing components.

In conclusion, while Nitinol offers significant benefits for flexible electronics, its environmental impact throughout the product lifecycle must be carefully managed. Balancing the material's unique properties with sustainable manufacturing practices and responsible end-of-life management will be key to ensuring the long-term viability of Nitinol in the evolving landscape of flexible electronics.

The manufacturing process of Nitinol involves energy-intensive methods, contributing to greenhouse gas emissions. The extraction and refining of nickel and titanium, the primary components of Nitinol, require significant energy inputs and can lead to habitat disruption and water pollution if not properly managed. Additionally, the shape memory effect of Nitinol, which is essential for its application in flexible electronics, is achieved through heat treatment processes that further increase energy consumption.

The use of nickel in Nitinol also presents potential environmental risks. Nickel is known to be toxic to aquatic life and can accumulate in ecosystems. Improper disposal or leaching of Nitinol-containing devices could lead to the release of nickel into the environment, potentially harming local flora and fauna.

However, the durability and longevity of Nitinol-based components in flexible electronics may offset some of these environmental concerns. The material's resistance to fatigue and corrosion can lead to longer-lasting devices, potentially reducing electronic waste. This aligns with sustainability goals by extending product lifecycles and reducing the need for frequent replacements.

Recycling Nitinol presents both challenges and opportunities. While the alloy can be recycled, the process is complex due to the strong bond between nickel and titanium. Developing efficient recycling methods for Nitinol is crucial to mitigate its environmental impact and promote a circular economy in the electronics industry.

As the demand for flexible electronics grows, manufacturers are exploring ways to minimize the environmental footprint of Nitinol production. This includes researching alternative production methods that require less energy, implementing closed-loop systems to reduce waste, and investigating bio-based or more environmentally friendly shape memory materials that could potentially replace Nitinol in certain applications.

The electronics industry is also focusing on designing products with end-of-life considerations in mind. This approach involves creating flexible electronic devices that are easier to disassemble and recycle, potentially reducing the environmental impact of Nitinol-containing components.

In conclusion, while Nitinol offers significant benefits for flexible electronics, its environmental impact throughout the product lifecycle must be carefully managed. Balancing the material's unique properties with sustainable manufacturing practices and responsible end-of-life management will be key to ensuring the long-term viability of Nitinol in the evolving landscape of flexible electronics.

Biocompatibility and Safety Considerations for Nitinol Devices

The biocompatibility and safety of Nitinol devices are crucial considerations in their application for flexible electronics, particularly in medical and wearable technology sectors. Nitinol, an alloy of nickel and titanium, exhibits unique properties such as shape memory and superelasticity, making it an attractive material for various biomedical applications. However, its use in the human body necessitates rigorous evaluation of its biocompatibility and potential health risks.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions, which can cause allergic reactions in some individuals. To address this issue, manufacturers have developed surface treatment techniques to create a stable titanium oxide layer on Nitinol devices, effectively reducing nickel ion release. These treatments include electropolishing, passivation, and thermal oxidation processes, which enhance the corrosion resistance and biocompatibility of Nitinol implants.

Long-term studies have shown that properly treated Nitinol exhibits excellent biocompatibility in various applications, including cardiovascular stents, orthodontic wires, and orthopedic implants. The material's ability to conform to body tissues and its mechanical properties that closely match those of human bone make it particularly suitable for long-term implantation. However, continuous monitoring and evaluation of Nitinol devices in vivo are essential to ensure their ongoing safety and efficacy.

In the context of flexible electronics, the use of Nitinol introduces additional safety considerations. The integration of electronic components with Nitinol structures must be carefully designed to prevent any potential electrical hazards or electromagnetic interference with other medical devices. Furthermore, the flexibility and shape-changing properties of Nitinol in flexible electronics applications must be thoroughly tested to ensure that they do not compromise the integrity of the electronic components or pose any risk to the user.

Regulatory bodies such as the FDA have established guidelines for the evaluation and approval of Nitinol-based medical devices. These guidelines encompass a range of safety assessments, including biocompatibility testing, mechanical performance evaluation, and risk analysis. Manufacturers must demonstrate compliance with these regulations through extensive pre-clinical and clinical studies before obtaining approval for their Nitinol-based flexible electronic devices.

As the field of flexible electronics continues to evolve, ongoing research is focused on further improving the biocompatibility and safety of Nitinol devices. This includes the development of novel surface modification techniques, exploration of alternative alloy compositions with reduced nickel content, and the implementation of advanced manufacturing processes to enhance material purity and consistency. These efforts aim to expand the potential applications of Nitinol in flexible electronics while ensuring the highest standards of patient safety and device performance.

One of the primary concerns regarding Nitinol's biocompatibility is the potential release of nickel ions, which can cause allergic reactions in some individuals. To address this issue, manufacturers have developed surface treatment techniques to create a stable titanium oxide layer on Nitinol devices, effectively reducing nickel ion release. These treatments include electropolishing, passivation, and thermal oxidation processes, which enhance the corrosion resistance and biocompatibility of Nitinol implants.

Long-term studies have shown that properly treated Nitinol exhibits excellent biocompatibility in various applications, including cardiovascular stents, orthodontic wires, and orthopedic implants. The material's ability to conform to body tissues and its mechanical properties that closely match those of human bone make it particularly suitable for long-term implantation. However, continuous monitoring and evaluation of Nitinol devices in vivo are essential to ensure their ongoing safety and efficacy.

In the context of flexible electronics, the use of Nitinol introduces additional safety considerations. The integration of electronic components with Nitinol structures must be carefully designed to prevent any potential electrical hazards or electromagnetic interference with other medical devices. Furthermore, the flexibility and shape-changing properties of Nitinol in flexible electronics applications must be thoroughly tested to ensure that they do not compromise the integrity of the electronic components or pose any risk to the user.

Regulatory bodies such as the FDA have established guidelines for the evaluation and approval of Nitinol-based medical devices. These guidelines encompass a range of safety assessments, including biocompatibility testing, mechanical performance evaluation, and risk analysis. Manufacturers must demonstrate compliance with these regulations through extensive pre-clinical and clinical studies before obtaining approval for their Nitinol-based flexible electronic devices.

As the field of flexible electronics continues to evolve, ongoing research is focused on further improving the biocompatibility and safety of Nitinol devices. This includes the development of novel surface modification techniques, exploration of alternative alloy compositions with reduced nickel content, and the implementation of advanced manufacturing processes to enhance material purity and consistency. These efforts aim to expand the potential applications of Nitinol in flexible electronics while ensuring the highest standards of patient safety and device performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!