Nitinol in Tunable Optics for Enhanced Vision Systems

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol in Optics: Background and Objectives

Nitinol, an alloy of nickel and titanium, has emerged as a revolutionary material in the field of optics, particularly in the development of enhanced vision systems. This shape memory alloy, discovered in the 1960s, has unique properties that make it ideal for tunable optics applications. The ability of Nitinol to change its shape in response to temperature variations has opened up new possibilities in the design and functionality of optical systems.

The evolution of Nitinol in optics can be traced back to its initial applications in aerospace and medical industries. As researchers began to explore its potential in other fields, the optical industry recognized its value in creating adaptive and responsive optical elements. The primary objective of incorporating Nitinol in optics is to develop systems that can dynamically adjust their optical properties, leading to improved performance and versatility in various environmental conditions.

One of the key trends driving the development of Nitinol-based optics is the increasing demand for high-performance vision systems in sectors such as automotive, defense, and consumer electronics. These industries require optical systems that can rapidly adapt to changing light conditions, focus at different distances, and maintain optimal performance across a wide range of temperatures. Nitinol's unique characteristics make it an ideal candidate for addressing these challenges.

The integration of Nitinol in tunable optics aims to achieve several technical goals. Firstly, it seeks to create adaptive lenses that can change their focal length or curvature without the need for complex mechanical systems. This could lead to more compact and efficient optical devices. Secondly, researchers are exploring the use of Nitinol in variable aperture systems, which could enhance the dynamic range and light-gathering capabilities of cameras and other optical instruments.

Another significant objective is the development of temperature-compensating optical mounts and housings. By utilizing Nitinol's shape memory properties, these components can automatically adjust to maintain optimal alignment and focus across a wide temperature range, crucial for applications in extreme environments. Additionally, the research aims to harness Nitinol's superelastic properties to create flexible optical elements that can withstand significant deformation without permanent damage.

The potential applications of Nitinol in enhanced vision systems are vast and diverse. From improving the performance of autonomous vehicle sensors to enhancing the capabilities of space-based telescopes, the material promises to revolutionize how we capture and process visual information. As research in this field progresses, we can expect to see increasingly sophisticated optical systems that leverage Nitinol's unique properties to push the boundaries of what is possible in vision technology.

The evolution of Nitinol in optics can be traced back to its initial applications in aerospace and medical industries. As researchers began to explore its potential in other fields, the optical industry recognized its value in creating adaptive and responsive optical elements. The primary objective of incorporating Nitinol in optics is to develop systems that can dynamically adjust their optical properties, leading to improved performance and versatility in various environmental conditions.

One of the key trends driving the development of Nitinol-based optics is the increasing demand for high-performance vision systems in sectors such as automotive, defense, and consumer electronics. These industries require optical systems that can rapidly adapt to changing light conditions, focus at different distances, and maintain optimal performance across a wide range of temperatures. Nitinol's unique characteristics make it an ideal candidate for addressing these challenges.

The integration of Nitinol in tunable optics aims to achieve several technical goals. Firstly, it seeks to create adaptive lenses that can change their focal length or curvature without the need for complex mechanical systems. This could lead to more compact and efficient optical devices. Secondly, researchers are exploring the use of Nitinol in variable aperture systems, which could enhance the dynamic range and light-gathering capabilities of cameras and other optical instruments.

Another significant objective is the development of temperature-compensating optical mounts and housings. By utilizing Nitinol's shape memory properties, these components can automatically adjust to maintain optimal alignment and focus across a wide temperature range, crucial for applications in extreme environments. Additionally, the research aims to harness Nitinol's superelastic properties to create flexible optical elements that can withstand significant deformation without permanent damage.

The potential applications of Nitinol in enhanced vision systems are vast and diverse. From improving the performance of autonomous vehicle sensors to enhancing the capabilities of space-based telescopes, the material promises to revolutionize how we capture and process visual information. As research in this field progresses, we can expect to see increasingly sophisticated optical systems that leverage Nitinol's unique properties to push the boundaries of what is possible in vision technology.

Market Demand for Tunable Optics

The market demand for tunable optics in enhanced vision systems has been experiencing significant growth, driven by advancements in various industries and applications. The integration of Nitinol, a shape memory alloy, into tunable optics has opened up new possibilities for adaptive and responsive optical systems, particularly in the field of enhanced vision.

One of the primary drivers for this market demand is the automotive industry. As autonomous vehicles and advanced driver assistance systems (ADAS) continue to evolve, there is an increasing need for adaptive optics that can adjust to various lighting conditions and environmental factors. Tunable optics incorporating Nitinol allow for rapid and precise adjustments to focal length, field of view, and other optical parameters, enhancing the performance of cameras and sensors used in these systems.

The aerospace and defense sectors also contribute significantly to the market demand for tunable optics. In military applications, enhanced vision systems with adaptive capabilities are crucial for surveillance, target acquisition, and navigation in diverse operational environments. The ability of Nitinol-based tunable optics to withstand extreme conditions while maintaining performance makes them particularly attractive for these applications.

In the medical field, there is a growing demand for advanced imaging technologies that can provide high-resolution, adaptable visualization for minimally invasive procedures. Tunable optics offer the potential to improve endoscopic and laparoscopic imaging systems, enabling surgeons to adjust focus and field of view in real-time during procedures. This capability can lead to more precise diagnoses and improved surgical outcomes.

The consumer electronics market is another area driving demand for tunable optics. As smartphone cameras and wearable devices become more sophisticated, there is an increasing interest in incorporating adaptive optical elements to enhance image quality and user experience. Nitinol-based tunable optics can enable compact, energy-efficient solutions for features such as variable focus and optical zoom in these devices.

Industrial inspection and quality control systems also benefit from the advancements in tunable optics. The ability to dynamically adjust optical parameters allows for more versatile and efficient inspection processes across various manufacturing sectors. This adaptability is particularly valuable in industries with diverse product lines or complex inspection requirements.

As the Internet of Things (IoT) and smart city initiatives continue to expand, there is a growing need for adaptive vision systems in surveillance and monitoring applications. Tunable optics can enhance the capabilities of security cameras and environmental sensors, allowing for improved performance across different lighting conditions and viewing distances.

The market demand for tunable optics is further fueled by ongoing research and development in the field of adaptive optics for astronomy and space exploration. These applications require highly precise and responsive optical systems capable of compensating for atmospheric distortions and other challenging conditions.

One of the primary drivers for this market demand is the automotive industry. As autonomous vehicles and advanced driver assistance systems (ADAS) continue to evolve, there is an increasing need for adaptive optics that can adjust to various lighting conditions and environmental factors. Tunable optics incorporating Nitinol allow for rapid and precise adjustments to focal length, field of view, and other optical parameters, enhancing the performance of cameras and sensors used in these systems.

The aerospace and defense sectors also contribute significantly to the market demand for tunable optics. In military applications, enhanced vision systems with adaptive capabilities are crucial for surveillance, target acquisition, and navigation in diverse operational environments. The ability of Nitinol-based tunable optics to withstand extreme conditions while maintaining performance makes them particularly attractive for these applications.

In the medical field, there is a growing demand for advanced imaging technologies that can provide high-resolution, adaptable visualization for minimally invasive procedures. Tunable optics offer the potential to improve endoscopic and laparoscopic imaging systems, enabling surgeons to adjust focus and field of view in real-time during procedures. This capability can lead to more precise diagnoses and improved surgical outcomes.

The consumer electronics market is another area driving demand for tunable optics. As smartphone cameras and wearable devices become more sophisticated, there is an increasing interest in incorporating adaptive optical elements to enhance image quality and user experience. Nitinol-based tunable optics can enable compact, energy-efficient solutions for features such as variable focus and optical zoom in these devices.

Industrial inspection and quality control systems also benefit from the advancements in tunable optics. The ability to dynamically adjust optical parameters allows for more versatile and efficient inspection processes across various manufacturing sectors. This adaptability is particularly valuable in industries with diverse product lines or complex inspection requirements.

As the Internet of Things (IoT) and smart city initiatives continue to expand, there is a growing need for adaptive vision systems in surveillance and monitoring applications. Tunable optics can enhance the capabilities of security cameras and environmental sensors, allowing for improved performance across different lighting conditions and viewing distances.

The market demand for tunable optics is further fueled by ongoing research and development in the field of adaptive optics for astronomy and space exploration. These applications require highly precise and responsive optical systems capable of compensating for atmospheric distortions and other challenging conditions.

Current Challenges in Nitinol-based Optical Systems

Despite the promising potential of Nitinol in tunable optics for enhanced vision systems, several significant challenges persist in the development and implementation of Nitinol-based optical systems. These challenges span across material properties, manufacturing processes, and system integration aspects.

One of the primary challenges lies in the precise control of Nitinol's shape memory and superelastic properties. While these characteristics are fundamental to its application in tunable optics, achieving consistent and repeatable performance across different batches of material remains difficult. The transformation temperatures and mechanical properties of Nitinol can vary significantly based on slight changes in composition and processing conditions, making it challenging to maintain uniform optical performance across devices.

The manufacturing of Nitinol-based optical components presents another set of hurdles. Traditional machining techniques often struggle with Nitinol due to its high elasticity and work hardening properties. Advanced manufacturing methods such as laser cutting and electrical discharge machining (EDM) have shown promise, but they come with their own set of challenges, including potential alterations to the material's properties and the need for specialized equipment and expertise.

Integration of Nitinol elements into complex optical systems poses significant design and engineering challenges. The unique thermal and mechanical properties of Nitinol require careful consideration in system design to ensure compatibility with other optical components and to maintain overall system stability. Additionally, the relatively slow response time of Nitinol to thermal stimuli can limit its applicability in high-speed adaptive optics applications.

The long-term stability and fatigue resistance of Nitinol in optical systems remain areas of concern. While Nitinol exhibits excellent fatigue properties compared to many conventional materials, the repeated shape changes required in tunable optics applications can lead to material degradation over time. This potential for performance drift necessitates the development of robust monitoring and calibration systems to ensure consistent optical performance throughout the device's lifetime.

Environmental factors also present challenges for Nitinol-based optical systems. Temperature fluctuations in the operating environment can significantly affect the performance of Nitinol components, potentially leading to unintended shape changes or alterations in optical properties. Developing effective thermal management strategies and compensation mechanisms is crucial for maintaining system reliability across various environmental conditions.

Lastly, the cost and scalability of Nitinol-based optical systems remain significant barriers to widespread adoption. The high cost of Nitinol, coupled with the specialized processing and manufacturing requirements, makes these systems expensive compared to conventional alternatives. Developing more cost-effective production methods and identifying high-value applications where the unique properties of Nitinol justify the increased cost are essential for broader market acceptance.

One of the primary challenges lies in the precise control of Nitinol's shape memory and superelastic properties. While these characteristics are fundamental to its application in tunable optics, achieving consistent and repeatable performance across different batches of material remains difficult. The transformation temperatures and mechanical properties of Nitinol can vary significantly based on slight changes in composition and processing conditions, making it challenging to maintain uniform optical performance across devices.

The manufacturing of Nitinol-based optical components presents another set of hurdles. Traditional machining techniques often struggle with Nitinol due to its high elasticity and work hardening properties. Advanced manufacturing methods such as laser cutting and electrical discharge machining (EDM) have shown promise, but they come with their own set of challenges, including potential alterations to the material's properties and the need for specialized equipment and expertise.

Integration of Nitinol elements into complex optical systems poses significant design and engineering challenges. The unique thermal and mechanical properties of Nitinol require careful consideration in system design to ensure compatibility with other optical components and to maintain overall system stability. Additionally, the relatively slow response time of Nitinol to thermal stimuli can limit its applicability in high-speed adaptive optics applications.

The long-term stability and fatigue resistance of Nitinol in optical systems remain areas of concern. While Nitinol exhibits excellent fatigue properties compared to many conventional materials, the repeated shape changes required in tunable optics applications can lead to material degradation over time. This potential for performance drift necessitates the development of robust monitoring and calibration systems to ensure consistent optical performance throughout the device's lifetime.

Environmental factors also present challenges for Nitinol-based optical systems. Temperature fluctuations in the operating environment can significantly affect the performance of Nitinol components, potentially leading to unintended shape changes or alterations in optical properties. Developing effective thermal management strategies and compensation mechanisms is crucial for maintaining system reliability across various environmental conditions.

Lastly, the cost and scalability of Nitinol-based optical systems remain significant barriers to widespread adoption. The high cost of Nitinol, coupled with the specialized processing and manufacturing requirements, makes these systems expensive compared to conventional alternatives. Developing more cost-effective production methods and identifying high-value applications where the unique properties of Nitinol justify the increased cost are essential for broader market acceptance.

Existing Nitinol-based Optical Solutions

01 Shape memory alloy for tunable optics

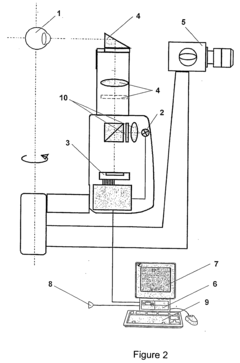

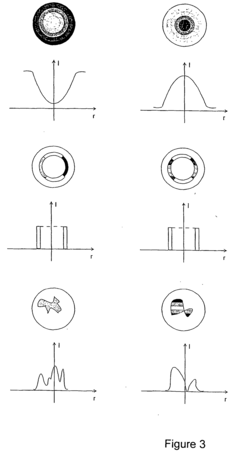

Nitinol, a shape memory alloy, is used in tunable optical systems. Its unique properties allow for controlled deformation and recovery, enabling precise adjustments in optical components. This material can be used to create adaptive lenses, mirrors, and other optical elements that can change shape or position in response to temperature or electrical stimuli.- Nitinol-based tunable optical devices: Nitinol, a shape memory alloy, is used in tunable optical devices due to its unique properties. These devices can adjust their optical characteristics in response to temperature changes or applied stress, allowing for adaptive optics and variable focus systems.

- Deformable mirrors using Nitinol: Deformable mirrors incorporating Nitinol actuators enable precise control of mirror shape for adaptive optics applications. These mirrors can correct for atmospheric distortions in astronomical observations or improve image quality in various optical systems.

- Tunable optical filters with Nitinol elements: Nitinol is used in tunable optical filters to adjust the filter's spectral characteristics. These filters can be thermally or mechanically actuated to change their transmission or reflection properties, enabling applications in spectroscopy and telecommunications.

- Variable focus lenses using Nitinol: Nitinol actuators are employed in variable focus lens systems to adjust focal length or optical power. These lenses can be used in cameras, microscopes, or other optical instruments to provide adaptive focusing capabilities without mechanical movement of lens elements.

- Optical alignment and stabilization systems with Nitinol: Nitinol components are used in optical alignment and stabilization systems to compensate for vibrations or maintain precise positioning of optical elements. These systems can improve image quality in cameras, telescopes, or other optical instruments subject to movement or environmental disturbances.

02 Adaptive optics using Nitinol actuators

Nitinol actuators are employed in adaptive optics systems to correct for wavefront distortions. These actuators can precisely control the shape of deformable mirrors or other optical surfaces, allowing for real-time compensation of atmospheric turbulence or other optical aberrations. This technology is particularly useful in astronomical telescopes and high-resolution imaging systems.Expand Specific Solutions03 Temperature-controlled optical switching

Nitinol's temperature-dependent phase transformation is utilized in optical switching applications. By controlling the temperature of Nitinol elements, optical paths can be altered, enabling the creation of tunable filters, switches, and other optical devices. This approach allows for the development of compact and efficient optical communication systems.Expand Specific Solutions04 Micro-electromechanical systems (MEMS) for optics

Nitinol is incorporated into MEMS devices for optical applications. These miniature systems leverage the material's shape memory properties to create tunable optical components on a microscale. Applications include adjustable mirrors for laser beam steering, variable focus lenses, and reconfigurable optical networks.Expand Specific Solutions05 Nitinol-based optical fiber technology

Nitinol is used in conjunction with optical fibers to create tunable devices. This includes fiber Bragg gratings with adjustable periods, variable attenuators, and reconfigurable optical add-drop multiplexers. The integration of Nitinol with optical fibers enables the development of advanced, tunable photonic systems for telecommunications and sensing applications.Expand Specific Solutions

Key Players in Nitinol and Tunable Optics

The research on Nitinol in tunable optics for enhanced vision systems is in an emerging stage, with significant potential for growth. The market is still relatively small but expanding rapidly as the technology matures. Key players in this field include academic institutions like the University of Washington and California Institute of Technology, as well as government entities such as the U.S. Government. Companies like Acucela, Inc. and GM Global Technology Operations LLC are also involved, indicating growing commercial interest. The technology's maturity is progressing, with universities and research institutes leading fundamental research, while companies are beginning to explore practical applications and product development.

University of Washington

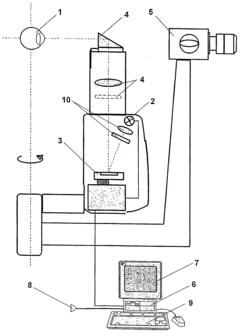

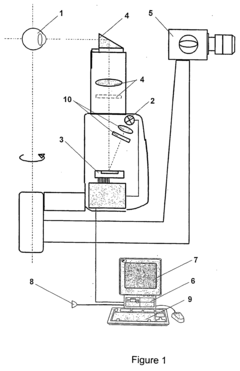

Technical Solution: The University of Washington has been at the forefront of research on Nitinol in tunable optics for enhanced vision systems. Their approach involves developing shape memory alloy (SMA) actuators using Nitinol for adaptive optics applications. The research team has created a novel SMA-based deformable mirror system that can correct for optical aberrations in real-time[1]. This system utilizes the unique properties of Nitinol, such as its shape memory effect and superelasticity, to achieve precise and rapid shape changes in optical elements. The university has also explored the integration of Nitinol-based actuators with flexible polymer substrates to create lightweight, compact adaptive optics devices suitable for wearable vision enhancement systems[3].

Strengths: Cutting-edge research in adaptive optics, expertise in Nitinol-based actuators, and potential for wearable applications. Weaknesses: Possible challenges in scaling up for mass production and long-term reliability of Nitinol-based systems in variable environmental conditions.

California Institute of Technology

Technical Solution: Caltech has made significant contributions to the field of tunable optics using Nitinol for enhanced vision systems. Their research focuses on developing advanced control algorithms for Nitinol-based adaptive optics systems. The institute has pioneered a machine learning approach to optimize the performance of Nitinol actuators in real-time, allowing for faster and more precise adjustments of optical elements[2]. Additionally, Caltech researchers have explored the use of Nitinol in multi-element adaptive lenses, which can simultaneously adjust focus, astigmatism, and higher-order aberrations. This technology has shown promise in applications ranging from high-resolution microscopy to adaptive eyewear for vision correction[4].

Strengths: Advanced control algorithms, multi-element adaptive lens technology, and potential for diverse applications. Weaknesses: Complexity of implementation and potential high costs associated with sophisticated control systems.

Core Innovations in Nitinol Optics

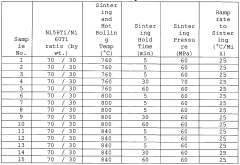

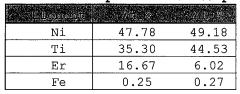

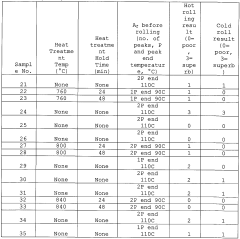

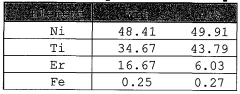

Mixture of powders for preparing a sintered nickel-titanium-rare earth metal (ni-ti-re) alloy

PatentWO2013109846A1

Innovation

- A mixture of nickel-titanium-rare earth (Ni-Ti-RE) alloy powders with specific compositions and sintering conditions to produce a sintered alloy that maintains workability and superelasticity while enhancing radiopacity, using spark plasma sintering and thermomechanical processing.

Arrangement and method for illuminating the lens of the human eye

PatentInactiveUS20050107708A1

Innovation

- An arrangement comprising an illumination unit, optical imaging system, evaluating unit, and central control unit that generates variable illumination patterns using a controllable light source and optoelectronic components like DMD or LCOS microdisplays, allowing for dynamic and spatial control of irradiation patterns, enabling precise adjustment of refractive power without mechanical fixation.

Regulatory Framework for Optical Devices

The regulatory framework for optical devices plays a crucial role in ensuring the safety, efficacy, and quality of vision enhancement systems incorporating Nitinol-based tunable optics. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing medical devices, including those used for vision correction and enhancement.

Under the FDA's classification system, tunable optics devices utilizing Nitinol would likely fall under Class II or Class III, depending on their intended use and level of risk. Class II devices typically require a 510(k) premarket notification, demonstrating substantial equivalence to a legally marketed predicate device. Class III devices, considered high-risk, may require a more rigorous premarket approval (PMA) process.

The FDA's Center for Devices and Radiological Health (CDRH) is responsible for evaluating the safety and effectiveness of optical devices. Manufacturers must comply with Quality System Regulation (QSR) requirements, which include design controls, manufacturing process controls, and post-market surveillance.

In the European Union, the regulatory landscape for optical devices is governed by the Medical Device Regulation (MDR). The MDR, which replaced the previous Medical Device Directive (MDD), imposes stricter requirements for clinical evaluation, post-market surveillance, and traceability of medical devices.

For Nitinol-based tunable optics, manufacturers must demonstrate compliance with essential requirements related to safety and performance. This includes providing clinical data to support claims of efficacy and conducting a thorough risk assessment. The devices must also bear the CE mark to indicate conformity with EU regulations.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of medical devices, including optical devices. The regulatory process involves pre-market submission, quality management system audits, and post-market surveillance requirements.

International standards, such as ISO 13485 for quality management systems and ISO 14971 for risk management, play a significant role in the global regulatory framework for optical devices. Adherence to these standards is often necessary for market approval in various jurisdictions.

As the field of tunable optics advances, regulatory bodies are likely to adapt their frameworks to address emerging technologies. This may include developing specific guidance documents for adaptive optics or shape-memory alloy-based devices. Manufacturers and researchers working on Nitinol-based tunable optics must stay informed about evolving regulatory requirements to ensure compliance and facilitate market access for their innovative vision enhancement systems.

Under the FDA's classification system, tunable optics devices utilizing Nitinol would likely fall under Class II or Class III, depending on their intended use and level of risk. Class II devices typically require a 510(k) premarket notification, demonstrating substantial equivalence to a legally marketed predicate device. Class III devices, considered high-risk, may require a more rigorous premarket approval (PMA) process.

The FDA's Center for Devices and Radiological Health (CDRH) is responsible for evaluating the safety and effectiveness of optical devices. Manufacturers must comply with Quality System Regulation (QSR) requirements, which include design controls, manufacturing process controls, and post-market surveillance.

In the European Union, the regulatory landscape for optical devices is governed by the Medical Device Regulation (MDR). The MDR, which replaced the previous Medical Device Directive (MDD), imposes stricter requirements for clinical evaluation, post-market surveillance, and traceability of medical devices.

For Nitinol-based tunable optics, manufacturers must demonstrate compliance with essential requirements related to safety and performance. This includes providing clinical data to support claims of efficacy and conducting a thorough risk assessment. The devices must also bear the CE mark to indicate conformity with EU regulations.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees the regulation of medical devices, including optical devices. The regulatory process involves pre-market submission, quality management system audits, and post-market surveillance requirements.

International standards, such as ISO 13485 for quality management systems and ISO 14971 for risk management, play a significant role in the global regulatory framework for optical devices. Adherence to these standards is often necessary for market approval in various jurisdictions.

As the field of tunable optics advances, regulatory bodies are likely to adapt their frameworks to address emerging technologies. This may include developing specific guidance documents for adaptive optics or shape-memory alloy-based devices. Manufacturers and researchers working on Nitinol-based tunable optics must stay informed about evolving regulatory requirements to ensure compliance and facilitate market access for their innovative vision enhancement systems.

Environmental Impact of Nitinol Production

The production of Nitinol, a nickel-titanium alloy used in tunable optics for enhanced vision systems, has significant environmental implications that warrant careful consideration. The manufacturing process of Nitinol involves energy-intensive procedures and the use of potentially hazardous materials, which can lead to various environmental impacts.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and processing of nickel and titanium require substantial amounts of electricity, often sourced from fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the vacuum arc remelting (VAR) process, commonly used in Nitinol production, demands considerable energy input, further exacerbating the carbon footprint of the material.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining processes for both metals generate significant amounts of waste and emissions, including sulfur dioxide and particulate matter, which can have detrimental effects on air quality and ecosystem health.

Water usage and pollution are additional concerns in Nitinol production. The manufacturing process requires large volumes of water for cooling and cleaning, potentially straining local water resources. Moreover, the discharge of industrial wastewater containing heavy metals and other contaminants can harm aquatic ecosystems if not properly treated.

The production of Nitinol also generates solid waste, including slag and other byproducts, which require proper disposal or recycling. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. Furthermore, the fine particles produced during machining and finishing processes of Nitinol components can pose respiratory hazards if not adequately controlled.

Despite these environmental challenges, efforts are being made to mitigate the impact of Nitinol production. Advancements in manufacturing technologies, such as improved energy efficiency in melting processes and the development of cleaner production methods, are helping to reduce the environmental footprint. Additionally, increased focus on recycling and reusing Nitinol scrap is contributing to a more circular economy approach in the industry.

As the demand for Nitinol in tunable optics and other applications continues to grow, it is crucial to balance technological advancements with environmental stewardship. Ongoing research into more sustainable production methods, coupled with stringent environmental regulations and industry best practices, will be essential in minimizing the ecological impact of Nitinol manufacturing while harnessing its unique properties for enhanced vision systems.

One of the primary concerns is the high energy consumption associated with Nitinol production. The melting and processing of nickel and titanium require substantial amounts of electricity, often sourced from fossil fuels, contributing to greenhouse gas emissions and climate change. Additionally, the vacuum arc remelting (VAR) process, commonly used in Nitinol production, demands considerable energy input, further exacerbating the carbon footprint of the material.

The extraction and processing of raw materials, particularly nickel and titanium, also pose environmental challenges. Mining operations for these metals can lead to habitat destruction, soil erosion, and water pollution. The refining processes for both metals generate significant amounts of waste and emissions, including sulfur dioxide and particulate matter, which can have detrimental effects on air quality and ecosystem health.

Water usage and pollution are additional concerns in Nitinol production. The manufacturing process requires large volumes of water for cooling and cleaning, potentially straining local water resources. Moreover, the discharge of industrial wastewater containing heavy metals and other contaminants can harm aquatic ecosystems if not properly treated.

The production of Nitinol also generates solid waste, including slag and other byproducts, which require proper disposal or recycling. Improper management of these wastes can lead to soil contamination and long-term environmental degradation. Furthermore, the fine particles produced during machining and finishing processes of Nitinol components can pose respiratory hazards if not adequately controlled.

Despite these environmental challenges, efforts are being made to mitigate the impact of Nitinol production. Advancements in manufacturing technologies, such as improved energy efficiency in melting processes and the development of cleaner production methods, are helping to reduce the environmental footprint. Additionally, increased focus on recycling and reusing Nitinol scrap is contributing to a more circular economy approach in the industry.

As the demand for Nitinol in tunable optics and other applications continues to grow, it is crucial to balance technological advancements with environmental stewardship. Ongoing research into more sustainable production methods, coupled with stringent environmental regulations and industry best practices, will be essential in minimizing the ecological impact of Nitinol manufacturing while harnessing its unique properties for enhanced vision systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!