Shape Memory Alloys: The Unique Properties of Nitinol

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nitinol Background and Objectives

Shape memory alloys (SMAs) have emerged as a revolutionary class of materials in the field of smart materials, with Nitinol standing out as the most prominent and widely used SMA. The development of Nitinol can be traced back to the 1960s when William J. Buehler and Frederick Wang at the Naval Ordnance Laboratory discovered its unique properties. This nickel-titanium alloy exhibits two remarkable characteristics: shape memory effect and superelasticity, which have since captivated researchers and engineers across various industries.

The evolution of Nitinol technology has been driven by a growing demand for materials that can adapt to their environment and perform complex functions. From its initial discovery, Nitinol has undergone significant advancements in composition, processing techniques, and application methodologies. The alloy's ability to remember and return to its original shape when heated, coupled with its superelastic properties, has opened up a wide range of possibilities in fields such as medicine, aerospace, and robotics.

As we look towards the future, the objectives for Nitinol research and development are multifaceted. One primary goal is to enhance the material's performance characteristics, including improving its fatigue resistance, expanding its temperature range of operation, and increasing its shape memory strain. Additionally, researchers aim to develop more precise control over the transformation temperatures and mechanical properties of Nitinol, allowing for tailored solutions in specific applications.

Another critical objective is to scale up the production of Nitinol while maintaining consistent quality and reducing costs. This is essential for broadening its commercial viability and enabling its integration into more mainstream applications. Furthermore, there is a push to explore new compositions and processing methods that could lead to SMAs with even more extraordinary properties or combine the benefits of Nitinol with other desirable material characteristics.

In the medical field, where Nitinol has found significant success, objectives include developing biocompatible variants with enhanced properties for implantable devices and minimally invasive surgical tools. The aerospace industry seeks to leverage Nitinol's unique properties for adaptive structures and morphing aircraft components, aiming to improve fuel efficiency and aircraft performance.

As we continue to unlock the full potential of Nitinol, the overarching goal is to bridge the gap between fundamental research and practical applications. This involves not only advancing the material science behind Nitinol but also developing innovative engineering solutions that can fully harness its shape memory and superelastic properties. By pursuing these objectives, we aim to position Nitinol as a cornerstone material in the development of next-generation smart technologies and adaptive systems across various industries.

The evolution of Nitinol technology has been driven by a growing demand for materials that can adapt to their environment and perform complex functions. From its initial discovery, Nitinol has undergone significant advancements in composition, processing techniques, and application methodologies. The alloy's ability to remember and return to its original shape when heated, coupled with its superelastic properties, has opened up a wide range of possibilities in fields such as medicine, aerospace, and robotics.

As we look towards the future, the objectives for Nitinol research and development are multifaceted. One primary goal is to enhance the material's performance characteristics, including improving its fatigue resistance, expanding its temperature range of operation, and increasing its shape memory strain. Additionally, researchers aim to develop more precise control over the transformation temperatures and mechanical properties of Nitinol, allowing for tailored solutions in specific applications.

Another critical objective is to scale up the production of Nitinol while maintaining consistent quality and reducing costs. This is essential for broadening its commercial viability and enabling its integration into more mainstream applications. Furthermore, there is a push to explore new compositions and processing methods that could lead to SMAs with even more extraordinary properties or combine the benefits of Nitinol with other desirable material characteristics.

In the medical field, where Nitinol has found significant success, objectives include developing biocompatible variants with enhanced properties for implantable devices and minimally invasive surgical tools. The aerospace industry seeks to leverage Nitinol's unique properties for adaptive structures and morphing aircraft components, aiming to improve fuel efficiency and aircraft performance.

As we continue to unlock the full potential of Nitinol, the overarching goal is to bridge the gap between fundamental research and practical applications. This involves not only advancing the material science behind Nitinol but also developing innovative engineering solutions that can fully harness its shape memory and superelastic properties. By pursuing these objectives, we aim to position Nitinol as a cornerstone material in the development of next-generation smart technologies and adaptive systems across various industries.

SMA Market Demand Analysis

The market demand for Shape Memory Alloys (SMAs), particularly Nitinol, has been experiencing significant growth across various industries. This surge in demand is primarily driven by the unique properties of SMAs, such as their ability to return to a predetermined shape when subjected to specific temperature changes or stress conditions.

In the medical device industry, Nitinol has become a material of choice for numerous applications. Its superelasticity and biocompatibility make it ideal for minimally invasive surgical instruments, stents, and orthodontic wires. The global medical Nitinol market is projected to grow at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026, reflecting the increasing adoption of Nitinol-based devices in healthcare.

The aerospace and automotive sectors are also contributing to the rising demand for SMAs. In aerospace, Nitinol is used in aircraft wing morphing, vibration damping, and noise reduction applications. The automotive industry utilizes SMAs in various components, including actuators, sensors, and adaptive headlights. As these industries continue to focus on lightweight, high-performance materials, the demand for SMAs is expected to increase further.

Consumer electronics represent another growing market for SMAs. Nitinol's unique properties are being leveraged in smartphone antennas, laptop hinges, and wearable devices. The miniaturization trend in electronics aligns well with the capabilities of SMAs, driving their adoption in this sector.

The robotics and automation industry is also exploring the potential of SMAs for developing more advanced and responsive systems. Nitinol-based actuators and sensors are being integrated into robotic systems to enhance their functionality and adaptability.

Despite the growing demand, challenges remain in the widespread adoption of SMAs. These include the relatively high cost of production, limited awareness of their potential applications, and the need for specialized manufacturing processes. However, ongoing research and development efforts are addressing these challenges, potentially opening up new market opportunities.

As environmental concerns gain prominence, the recyclability and energy efficiency aspects of SMAs are becoming increasingly important. This trend is likely to create new demand in sustainable technology applications, further expanding the market for SMAs.

In conclusion, the market demand for Shape Memory Alloys, particularly Nitinol, shows a strong upward trajectory across multiple industries. The unique properties of these materials continue to drive innovation and create new applications, suggesting a promising future for SMA technology in various market segments.

In the medical device industry, Nitinol has become a material of choice for numerous applications. Its superelasticity and biocompatibility make it ideal for minimally invasive surgical instruments, stents, and orthodontic wires. The global medical Nitinol market is projected to grow at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026, reflecting the increasing adoption of Nitinol-based devices in healthcare.

The aerospace and automotive sectors are also contributing to the rising demand for SMAs. In aerospace, Nitinol is used in aircraft wing morphing, vibration damping, and noise reduction applications. The automotive industry utilizes SMAs in various components, including actuators, sensors, and adaptive headlights. As these industries continue to focus on lightweight, high-performance materials, the demand for SMAs is expected to increase further.

Consumer electronics represent another growing market for SMAs. Nitinol's unique properties are being leveraged in smartphone antennas, laptop hinges, and wearable devices. The miniaturization trend in electronics aligns well with the capabilities of SMAs, driving their adoption in this sector.

The robotics and automation industry is also exploring the potential of SMAs for developing more advanced and responsive systems. Nitinol-based actuators and sensors are being integrated into robotic systems to enhance their functionality and adaptability.

Despite the growing demand, challenges remain in the widespread adoption of SMAs. These include the relatively high cost of production, limited awareness of their potential applications, and the need for specialized manufacturing processes. However, ongoing research and development efforts are addressing these challenges, potentially opening up new market opportunities.

As environmental concerns gain prominence, the recyclability and energy efficiency aspects of SMAs are becoming increasingly important. This trend is likely to create new demand in sustainable technology applications, further expanding the market for SMAs.

In conclusion, the market demand for Shape Memory Alloys, particularly Nitinol, shows a strong upward trajectory across multiple industries. The unique properties of these materials continue to drive innovation and create new applications, suggesting a promising future for SMA technology in various market segments.

Nitinol Tech Status and Challenges

Nitinol, a nickel-titanium alloy, has emerged as a prominent shape memory alloy (SMA) with unique properties that have revolutionized various industries. The current technological status of Nitinol is characterized by significant advancements in manufacturing processes, material composition, and application development. However, several challenges persist in fully harnessing its potential.

One of the primary technological achievements in Nitinol development has been the refinement of its production techniques. Advanced melting and casting methods, such as vacuum induction melting and vacuum arc remelting, have enabled the creation of high-purity Nitinol with consistent composition. These improvements have led to enhanced material properties and more reliable shape memory and superelastic behaviors.

The optimization of Nitinol's microstructure through heat treatment and thermomechanical processing has been another area of significant progress. Researchers have developed sophisticated techniques to control the alloy's transformation temperatures and mechanical properties, allowing for tailored performance in specific applications. This level of customization has expanded Nitinol's utility across diverse fields, from medical devices to aerospace components.

Despite these advancements, several challenges continue to impede the widespread adoption of Nitinol technology. One major hurdle is the complexity of Nitinol's phase transformation behavior, which can be sensitive to slight variations in composition and processing conditions. This sensitivity makes it difficult to achieve consistent performance across different batches or applications, necessitating stringent quality control measures.

Another significant challenge lies in the fatigue behavior of Nitinol, particularly in cyclic loading conditions. While Nitinol exhibits excellent fatigue resistance compared to many conventional alloys, predicting and mitigating fatigue failure in complex geometries and under varied stress states remains a critical area of research. This is especially crucial in applications such as medical implants, where long-term reliability is paramount.

The biocompatibility of Nitinol, while generally favorable, still presents challenges in certain medical applications. The potential release of nickel ions from the alloy surface has raised concerns about long-term implant safety. Ongoing research focuses on developing surface treatments and coatings to mitigate this issue and improve the overall biocompatibility of Nitinol devices.

From a manufacturing perspective, the machining and processing of Nitinol components continue to pose difficulties. The material's superelastic properties, while beneficial in many applications, make it challenging to machine using conventional techniques. This has led to the development of specialized manufacturing processes, such as laser cutting and electrical discharge machining, which, while effective, can be costly and time-consuming.

Lastly, the scalability of Nitinol production remains a challenge, particularly for large-scale industrial applications. The current production methods are often limited in terms of the size and complexity of components that can be manufactured, restricting Nitinol's use in certain sectors.

One of the primary technological achievements in Nitinol development has been the refinement of its production techniques. Advanced melting and casting methods, such as vacuum induction melting and vacuum arc remelting, have enabled the creation of high-purity Nitinol with consistent composition. These improvements have led to enhanced material properties and more reliable shape memory and superelastic behaviors.

The optimization of Nitinol's microstructure through heat treatment and thermomechanical processing has been another area of significant progress. Researchers have developed sophisticated techniques to control the alloy's transformation temperatures and mechanical properties, allowing for tailored performance in specific applications. This level of customization has expanded Nitinol's utility across diverse fields, from medical devices to aerospace components.

Despite these advancements, several challenges continue to impede the widespread adoption of Nitinol technology. One major hurdle is the complexity of Nitinol's phase transformation behavior, which can be sensitive to slight variations in composition and processing conditions. This sensitivity makes it difficult to achieve consistent performance across different batches or applications, necessitating stringent quality control measures.

Another significant challenge lies in the fatigue behavior of Nitinol, particularly in cyclic loading conditions. While Nitinol exhibits excellent fatigue resistance compared to many conventional alloys, predicting and mitigating fatigue failure in complex geometries and under varied stress states remains a critical area of research. This is especially crucial in applications such as medical implants, where long-term reliability is paramount.

The biocompatibility of Nitinol, while generally favorable, still presents challenges in certain medical applications. The potential release of nickel ions from the alloy surface has raised concerns about long-term implant safety. Ongoing research focuses on developing surface treatments and coatings to mitigate this issue and improve the overall biocompatibility of Nitinol devices.

From a manufacturing perspective, the machining and processing of Nitinol components continue to pose difficulties. The material's superelastic properties, while beneficial in many applications, make it challenging to machine using conventional techniques. This has led to the development of specialized manufacturing processes, such as laser cutting and electrical discharge machining, which, while effective, can be costly and time-consuming.

Lastly, the scalability of Nitinol production remains a challenge, particularly for large-scale industrial applications. The current production methods are often limited in terms of the size and complexity of components that can be manufactured, restricting Nitinol's use in certain sectors.

Current Nitinol Applications

01 Manufacturing and processing of Nitinol shape memory alloys

This category focuses on the methods and techniques used to manufacture and process Nitinol shape memory alloys. It includes various heat treatment processes, cold working techniques, and surface treatments that can be applied to enhance the properties of Nitinol. These processes are crucial for optimizing the shape memory and superelastic properties of the alloy for specific applications.- Manufacturing and processing of Nitinol shape memory alloys: This category focuses on the methods and techniques used to manufacture and process Nitinol shape memory alloys. It includes processes such as heat treatment, cold working, and surface modification to enhance the material's properties and performance. These techniques are crucial for tailoring the shape memory and superelastic behaviors of Nitinol for specific applications.

- Medical applications of Nitinol shape memory alloys: Nitinol's unique properties make it ideal for various medical applications. This category covers the use of Nitinol in medical devices such as stents, guidewires, and surgical instruments. The shape memory effect allows for minimally invasive procedures, while the superelasticity provides flexibility and durability in medical implants.

- Actuators and sensors using Nitinol shape memory alloys: This category explores the application of Nitinol in actuators and sensors. The shape memory effect is utilized to create compact, efficient actuators that can generate significant force or displacement. Nitinol-based sensors can detect changes in temperature or stress, making them useful in various industries, including aerospace and automotive.

- Nitinol shape memory alloy composites and hybrid materials: This category focuses on the development and characterization of Nitinol-based composites and hybrid materials. By combining Nitinol with other materials, researchers aim to enhance its properties or create new functionalities. These composites can offer improved strength, wear resistance, or tailored shape memory behaviors for specific applications.

- Shape memory effect control and programming in Nitinol alloys: This category deals with techniques for controlling and programming the shape memory effect in Nitinol alloys. It includes methods for setting multiple shape memory states, improving shape recovery, and optimizing the transformation temperatures. These advancements enable more precise and reliable shape memory behaviors in various applications.

02 Medical applications of Nitinol shape memory alloys

Nitinol's unique properties make it ideal for various medical applications. This category covers the use of Nitinol in medical devices such as stents, guidewires, orthodontic arches, and surgical instruments. The shape memory effect allows for minimally invasive procedures, while the superelasticity provides flexibility and durability in medical implants.Expand Specific Solutions03 Actuators and sensors using Nitinol shape memory alloys

This category explores the application of Nitinol in actuators and sensors. The shape memory effect of Nitinol can be utilized to create compact and efficient actuators for various industries, including aerospace and robotics. Additionally, Nitinol-based sensors can detect changes in temperature or stress, making them useful in monitoring systems and smart structures.Expand Specific Solutions04 Automotive applications of Nitinol shape memory alloys

Nitinol finds applications in the automotive industry due to its unique properties. This category covers the use of Nitinol in various automotive components such as valves, actuators, and safety devices. The shape memory effect can be utilized for self-repairing structures or temperature-activated mechanisms in vehicles.Expand Specific Solutions05 Characterization and testing of Nitinol shape memory alloys

This category focuses on the methods and techniques used to characterize and test Nitinol shape memory alloys. It includes various analytical techniques, mechanical testing procedures, and thermal analysis methods used to evaluate the properties and performance of Nitinol. These tests are essential for quality control and ensuring the reliability of Nitinol-based products in different applications.Expand Specific Solutions

Key Players in SMA Industry

The shape memory alloy market, particularly for Nitinol, is in a growth phase with increasing applications across various industries. The global market size is projected to expand significantly in the coming years, driven by demand in medical devices, aerospace, and automotive sectors. Technologically, shape memory alloys are maturing, with ongoing research to enhance their properties and expand applications. Key players like W. L. Gore & Associates, Boston Scientific Scimed, and Abbott Laboratories are leading in medical device applications, while universities such as South China University of Technology and Shandong University are contributing to fundamental research and innovation in this field.

Boston Scientific Scimed, Inc.

Technical Solution: Boston Scientific Scimed has developed advanced Nitinol-based medical devices, particularly in the field of cardiovascular interventions. Their technology utilizes the superelastic properties of Nitinol to create self-expanding stents that can be compressed into a small diameter for delivery and then expand to their pre-set shape once deployed in the body[1]. The company has also pioneered the use of Nitinol in guidewires, which benefit from the material's kink resistance and shape memory[2]. Their research extends to surface modifications of Nitinol to enhance biocompatibility and reduce the risk of nickel ion release, addressing potential concerns in long-term implantation[3].

Strengths: Expertise in Nitinol-based medical devices, particularly for cardiovascular applications. Advanced surface modification techniques. Weaknesses: Potential long-term biocompatibility concerns, higher production costs compared to traditional materials.

National Aeronautics & Space Administration

Technical Solution: NASA has been at the forefront of Shape Memory Alloy (SMA) research, particularly focusing on Nitinol for aerospace applications. They have developed Nitinol-based actuators that can operate in extreme space environments, leveraging the material's ability to change shape in response to temperature variations[4]. NASA's research includes the creation of adaptive structures using Nitinol, such as morphing aircraft wings that can change shape during flight to optimize aerodynamic performance[5]. Additionally, they have explored the use of Nitinol in deployable space structures, where the material's shape memory effect allows for compact storage during launch and controlled expansion in space[6].

Strengths: Cutting-edge research in aerospace applications, expertise in extreme environment performance. Weaknesses: High development costs, limited immediate commercial applications outside of aerospace.

Core Nitinol Properties Analysis

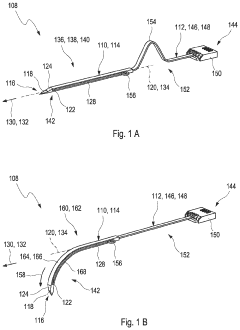

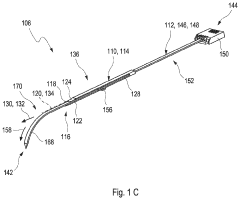

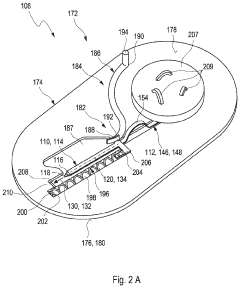

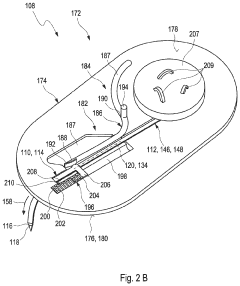

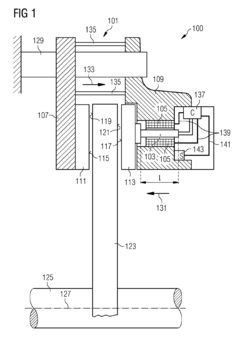

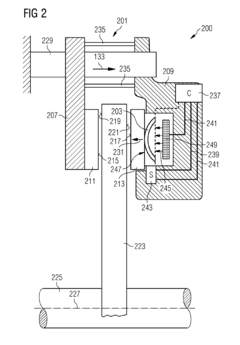

Medical device for transcutaneously inserting an insertable element into a body tissue

PatentActiveUS11998328B2

Innovation

- A medical device with an insertion cannula made of shape memory alloy, capable of transforming from a straight to an arch shape for easy insertion and removal, integrated within a patch system that includes a drive unit and return spring for simplified handling and reduced component count, allowing for a compact, all-in-one device design.

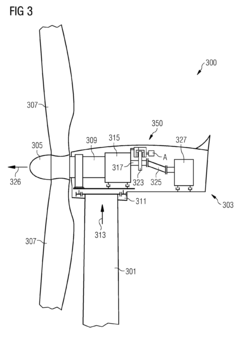

Braking system for a wind turbine

PatentInactiveEP2597329A1

Innovation

- A braking system utilizing shape memory material within a brake caliper, activated by heating, magnetic fields, or electromagnetic radiation, which changes shape to apply friction forces to a brake disk, eliminating the need for hydraulic or pneumatic fluids and associated components, thereby reducing weight, space, and energy consumption.

Regulatory Framework for SMAs

The regulatory framework for Shape Memory Alloys (SMAs), particularly Nitinol, is complex and multifaceted, reflecting the diverse applications of these materials across various industries. In the medical field, which is one of the primary sectors for SMA use, regulatory bodies such as the U.S. Food and Drug Administration (FDA) play a crucial role. The FDA classifies medical devices containing SMAs based on their intended use and potential risk, with most Nitinol-based devices falling under Class II or III, requiring premarket notification (510(k)) or premarket approval (PMA) processes.

For aerospace and automotive applications, SMAs must comply with stringent safety and performance standards set by organizations like the Federal Aviation Administration (FAA) and the National Highway Traffic Safety Administration (NHTSA). These regulations often focus on the material's fatigue resistance, corrosion behavior, and long-term stability under various environmental conditions.

In the consumer products sector, SMAs are subject to general product safety regulations. The Consumer Product Safety Commission (CPSC) in the United States, for instance, oversees the safety of consumer goods that may incorporate SMAs, ensuring they meet specific safety standards and do not pose undue risks to users.

Environmental regulations also impact the use and disposal of SMAs. The European Union's Restriction of Hazardous Substances (RoHS) directive, for example, limits the use of certain hazardous materials in electrical and electronic equipment, which can affect the composition and manufacturing processes of SMAs used in these applications.

Standardization bodies such as ASTM International and the International Organization for Standardization (ISO) have developed specific standards for SMAs, including ASTM F2063 for wrought nickel-titanium shape memory alloys for medical device applications. These standards provide guidelines for material composition, processing, testing, and quality control, ensuring consistency and reliability across different manufacturers and applications.

As SMAs find new applications in emerging technologies, regulatory frameworks continue to evolve. For instance, the use of SMAs in smart textiles and wearable technologies has prompted discussions on how to regulate these hybrid products that blur the lines between traditional categories. This ongoing development of regulations highlights the need for manufacturers and researchers to stay informed about the latest regulatory requirements and participate in shaping future standards for SMA applications.

For aerospace and automotive applications, SMAs must comply with stringent safety and performance standards set by organizations like the Federal Aviation Administration (FAA) and the National Highway Traffic Safety Administration (NHTSA). These regulations often focus on the material's fatigue resistance, corrosion behavior, and long-term stability under various environmental conditions.

In the consumer products sector, SMAs are subject to general product safety regulations. The Consumer Product Safety Commission (CPSC) in the United States, for instance, oversees the safety of consumer goods that may incorporate SMAs, ensuring they meet specific safety standards and do not pose undue risks to users.

Environmental regulations also impact the use and disposal of SMAs. The European Union's Restriction of Hazardous Substances (RoHS) directive, for example, limits the use of certain hazardous materials in electrical and electronic equipment, which can affect the composition and manufacturing processes of SMAs used in these applications.

Standardization bodies such as ASTM International and the International Organization for Standardization (ISO) have developed specific standards for SMAs, including ASTM F2063 for wrought nickel-titanium shape memory alloys for medical device applications. These standards provide guidelines for material composition, processing, testing, and quality control, ensuring consistency and reliability across different manufacturers and applications.

As SMAs find new applications in emerging technologies, regulatory frameworks continue to evolve. For instance, the use of SMAs in smart textiles and wearable technologies has prompted discussions on how to regulate these hybrid products that blur the lines between traditional categories. This ongoing development of regulations highlights the need for manufacturers and researchers to stay informed about the latest regulatory requirements and participate in shaping future standards for SMA applications.

Environmental Impact of Nitinol

The environmental impact of Nitinol, a shape memory alloy primarily composed of nickel and titanium, is a complex issue that requires careful consideration. While Nitinol offers unique properties that make it valuable in various applications, its production and use have both positive and negative environmental implications.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc melting and multiple heat treatments. These processes contribute to increased energy consumption and associated greenhouse gas emissions. Additionally, the extraction and refining of nickel and titanium, the primary components of Nitinol, have their own environmental footprints, including habitat disruption, water pollution, and energy consumption.

However, the durability and longevity of Nitinol products can offset some of these environmental costs. The material's ability to withstand repeated stress and strain without fatigue or deformation means that Nitinol-based devices often have longer lifespans than alternatives made from conventional materials. This longevity reduces the need for frequent replacements, potentially lowering overall resource consumption and waste generation in the long term.

Nitinol's unique properties also enable the development of more efficient and environmentally friendly technologies. For instance, in the automotive industry, Nitinol-based actuators can improve fuel efficiency by reducing vehicle weight. In the field of renewable energy, Nitinol is being explored for use in solar panels and wind turbines, potentially enhancing their efficiency and durability.

The recyclability of Nitinol is another important environmental consideration. While the alloy can be recycled, the process is challenging due to the difficulty in separating nickel and titanium. Current recycling methods are energy-intensive and not widely implemented, which can lead to increased waste if Nitinol products are not properly disposed of or recycled.

Regarding toxicity, Nitinol is generally considered biocompatible, which reduces environmental concerns related to its use in medical applications. However, the potential release of nickel ions in certain conditions raises some environmental and health concerns, particularly in aquatic ecosystems.

As the use of Nitinol expands, there is a growing need for life cycle assessments to fully understand its environmental impact. These assessments should consider the entire lifecycle of Nitinol products, from raw material extraction to end-of-life disposal or recycling. Such comprehensive analyses will help guide more sustainable practices in the production, use, and disposal of Nitinol-based technologies.

The manufacturing process of Nitinol involves energy-intensive procedures, including vacuum arc melting and multiple heat treatments. These processes contribute to increased energy consumption and associated greenhouse gas emissions. Additionally, the extraction and refining of nickel and titanium, the primary components of Nitinol, have their own environmental footprints, including habitat disruption, water pollution, and energy consumption.

However, the durability and longevity of Nitinol products can offset some of these environmental costs. The material's ability to withstand repeated stress and strain without fatigue or deformation means that Nitinol-based devices often have longer lifespans than alternatives made from conventional materials. This longevity reduces the need for frequent replacements, potentially lowering overall resource consumption and waste generation in the long term.

Nitinol's unique properties also enable the development of more efficient and environmentally friendly technologies. For instance, in the automotive industry, Nitinol-based actuators can improve fuel efficiency by reducing vehicle weight. In the field of renewable energy, Nitinol is being explored for use in solar panels and wind turbines, potentially enhancing their efficiency and durability.

The recyclability of Nitinol is another important environmental consideration. While the alloy can be recycled, the process is challenging due to the difficulty in separating nickel and titanium. Current recycling methods are energy-intensive and not widely implemented, which can lead to increased waste if Nitinol products are not properly disposed of or recycled.

Regarding toxicity, Nitinol is generally considered biocompatible, which reduces environmental concerns related to its use in medical applications. However, the potential release of nickel ions in certain conditions raises some environmental and health concerns, particularly in aquatic ecosystems.

As the use of Nitinol expands, there is a growing need for life cycle assessments to fully understand its environmental impact. These assessments should consider the entire lifecycle of Nitinol products, from raw material extraction to end-of-life disposal or recycling. Such comprehensive analyses will help guide more sustainable practices in the production, use, and disposal of Nitinol-based technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!